Preparation method of inorganic salt-ceramic high-temperature phase change composite heat storage material

A composite heat storage material and high temperature phase change technology, which is applied in the field of preparation of inorganic salt-ceramic high temperature phase change composite heat storage materials, can solve the problems of high material cost, poor thermal conductivity of materials, loss of phase change materials, etc. Low cost, strong adhesion, high phase transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

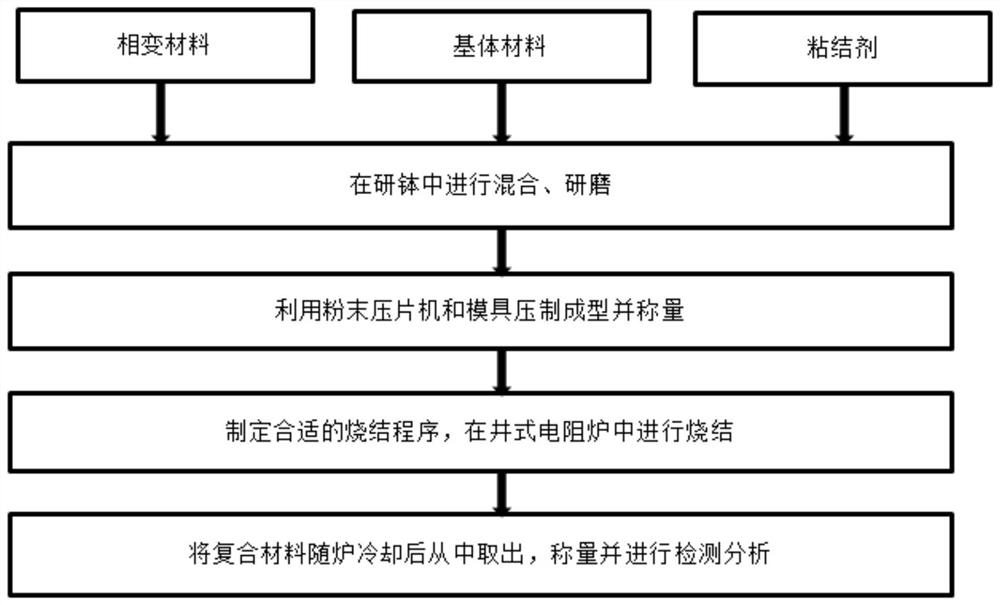

[0035] The preparation method of an inorganic salt-ceramic high-temperature phase-change composite heat storage material of the present invention is specifically implemented according to the following steps:

[0036] Step 1, pour the phase change material NaCl (30% by mass) and SiC (69.5% by mass) as the ceramic matrix material into a mortar, mix and grind for 30 minutes, so that the materials are fully and evenly mixed, and an appropriate amount of Aluminum dihydrogen phosphate (0.5% by mass) was used as a binding agent to obtain a mixture.

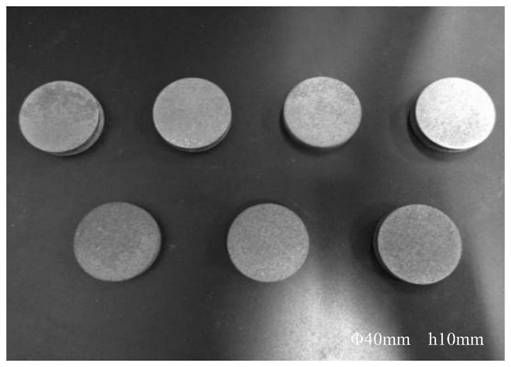

[0037] Step 2. Pour the ground mixture into the specified abrasive tool, and use a powder tablet press to slowly pressurize in a one-way press. The maximum pressure is 20MPa, and the holding time is 15 minutes. Press to obtain the diameter It is a cylindrical embryo body with a height of 40mm and a height of 10mm.

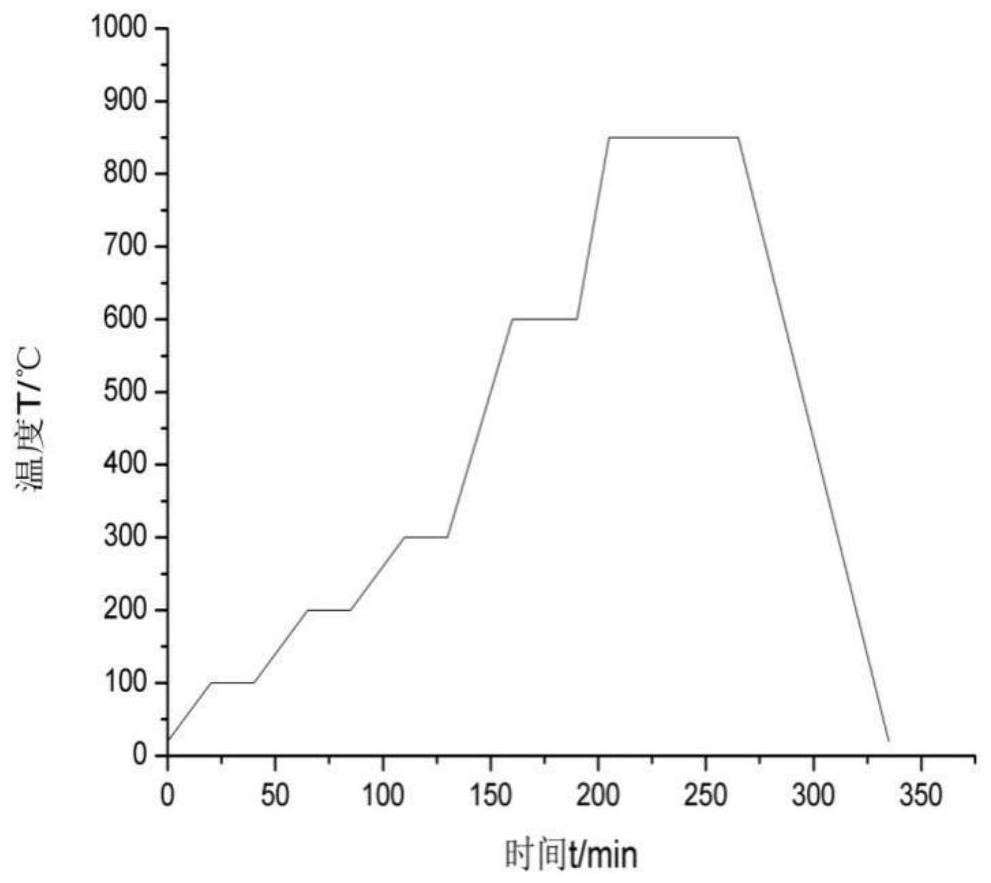

[0038] Step 3: Put the green body obtained after pressing into a well-type resistance furnace, and sinter according to the...

Embodiment 2

[0043] The preparation method of an inorganic salt-ceramic high-temperature phase-change composite heat storage material of the present invention is specifically implemented according to the following steps:

[0044] Step 1, weighing the following components in sequence according to mass percentage: phase change material NaCl 30%, ceramic matrix material SiC 69%, binder aluminum dihydrogen phosphate 1%, the sum of the mass percentages of the above components is 100%;

[0045] Step 2, pouring the phase change material NaCl and the ceramic matrix material SiC into a mortar, mixing and grinding for 20 minutes, so that the materials are fully and evenly mixed, and adding aluminum dihydrogen phosphate as a binder during the grinding process to obtain a mixture;

[0046] Step 3, pour the ground mixture into the abrasive tool, use a powder tablet press to pressurize in a one-way pressurization rate: 1Mpa / min, pressurize to 15MPa, and then hold the pressure for 10 minutes , and then p...

Embodiment 3

[0049] The preparation method of an inorganic salt-ceramic high-temperature phase-change composite heat storage material of the present invention is specifically implemented according to the following steps:

[0050] Step 1, weighing the following components in sequence according to mass percentage: phase change material NaCl 25%, ceramic matrix material SiC 74%, binder aluminum dihydrogen phosphate 1%, the sum of the mass percentages of the above components is 100%;

[0051] Step 2, pouring the phase change material NaCl and the ceramic matrix material SiC into a mortar, mixing and grinding for 30 minutes, so that the materials are fully and evenly mixed, and adding aluminum dihydrogen phosphate as a binder during the grinding process to obtain a mixture;

[0052] Step 3, pour the ground mixture into the abrasive tool, use a powder tablet press to pressurize in a one-way pressurization rate: 3Mpa / min, pressurize to 20MPa, and then hold the pressure for 20 minutes , and then p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com