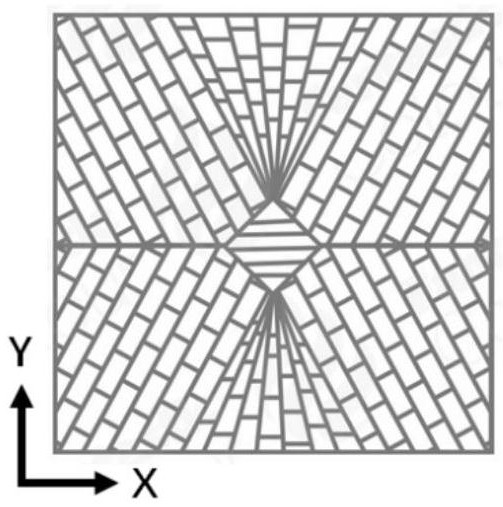

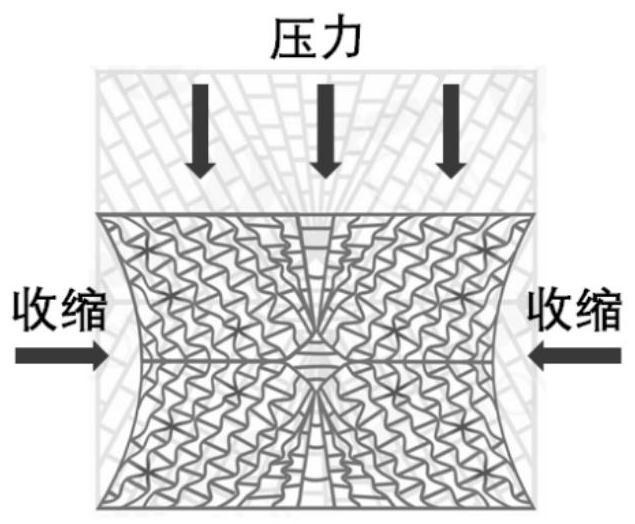

Conductive porous pressure-sensitive metamaterial with negative Poisson's ratio characteristic and preparation method and application thereof

A technology of negative Poisson's ratio and metamaterials, applied in the measurement and application of the property force of piezoelectric resistance materials, fluid pressure measurement by changing ohmic resistance, etc., to achieve the effect of excellent compressive elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Weigh 30 mg of MXene with a sheet size of about 1-2 μm prepared by chemical method (MILD method) and place it in a reagent bottle, add 3 ml of deionized water, and ultrasonically (power 700W) for 2 minutes to obtain 10 mg / mL of MXene dispersion liquid.

[0029] (2) Add 6 mg of trimethoxysilane coupling agent (KH560) to the MXene solution and shake for 3 minutes.

[0030] (3) Pour the mixed solution of MXene and trimethoxysilane coupling agent obtained in step (2) into a hydrothermal reaction kettle. Put it into an oven to carry out hydrothermal reaction for one hour under the condition of 80°C.

[0031] (4) Put the solution obtained in step (3) into a square reaction tube after waiting for cooling. Pour half of the volume of liquid nitrogen into the Dewar, and place the reaction tube above the liquid nitrogen, inside the Dewar. Wait for the solution to completely freeze.

[0032] (5) Place the solid obtained in step (4) in a freeze dryer, and wait for 5-7 days f...

Embodiment 2

[0035] This example adopts conductive nanomaterials and organic crosslinking agents different from those in Example 1, and through directional freeze-drying technology, a porous block material with a symmetrical concave honeycomb microporous structure is formed; the final conductive porous pressure-sensitive super material product.

[0036](1) Weigh 40 mg of graphene oxide with a sheet size of about 1-2 μm prepared by a chemical method (improved Hummers method) and place it in a reagent bottle, add 2 ml of deionized water, and ultrasonically (power 700W) for 60 minutes to obtain 20 mg / mL graphene oxide dispersion.

[0037] (2) Add 2 mg of carbon nanofibers (CNF) to the graphene oxide dispersion and shake for 3 minutes.

[0038] (3) Pour the mixed solution of MXene and carbon nanofibers obtained in step (2) into a hydrothermal reaction kettle. Put it into an oven to carry out a hydrothermal reaction at 100° C. for three hours.

[0039] (4) Put the solution obtained in step (...

Embodiment 3

[0043] This example adopts conductive nanomaterials and organic crosslinking agents different from those in Example 1 and Example 2, and through directional freeze-drying technology, a porous block material with a symmetrical concave honeycomb microporous structure is formed; the final conductive material is obtained by heating and roasting. Porous pressure-sensitive metamaterial products.

[0044] (1) Weigh 6ml of silver nanowire dispersion (10mg / ml) into a reagent bottle, add water to dilute to 5mg / ml, and oscillate evenly.

[0045] (2) Add 2 mg of polyvinyl alcohol (PVA, molecular weight: 120,000) to the silver nanowire dispersion, vibrate for 30 minutes and then sonicate for 30 seconds.

[0046] (3) Put the solution obtained in step (2) into a square reaction tube. Pour half of the volume of liquid nitrogen into the Dewar, and place the reaction tube above the liquid nitrogen, inside the Dewar. Wait for the solution to completely freeze.

[0047] (4) Place the solid obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com