Lithium ion battery diaphragm, preparation method thereof and lithium ion battery

A technology of lithium-ion batteries and diaphragms, which is applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of high impedance of ceramic coatings and inability to effectively absorb metal ions, achieve low impedance, improve battery performance, Avoid the effect of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] On the other hand, the embodiment of the present invention also provides a preparation method of lithium-ion battery diaphragm, comprising the following steps:

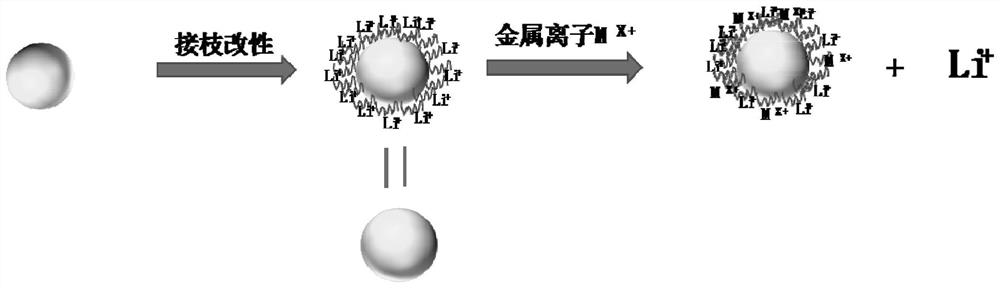

[0040] S01: Prepare a ceramic slurry containing the first type of particles and the second type of particles; wherein, the first type of particles contain ceramic particles and polymer lithium salt, and the ceramic particles and polymer lithium salt are connected by chemical groups;

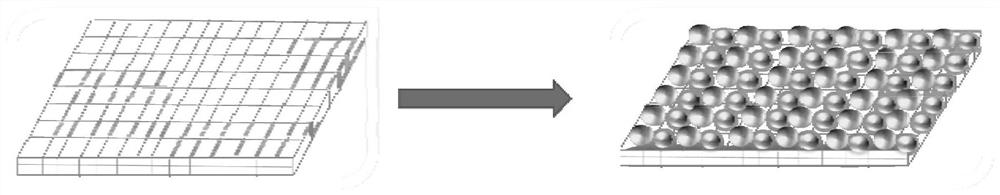

[0041] S02: coating the ceramic slurry on at least one surface of the base film, and then performing drying treatment to obtain a ceramic coating.

[0042] In the preparation method of lithium-ion battery diaphragm provided in the embodiment of the present invention, a ceramic coating containing the first type of particles and the second type of particles is formed on the surface of the base film, and the first type of particles modified with polymer lithium salt and the The combination of unmodified second-type particles can impr...

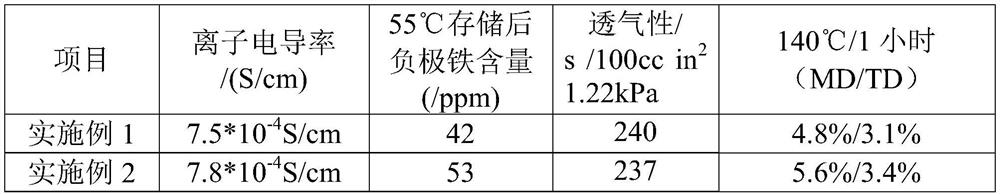

Embodiment 1

[0053] A preparation method for a lithium ion battery, comprising the steps of:

[0054] (1) Preparation of the positive electrode: disperse and dissolve the lithium iron phosphate positive electrode material, 1% SP, 1% CNT, and 3% PVDF binder in N-methylpyrrolidone, then coat it on a 12um aluminum foil, and dry it into the positive pole.

[0055] (2) Preparation of negative electrode: disperse graphite, 2% SBR, 1.5% CMC, and 1% SP in water, then coat on 8um copper foil, and dry to make negative electrode.

[0056] (3) Preparation of diaphragm:

[0057] Put the alumina ceramic powder with an average particle size of about 500nm into methyl ethyl ketone to disperse by ball milling, then add 3% KH550 (γ-aminopropyltriethoxysilane), reflux reaction, then cool, filter and wash to obtain Surface NH 2 - Chemically modified alumina particles.

[0058] Put the above-mentioned modified alumina particles and 3% acryloyl chloride into the dichloromethane solution to disperse and reac...

Embodiment 2

[0062] A preparation method of a lithium-ion battery, the preparation method of the separator is different, and the others are the same as in Example 1.

[0063] The membrane preparation method of the present embodiment is as follows:

[0064] Put the alumina ceramic powder with an average particle size of about 500nm into methyl ethyl ketone for ball mill dispersion, then add 3% KH550, reflux reaction, then cool, filter, and wash to obtain surface NH 2 - Chemically modified alumina particles.

[0065] Put the above-mentioned modified alumina particles and 3% p-vinylbenzenesulfonyl chloride into a dichloromethane solution for dispersion reaction, then disperse them in water with 30% lithium p-styrenesulfonate, add 0.3% ammonium persulfate / sodium bisulfate initiator, heated at 50° C. for 4 hours for polymerization reaction, and then centrifuged to obtain alumina particles grafted with polymer lithium salt (mass fraction of polystyrene sulfonate lithium 15%) on the surface.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com