Silicate ceramic composition detection method

A detection method and silicate technology, applied in the field of analysis and detection, can solve problems such as large error in results, and achieve the effect of ensuring accuracy and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

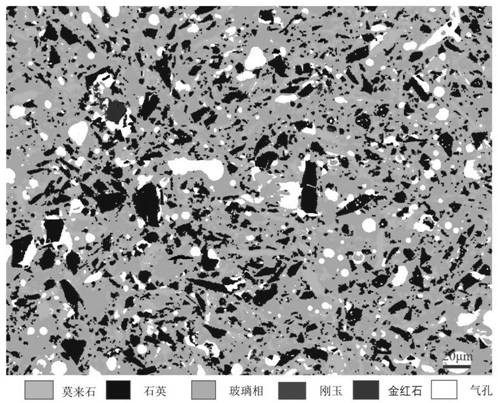

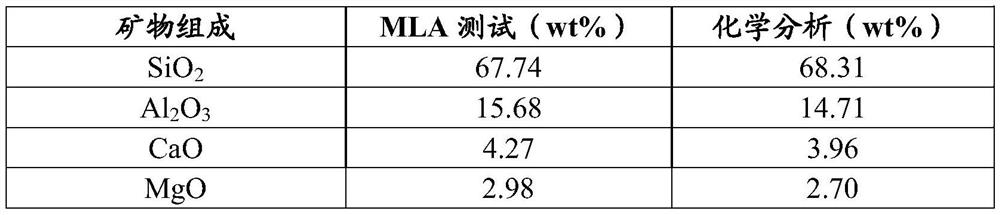

[0022] In this embodiment, a daily-use silicate ceramic sample is detected, and the specific detection process is as follows:

[0023] Step 1: Cut the ceramic sample to a block size below 10mm, dry it and embedding it with epoxy resin for cold mounting to make an epoxy resin light sheet.

[0024] Step 2: Polish the cured epoxy resin light sheet, spray carbon, and then perform MLA system (model: MLA650) measurement. Set the SEM acceleration voltage to 20KV, the beam spot to 7.0nm, and select epoxy resin and metal copper as gray scale standard samples respectively in BSE mode to adjust the contrast and brightness of SEM, so that the gray value of epoxy resin is adjusted to 10, and the gray value of metal copper is adjusted to 10. Adjust the gray value to 255. Select a representative rectangular area, the number of measurement frames is 25, the grid measurement mode is adopted, the image resolution is 500*500, the X-ray acquisition resolution is 2*2, the dwell time of the energy...

Embodiment 2

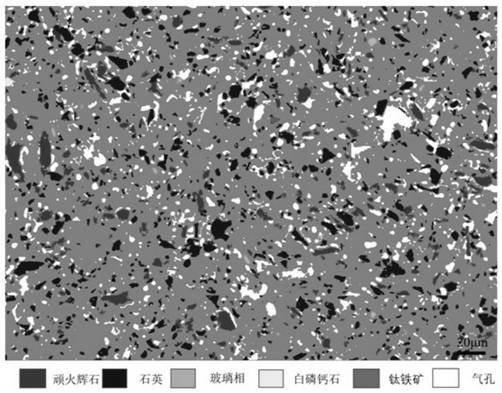

[0037] In this embodiment, a silicate ceramic sample is detected, and the specific detection process is as follows:

[0038] Step 1: Cut the ceramic sample to a block size below 10mm, dry it and embedding it with epoxy resin for cold mounting to make an epoxy resin light sheet.

[0039] Step 2: Polish and carbon-spray the cured epoxy resin light sheet, and then measure it with the MLA system (model: MLA650). Set the SEM acceleration voltage to 20KV, the beam spot to 7.0nm, and select epoxy resin and metal copper as gray scale standard samples respectively in BSE mode to adjust the contrast and brightness of SEM, so that the gray value of epoxy resin is adjusted to 10, and the gray value of metal copper is adjusted to 10. Adjust the gray value to 255. Select a representative rectangular area, the number of measurement frames is 25, the grid measurement mode is adopted, the image resolution is 500*500, the X-ray acquisition resolution is 2*2, the dwell time of the energy spectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com