Special weld joint back chipping equipment for iron tower angle steel full penetration welding

A technology of iron tower angle steel and full penetration, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. It can solve the position deviation of grinding tools, reduce the quality of root cleaning of angle steel, and reduce the working efficiency of equipment, etc. problems, to achieve the effect of improving convenience, improving root cleaning quality, and reducing position deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

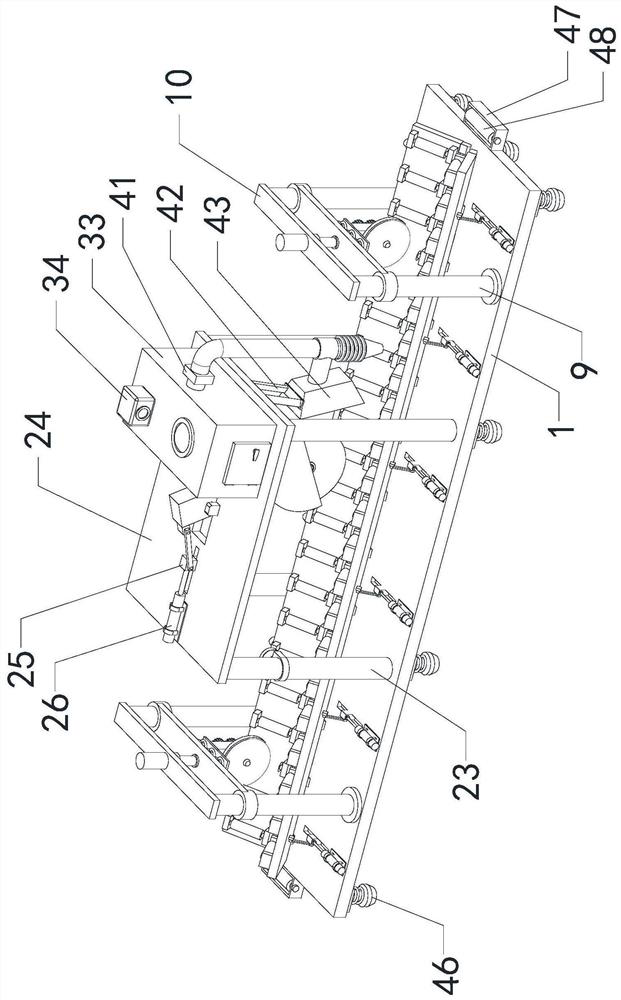

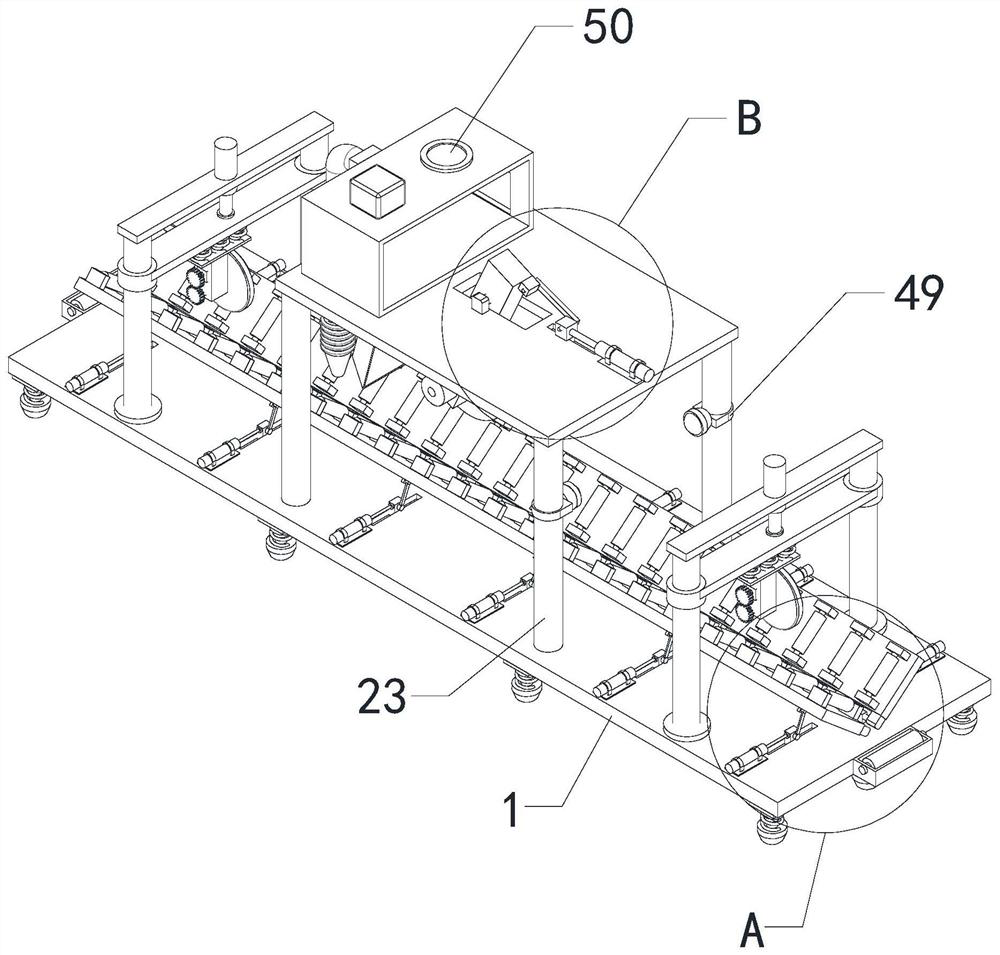

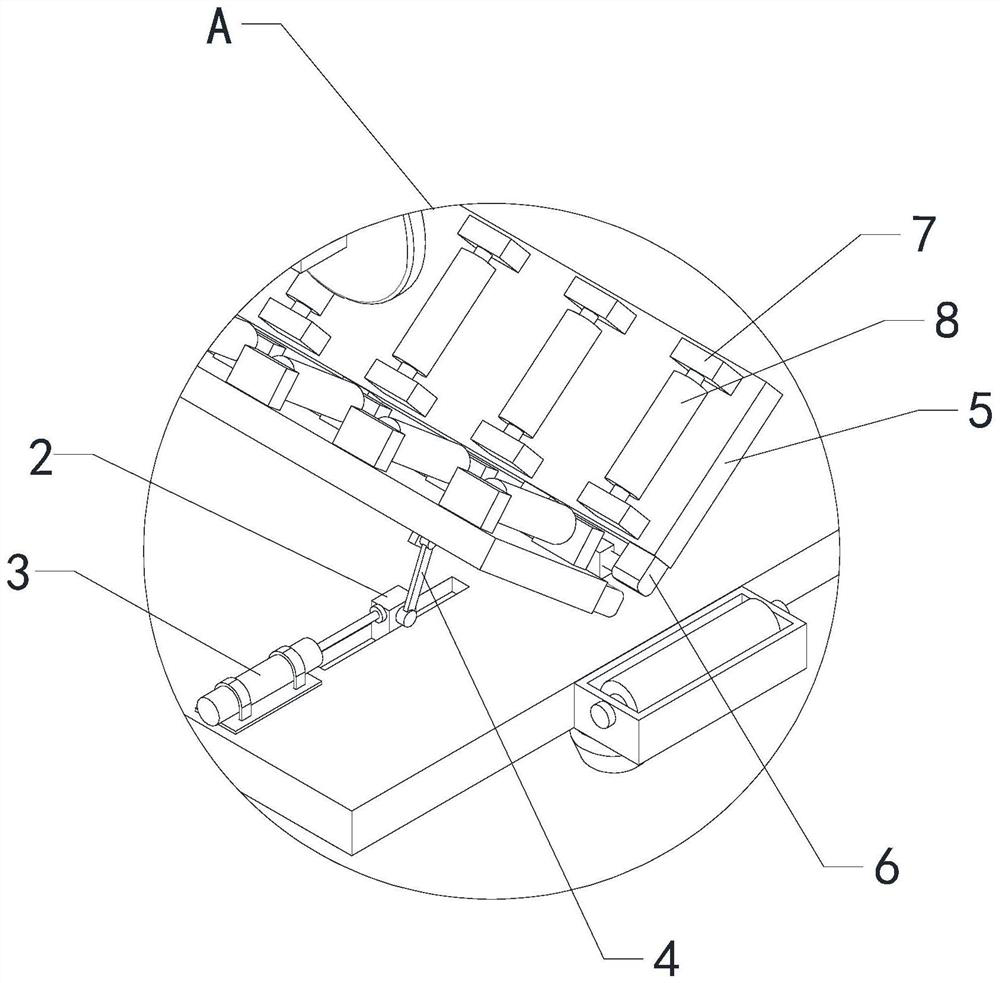

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0023] Such as Figure 1 to Figure 7 As shown, a special welding seam cleaning equipment for iron tower angle steel full penetration welding of the present invention, when it is working, first place the iron tower angle steel to be processed between two sets of support plates 5 and pass through multiple sets of first rollers The shaft 8 supports the angle steel. After the placement is completed, the second connecting plate 13 is pushed down by opening the second hydraulic cylinder 11 to move, and the second connecting plate 13 moves through multiple sets of first telescopic columns 14, third connecting plates 16, The mounting part 17 and the bearing 18 drive the shifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com