Patents

Literature

48results about How to "Good compression elasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

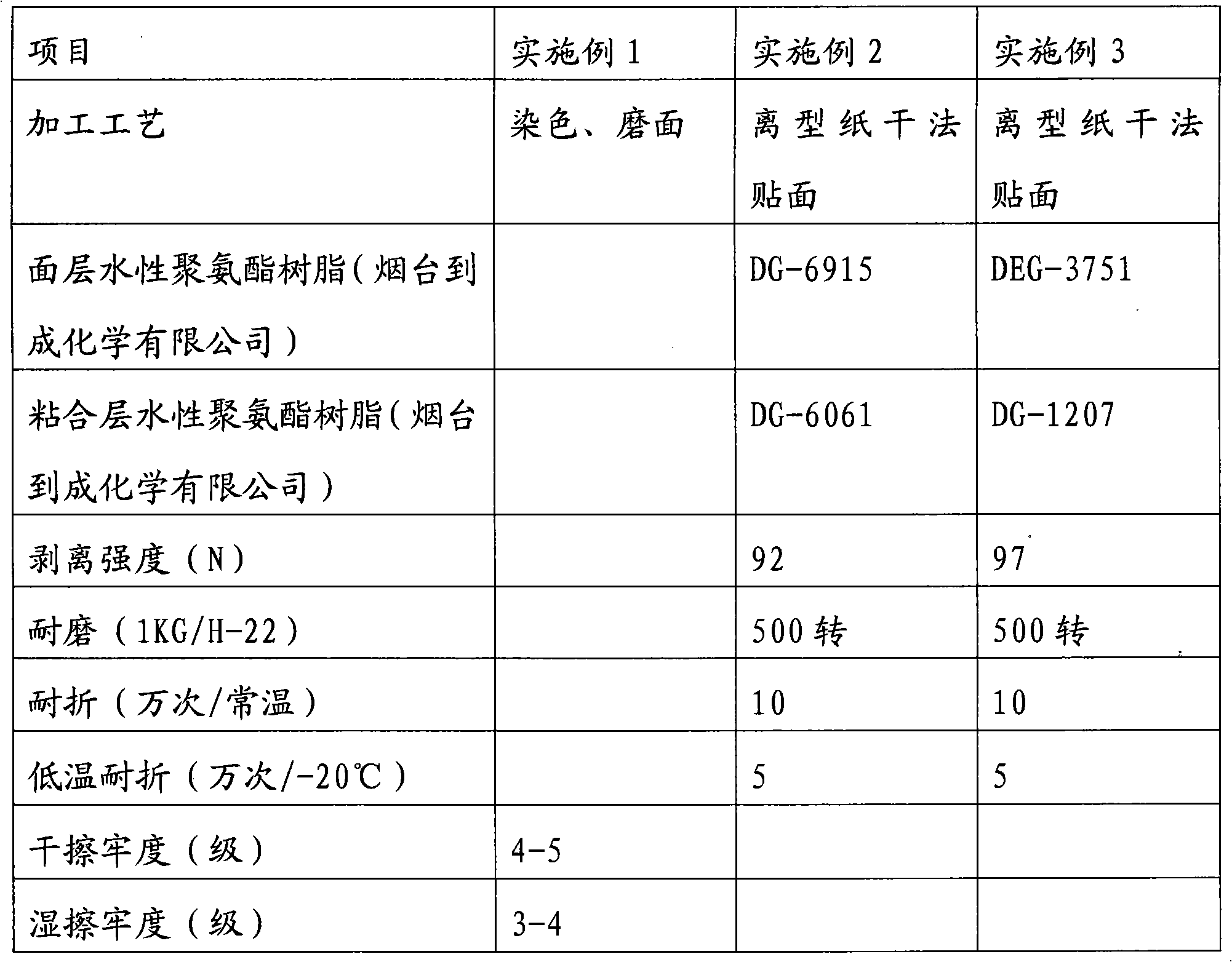

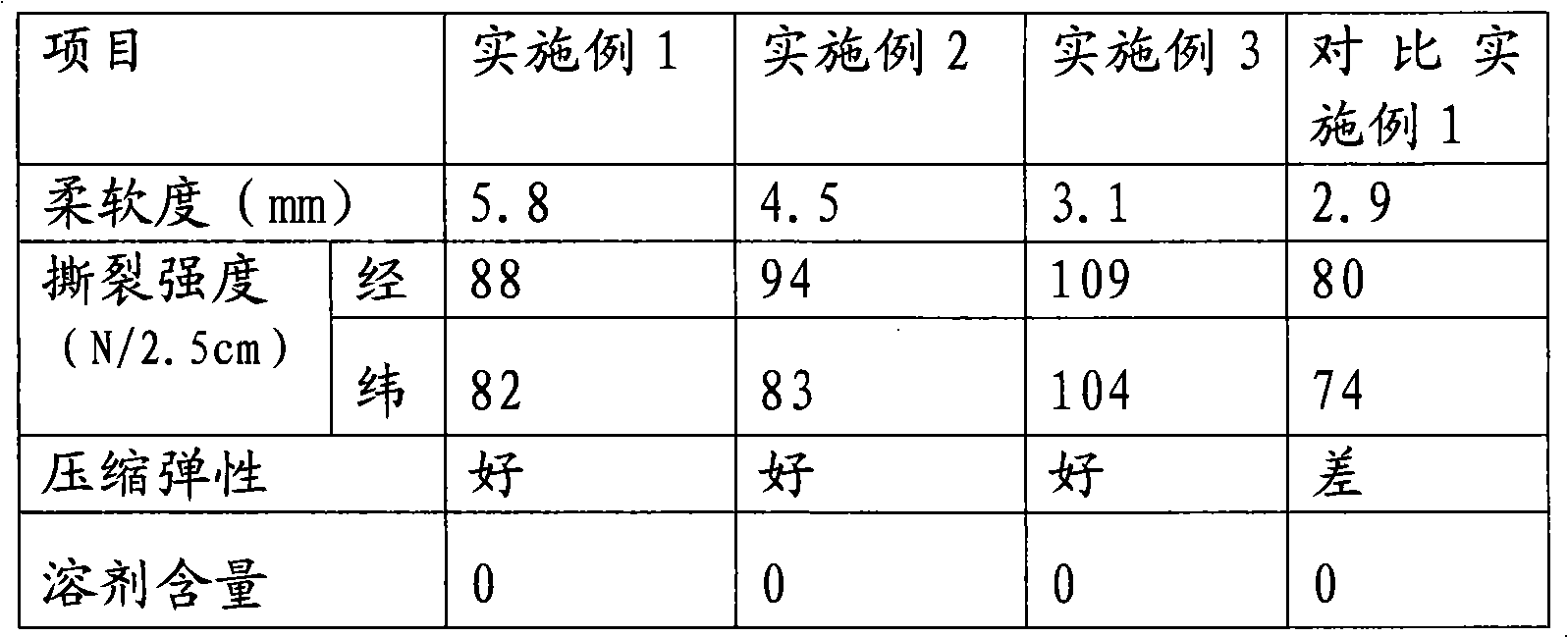

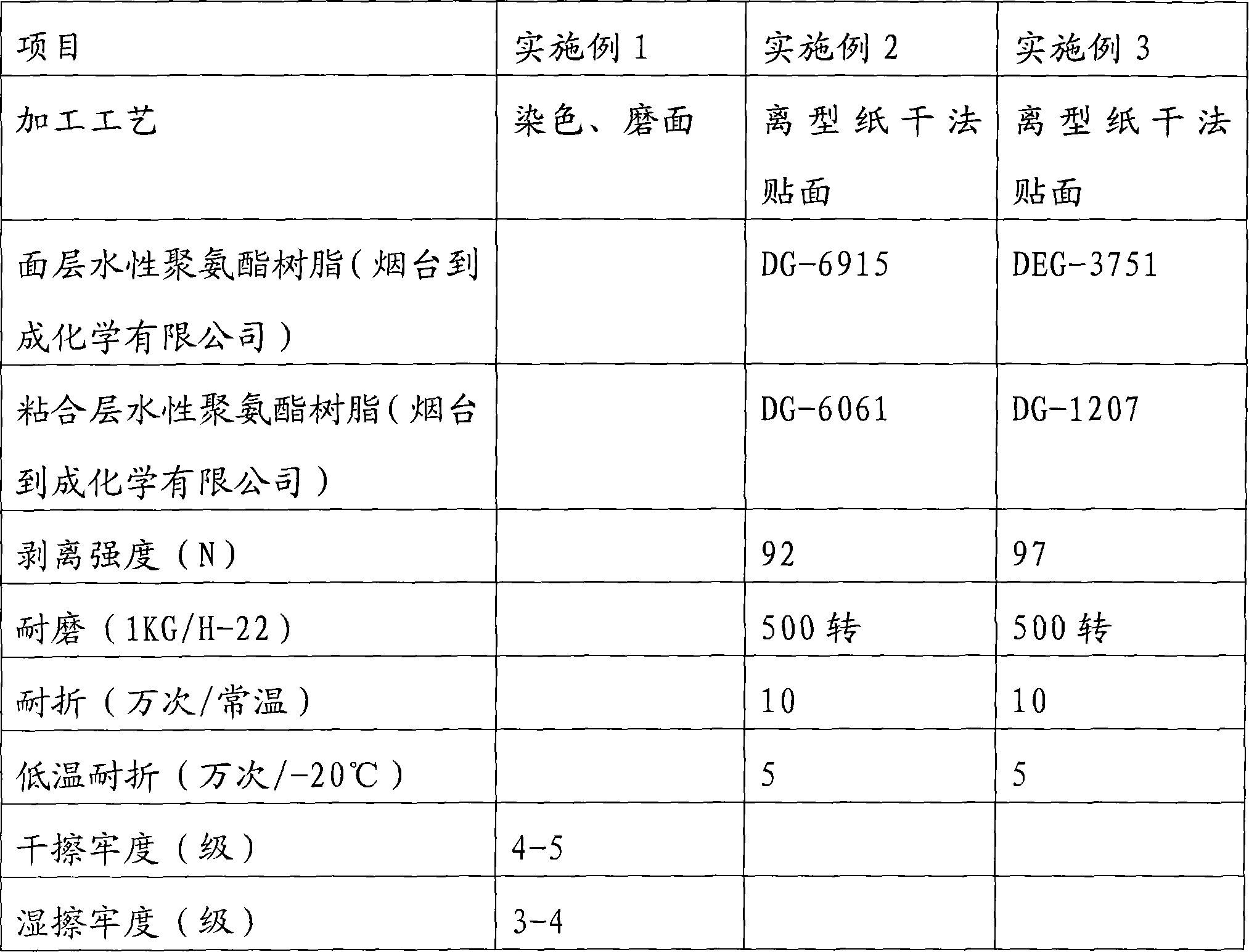

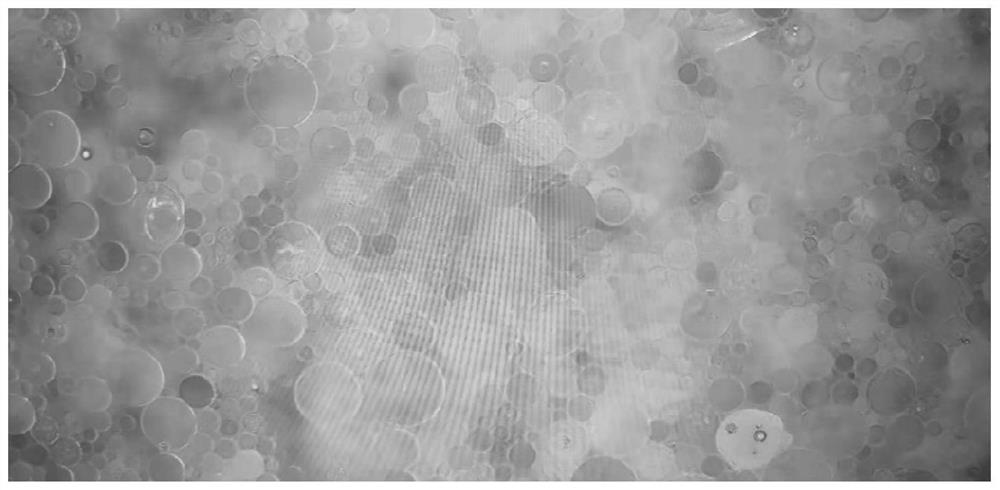

Aqueous polyurethane superfine fiber synthetic leather and preparation method thereof

The invention relates to aqueous polyurethane superfine fiber synthetic leather and a preparation method thereof. The preparation method comprises the following steps of: firstly, adding the following components according to parts by weight, i.e. 2-5 parts of foaming agents, 50-200 parts of water, 2-3 parts of foam stabilizers and 0-3 parts of waterborne colorants, into 100 parts of aqueous anionic polyurethane dipping sizing agents, and stirring the components and the sizing agents uniformly at high speed by using a blender so as to prepare a sizing agent; secondly, dipping non-woven fabricsin the sizing agent, scrapping the surface of the fabrics and keeping partial cells; thirdly, solidifying aqueous polyurethane on the dipped non-woven fabrics through aqueous coagulating liquid so asto form cells; fourthly, carrying out water scrubbing after aqueous polyurethane resin is completely solidified, and drying the aqueous polyurethane resin by an infrared drying oven so as to obtain base cloth; fifthly, treating the dried base cloth through an alkali reducing process; sixthly, treating the base cloth treated through the alkali reducing process through an postprocessing process; and seventhly, preparing the obtained base cloth into the synthetic leather. The aqueous polyurethane superfine fiber synthetic leather is prepared by the method.

Owner:HUADA CHEM GRP CO LTD

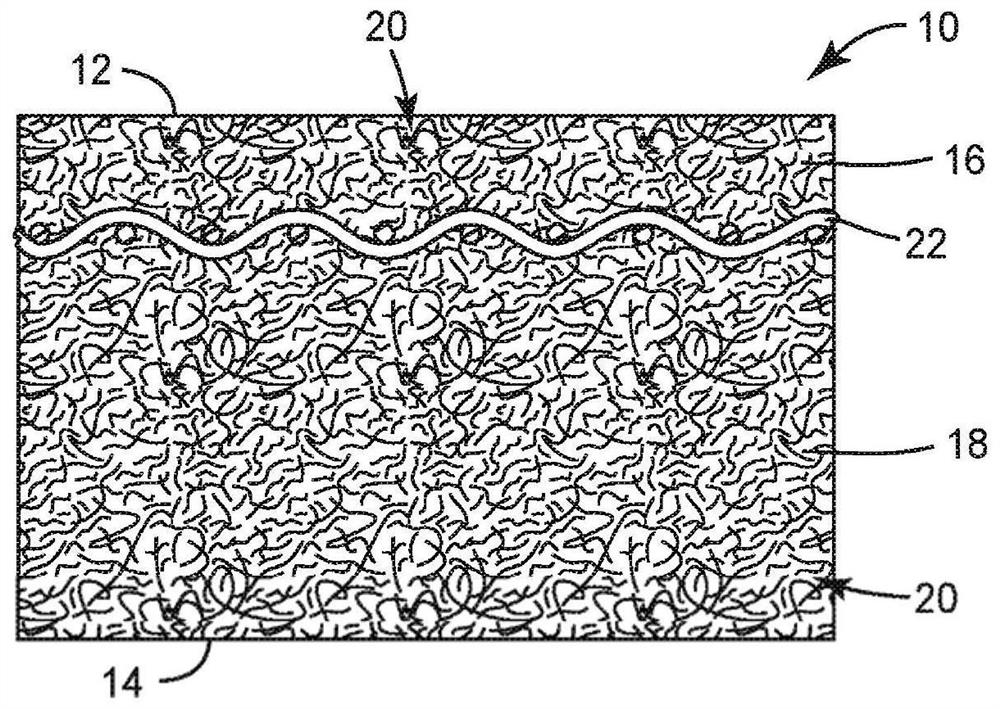

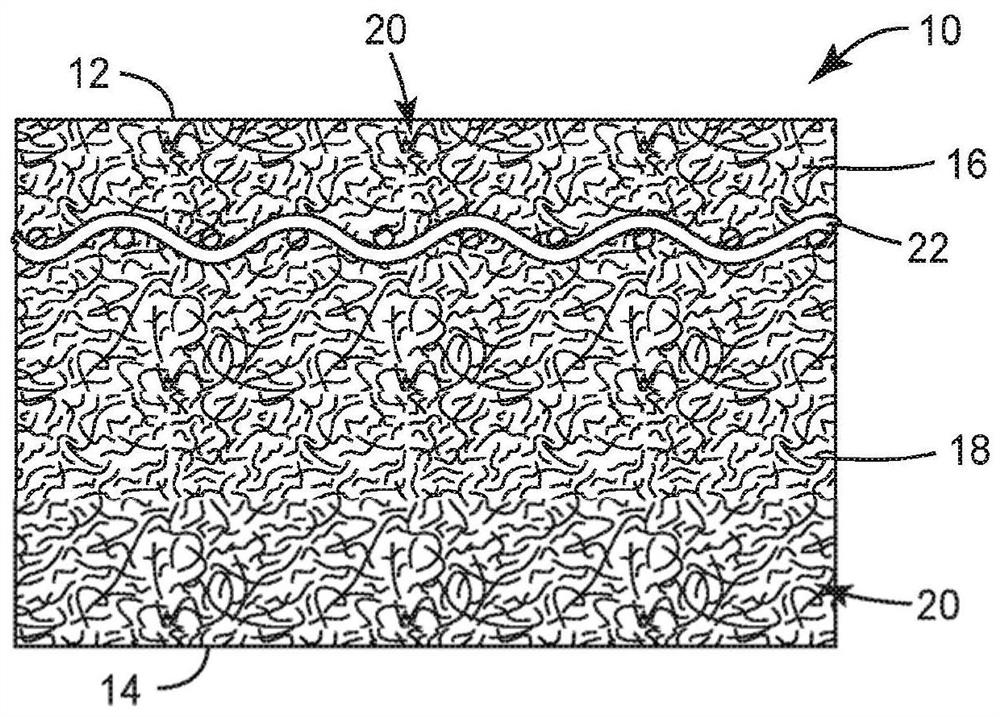

Alkaline battery separator and process for producing the same

InactiveUS6607859B1Increase stiffnessGood compression elasticityFinal product manufactureSecondary cells manufacturePolyolefinPolymer science

An alkaline battery separator which enables the preparation of a battery with a good yield and workability is provided. The alkaline battery separator of the present invention comprises a fiber sheet mainly comprising hydrophilicity-imparted polyolefin fibers having a fiber diameter of 8 mum or more, and a part of the hydrophilicity-imparted polyolefin fibers is composed of high-strength fibers having a tensile strength of 5 g / d or more.

Owner:NIPPON BAIRIIN

Water-based polyurethane superfine fiber synthetic leather and preparation method thereof

InactiveCN103774455AFeel goodEliminate solvent wasteLamination ancillary operationsSynthetic resin layered productsWoven fabricStabilizing Agents

The invention relates to a water-based polyurethane superfine fiber synthetic leather and a preparation method thereof. The preparation method comprises the following steps: 1) adding 4-8 parts by weight of a foaming agent, 50-200 parts by weight of water, 1-6 parts by weight of a foam stabilizing agent and 0-3 parts by weight of a water-based colorant into 120 parts by weight of a water-based anionic polyurethane impregnating slurry, and uniformly stirring at a high speed by a stirrer, to obtain a slurry; 2) impregnating a non-woven fabric in the slurry, scraping the surface flatly, and keeping a part of foam pores; 3) adopting a water-based solidification liquid to solidify water-based polyurethane of the impregnated non-woven fabric, and after the water-based polyurethane is solidified, forming foam pores; 4) after the water-based polyurethane resin is completely solidified, washing with water, drying by an infrared drying box, and thus obtaining base cloth; 5) carrying out an alkali deweighting process of the dried base cloth; 6) carrying out a posttreatment process of the base cloth obtained after the alkali deweighting process, and 7) preparing the synthetic leather from the obtained base cloth. The water-based polyurethane superfine fiber synthetic leather is prepared by the above preparation method.

Owner:李翠平

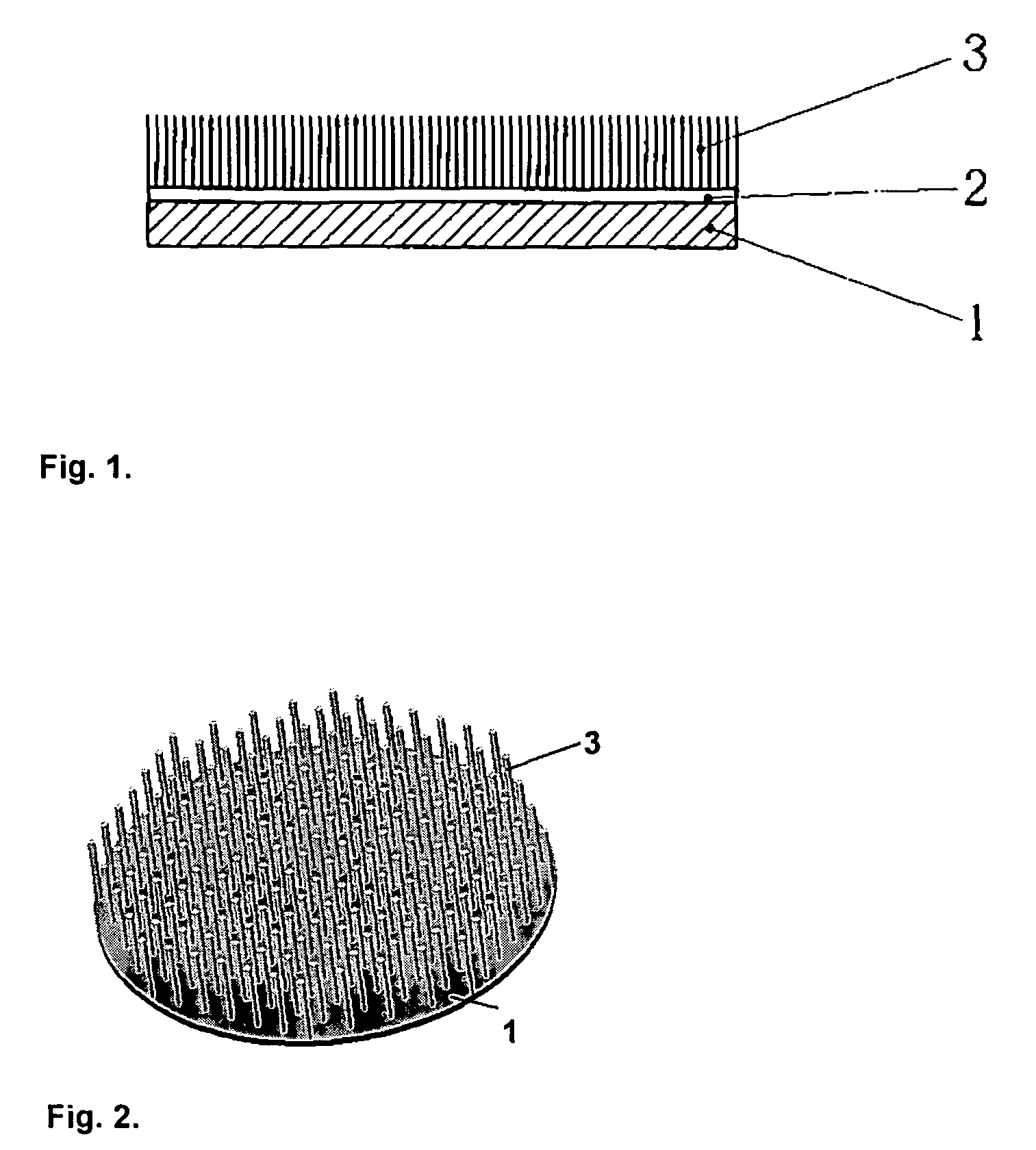

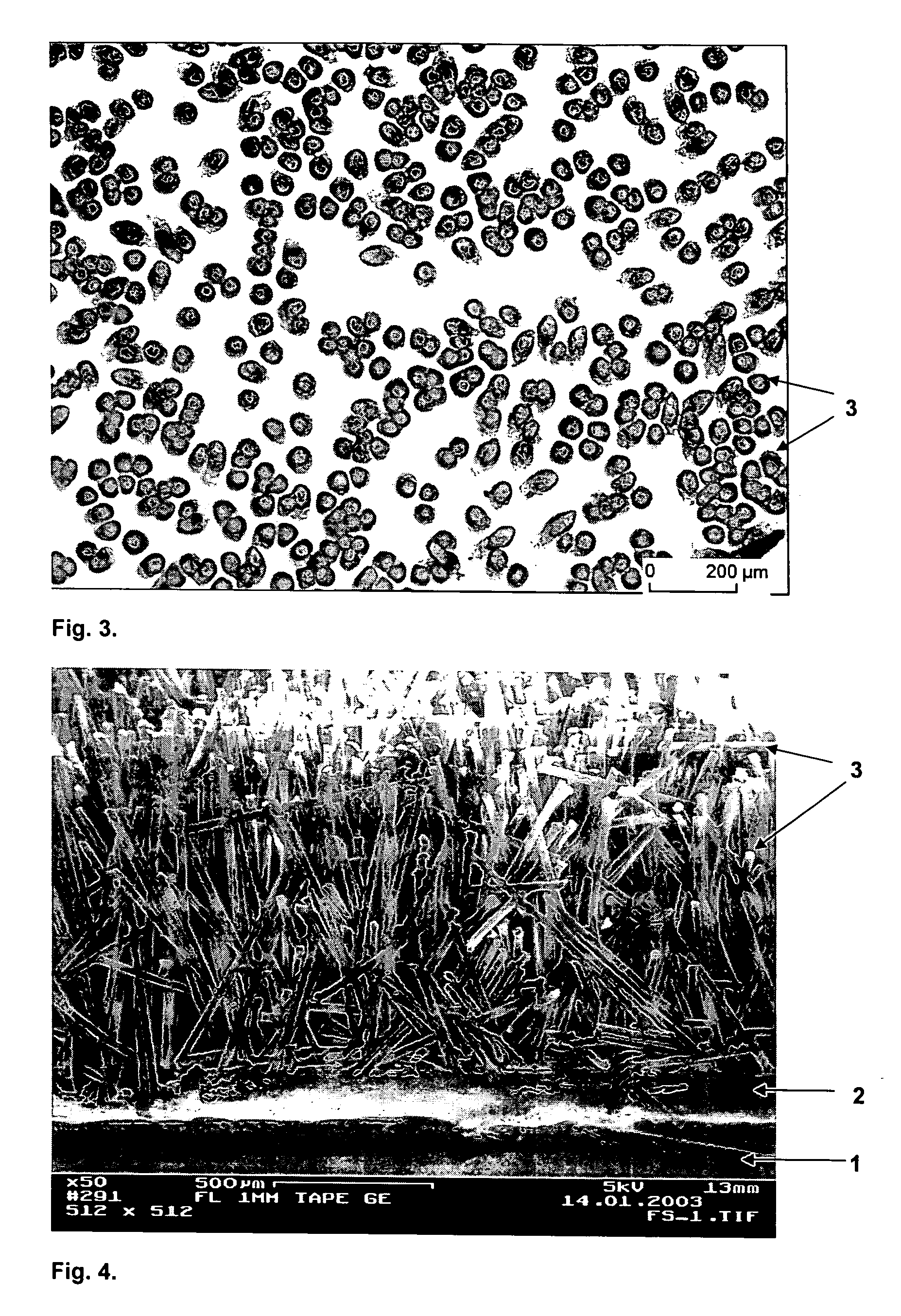

Support material for tissue engineering, for producing implants or implant materials, and an implant produced with the support material

InactiveUS7763272B2High fiber densityStable against compressionAdditive manufacturing apparatusSkin implantsIn vivoColonization

A scaffold for tissue culture and cell culture and for producing implant materials, in particular bone, cartilage or skin replacements or extra-corporal organ replacements or for other applications in medicine or biotechnology is made of biocompatible materials. It has at least one base material which is electrostatically flocked with fibers on at least one side. Through the electrostatic flocking the fibers are arranged almost perpendicularly on the surface of the base material and exhibits a high fiber pull-out resistance. The scaffold provides an elastic growth lattice, which is stable against compression, for cell colonization in vitro or the ingrowth of cells in vivo. Implants or implant materials can be produced with the scaffold.

Owner:DRESDEN UNIVERSITY OF TECHNOLOGY

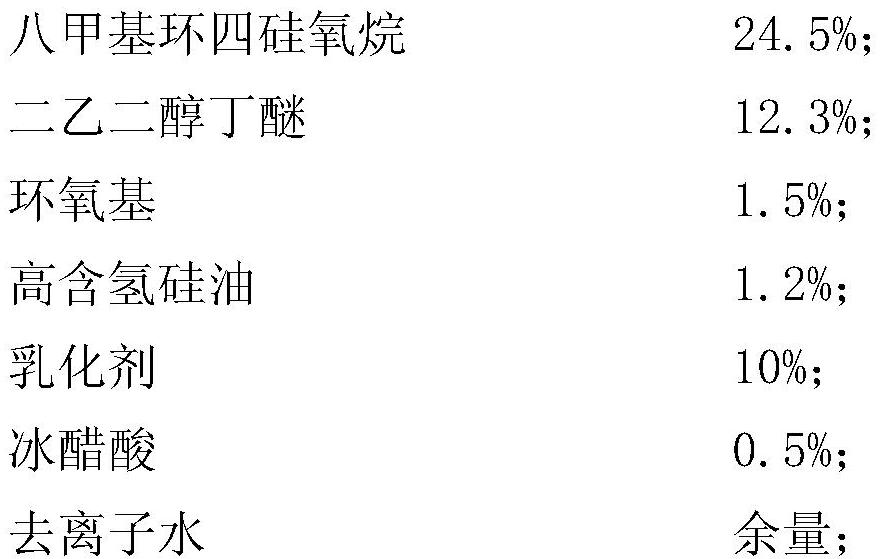

Silicone foam material and preparation method thereof

The invention belongs to high polymer fire-proof sealing materials and relates to a silicone foam material and a preparation method thereof. The material has the starting material formulation as follows based on parts by weight: 10-90 parts of alpha, omega-dihydroxyl polysiloxane, 1-10 parts of emulsifiers, 10-90 parts of fillers, 20-50 parts of flame retardants, 1-10 parts of cross linkers, 1-5 parts of catalysts and 5-15 parts of foaming agents. The silicone foam body of the invention is free from impurities, cracks and obvious coarse pores, has fine stretching property, pressure elasticity, toughness, water and air tightness, has heat insulation and refractory oxidation functions, can compensate mechanical displacement caused by mechanical pipeline vibration and building subsidence, has good sealing property, has fine adhesive properties to various metallic and non-metallic materials, has no corrosivity and toxic and harmful components, produces no toxic gas and is secure to human bodies.

Owner:HAILONG EMERSON ZHENJIANG ENERGY TECH

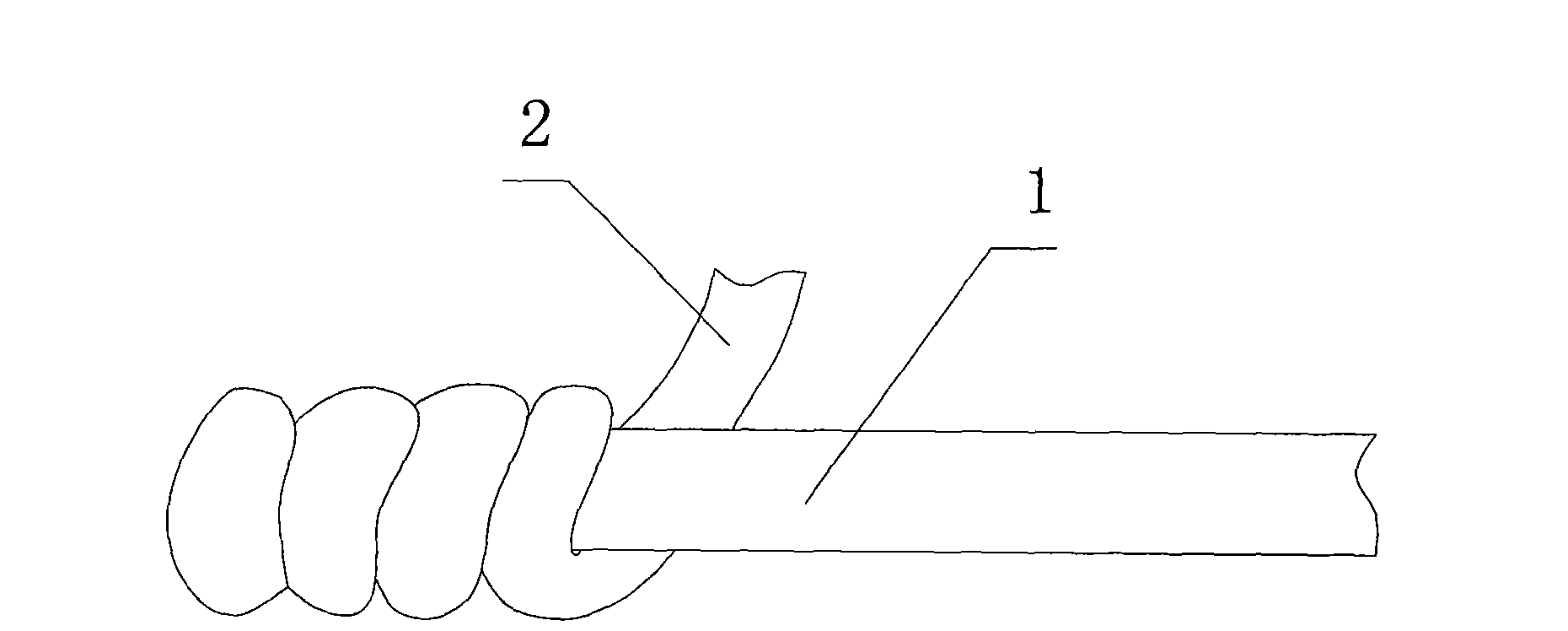

High performance flexibility heat-resisting material and process thereof

InactiveCN101666011AHigh strengthImprove impact resistanceWeft knittingWarp knittingHigh resistanceYarn

The invention discloses a high performance flexibility heat-resisting material, comprising PBO staple fibre yarn and stainless steel fibre yarn, wherein, the number of the stainless steel yarn is 5-50Nm and the diameter is 6-50 mu; and the number of PBO fibre yarn is 5-60 Ne, the content of PBO staple fibre yarn is 20% to 80% and the content of stainless steel fibre yarn is 80% to 20%. The preparation process of the material is as follows: firstly taking the stainless steel fibre yarn as the core yarn, and winding the PBO staple fibre yarn spirally on the stainless steel fibre yarn to form cladding yarn; then entwisting the cladding yarn into two threads; and finally weaving the threads into knitting fabric to obtain the finished products. The invention has the beneficial effects of integrating the advantages of PBO fibre and stainless steel fibre, having high strength, high shock resistance, high buffering, high heat resistance and high corrosion resistance, being very flexible, andhaving long service life and low cost.

Owner:CHENGDU JUHE NEW MATERIALS TECH

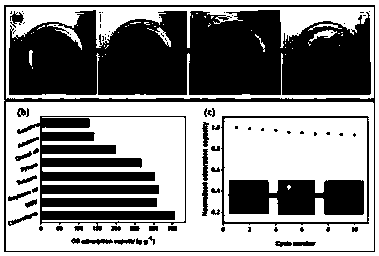

Preparation method and application of porous foam material based on biomass nano material

The invention discloses a preparation method and application of a porous foam material based on a biomass nano material. The preparation method specifically comprises the following steps: 1) mixing the biomass nano material with an organic amine, a cross-linking agent, a solvent and a filler to form a dispersion liquid; 2) freezing the dispersion liquid at a low temperature; carrying out cross-linking reaction on the organic amine and a cross-linking agent under a freezing condition to form cross-linked ice gel; and 3) drying the ice gel to obtain the solid porous material. The organic amine comprises one or a mixture of more of amine-containing polymer and polyamine, and the porous foam material has low thermal conductivity and good flexibility, and can be used for heat insulation and preservation, buffer materials, pollution adsorption materials and the like.

Owner:浙江跃维新材料科技有限公司

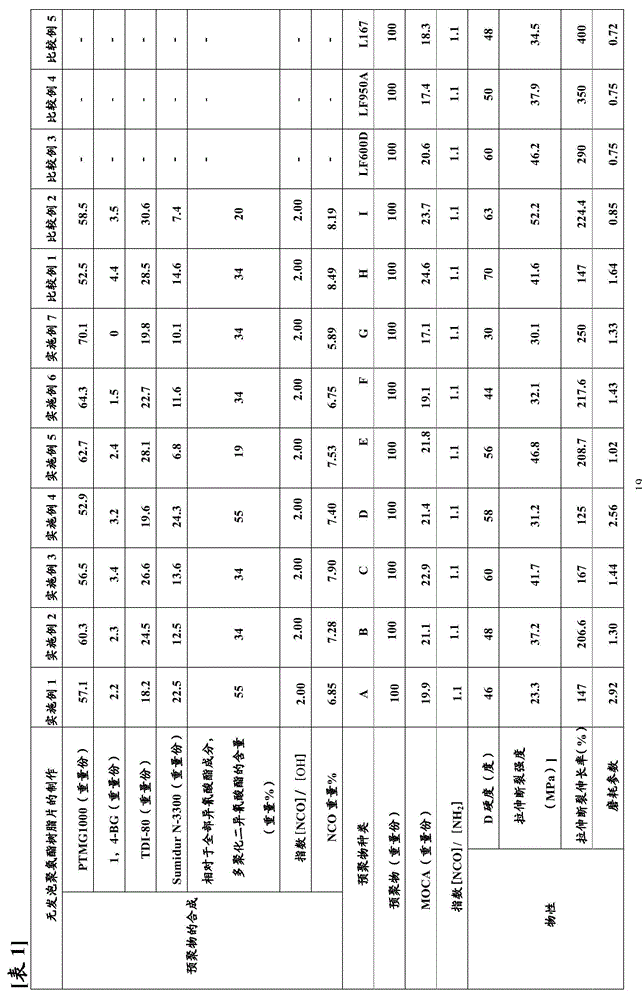

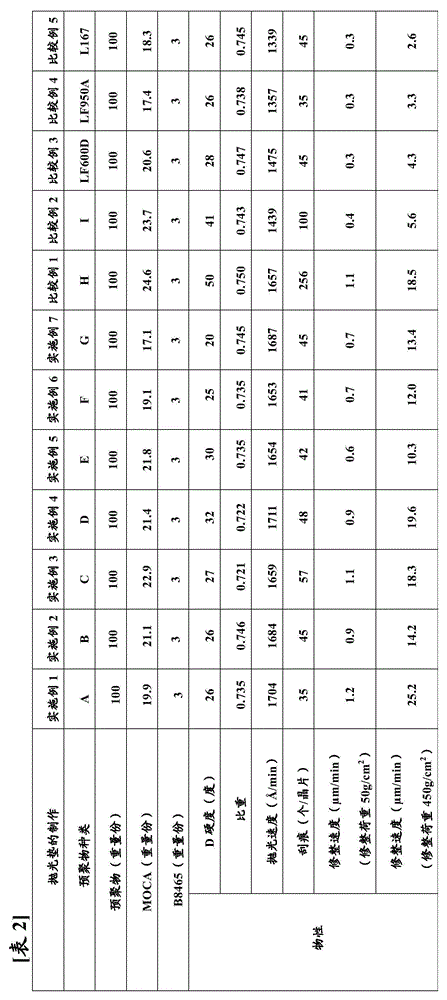

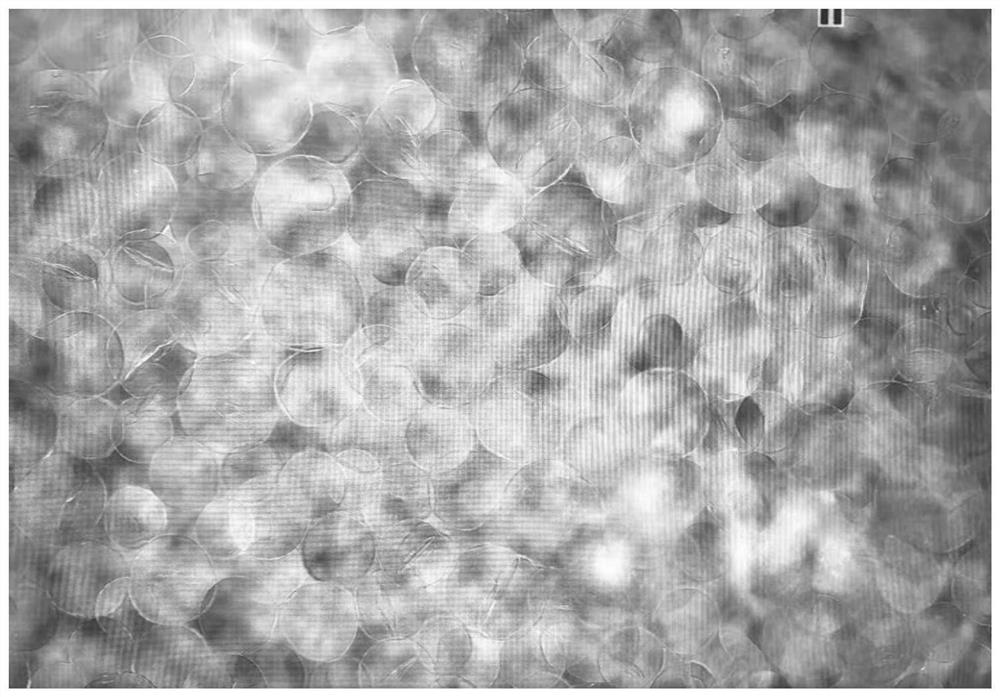

Polishing pad

InactiveCN103958125ALow hardness and softLarge wear parametersAbrasion apparatusSemiconductor/solid-state device manufacturingBreaking strengthHardness

An aim of the present invention is to provide a polishing pad which generates almost no scratches on the surface of an object to be polished, and has improved dressability. Another aim of the present invention is to provide a semiconductor device manufacturing method using the polishing pad. The polishing pad according to the present invention comprises a polishing layer formed of a microbubble-containing polyurethane resin foam. The polyurethane resin foam contains a polyurethane resin whose asker D hardness is between 20 degrees and 60 degrees, and whose wear parameter, which is expressed by the following formula, is between 1 and 3. Wear parameter = {1 / (tensile breaking strength [MPa] tensile breaking elongation [%] / 100)} 100

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

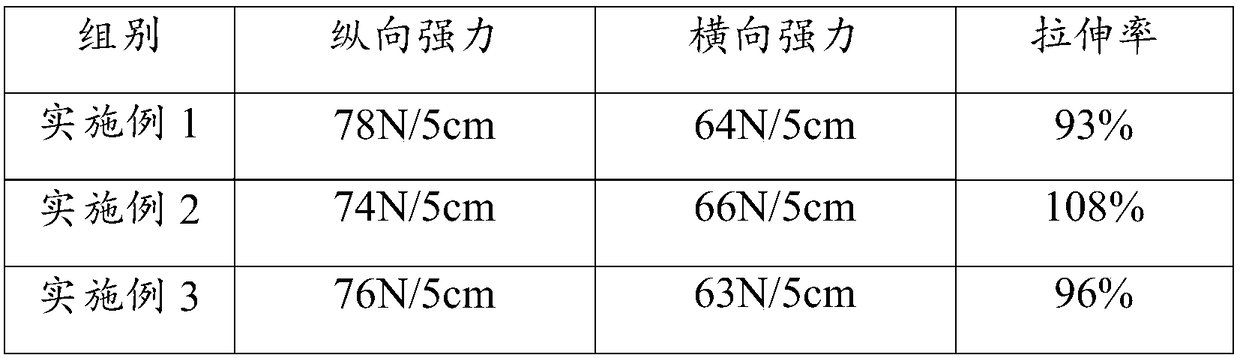

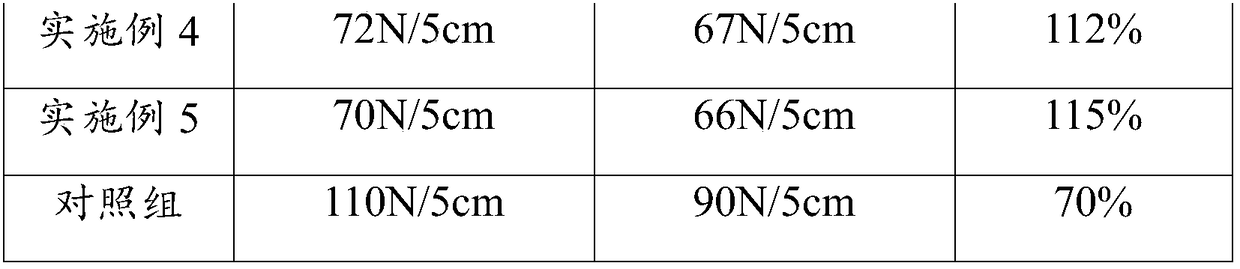

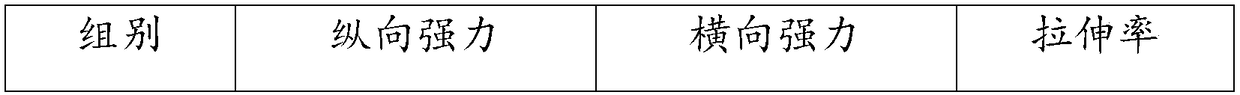

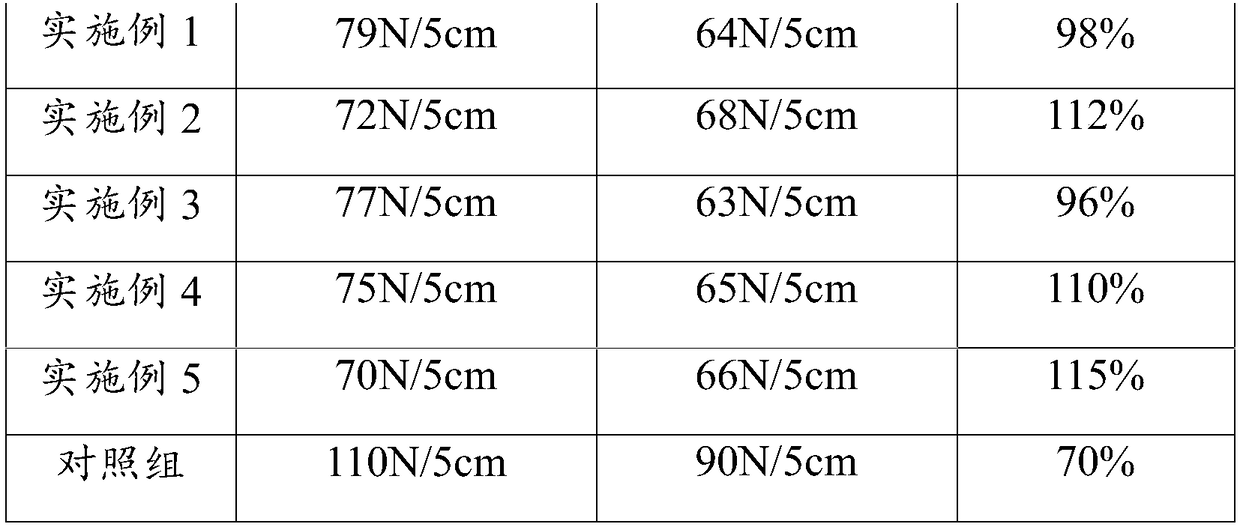

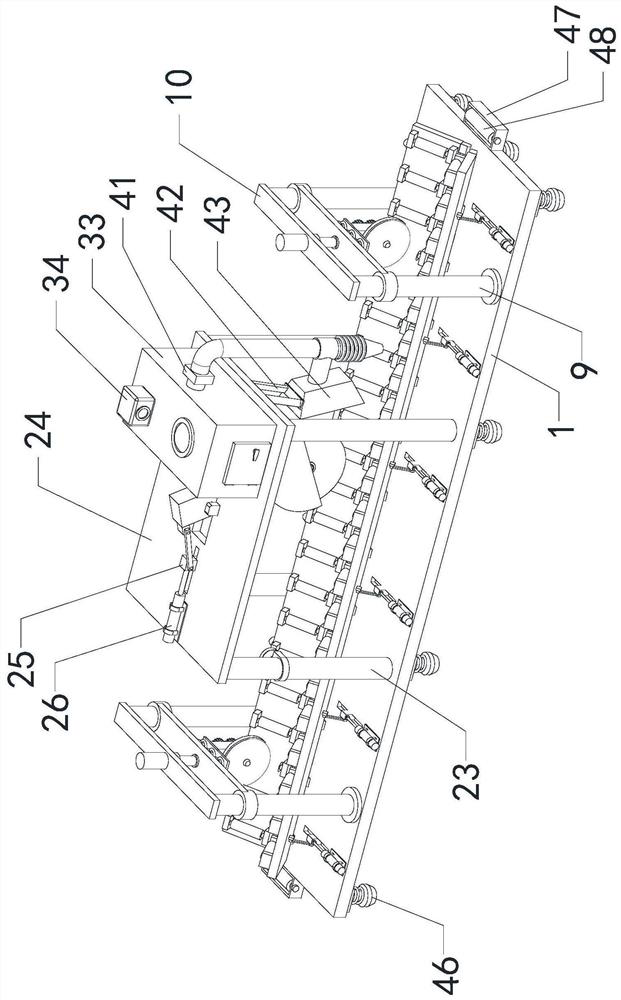

Production technology of high-performance composite material based on Chinese hemp fibers

ActiveCN111607898AGood compression elasticityIncrease elasticityBiochemical treatment with enzymes/microorganismsGrip property fibresHemp fibreCeramic materials

The invention discloses a production technology of a high-performance composite material based on Chinese hemp fibers. The production technology comprises the steps of firstly, Chinese hemp fiber pretreatment, specifically, the process comprises the steps of (1) mechanical neatening operation; (2) acid pickling operation; (3) enzyme cold heaping operation, specifically, by the mass percentage, 0g / L-5g / L of degumming compound enzymes, 2g / L-4g / L of wetting softening agents and 1g / L-2g / L of metal ion complexing agents are heated to enable the temperature to range from 35 DEG C to 40 DEG C under the condition that the bath ratio is 1:5-20, the temperature is kept for 12-60 hours, and then water cleaning operation is conducted for 1-2 times; (4) oxygen bleaching operation; (5) water cleaning operation; and (6) softening operation, specifically, by the mass percentage, 5g / l-10g / l of elastic finishing agents are added, the temperature is increased to range from 30 DEG C to 50 DEG C, and the temperature is kept for 20 minutes; and secondly, composite material forming, specifically, pre-opening treatment, roller carding treatment and stretch-breaking treatment are conducted, the Chinese hemp fibers which are subjected to stretch-breaking treatment is subjected to opening treatment, low-melting point fibers are subjected to opening treatment, the Chinese hemp fibers and the low-melting-point fibers are subjected to carding treatment respectively, cross laying treatment and needling treatment are conducted, and finally, the fibers are dried to form the high-performance composite material. The utilization rate of Chinese hemp raw materials is effectively improved, and the comprehensive excellent performance of compression resistance, elasticity, breathability, flame retardance andthe like is achieved.

Owner:马建伟 +1

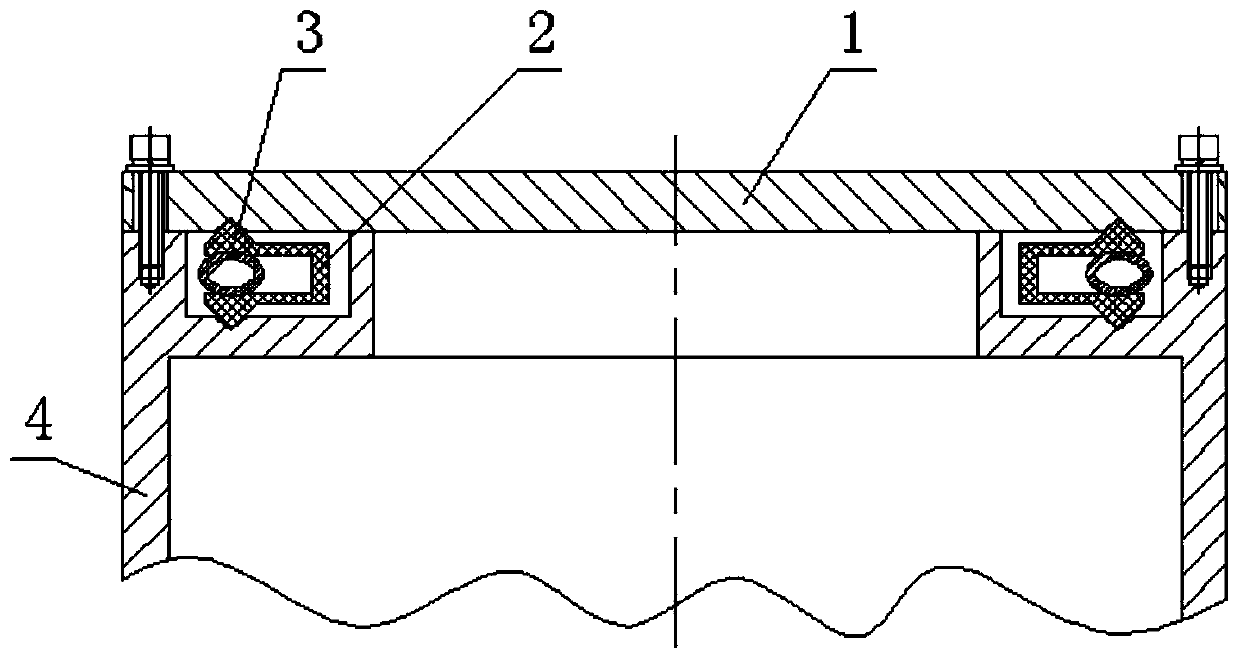

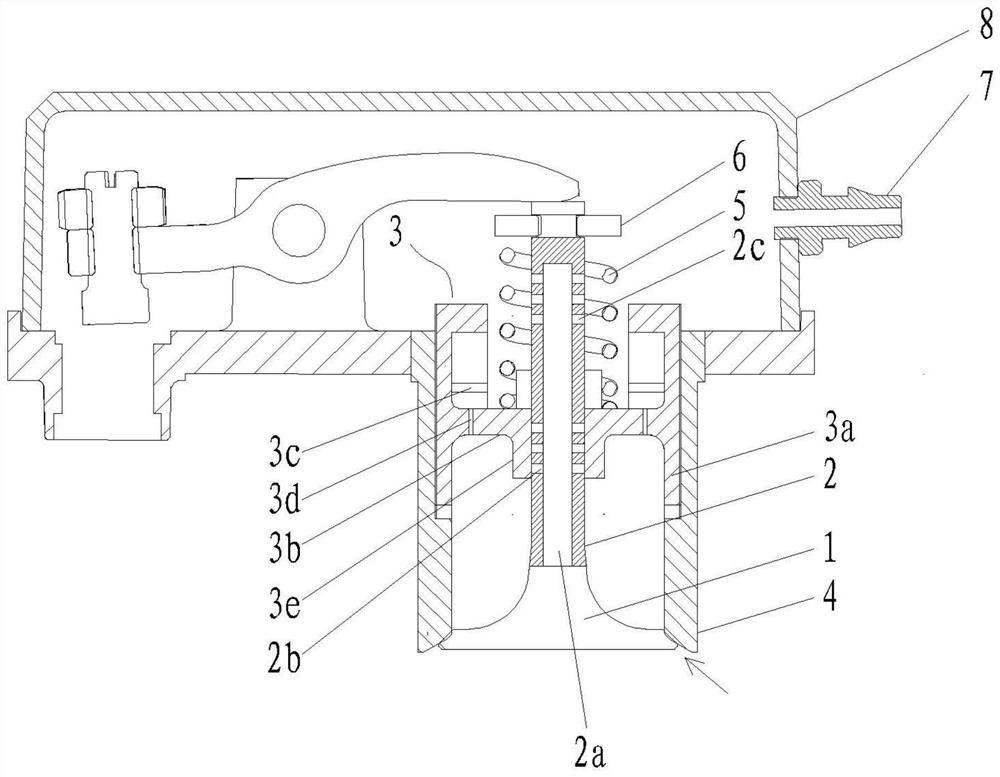

Sealing device suitable for corrosive liquid

ActiveCN110748645AGuaranteed a reliable sealGood compression elasticityAmmunition projectilesEngine sealsEngineeringMechanical engineering

The invention discloses a sealing device suitable for corrosive liquid. The axis of a revolving body of a lower-end part coincides with the axis of a revolving body of an upper-end part; the lower-endpart is positioned at the lower end of the upper-end part; a fourth upper-end concentric annular surface of the lower-end part makes contact with a first circular plane of the upper-end part; the lower-end part is connected with the upper-end part through screws; sealing original parts are positioned in fourth upper-end annular grooves of the lower-end part; and second lower end annular protrusions of the sealing original parts make contact with the fourth annular grooves of the lower end part. According to the sealing device suitable for the corrosive liquid, spring rings are embedded in polytetrafluoroethylene, the compression elasticity of the polytetrafluoroethylene is improved through the spring rings, so that the combination of the polytetrafluoroethylene and the spring rings has two characteristics of good elasticity and corrosion resistance at the same time, so that the corrosion resistance requirement and the sealing requirement of a warhead shell are met at a mechanical interface, and the reliable sealing performance of a corrosive liquid charge warhead in the long-term storage process is guaranteed.

Owner:XIAN MODERN CHEM RES INST

Silicone foam fireproof blocking material

The invention provides a fire-resistant silicone blocking material, which relates to a fire-resistant blocking material for seams when pipelines pass walls. The fire-resistant blocking material contains no toxic component, is fire resistant, of stretching and compression elasticity, can compensate the displacement caused by vibration in mechanical pipelines and settlement of buildings, and are easy for maintaining pipelines and cables. The invention uses silicon oil, silica gel, color additive, reinforcing agent, structure controlling agent, retardant, catalyst and solvent, and is characterized in that the substrate gel is synthesized by silica gel, silicone oil, reinforcing agent, structure controlling agent and solvent. At using, a black even thick gel that is prepared by synthesizing the substrate gel, silicone oil and color agent is mixed at 1:1 proportion with a white even thick gel that is prepared by synthesizing the substrate gel, silicone oil, retardant, catalyst and solvent, then they are vulcanized and foamed to form an elastic foam body. The invention is for blocking in a fire resistant way the seams when pipes, cables, vent tubes pass walls.

Owner:SHANGHAI SENLIN SPECIAL TYPE STEEL DOOR

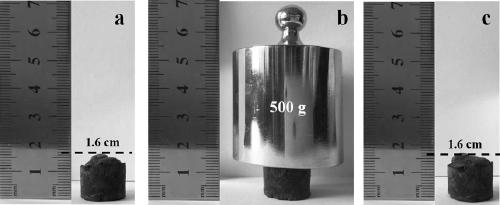

Preparation method of carbon aerogel

ActiveCN110040713AImprove mechanical propertiesGood compression elasticityOther chemical processesCarbon preparation/purificationOrganic solventPolyvinyl alcohol

The invention discloses a preparation method of carbon aerogel. The carbon aerogel is prepared through a one-step method by taking carbon nanospheres as raw materials, and performing a heating reaction in a water solution system and performing freeze drying in the presence of polyvinyl alcohol serving as a crosslinking agent and borax serving as a structure-directing agent. The carbon aerogel prepared by the invention has good mechanical performance, strong adsorption capacity for oil products and organic solvent, high adsorption rate, good recycling and reproduction performance, and high practicability, and can be applied in the fields of oil-water separation, oil stain collection and the like.

Owner:TAIYUAN UNIV OF TECH

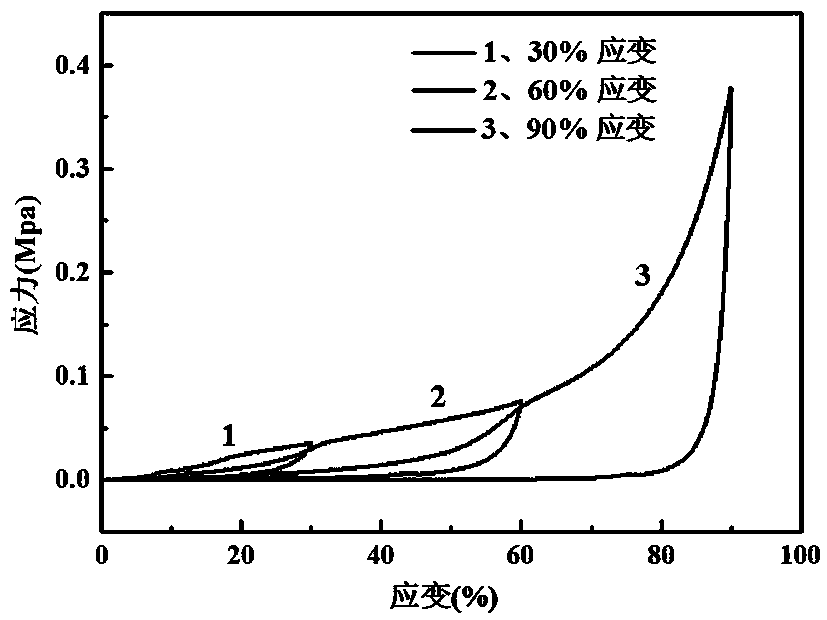

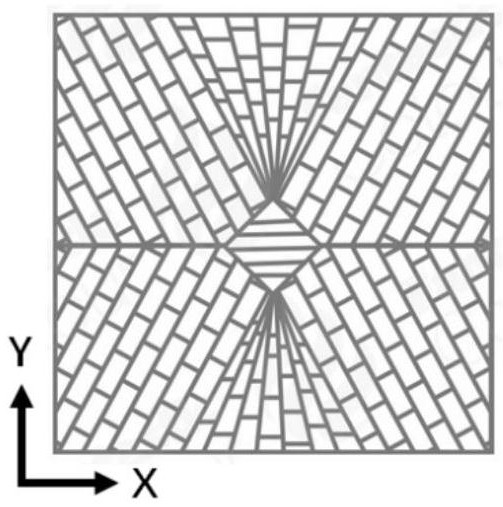

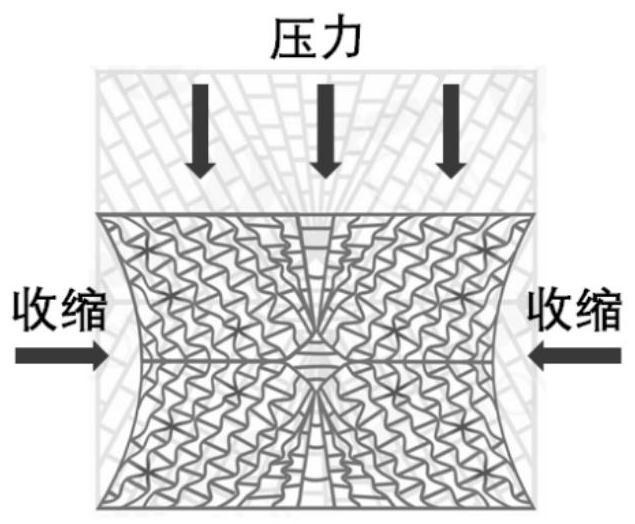

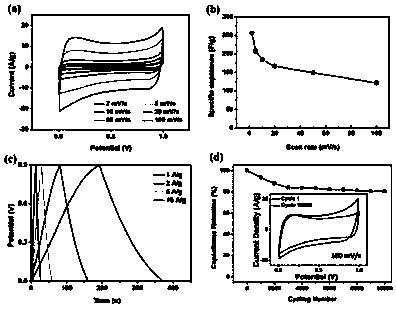

Conductive porous pressure-sensitive metamaterial with negative Poisson's ratio characteristic and preparation method and application thereof

ActiveCN112945431ACompressible hyperelasticHas ultra-sensitive pressure-sensitive propertiesFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsFreeze-dryingCross linker

The invention relates to a conductive porous pressure-sensitive metamaterial with a negative Poisson's ratio characteristic and a preparation method and application thereof, and belongs to the field of sensing material and sensing device research. The conductive nano material is mixed with an organic cross-linking agent, and hydrothermal reaction is performed to form a uniformly dispersed aqueous solution; a porous block material with a symmetrical concave honeycomb-shaped micropore structure is formed through a directional freeze-drying technology; through heating and roasting, the nanometer material and the organic cross-linking agent form a cross-linked network. When the porous metamaterial disclosed by the invention is pressed, bidirectional shrinkage is caused by the negative Poisson's ratio, so that the density of the metamaterial and the number of conductive paths are quickly increased, and the pressure-sensitive characteristic, the compression elasticity, the impact resistance and other mechanical properties of the metamaterial are remarkably improved. The invention also relates to an ultra-sensitive flexible pressure sensor based on the conductive porous metamaterial.

Owner:NANKAI UNIV

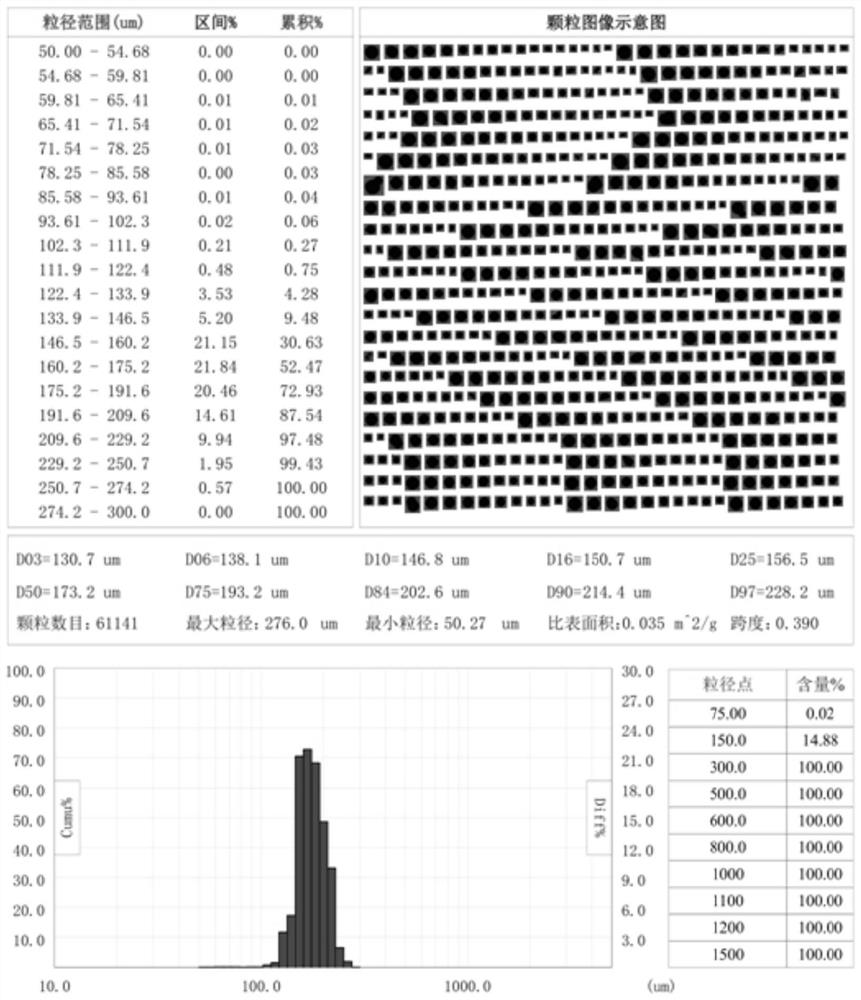

Injectable hyaluronic acid microsphere as well as preparation method and application thereof

PendingCN113663126AEasy to prepareGood biocompatibilityCosmetic preparationsToilet preparationsMicrosphereCross linker

The invention relates to A61L, in particular to injectable hyaluronic acid microspheres as well as a preparation method and an application thereof. The method comprises the following steps: activating hyaluronic acid; preparing a water phase; and preparing the microspheres. According to the hyaluronic acid microspheres and the preparation method thereof, natural polymers such as chitosan are adopted as a cross-linking agent, the cross-linking agent and hyaluronic acid subjected to acid activation are subjected to cross-linking in an oil-water mixed system, the microspheres can be obtained, and compared with an existing method that a cross-linking agent needs to be supplemented in the microsphere cross-linking process, synthesis can be conducted in one step the preparation method is simple, and the biocompatibility is good. According to the method provided by the invention, the hyaluronic acid microspheres can be formed through one-step crosslinking, and the hyaluronic acid microspheres can be applied to the fields of medicine, beauty, skin care, cosmetics, tissue filling and repairing, biological scaffolds, ophthalmology, drug sustained release and targeted drug delivery and the like, and have a wider application prospect.

Owner:上海玮沐医疗科技有限公司

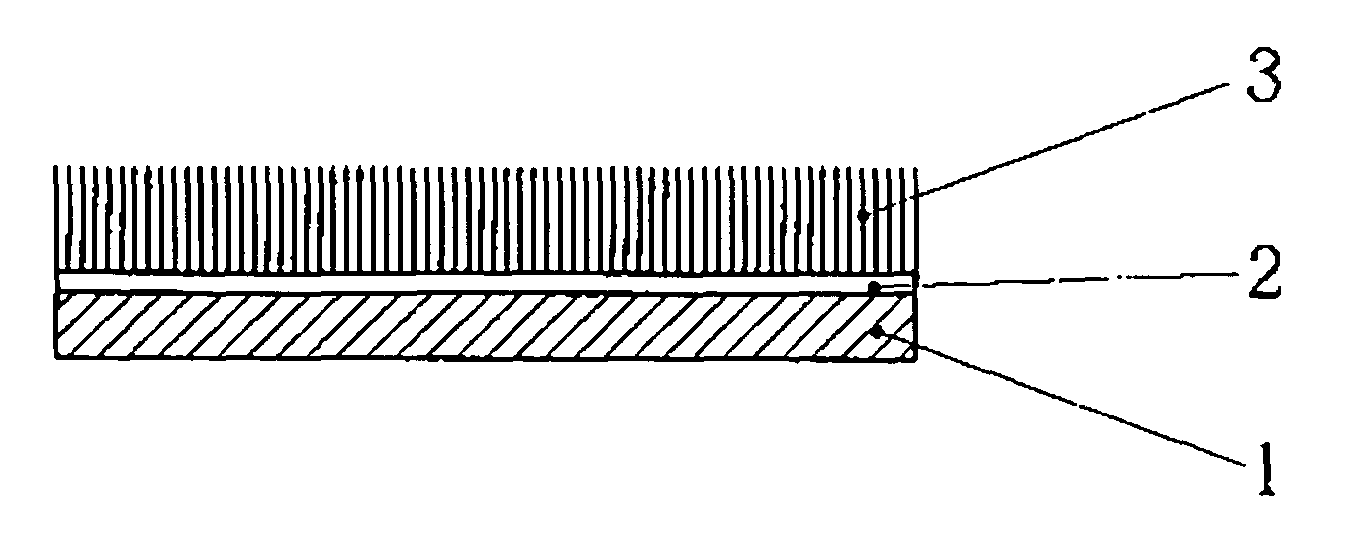

Artificial leather and method for manufacturing the same

InactiveUS20130209738A1Increase elasticityDifferent elastic recoverySynthetic resin layered productsWoven fabricsPolyesterElastomer

Disclosed are an artificial leather that comprises two or more types of short fibers made of different components and thus exhibits superior texture, flexibility, breathability and fullness and enables great weight reduction, and a method for manufacturing the same.The artificial leather includes a non-woven fabric having a fineness of 0.001 to 0.5 denier, and a polymeric elastomer impregnated in the non-woven fabric, wherein the short fibers are two or more types of polyester short fibers having different numbers of repeat units of —CH2—.

Owner:KOLON IND INC

Jacquard non-woven fabric and preparation method thereof

The invention provides a jacquard non-woven fabric and a preparation method of the jacquard non-woven fabric, and relates to the technical field of production of non-woven fabrics. The jacquard non-woven fabric is mainly prepared from a three-dimensional crimp hollow fiber, a polypropylene fiber and a common polyester staple fiber, the three-dimensional crimp hollow fiber has a crimping arc, the radius of curvature is relatively large, the jacquard non-woven fabric has the characteristic that the jacquard non-woven fabric does not cause fatigue yield easily after deforming because of compression for multiple times; the common polyester staple fiber increases the entanglement degree of the non-woven fabric; the polypropylene fiber improves the strength of the non-woven fabric, and the jacquard non-woven fabric does not deform easily. Therefore, the jacquard non-woven fabric has the advantages that the pattern is clear, the hand feeling is soft, the stereoscopic impression is strong, thestatic electricity is high, the elasticity of compression is good, the surface is fluffy, and the dust collection effect is good.

Owner:高长水

Preparation method of composite sponge with graphene and three-dimensional polypyrrole skeleton

InactiveCN110878419AGood compression elasticityEasy to operateElectrolytic organic material coatingPlatinumAlcohol

The invention provides a preparation method of a composite sponge with a graphene and three-dimensional polypyrrole skeleton. The method comprises the following steps of first, washing nickel foam clean with absolute ethyl alcohol, acetone and a deionized water solution, and drying the washed nickel foam for use; second, cutting the nickel foam which is washed clean to the needed size, placing thenickel foam into a 0.3 M NaClO4 solution containing 5% (volume ratio) of a pyrrole solution to use the nickel foam as a working electrode, using a platinum wire as a counter electrode, and using a calomel electrode as a reference electrode; third, taking out a black complex of polypyrrole and nickel foam subjected to electroplating, washing the complex in deionized water to remove unoxidized pyrrole monomers on the surface of the complex, and placing the complex which is washed clean into a 1 M FeCl3 solution to be etched; and fourth, air-drying the complex at the room temperature after washing the complex in deionized water, and obtaining the three-dimensional polypyrrole skeleton. The preparation method of the composite sponge with the graphene and three-dimensional polypyrrole skeletonis easy to operate.

Owner:季懿

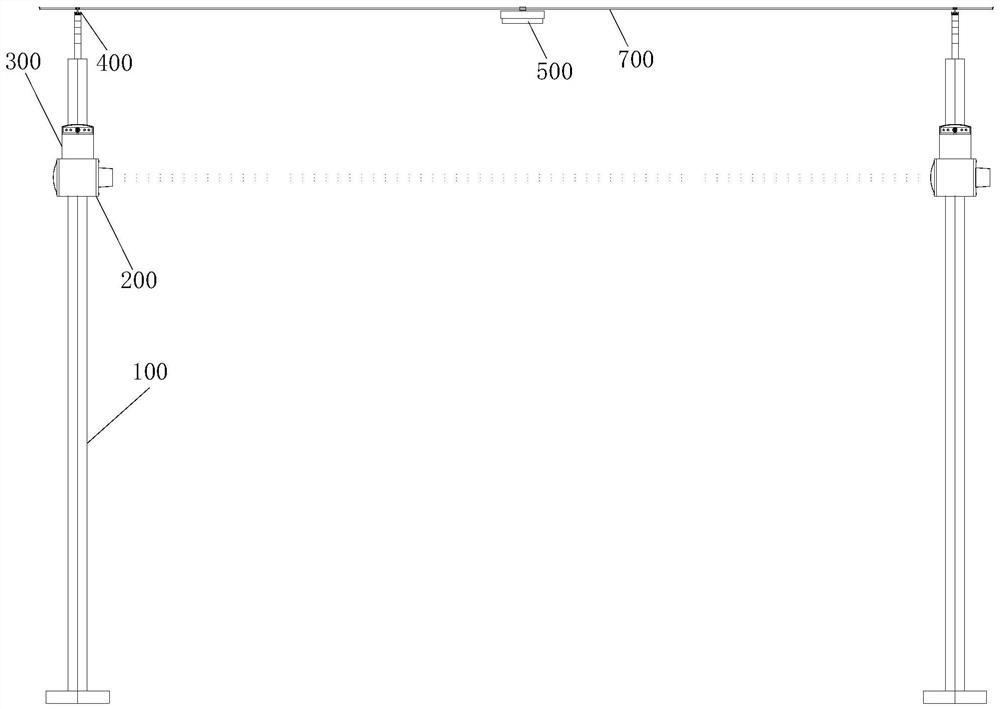

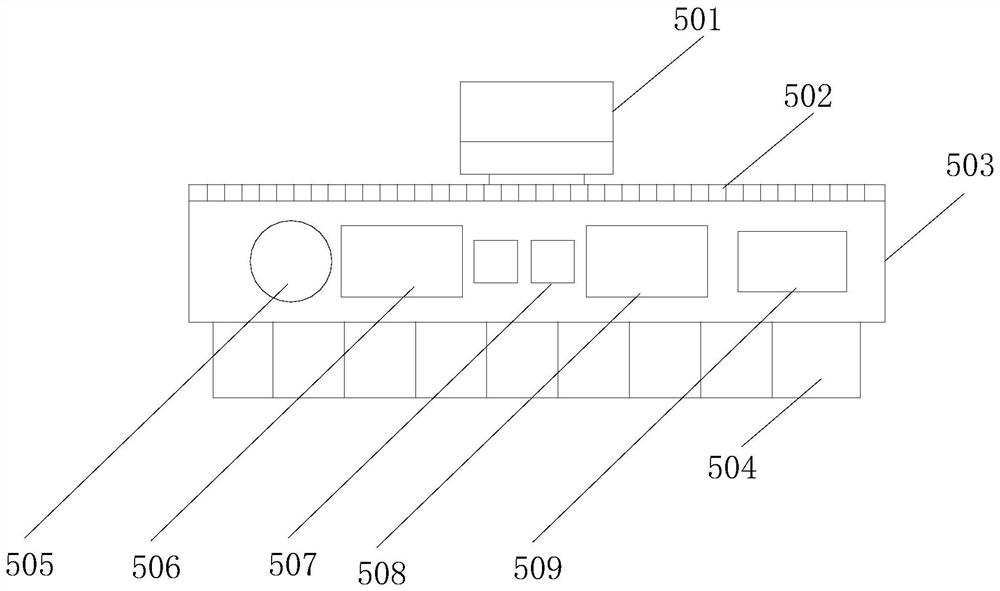

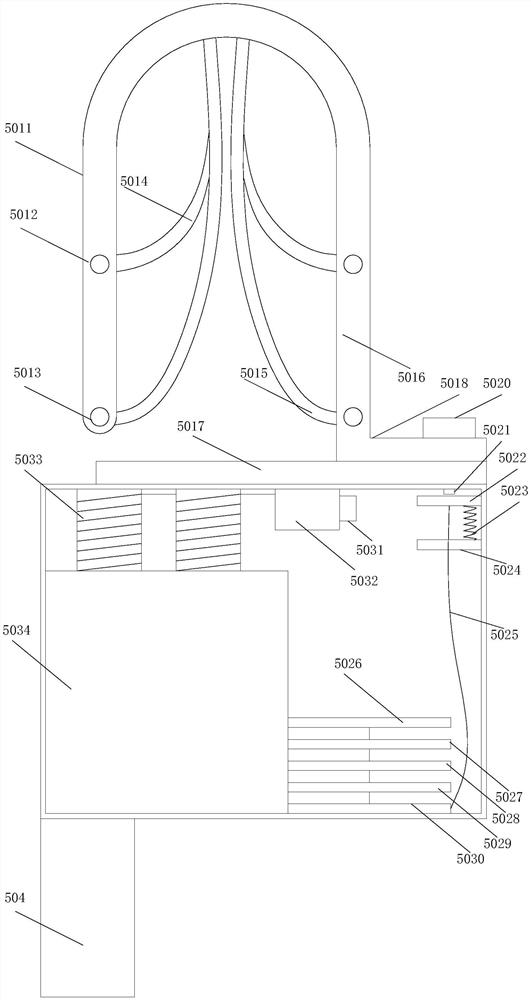

Anti-theft device for power cable

PendingCN113963498APrevent pulling and stealingReduce the loss of theftOverhead installationElectric/electromagnetic visible signallingVisual monitoringPower cable

The invention discloses an anti-theft device for a power cable, which can timely and reliably discover abnormity along the cable erection direction, can perform evidence collection, warning and anti-disassembly and anti-theft on external damage, reduces the theft probability, and effectively protects the power cable. Two adjacent telegraph poles are respectively provided with a monitoring assembly used for monitoring that a thief gets close to the cable; an anti-theft sensing assembly is hung at the middle position of the cable on the two adjacent telegraph poles; the top end of each telegraph pole is further provided with a pulling anti-theft assembly used for monitoring cable pulling. The monitoring assembly comprises a laser monitoring assembly and a visual monitoring assembly; the laser monitoring assembly comprises a lower box body, and one side surface of the lower box body is provided with a laser receiving assembly used for receiving laser signals of the laser monitoring assembly on the previous telegraph pole. The other side face of the lower box body is provided with a laser emitting assembly used for emitting laser to the laser monitoring assembly of the rear telegraph pole in the cable erecting direction.

Owner:国网河南省电力公司尉氏县供电公司

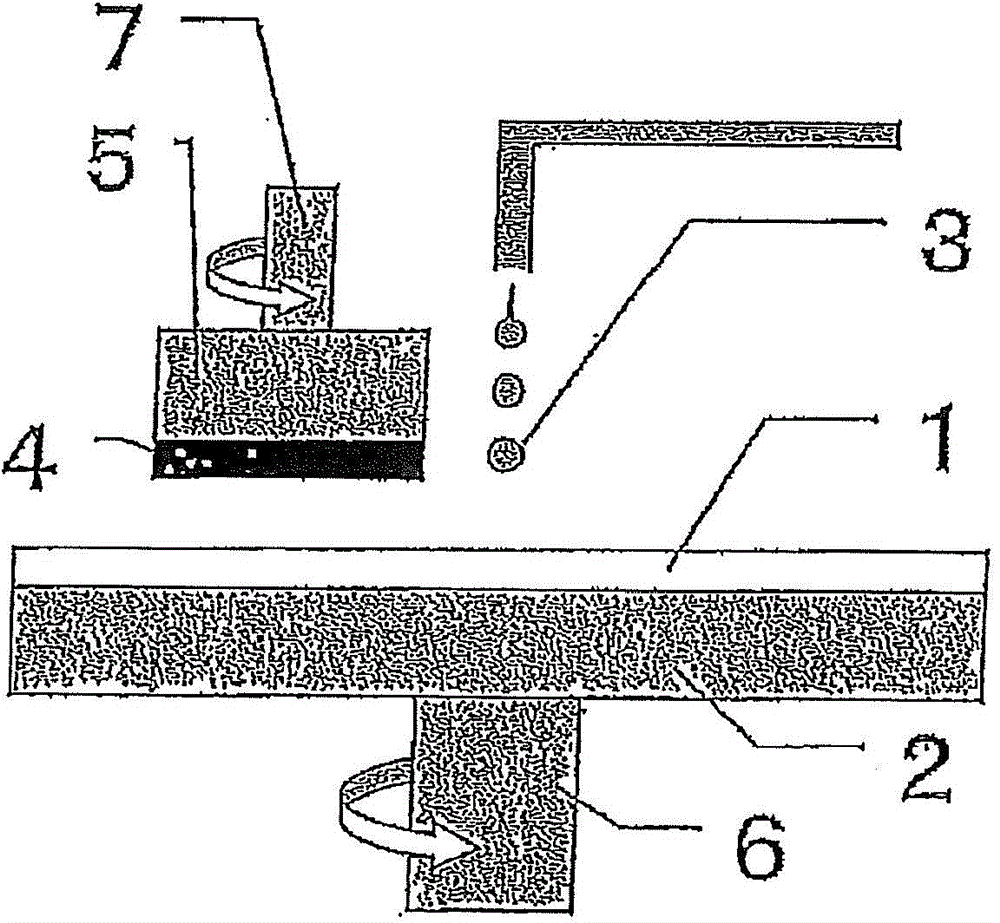

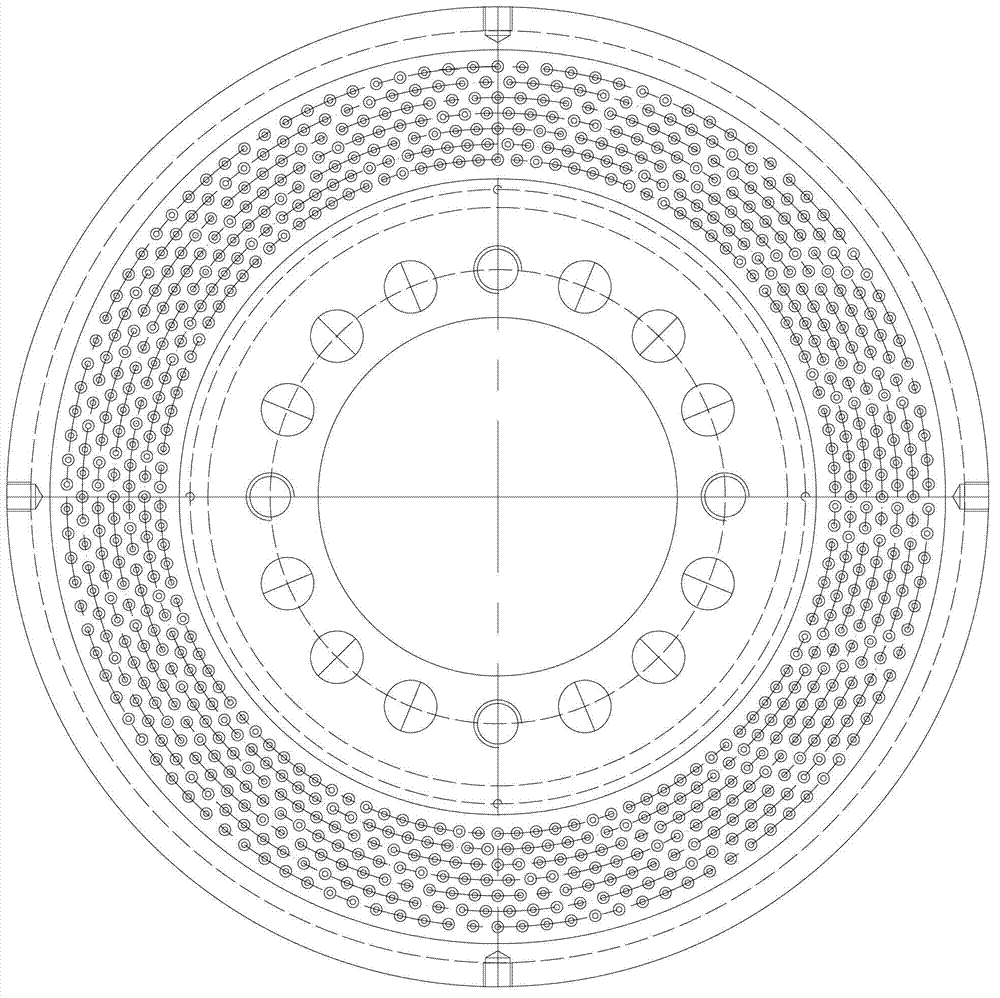

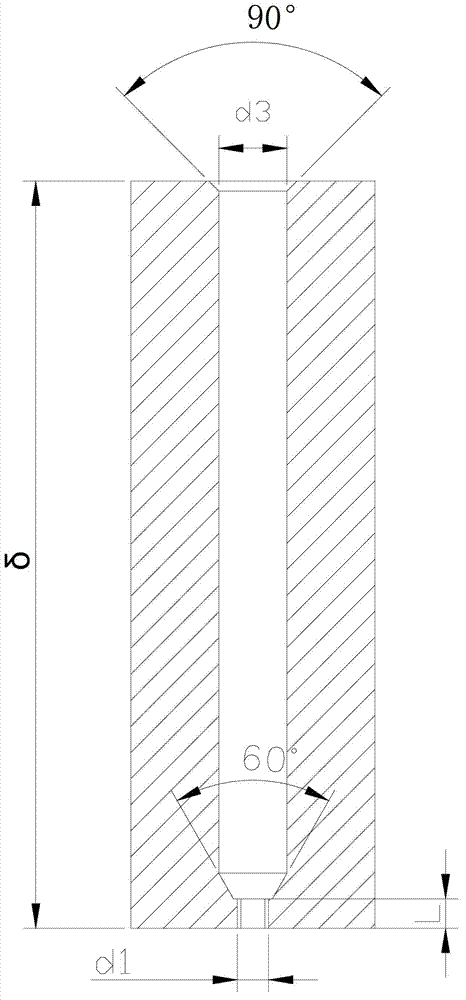

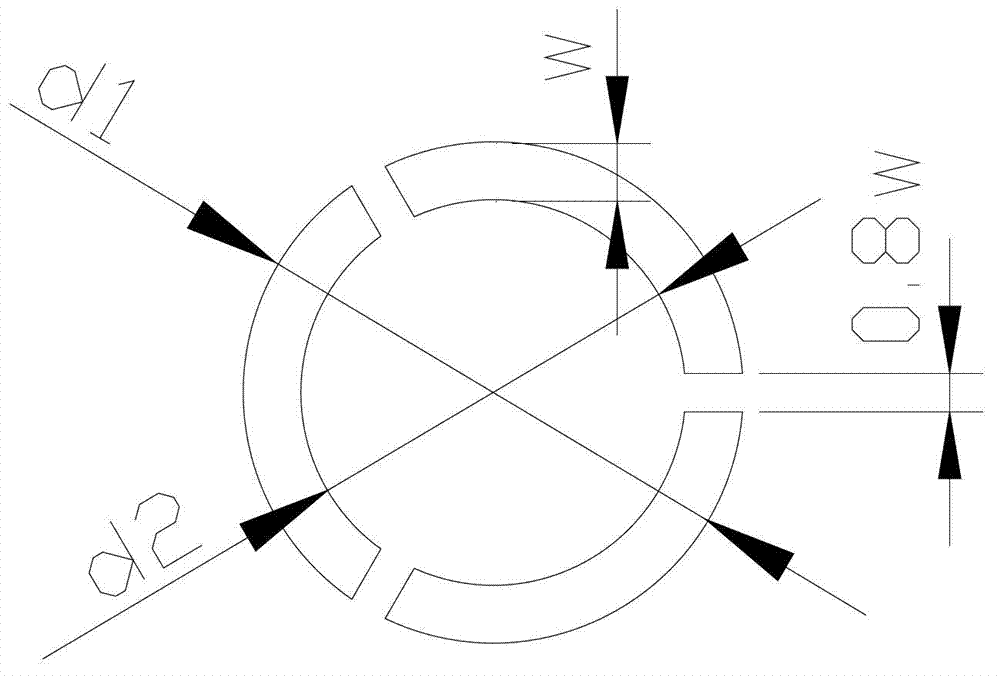

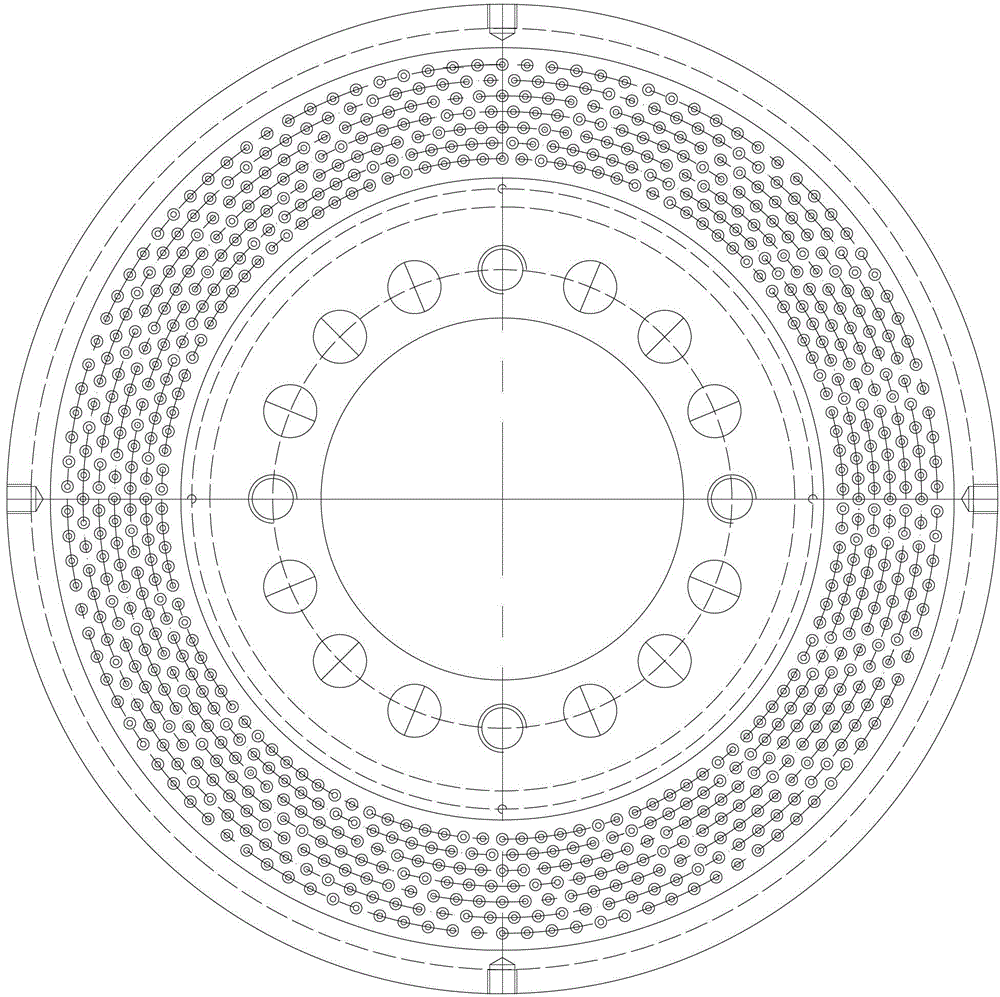

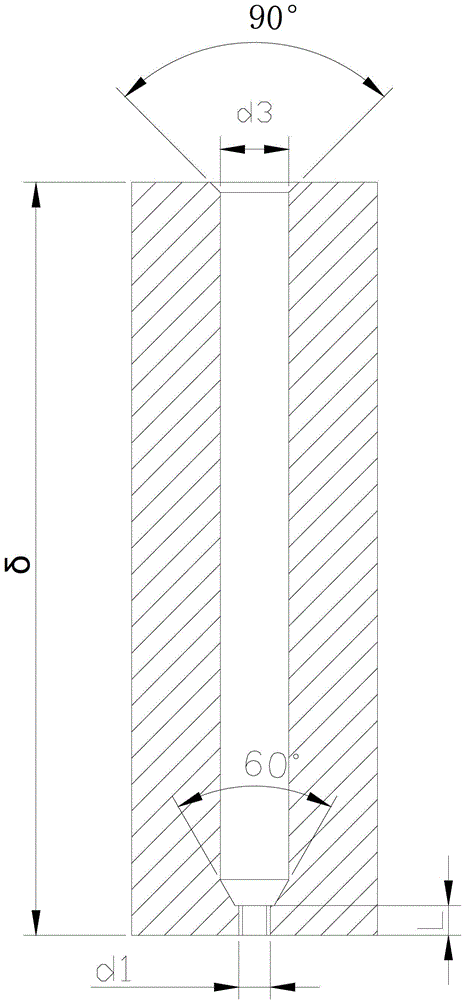

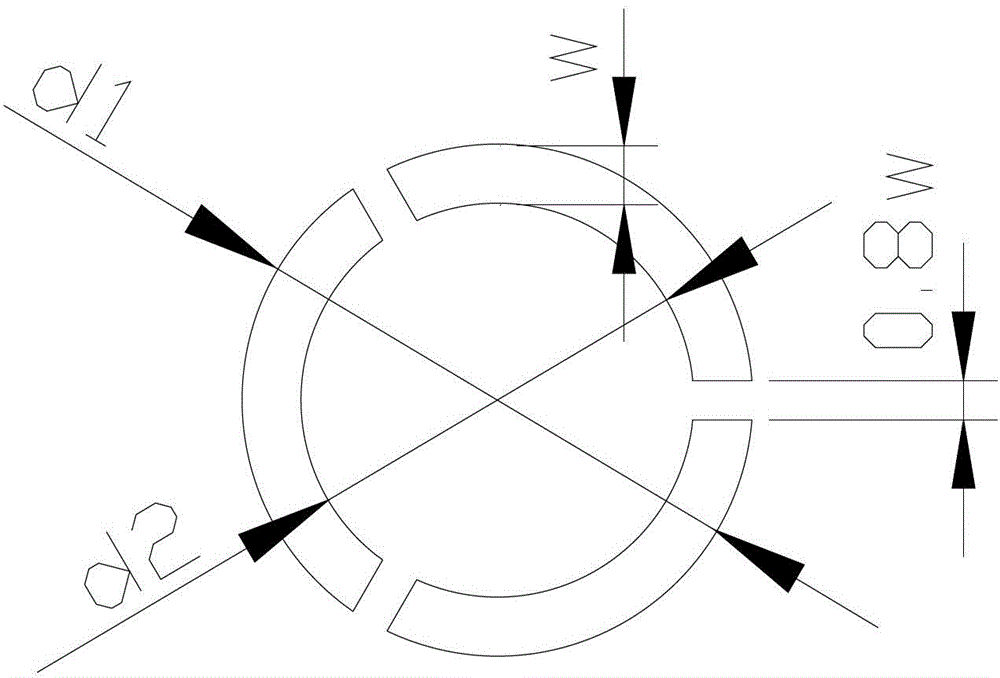

High-viscosity melt spinning spinneret plate

InactiveCN102926004AGuaranteed spinnabilityGood compatibilityHollow filament manufactureEngineeringMelt spinning

The invention relates to a spinneret plate and particularly relates to a high-viscosity polyester melt spinning spinneret plate with the intrinsic viscosity ranging between 0.74dL / g-0.78dL / g. The overall shape of the spinneret plate is in a cylindrical shape, a plurality of spinneret orifices are arranged evenly on the spinneret plate in a circular mode, each of the spinneret orifice comprises a guide hole and a micro hole, the guide hole is connected with the micro hole, the shape of a cross section of the micro hole is a circular ring with three openings, the three openings are distributed on the circular ring evenly, the outer diameter d1of the circular ring ranges between 2.25mm and 2.45mm, the inner diameter d2 ranges between 1.5mm and 2.0mm, the width of the openings is 0.70-0.90 time of the width w of the circular ring, the length L of the micro hole ranges between 1.5mm and 2.0mm, the diameter d3 of the guide hole ranges between 4.0mm and 5.5mm, and the thickness Delta of the spinneret plate ranges between 35mm and 40mm. The spinneret plate has the advantages that coarse denier three-dimensional crimp polyester produced by the spinneret plate is low in spinning speed, good in spinnability, high in filling power, sufficient in stiffness and good in compression elasticity.

Owner:NINGBO DAFA CHEM FIBER

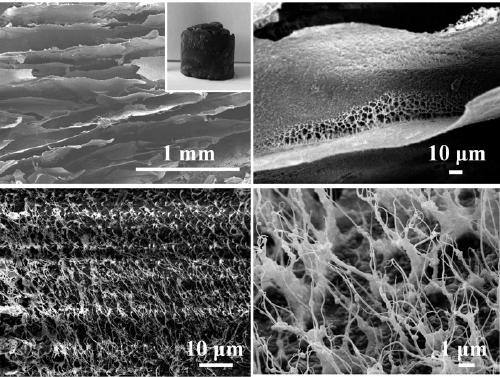

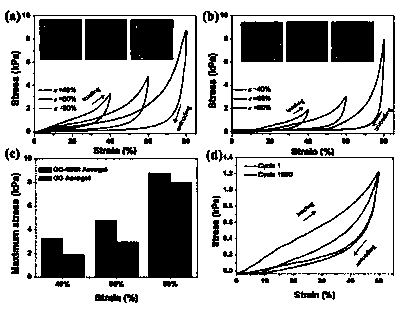

Method for preparation, characterization and performance test of graphene-graphene nanoribbon sponge

InactiveCN110873668AGood compression elasticityEasy to operateComponent separationMaterial strength using repeated/pulsating forcesGraphite oxideGraphene nanoribbons

The invention provides a method for preparation, characterization and performance test of graphene-graphene nanoribbon sponge in the field of chemistry. The method comprises the steps of (1) measuringthe concentrations of a graphene oxide (GO) solution and a graphene oxide nanoribbon (GONR) solution; (2) respectively extracting solutions with corresponding volumes into a mold according to a massratio of GO to GONR of 1:1, and uniformly stirring and mixing; (3) freezing the uniformly mixed GO-GONR solution in a cold well of a freeze dryer for 24 hours, vacuumizing, and starting freeze drying;(4) taking out the completely freeze-dried sample to obtain unreduced GO-GONR sponge at the moment; (5) putting the unreduced GO-GONR sponge into 90 DEG C hydrazine hydrate steam, reducing for 24 hours, cooling to the room temperature, taking out, putting into a vacuum drying oven, carrying out vacuum drying at the temperature of 100 DEG C, and cooling to the room temperature; and (6) characterizing the prepared sponge. The method is simple to operate.

Owner:季懿

Spunlace jacquard non-woven fabric and production method thereof

The invention provides spunlace jacquard non-woven fabric and a production method thereof and relates to the technical field of nonwoven fabric production. The spunlace jacquard non-woven fabric is mainly produced by three-dimensional hollow crimped fibers, polypropylene fibers and common polyester staple fibers, wherein the three-dimensional hollow crimped fibers have curled arcs and are large incurvature radius and less prone to fatigue yield generation when being subjected to repeated compressive deformation; the common polyester staple fibers can increase the twist degree of the nonwovenfabric; the polypropylene fibers can increase the strength of the nonwoven fabric to allow the spunlace jacquard non-woven fabric to be less prone to deformation. By the arrangement, the spunlace jacquard non-woven fabric is high in static resistance, good in compression elasticity, high in fluffiness, good in dust collection effect and the like.

Owner:高长水

Artificial leather and method for manufacturing same

ActiveCN103154358AGood compression elasticityImprove textureWoven fabricsNon-woven fabricsElastomerPolyester

Disclosed are artificial leather and a method for manufacturing same, wherein the artificial leather comprises two or more types of short fibers made of different components so as to achieve superior feel, flexibility, breathability, fullness, and significantly improved lightweight properties. The artificial leather of the present invention comprises: non-woven fabric including short fibers having a fineness of 0.001 to 0.5 denier; and a polymeric elastomer with which the non-woven fabric is impregnated, wherein the short fibers are two or more types of polyester-based short fibers having different numbers of repeating -CH2-units.

Owner:KOLON IND INC

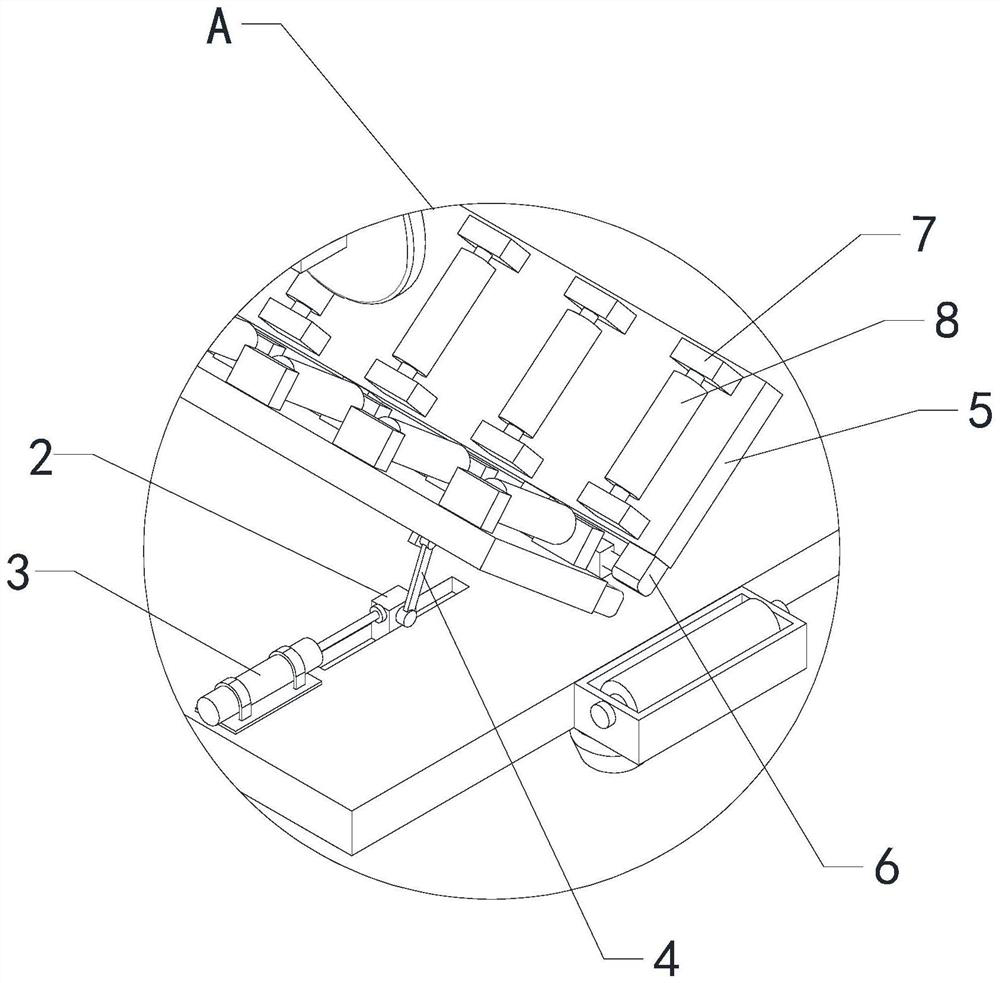

Special weld joint back chipping equipment for iron tower angle steel full penetration welding

InactiveCN113334178AEasy to observeImprove convenienceEdge grinding machinesGrinding drivesHydraulic cylinderEngineering

The invention relates to the technical field of mechanical equipment, and particularly relates to special weld joint back chipping equipment for iron tower angle steel full penetration welding. The position of a grinding mechanism is fixed, and back chipping treatment is carried out in an angle steel moving manner, so that the stability of the equipment for angle steel back chipping is improved, the position deviation condition of the grinding mechanism in the moving process is reduced, and the back chipping quality of the equipment for angle steel is improved; and by controlling the telescopic lengths of a plurality of sets of first hydraulic cylinders, the plurality of sets of first hydraulic cylinders adjust the angle of the included angle between two sets of supporting plates through a plurality of sets of first sliding blocks and a plurality of sets of first supporting rods, so that the equipment can conveniently fix and convey the angle steel with different included angle sizes, the use limitation of the equipment is reduced, and the back chipping efficiency of the equipment for the angle steel is improved. The special weld joint back chipping equipment comprises a base, two conveying mechanisms, the grinding mechanism, a dust collecting device, the plurality of sets of first sliding blocks, the plurality of sets of first hydraulic cylinders, the plurality of sets of first supporting rods, the two sets of supporting plates, a plurality of sets of fixing pieces and a plurality of sets of first roller shafts.

Owner:SHANDONG LUNENG TAISHAN TOWER

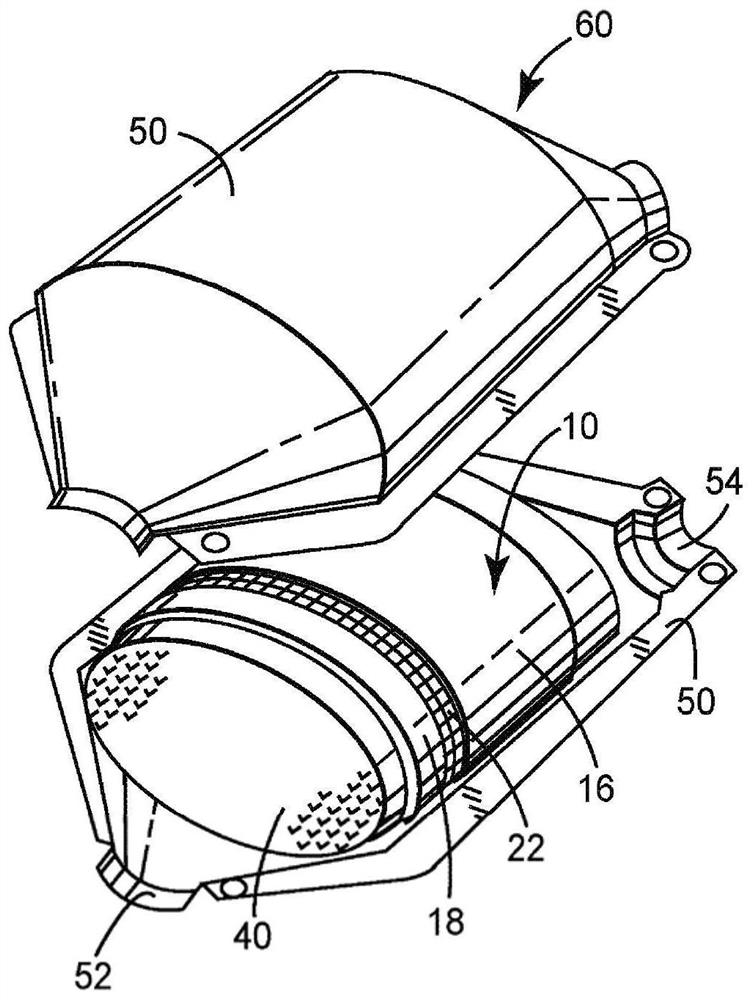

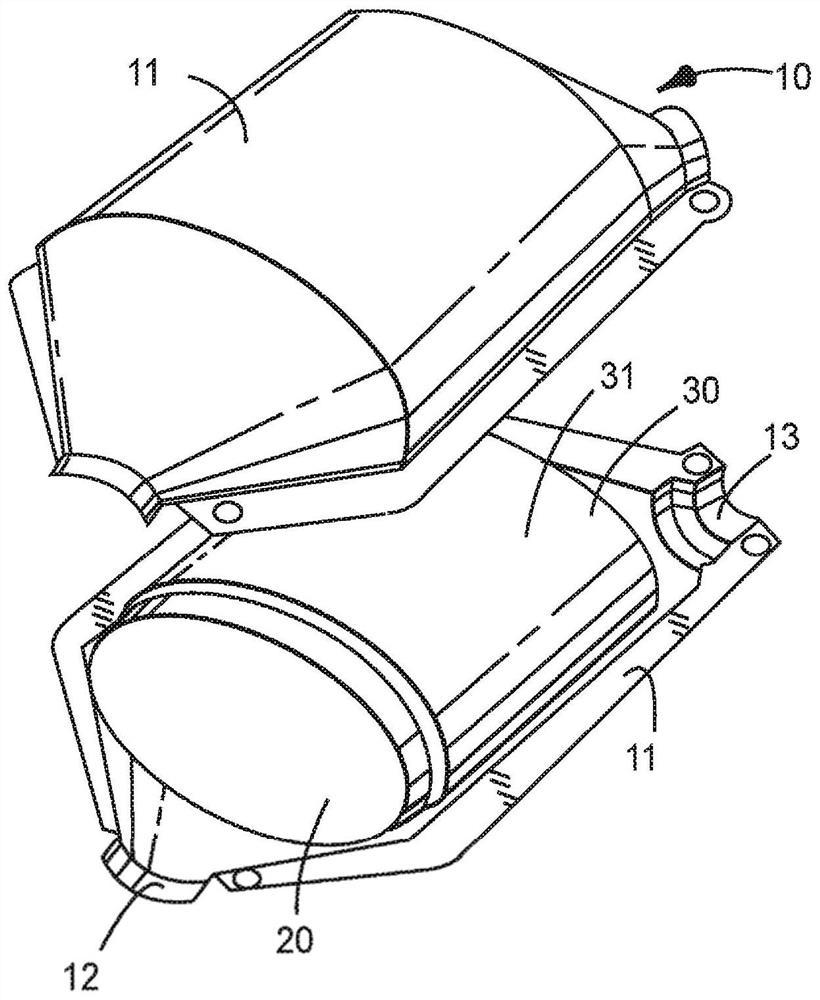

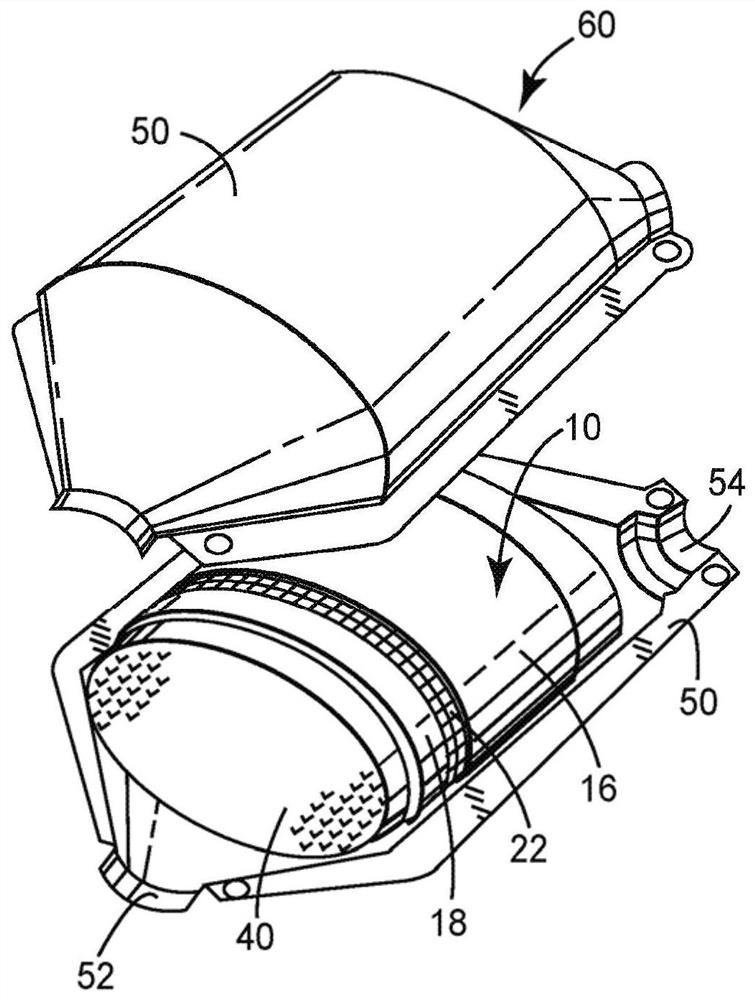

Polycrystalline, aluminosilicate ceramic filaments, fibers, and nonwoven mats, and methods of making and using the same

InactiveCN112118909AImprove thermal conductivityImproved thermomechanical propertiesPhysical/chemical process catalystsExhaust apparatusSalt ceramicSilk fiber

Provided is a nonwoven article comprising a two-dimensional nonwoven structure having a longest major surface dimension and a shortest major surface dimension. The two-dimensional nonwoven structure comprises a plurality of discontinuous polycrystalline, with aluminosilicate ceramic fibers having a length equal to the longest or shortest major surface dimension of the two-dimensional nonwoven structure or a length in between those dimensions.

Owner:3M INNOVATIVE PROPERTIES CO

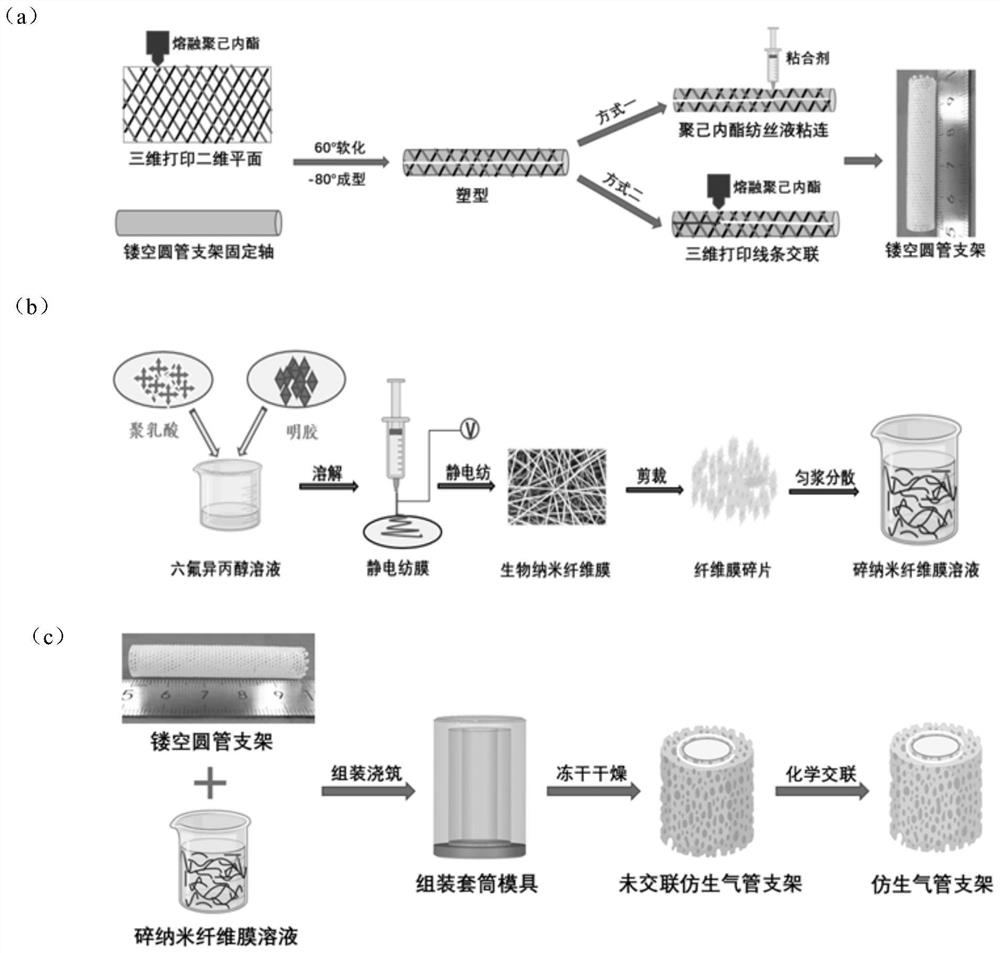

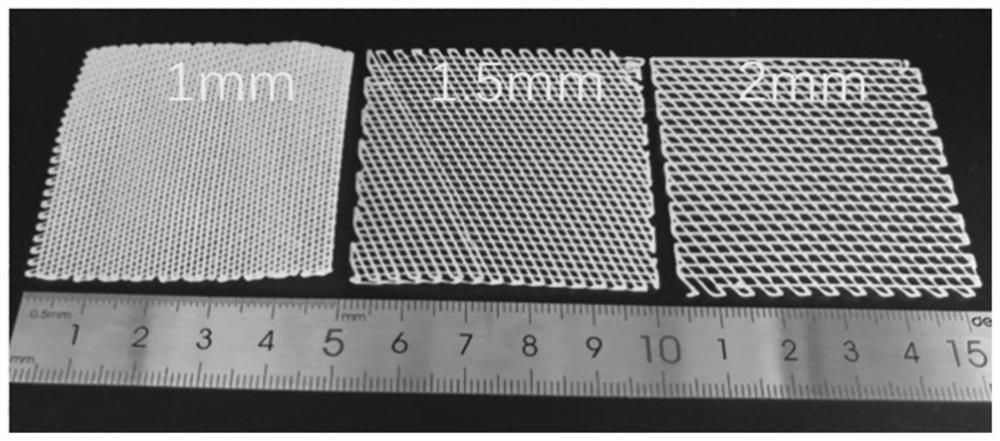

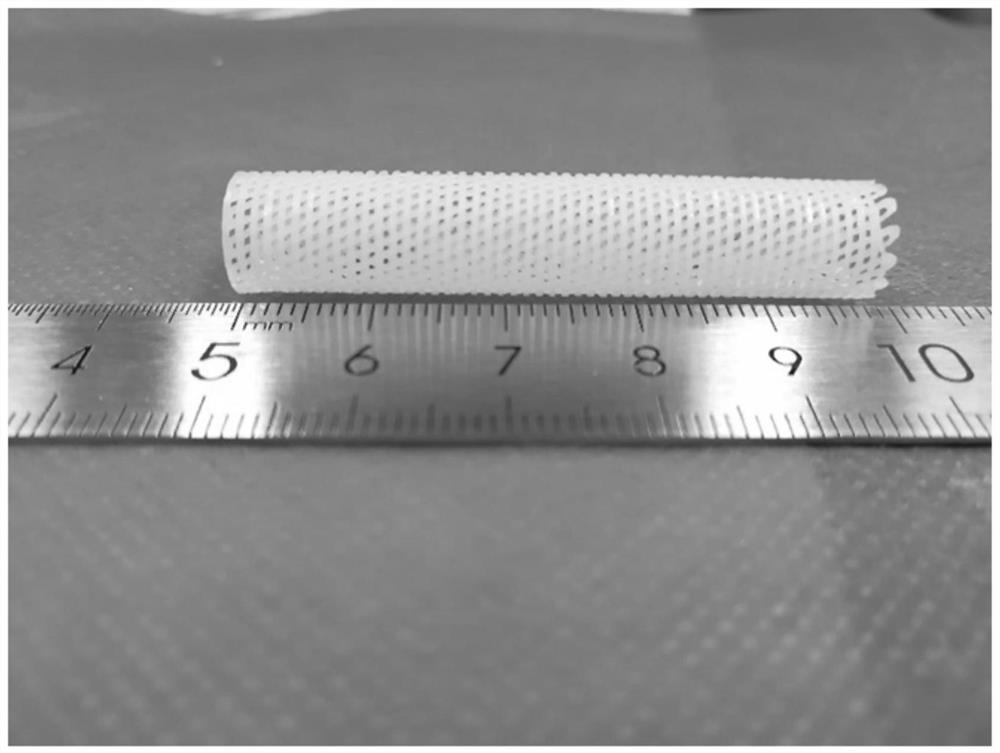

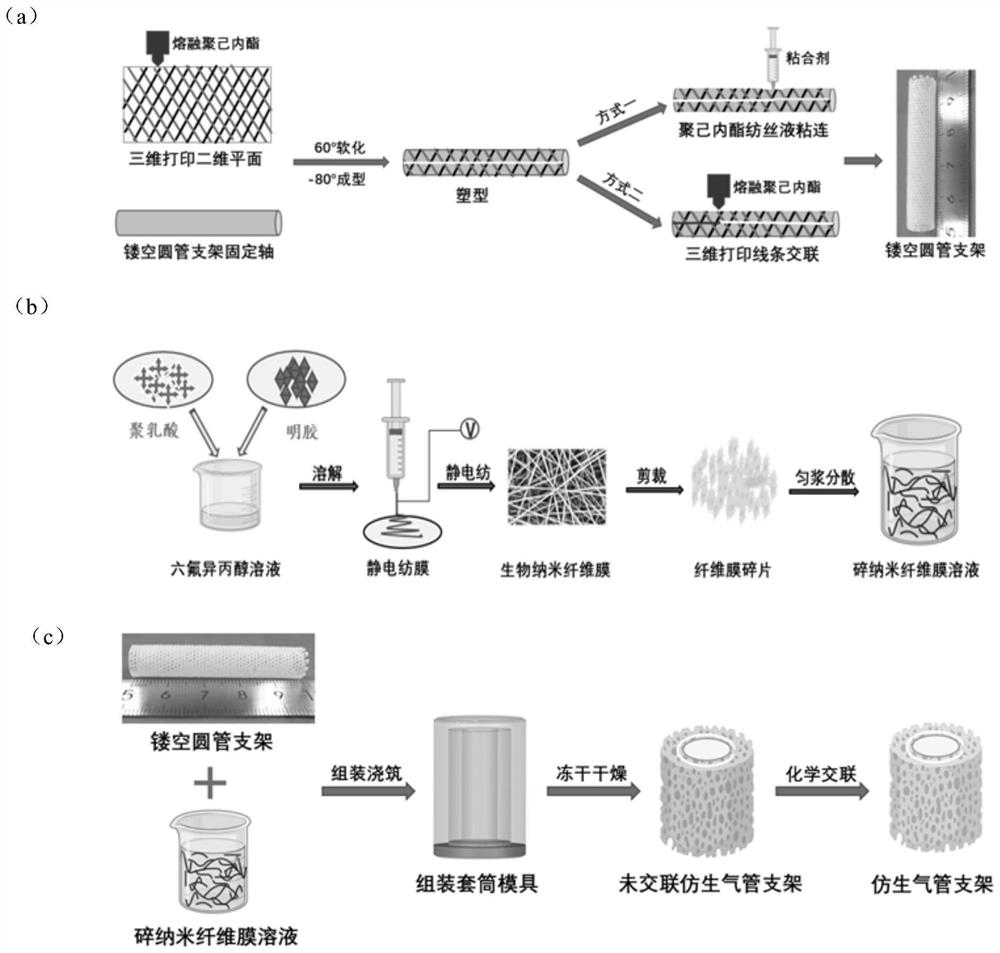

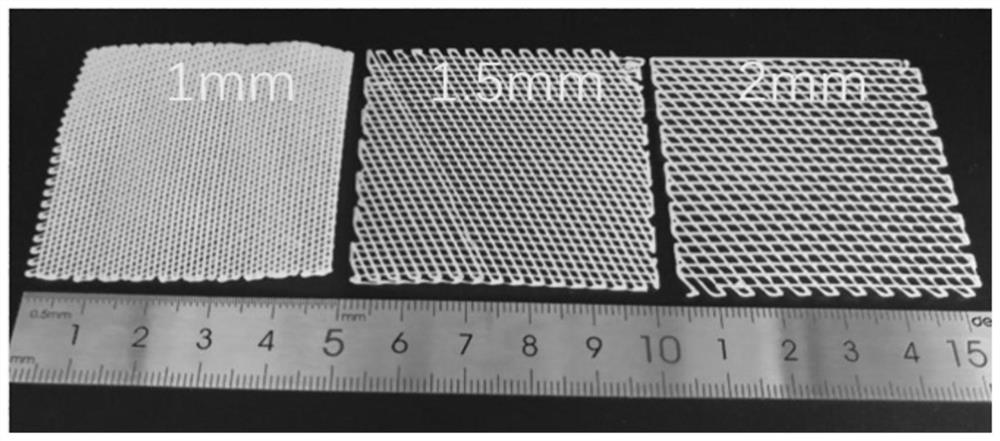

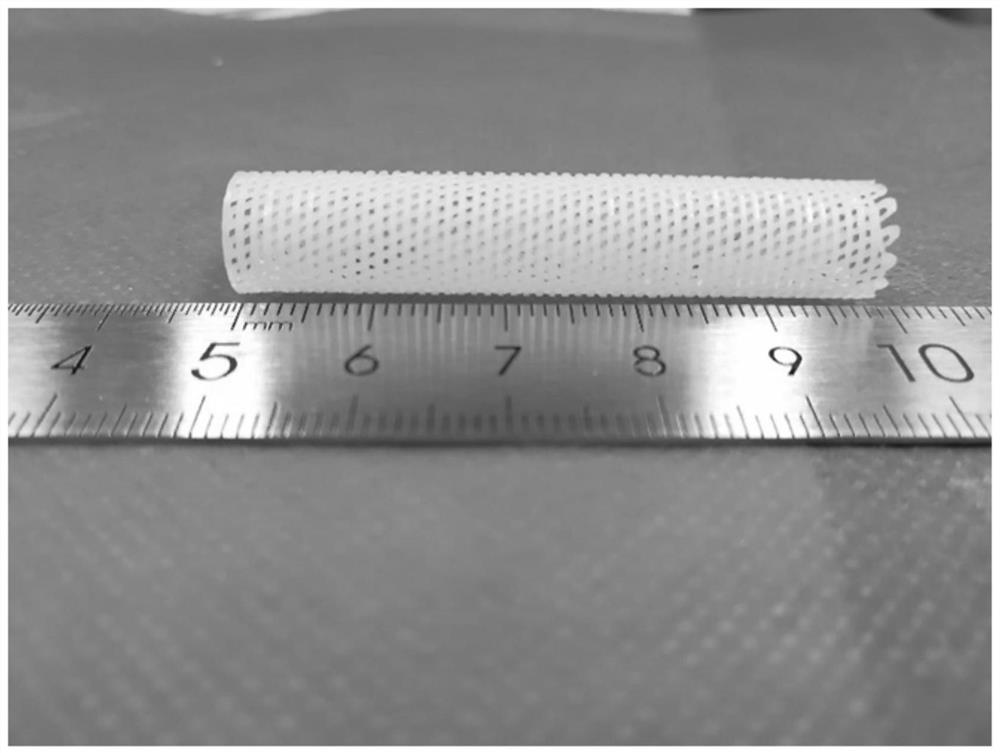

Bionic trachea constructed by three-dimensional printing composite aerogel and preparation method thereof

ActiveCN112843334APromote growthImprove adhesionAdditive manufacturing apparatusPharmaceutical delivery mechanismCartilage cellsPolymer science

The invention relates to a bionic trachea constructed by three-dimensional printing composite aerogel and a preparation method thereof. The preparation method comprises the following steps: pouring and molding a crushed fiber mixed solution and a hollow round tube bracket in a mold, crosslinking, carrying out heat treatment, and soaking to obtain the bionic trachea. The polylactic acid / gelatin aerogel provided by the invention has a nanofiber structure, and is a porous and extrudable sponge structure material with excellent water absorption. The material obtained by the method can promote the formation of cartilage cell matrix, and provides effective support for long-term stability of bionic tracheal structure functions.

Owner:DONGHUA UNIV

A kind of three-dimensional printing composite aerogel to construct a simulated gas pipe and its preparation method

ActiveCN112843334BPromote growthImprove adhesionAdditive manufacturing apparatusPharmaceutical delivery mechanismPolymer scienceNanofiber

Owner:DONGHUA UNIV

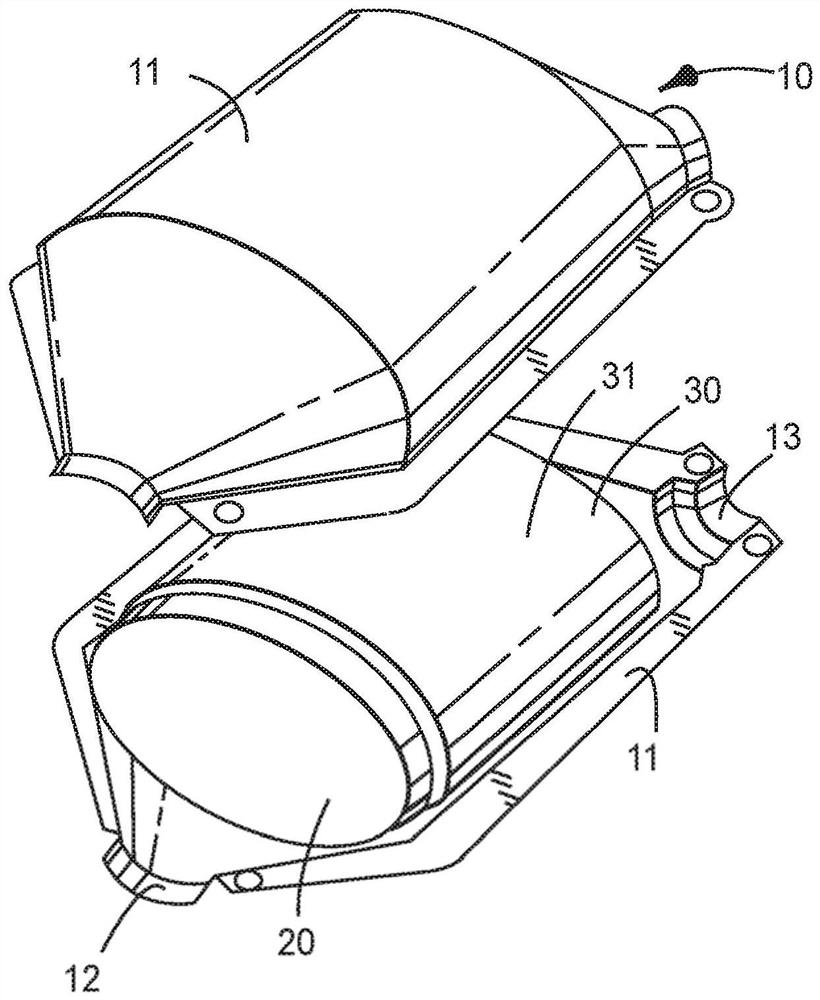

Self-adjusting exhaust valve

PendingCN114856748AIncrease compression elasticityIncrease return elasticityInternal combustion piston enginesLift valveAutomotive engineeringPiston cylinder

The self-adjusting exhaust valve comprises a valve head, a valve rod, a valve seat, a valve sleeve and an elastic piece, the valve seat comprises a seat sleeve sleeve, a seat ring connected to the inner circle of the seat sleeve and a blade connected to the inner circle of the seat sleeve, the blade is located above the seat ring, and the valve rod is axially sleeved with the seat ring in a sealing and sliding mode. The seat ring sleeve is connected to the inner circle of the valve sleeve in a threaded mode, a plurality of spraying holes are vertically formed in the seat ring, and the spraying holes are located under the blades, so that gas leaked by the piston cylinder is sprayed to the blades through the spraying holes, the valve seat is driven to rotate relative to the valve sleeve, and then the valve seat is lifted. When high-pressure gas leaks through the gap between the valve head and the valve sleeve, the leaked high-pressure gas is sprayed out through the spraying holes to impact the blades and drive the valve seat to rotate and move upwards, then the distance between the upper end of the valve rod and the seat ring is reduced, the reset elastic force of the valve rod is increased, and the valve head can be sealed again.

Owner:重庆乐瑞斯科技有限公司

High-viscosity melt spinning spinneret plate

InactiveCN102926004BGuaranteed spinnabilityGood compatibilityHollow filament manufacturePolyesterEngineering

The invention relates to a spinneret plate and particularly relates to a high-viscosity polyester melt spinning spinneret plate with the intrinsic viscosity ranging between 0.74dL / g-0.78dL / g. The overall shape of the spinneret plate is in a cylindrical shape, a plurality of spinneret orifices are arranged evenly on the spinneret plate in a circular mode, each of the spinneret orifice comprises a guide hole and a micro hole, the guide hole is connected with the micro hole, the shape of a cross section of the micro hole is a circular ring with three openings, the three openings are distributed on the circular ring evenly, the outer diameter d1of the circular ring ranges between 2.25mm and 2.45mm, the inner diameter d2 ranges between 1.5mm and 2.0mm, the width of the openings is 0.70-0.90 time of the width w of the circular ring, the length L of the micro hole ranges between 1.5mm and 2.0mm, the diameter d3 of the guide hole ranges between 4.0mm and 5.5mm, and the thickness Delta of the spinneret plate ranges between 35mm and 40mm. The spinneret plate has the advantages that coarse denier three-dimensional crimp polyester produced by the spinneret plate is low in spinning speed, good in spinnability, high in filling power, sufficient in stiffness and good in compression elasticity.

Owner:NINGBO DAFA CHEM FIBER

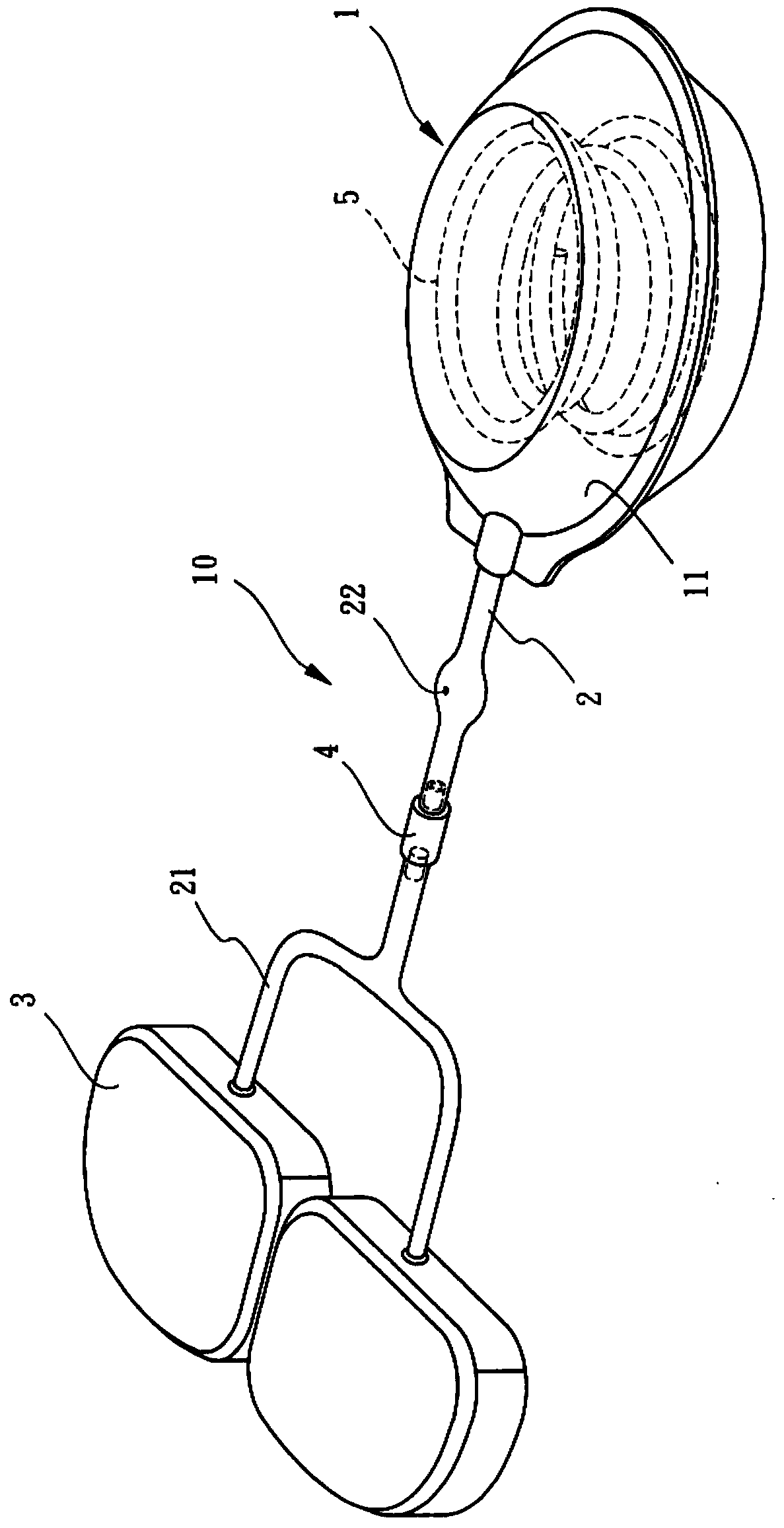

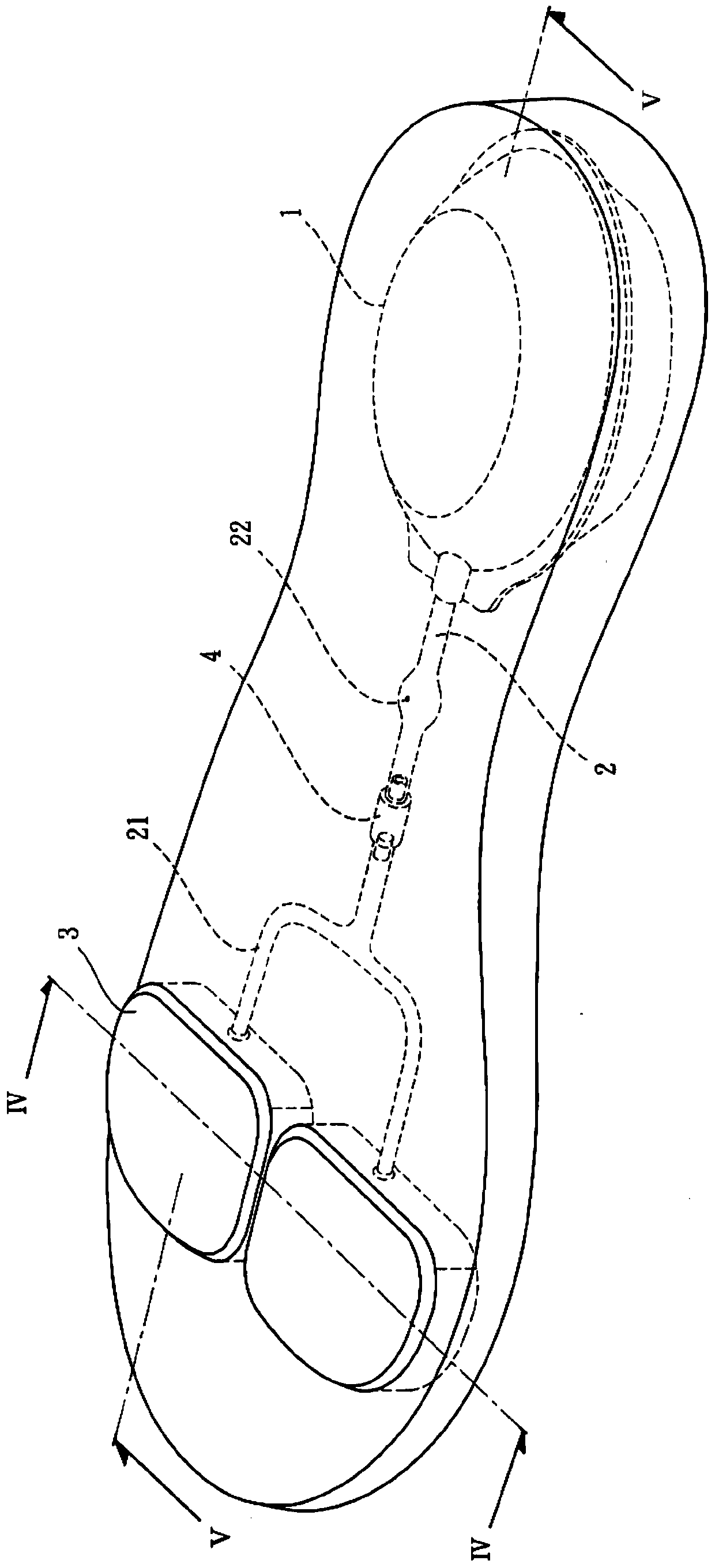

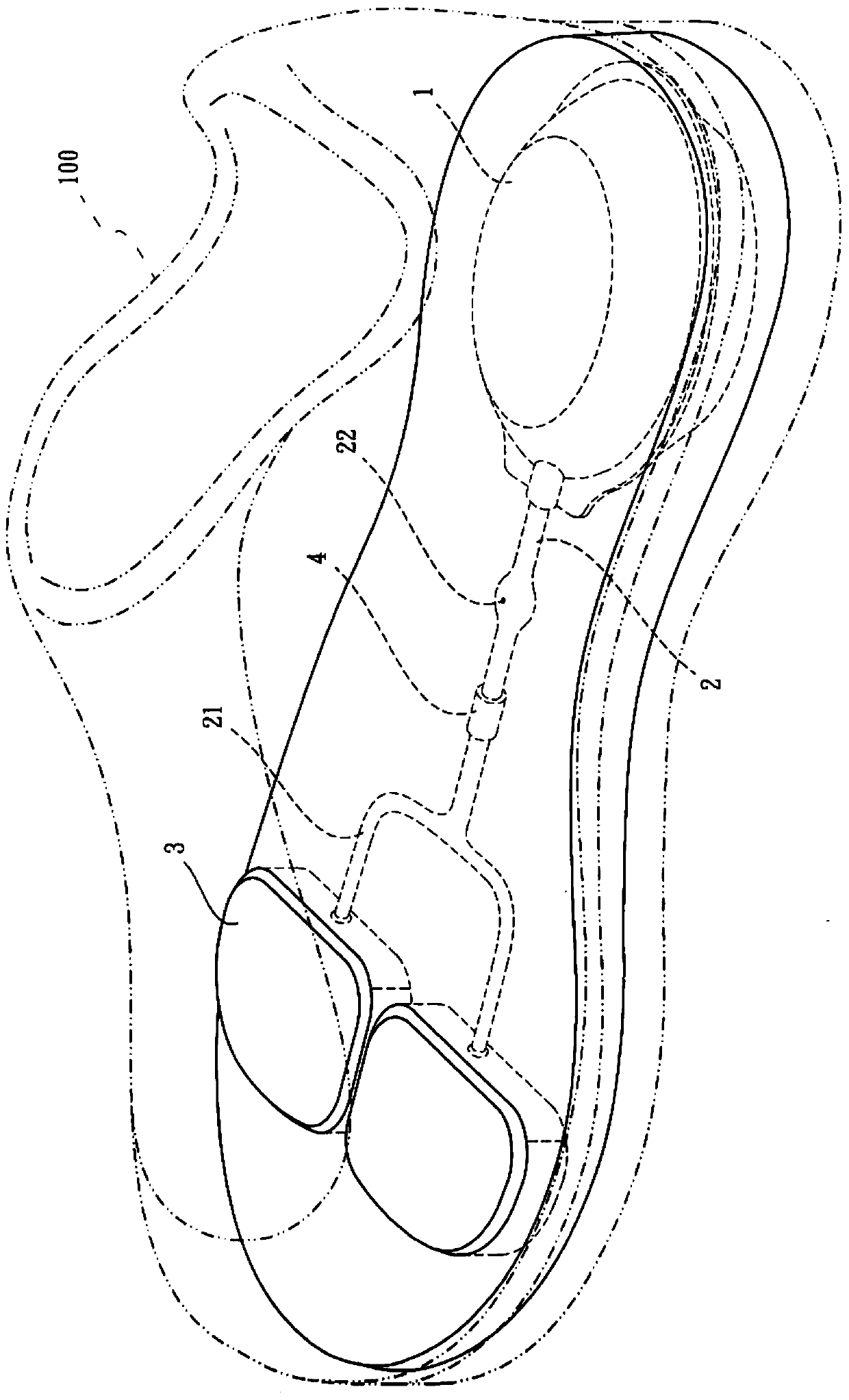

Shoe Air Cushion Device

ActiveCN107280139BComfort and decompression effectGood compression elasticitySolesAir cushionEngineering

A shoe air cushion device is used for being installed in a shoe. The shoe air cushion device comprises an air cushion device. The air cushion device comprises a backward pressing part, a guide pipe and multiple air bags. One end of the guide pipe is communicated with the backward pressing part, the other end of the guide pipe is provided with multiple branch pipes with the number corresponding to that of the air bags, the branch pipes are communicated with the air bags respectively, a one-way valve is arranged between the guide pipe and the branch pipes, and therefore air flowing from the backward pressing part to the air bags cannot flow back. An air hole is formed at the position, between the backward pressing part and the one-way valve, of the guide pipe, external air enters the guide pipe from the air hole and then flows to the backward pressing part in order to fill in the air in the backward pressing part, when the backward pressing part is pressed downwards after bearing force, the air in the backward pressing part is extruded to flow to the branch pipes from the guide pipe through the one-way valve and then flow to the air bags, the air in the air bags is filled to a saturated state, and therefore impact generated between the feet and the ground is relieved.

Owner:欣合信股ふん

Polycrystalline, aluminosilicate ceramic filaments, fibers, and nonwoven mats, and methods of making and using the same

PendingCN112135805AImprove thermal conductivityImproved thermomechanical propertiesExhaust apparatusSilencing apparatusSalt ceramicSilk fiber

A nonwoven article comprising a two-dimensional nonwoven structure or a three-dimensional nonwoven structure comprising a plurality of discontinuous polycrystalline, aluminosilicate ceramic fibers that are cohesively bonded together by a fired precursor inorganic binder, wherein each cohesively bonded discontinuous fiber is bonded to one or a plurality of other said discontinuous fibers at one ormore locations along its length.

Owner:3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com