Self-adjusting exhaust valve

An exhaust valve, self-adjusting technology, applied in valve devices, combustion engines, machines/engines, etc., can solve problems such as poor power performance, easy attenuation of spring elasticity, weakened exhaust valve sealing performance, etc., to improve economy. And dynamic, increase the elastic force of reset, ensure the effect of reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

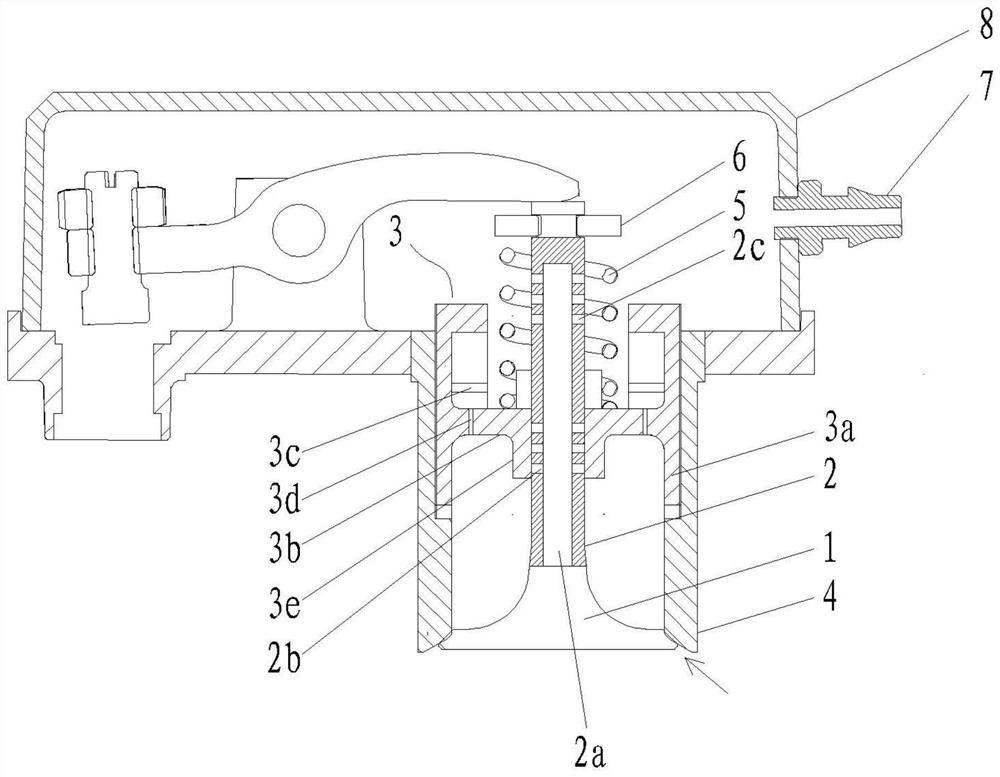

[0017] As shown in the figure, this embodiment provides a self-adjusting exhaust valve, which includes a valve head 1, a valve stem 2 connected to the valve head 1, a valve seat 3, a valve sleeve 4 and an elastic member 5, so The valve seat 3 includes a seat ring sleeve 3a, a seat ring 3b connected to the inner circle of the seat sleeve, and a blade 3c connected to the inner circle of the seat sleeve. The blade 3c is located above the seat ring 3b. Sleeve inside the seat ring 3b, the seat ring sleeve 3a is threadedly connected to the inner circle of the valve sleeve 4, the elastic member 5 is arranged between the upper end of the valve stem 2 and the seat ring 3b to provide the valve stem 2 with an elastic force for resetting, the A plurality of nozzle holes 3d are vertically opened on the seat ring 3b, and the nozzle holes are located directly below the blades 3c, so that the gas leaked from the piston cylinder is sprayed to the blades through the nozzle holes, and drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com