Polycrystalline, aluminosilicate ceramic filaments, fibers, and nonwoven mats, and methods of making and using the same

An aluminosilicate, ceramic fiber technology, applied in non-woven fabrics, chemical instruments and methods, textiles and papermaking, etc., can solve problems such as brittleness and breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

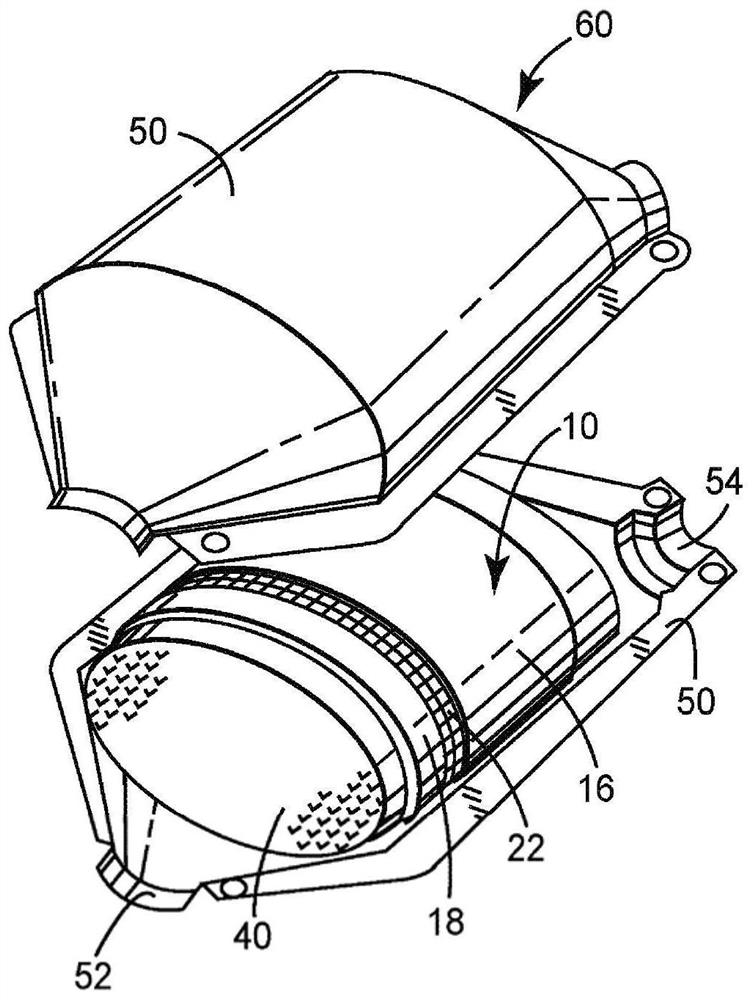

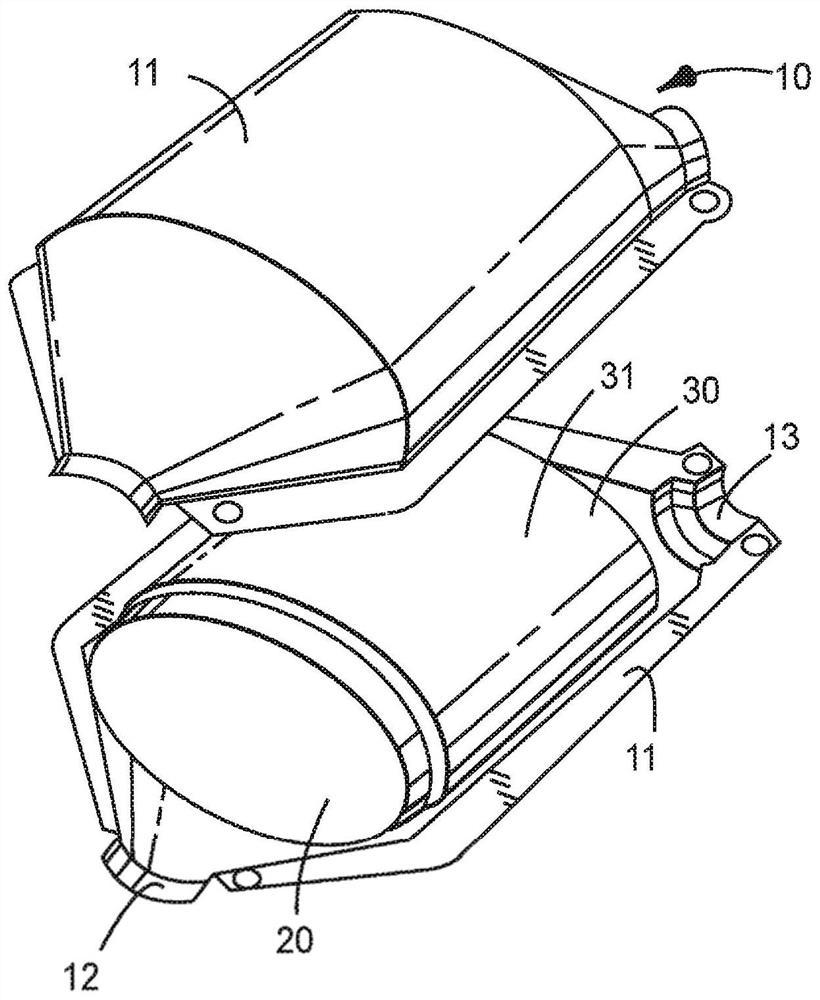

[0113] Suitable apparatus and exemplary orifices that can be used to practice the various embodiments of the disclosed method of making at least one substantially continuous or continuous filament are described in U.S. Patent 6,607,624, the entire disclosure of which Incorporated herein by reference in its entirety.

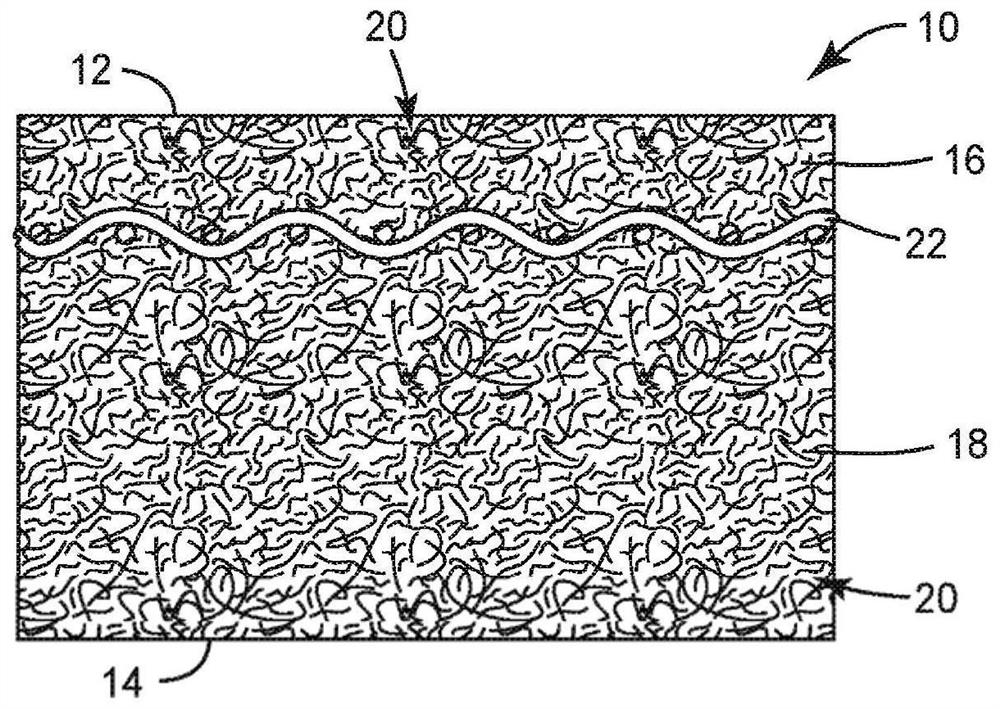

[0114]In a particularly preferred embodiment, the nonwoven web is formed at a temperature sufficient to convert the nonwoven web into a fluffy / loose structure consisting of at least one polycrystalline aluminosilicate ceramic filament having an average mullite percentage of at least 45% by weight. , layered, cohesive and / or bonded nonwoven web or mat temperature and time under heating (for example, firing). It may be desirable for the discontinuous fibers to be non-breathable. Generally, the nonwoven web of green filaments or fibers should be heated to a firing temperature of at least 500°C, 750°C, 1,000°C, 1,250°C, 1,500°C, or even higher. Higher firing temper...

Embodiment

[0131] These examples are for illustrative purposes only, and are not intended to unduly limit the scope of the appended claims. Notwithstanding that the numerical ranges and parameters setting forth the broad scope of the disclosure are approximations, the numerical values set forth in the specific examples are reported as precisely as possible. Any numerical value, however, inherently contains certain errors necessarily resulting from the standard deviation found in their respective testing measurements. At the very least, and without attempting to limit the application of the doctrine of equivalents to the scope of the claims, each numerical parameter should at least be construed in light of the number of reported significant digits and by applying ordinary rounding techniques.

[0132] Material summary

[0133] All parts, percentages, ratios, etc. in the examples, as well as in the remainder of this specification, are by weight unless otherwise indicated. Solvents an...

Embodiment 1

[0222] Green fiber nonwoven webs were produced using the sol preparation method (72 / 28 alumina / silica) and fiber spinning method 1 described above. A green fiber web was produced using a 160 hole die with a 5 mil orifice size (0.30 inch (7.6 mm) pitch) and an L / D of 2 / 1. The sol was fed through the die using a Zenith pump (1.168 cc / rev) at 20 rpm to achieve a theoretical sol rate of 0.233 g / hole / min. The sol was dried with heated air (58° C.) blown at 40 fpm (0.20 m / s) perpendicular to the fiber motion. The sol was attenuated into green fibers by air knives spaced 0.50 inches (1.3 cm).

[0223] Several layers of the green fiber web were needled together using a custom needle board with 15x25x40x3 CB needles from Foster Needle Co. Inc. of Manitowoc, WI, with a square spacing of 1.9 cm.

[0224] The needled green fiber web was pre-fired by heating first to 750°C within 50 minutes and then to 850°C within 40 minutes. When the furnace temperature reached about 130°C, about 75 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com