Composite solid electrolyte with wide electrochemical window and and preparation method of composite solid electrolyte

A solid electrolyte, electrochemical technology, applied in the field of electrochemical energy storage, can solve the problems of poor oxidation resistance of the positive electrode, narrow electrochemical window, unsuitable for ternary batteries, etc., and achieve the effects of high yield and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The specific preparation process of the wide electrochemical window composite solid electrolyte in this example is as follows:

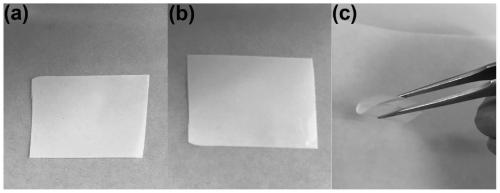

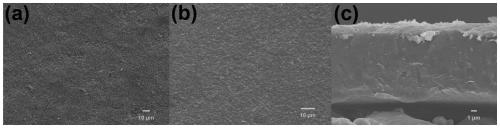

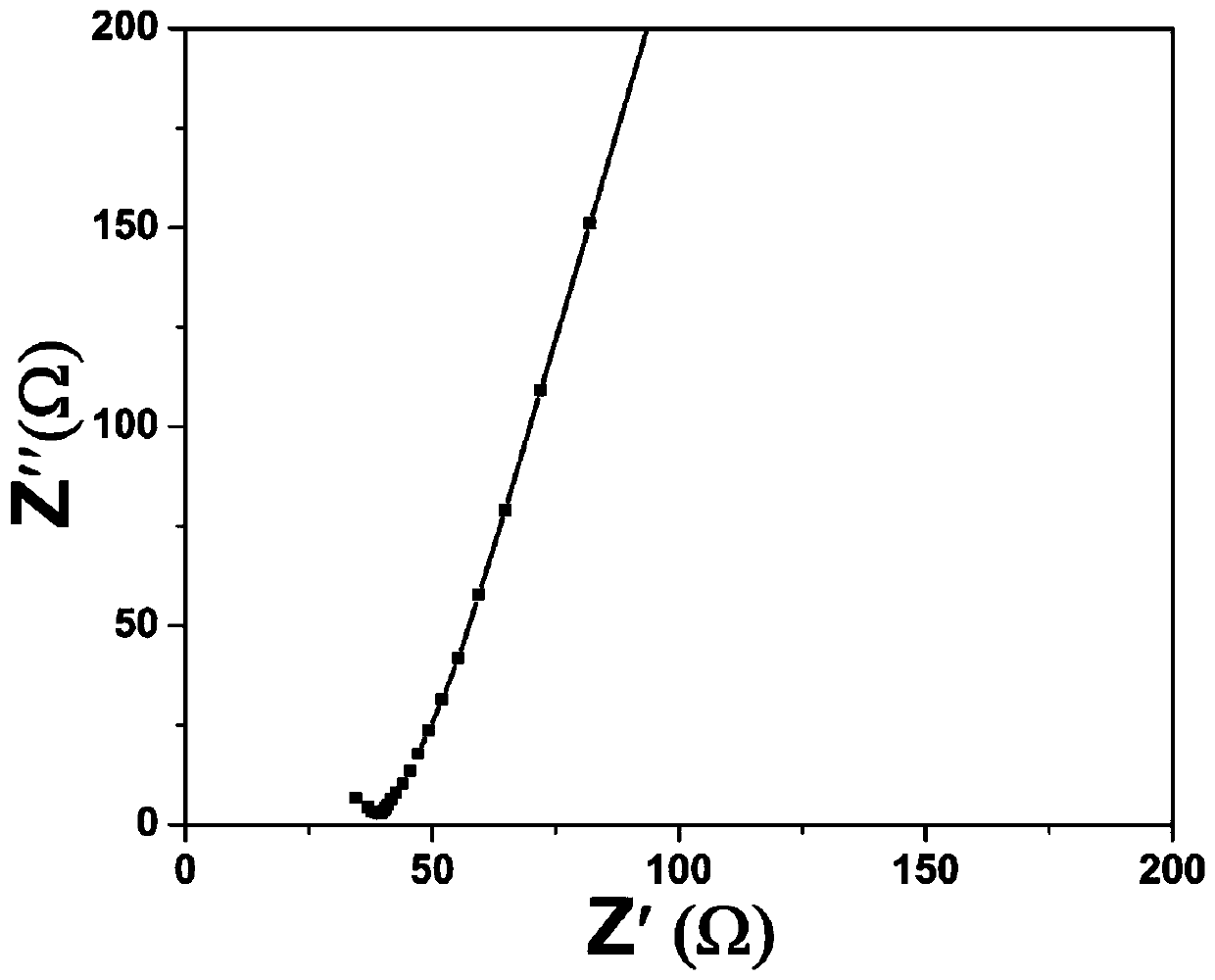

[0036] Weigh 0.1 g of nano-boron nitride (BN) and place it in 10 ml of N,N-dimethylformamide (DMF), sonicate for 48 hours, and then centrifuge to obtain exfoliated BN nanosheets. Weigh 0.5g polyacrylonitrile (PAN), 0.25g lithium perchlorate (LiClO 4 ) and 0.05g of BN nanosheets, add 10ml of N,N-dimethylformamide (DMF), heat and stir at 80°C to make PAN, LiClO4 Completely dissolved to obtain the precursor slurry of the composite solid electrolyte. Then, the obtained slurry was coated on a clean glass plate by tape casting, and dried in a vacuum oven at 80° C. for 12 hours to obtain a PAN-BN composite solid electrolyte. Then weigh 0.5 g of BN nanosheets and 0.06 g of polyvinylidene fluoride (PVDF), add 10 ml of DMF, heat and stir to dissolve PVDF, and obtain a protective layer slurry. Finally, the BN-PVDF slurry was evenly coated on the surfac...

Embodiment 2

[0040] The specific preparation process of the wide electrochemical window composite solid electrolyte in this example is as follows:

[0041] Weigh 0.5g polyacrylonitrile (PAN), 1.0g lithium perchlorate (LiClO 4 ) and 0.1gZrO 2 Mix particles (particle size: ~100nm), add 15ml dimethyl sulfoxide (DMSO), heat and stir at 60°C to make PAN, LiClO 4 Completely dissolved to obtain the precursor slurry of the composite solid electrolyte. Then the resulting slurry was coated on a clean glass plate by tape casting, and dried in a vacuum oven at 60°C for 24 hours to obtain PAN-ZrO 2 Composite solid electrolyte. Then weigh 0.5g of BN nanosheets (diameter: ~100nm) and 0.01g of polyvinylidene fluoride (PVDF), add 15ml of DMF, heat and stir to dissolve PVDF, and obtain the protective layer slurry. Finally, the tape casting method was used to evenly coat the BN-PVDF slurry on the PAN-ZrO 2 The surface of the composite solid electrolyte was kept in a vacuum oven at 100° C. for 6 hours to...

Embodiment 3

[0043] The specific preparation process of the wide electrochemical window composite solid electrolyte in this example is as follows:

[0044] Weigh 0.1 g of nanometer boron nitride (BN) and place it in 10 ml of N,N-dimethylformamide (DMF), sonicate for 48 hours, and then centrifuge to obtain BN nanosheets. Weigh 0.5g of polyacrylonitrile (PAN), 0.6g of lithium bistrifluoromethanesulfonimide (LiTFSI) and 0.1g of the resulting BN nanosheets, add 30ml of dimethyl sulfoxide (DMSO), and heat and stir at 80°C Make PAN, LiClO 4 completely dissolved. Then, the obtained slurry was coated on a clean glass plate by tape casting, and dried in a vacuum oven at 40° C. for 30 h to obtain a PAN-BN composite solid electrolyte. Then weigh 0.5g of LiF particles (particle size: ~1um) and 0.3g of polyvinylidene fluoride (PVDF), add 10ml of DMSO, heat and stir to dissolve PVDF, and obtain the protective layer slurry. Finally, the LiF-PVDF slurry was evenly coated on the surface of the PAN-BN co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com