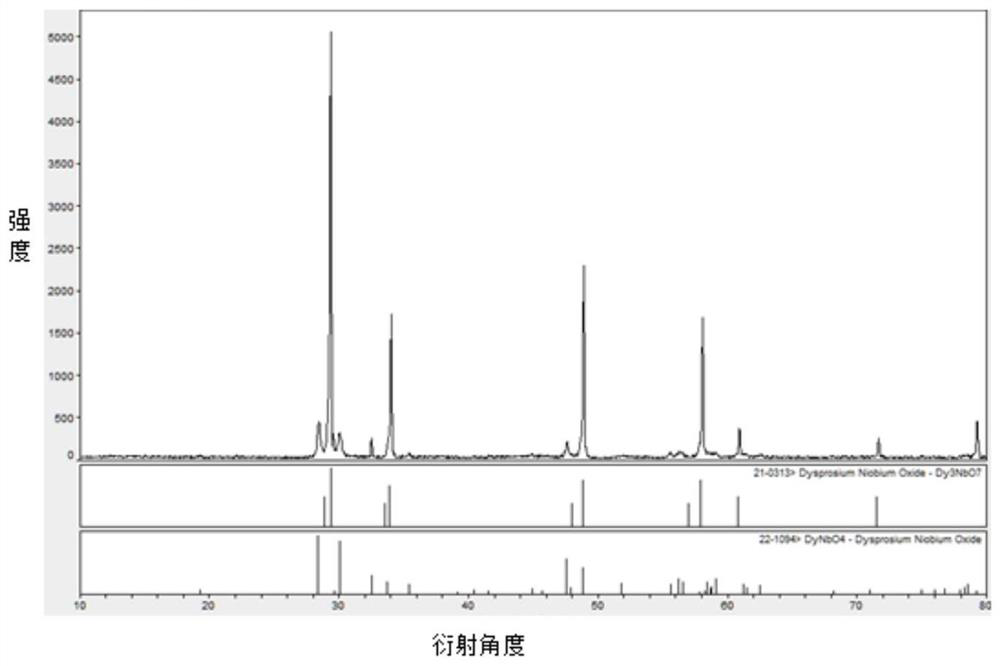

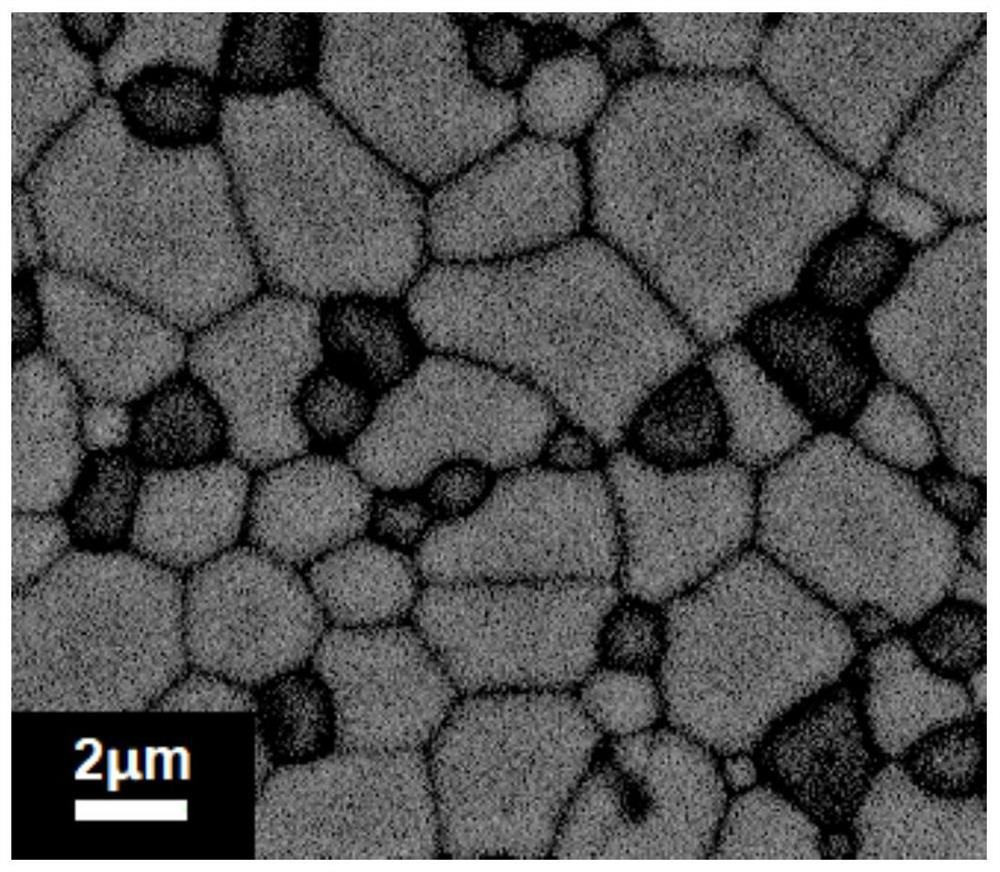

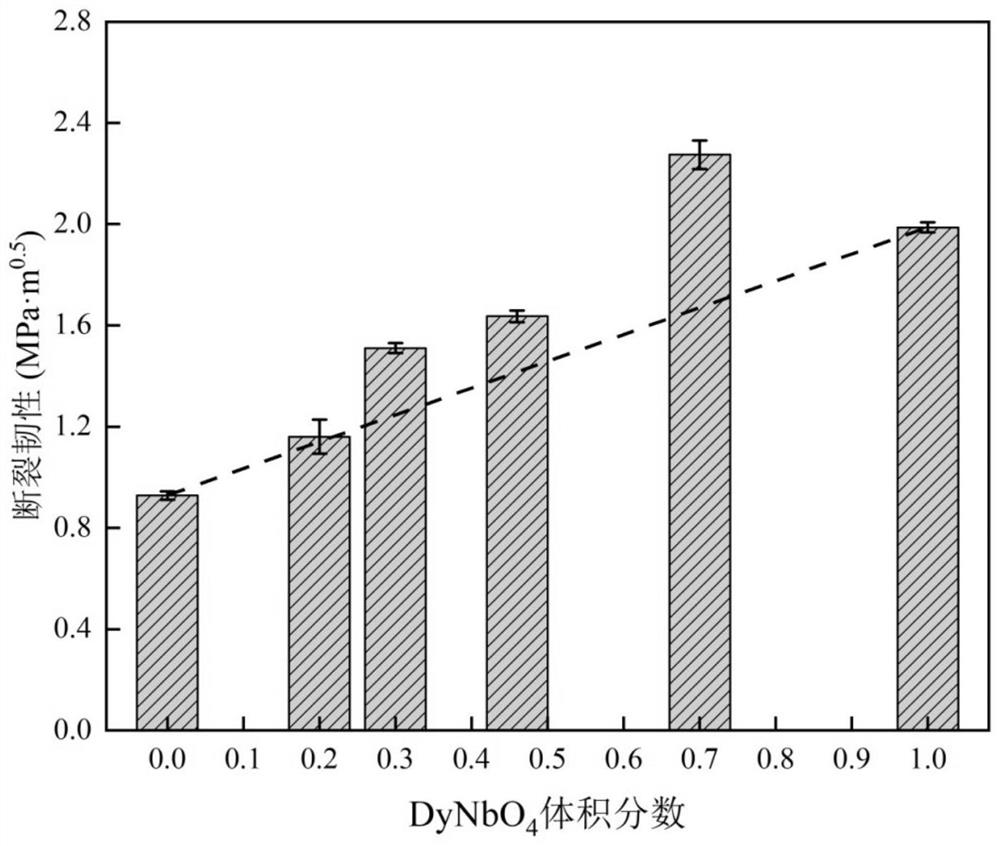

A kind of in-situ synthesis of pseudo-binary complex-phase rare earth niobate ceramics and its preparation method

An in-situ synthesis and pseudo-binary technology, applied in the field of high temperature materials, can solve the problems of low fracture toughness and cannot be directly applied, and achieve the effects of improved fracture toughness, low preparation cost and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of pseudo-binary complex-phase yttrium niobate (Y 3 NbO 7 -YNbO 4 ) high-temperature ceramic material and preparation method thereof, specifically comprising the following steps:

[0032] (1) Weigh 6.1036g of yttrium oxide and 3.4475g of niobium oxide, mix them in absolute ethanol, and place them in a planetary ball mill for ball milling (the speed of the ball mill is 250r / min, and the ball milling time is 240min), and the milled solution Pre-fired at 1250° C. for 10 hours after rotary evaporation drying.

[0033] (2) After pre-sintering, grind the mixed powder evenly, mix and grind the powder with absolute ethanol as a solvent, and place it in a planetary ball mill for ball milling (the speed of the ball mill is 250r / min, and the ball milling time is 600min); ball mill the powder After rotary evaporation and drying, pass through a 200-mesh sieve to obtain a fine powder; then use hydraulic pressure to form (holding pressure is 5 MPa, holding time is 5min), and...

Embodiment 2

[0035] A new pseudo-binary complex phase lanthanum niobate (La 3 NbO 7 -LaNbO 4 ) high-temperature ceramic material and preparation method thereof, specifically comprising the following steps:

[0036] (1) Weigh 8.8002g of lanthanum oxide and 3.4526g of niobium oxide, mix them in absolute ethanol, place them in a planetary ball mill for ball milling (the speed of the ball mill is 250r / min, and the ball milling time is 240min), and the milled solution Pre-fired at 1250° C. for 10 hours after rotary evaporation drying.

[0037](2) After pre-sintering, grind the mixed powder evenly, mix and grind the powder with absolute ethanol as a solvent, and place it in a planetary ball mill for ball milling (the speed of the ball mill is 250r / min, and the ball milling time is 600min); ball mill the powder After rotary evaporation and drying, pass through a 200-mesh sieve to obtain a fine powder; then use hydraulic pressure to form (holding pressure is 5 MPa, holding time is 5min), and th...

Embodiment 3

[0039] A new type of pseudo-binary complex phase cerium niobate (Ce 3 NbO 7 -CeNbO 4 ) high-temperature ceramic material and preparation method thereof, specifically comprising the following steps:

[0040] (1) Weigh 8.8502g of cerium oxide and 3.4478g of niobium oxide, mix them in absolute ethanol, place them in a planetary ball mill for ball milling (the speed of the ball mill is 250r / min, and the ball milling time is 240min), and the milled solution Pre-fired at 1250° C. for 10 hours after rotary evaporation drying.

[0041] (2) After pre-sintering, grind the mixed powder evenly, mix and grind the powder with absolute ethanol as a solvent, and place it in a planetary ball mill for ball milling (the speed of the ball mill is 250r / min, and the ball milling time is 600min); ball mill the powder After rotary evaporation and drying, pass through a 200-mesh sieve to obtain a fine powder; then use hydraulic pressure to form (holding pressure is 5 MPa, holding time is 5min), and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com