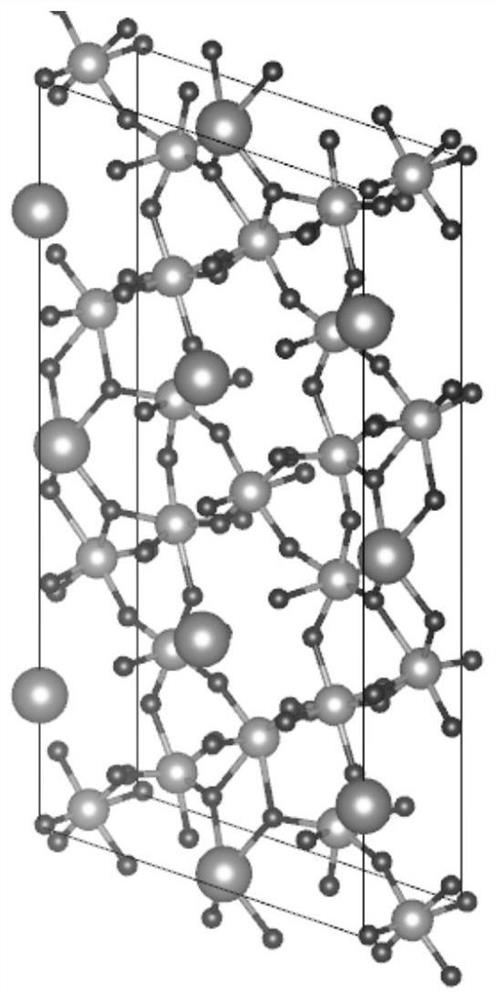

Method for preparing low-thermal-conductivity high-temperature thermal barrier ceramic CaWTa2O9 by solid-phase method

A technology of low thermal conductivity and solid-state method, applied in the field of high-temperature ceramic coatings, can solve problems such as low thermal conductivity, coating peeling, coating cracks, etc., and achieve high thermal expansion coefficient, simple preparation process, and good phase stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

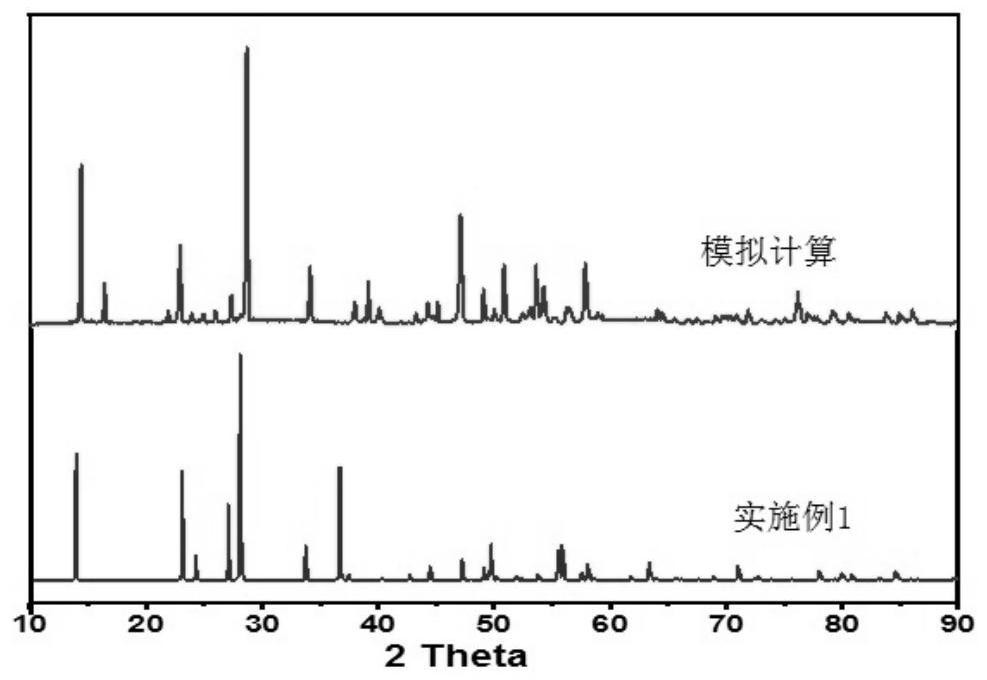

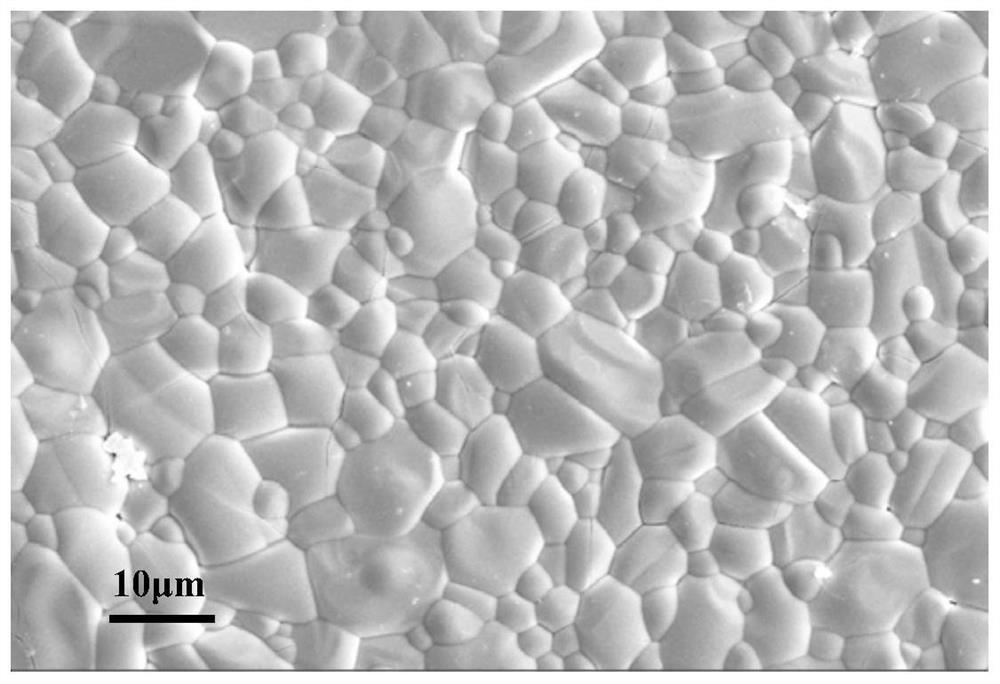

[0028] Preparation of low thermal conductivity and high temperature thermal barrier ceramics CaWTa by a solid phase method 2 o 9 method, including the following steps:

[0029] Step 1: Follow Ta 2 o 5 with CaWO 4 The molar ratio is 1:1 and weighs tantalum pentoxide (Ta 2 o 5 ) and calcium tungstate (CaWO 4 ), mixed in absolute ethanol, placed in a planetary ball mill for ball milling, the speed of the ball mill was 300r / min, and the ball milling time was 600min, then the milled solution was dried at 80°C for 24h and passed through a 300-mesh sieve for subsequent use.

[0030] Step 2: Compress the powder sieved in step 1 with a mold, wherein the holding pressure is 8 MPa, and the holding time is 30 minutes. After pressing and forming, it is sintered at 1400 ° C for 8 hours to obtain a good firing shape. wxya 2 o 9 ceramics.

[0031] Wherein the reaction equation in the step 2 is:

[0032] wxya 4 (G 1 )+Ta 2 o 5 (G 2 ) = CaWTa 2 o 9 (G 3 )

[0033] Among them...

Embodiment 2~6

[0035] The difference from Example 1 is that the process parameters in Examples 2-6 are different, as shown in Table 1 below for details.

[0036] Table 1 is the technological parameter table of embodiment 2~6

[0037]

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com