Method for preparing ceramic microbeads, ceramic microbeads and application thereof

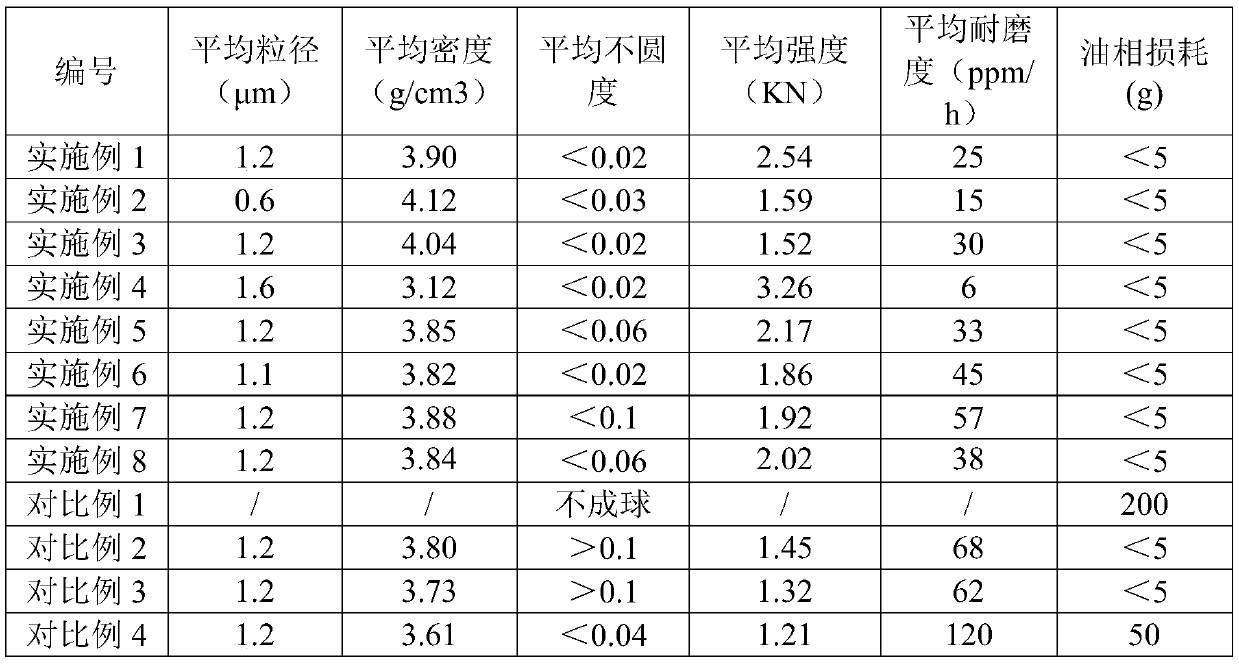

A ceramic microbead and microbead technology, which is applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of high non-roundness of microbeads, difficult to disperse into balls, and low non-roundness, and achieve non-roundness. The effect of low degree, high density and low oil phase loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

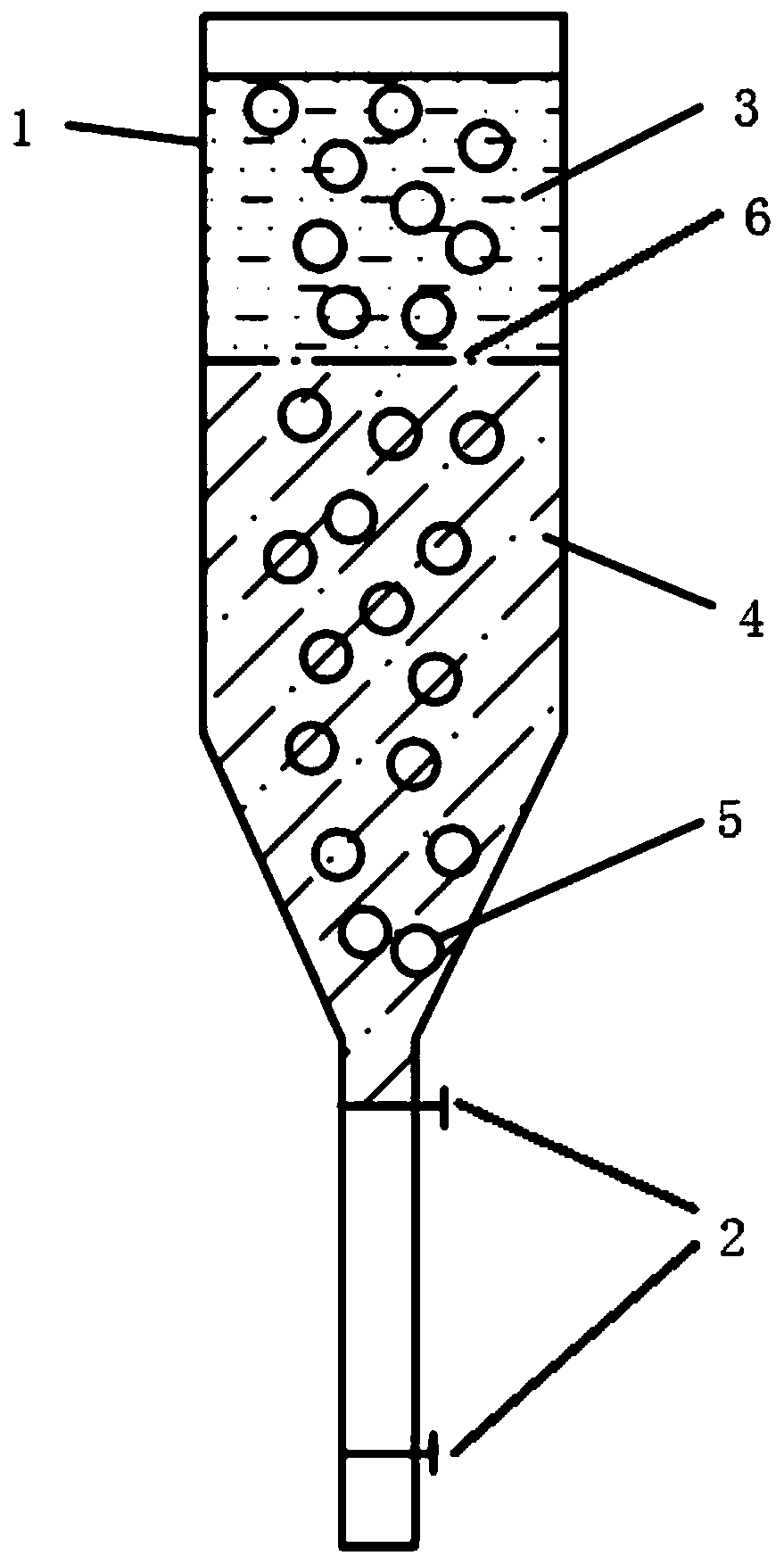

Image

Examples

Embodiment 1

[0082] (1) Prepare 100g premix solution, wherein the weight content of each component is: 10% of acrylamide, 0.4% of N,N-methylenebisacrylamide, 0.12% of sodium alginate (the number average molecular weight is 100000), and the balance for water;

[0083] 315.4g of α-alumina (α-Al 2 o 3 , the average particle size is 1 μm, and the purity is 99.95%), 1.9g of magnesite (magnesia content is 42% by weight) and 1.6g of ammonium citrate are added in the premixed liquid, and in a ball mill, at 2000rpm, quickly ball mill 5min to obtain a suspension; wherein the volume of α-alumina accounts for 45% of the sum of the volume of α-alumina and the volume of the premixed solution;

[0084] Then add an aqueous solution of ammonium persulfate with a mass concentration of 10% into the suspension, stir evenly, and then vacuum defoam at 0.001 MPa and a rotating speed of 70 rpm for 10 minutes to obtain a slurry. The amount of ammonium persulfate added is 0.017% of the total mass of the slurry ....

Embodiment 2

[0090] (1) Prepare 100g premix solution, wherein the weight content of each component is: 12% of acrylamide, 0.25% of N,N-methylenebisacrylamide, 0.16% of sodium alginate (number average molecular weight is 50000), and the balance for water;

[0091] 323.6g of α-alumina (average particle size of 1 μm, purity of 99.95% by weight), 76g of zirconia (ZrO 2 (3Y), the average particle size is 0.8 μm, and the purity is 99.5% by weight), 0.4 g of La 2 o 3 And the ammonium polyacrylate of 4g is added in the premixed liquid, in ball mill, under 1500rpm, quick ball mill 15min, obtain suspension; Wherein, α-alumina and zirconium dioxide (ZrO 2 The total volume of (3Y) accounts for the volume of α-alumina, zirconia (ZrO2 50% of the sum of the volume of (3Y) and the volume of premix solution;

[0092] Then add ammonium persulfate solution with a mass concentration of 10% into the suspension, stir evenly, then add antifoaming agent methyl silicone oil and stir, remove foam, and obtain slu...

Embodiment 3

[0098] (1) Prepare 100g of premix solution, wherein the weight content of each component is: 15% of acrylamide, 0.6% of N,N-methylenebisacrylamide, 0.22% of sodium alginate, and the balance is water;

[0099] Add 456 zirconium silicate (average particle size of 0.9 μm, purity of 99.5%) and 5 g of sodium polyacrylate into the premix, and quickly ball mill for 3 minutes at 1500 rpm in a ball mill to obtain a suspension; among them, silicic acid The volume of zirconium accounts for 50% of the sum of the volume of zirconium silicate and the volume of premixed solution;

[0100] Add the ammonium persulfate solution with a mass concentration of 10% into the suspension, then add the defoamer n-octanol, stir evenly, and then vacuum defoam at 0.003 MPa and 50 rpm for 5 minutes to obtain a slurry. The amount of ammonium persulfate added It is 0.026% of the total mass of the slurry.

[0101] (2) Add the above-mentioned slurry to the titrator, make it dispersed into droplets with a diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com