Low-expansion phosphate ceramic material and preparation method thereof

A ceramic material and phosphate technology, applied in the field of low-expansion ceramics, can solve problems affecting mechanical properties, low thermal expansion coefficient, and low density, and achieve high sintering temperature, good thermal shock resistance, and high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

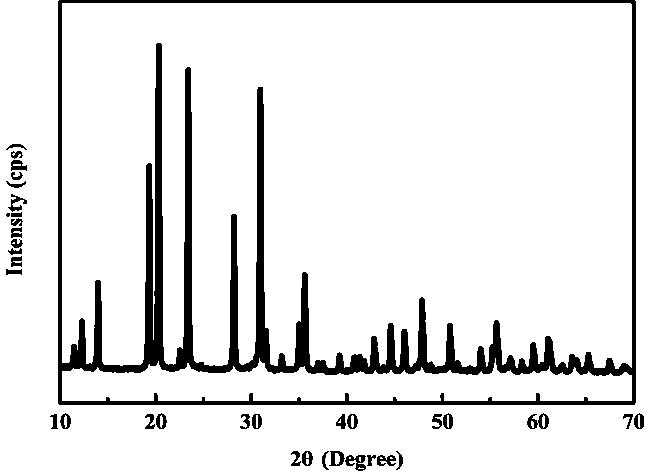

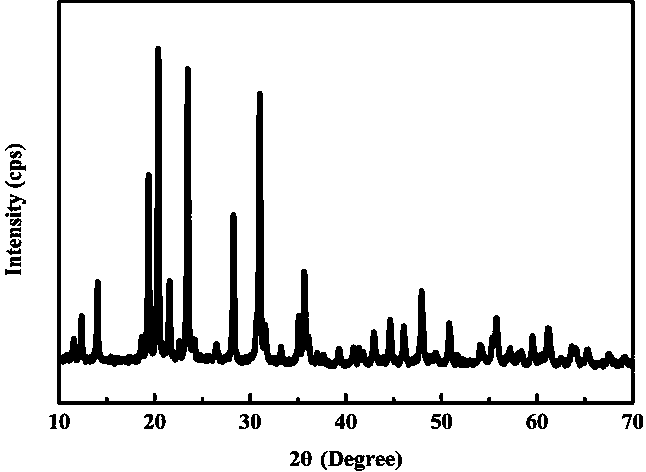

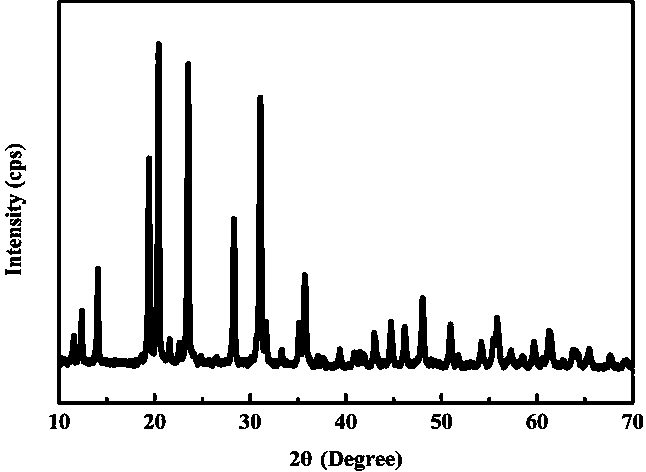

Image

Examples

Embodiment 1

[0016] (1) Calculate raw material CaCO according to x=0.03 3 , SrCO 3 、C 16 h 36 o 4 Ti, ZrOCl 2 ·8H 2 O and (NH 4 ) 2 HPO 4 quality, and then weighed with a balance. ZrOCl 2 ·8H 2 O was dissolved in distilled water to prepare an aqueous solution with a concentration of 0.6mol / L; the C 16 h 36 o 4 Ti was dissolved in ethanol and prepared into a 0.5mol / L ethanol solution; (NH 4 ) 2 HPO 4 Dissolved in distilled water to prepare an aqueous solution with a concentration of 1mol / L. CaCO 3 and SrCO 3dissolved in ZrOCl 2 ·8H 2 O aqueous solution, prepared as CaCO 3 , SrCO 3 and ZrOCl 2 ·8H 2 Aqueous solution of O salt, and C 16 h 36 o 4 Ti ethanol solution was added to the above CaCO 3 , SrCO 3 and ZrOCl 2 ·8H 2 In the aqueous solution of O salt, the formation simultaneously contains Ca 2+ 、Sr 2+ 、Ti 4+ 、Zr 4+ mixed solution. The above mixed solution was added dropwise to (NH 4 ) 2 HPO 4 In the aqueous solution, ammonia water was added dropwise ...

Embodiment 2

[0018] (1) Calculate raw material CaCO according to x=0.1 3 , SrCO 3 、C 16 h 36 o 4 Ti, ZrOCl 2 ·8H 2 O and (NH 4 ) 2 HPO 4 quality, and then weighed with a balance. ZrOCl 2 ·8H 2 O was dissolved in distilled water to prepare an aqueous solution with a concentration of 0.8mol / L; the C 16 h 36 o 4 Ti was dissolved in ethanol to prepare a 0.6mol / L ethanol solution; (NH 4 ) 2 HPO 4 Dissolved in distilled water to prepare an aqueous solution with a concentration of 1mol / L. CaCO 3 and SrCO 3 dissolved in ZrOCl 2 ·8H 2 O aqueous solution, prepared as CaCO 3 , SrCO 3 and ZrOCl 2 ·8H 2 Aqueous solution of O salt, and C 16 h 36 o 4 Ti ethanol solution was added to the above CaCO 3 , SrCO 3 and ZrOCl 2 ·8H 2 In the aqueous solution of O salt, the formation simultaneously contains Ca 2+ 、Sr 2+ 、Ti 4+ 、Zr 4+ mixed solution. The above mixed solution was added dropwise to (NH 4 ) 2 HPO 4 In the aqueous solution, ammonia water was added dropwise during ...

Embodiment 3

[0020] (1) Calculate raw material CaCO according to x=0.16 3 , SrCO 3 、C 16 h 36 o 4 Ti, ZrOCl 2 ·8H 2 O and (NH 4 ) 2 HPO 4 quality, and then weighed with a balance. ZrOCl 2 ·8H 2 O was dissolved in distilled water to prepare an aqueous solution with a concentration of 1mol / L; the C 16 h 36 o 4 Ti was dissolved in ethanol to prepare a 0.8mol / L ethanol solution; the (NH 4 ) 2 HPO 4 Dissolved in distilled water to prepare an aqueous solution with a concentration of 1.2mol / L. CaCO 3 and SrCO 3 dissolved in ZrOCl 2 ·8H 2 O aqueous solution to prepare CaCO 3 , SrCO 3 and ZrOCl 2 ·8H 2 Aqueous solution of O salt, and C 16 h 36 o 4 Ti ethanol solution was added to the above CaCO 3 , SrCO 3 and ZrOCl 2 ·8H 2 In the aqueous solution of O salt, the formation simultaneously contains Ca 2+ 、Sr 2+ 、Ti 4+ 、Zr 4+ mixed solution. The above mixed solution was added dropwise to (NH 4 ) 2 HPO 4 In the aqueous solution, ammonia water was added dropwise duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com