Method for preparing rare earth silicate ceramics by chemical vapor deposition of oxygen-containing precursor

A chemical vapor deposition and rare earth silicate technology, which is applied in the field of preparing rare earth silicate ceramics by chemical vapor deposition of oxygen-containing precursors, can solve problems such as affecting the service life of SiCSiC materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1: Raw material preparation: wt20% yttrium oxide, wt75% water, wt2% binder polyvinyl alcohol, wt1% dispersant ammonium polyacrylate, wt2% sintering aid lithium carbonate

[0029] Step 2: Slurry configuration and impregnation:

[0030] a. The mixed solution of wt75% water, wt2% polyvinyl alcohol, wt1% ammonium polyacrylate and wt2% lithium carbonate was magnetically stirred, the stirring time was 30min, and the stirring rate was 100r / min;

[0031] b. Add wt20% yttrium oxide to the obtained uniformly mixed liquid, and perform ball milling, the rotating speed of the ball milling drum is 120r / min, and the ball milling time is 12h, to obtain a uniformly mixed yttrium oxide slurry;

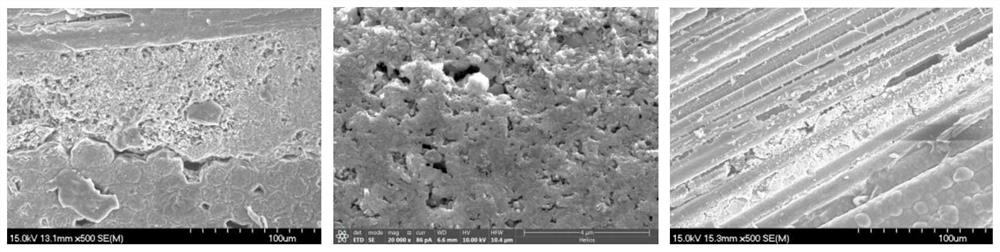

[0032] c. Vacuum and pressure impregnate the semi-dense ceramic matrix composite with yttrium oxide slurry, and dry at 120°C.

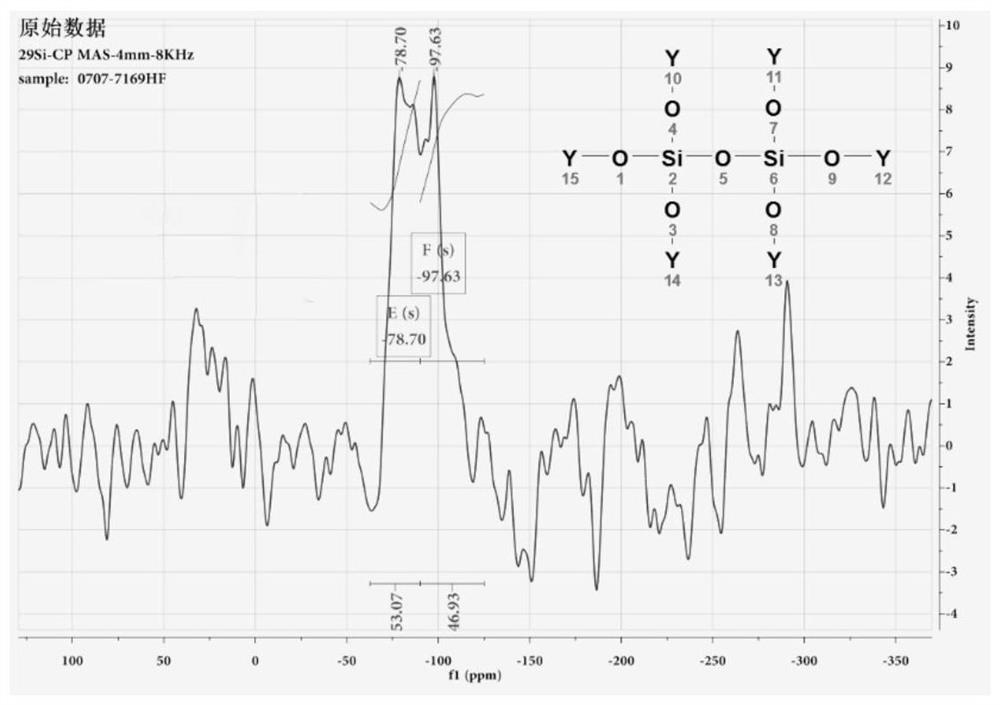

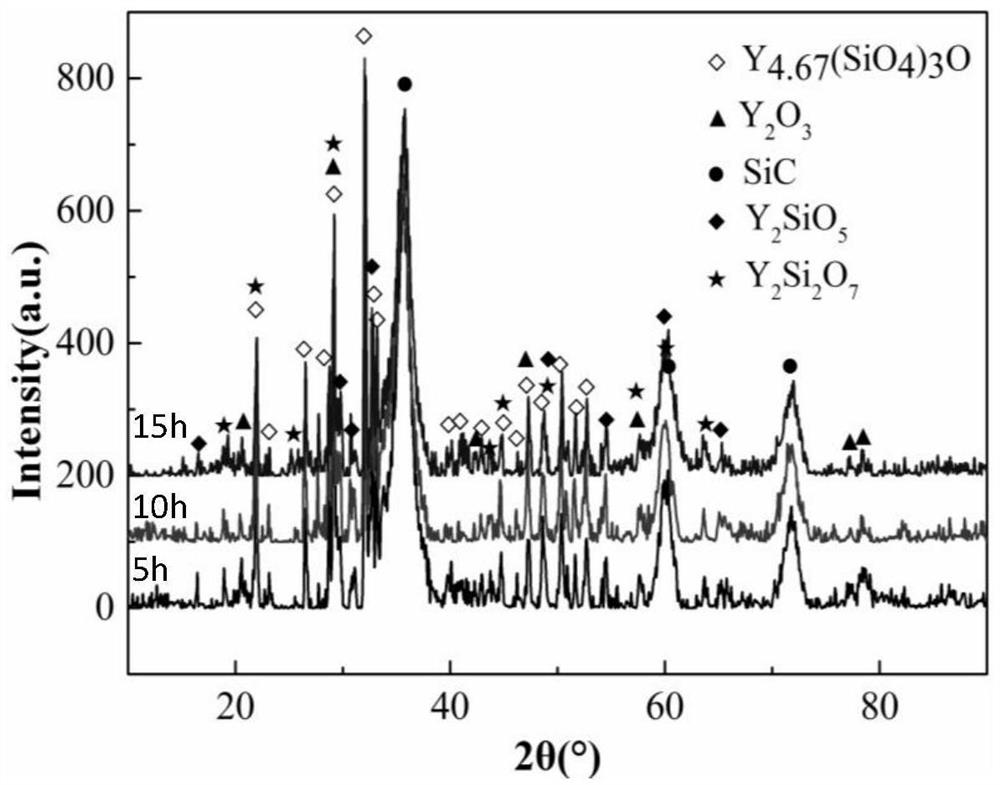

[0033] Step 3: Preparation of yttrium silicate by chemical vapor deposition: CH 3 SiCl 3 As a precursor, CO 2 As oxygen source, hydrogen as carrier gas and dilu...

Embodiment 2

[0036] Step 1: Raw material preparation: wt20% yttrium oxide, wt75% water, wt2% binder polyvinyl alcohol, wt1% dispersant ammonium polyacrylate, wt2% sintering aid lithium carbonate

[0037] Step 2: Slurry configuration and impregnation:

[0038] a. The mixed solution of wt75% water, wt2% polyvinyl alcohol, wt1% ammonium polyacrylate and wt2% lithium carbonate was magnetically stirred, the stirring time was 30min, and the stirring rate was 100r / min;

[0039] b. Add wt20% yttrium oxide to the obtained uniformly mixed liquid, and perform ball milling, the rotating speed of the ball milling drum is 120r / min, and the ball milling time is 12h, to obtain a uniformly mixed yttrium oxide slurry;

[0040] c. Vacuum and pressure impregnate the semi-dense ceramic matrix composite with yttrium oxide slurry, and dry at 120°C.

[0041] Step 3: Preparation of yttrium silicate by chemical vapor deposition: CH 3 SiCl 3 As a precursor, CO 2 As oxygen source, hydrogen as carrier gas and dilu...

Embodiment 3

[0044] Step 1: Raw material preparation: wt20% yttrium oxide, wt75% water, wt2% binder polyvinyl alcohol, wt1% dispersant ammonium polyacrylate, wt2% sintering aid lithium carbonate

[0045] Step 2: Slurry configuration and impregnation:

[0046] a. The mixed solution of wt75% water, wt2% polyvinyl alcohol, wt1% ammonium polyacrylate and wt2% lithium carbonate was magnetically stirred, the stirring time was 30min, and the stirring rate was 100r / min;

[0047] b. Add wt20% yttrium oxide to the obtained uniformly mixed liquid, and perform ball milling, the rotating speed of the ball milling drum is 120r / min, and the ball milling time is 12h, to obtain a uniformly mixed yttrium oxide slurry;

[0048] c. Vacuum and pressure impregnate the semi-dense ceramic matrix composite with yttrium oxide slurry, and dry at 120°C.

[0049] Step 3: Preparation of yttrium silicate by chemical vapor deposition: CH 3 SiCl 3 As a precursor, CO 2 As oxygen source, hydrogen as carrier gas and dilu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com