High-viscosity melt spinning spinneret plate

A technology of melt spinning and spinneret, which is applied in the fields of rayon manufacturing, hollow filament manufacturing, fiber chemical characteristics, etc., and can solve the problems of increasing the intensity of market competition, loss of fiber rigidity and elasticity, and the impact of fiber compression elasticity and other problems, to achieve the effect of good spinnability, low spinning speed and good compression elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

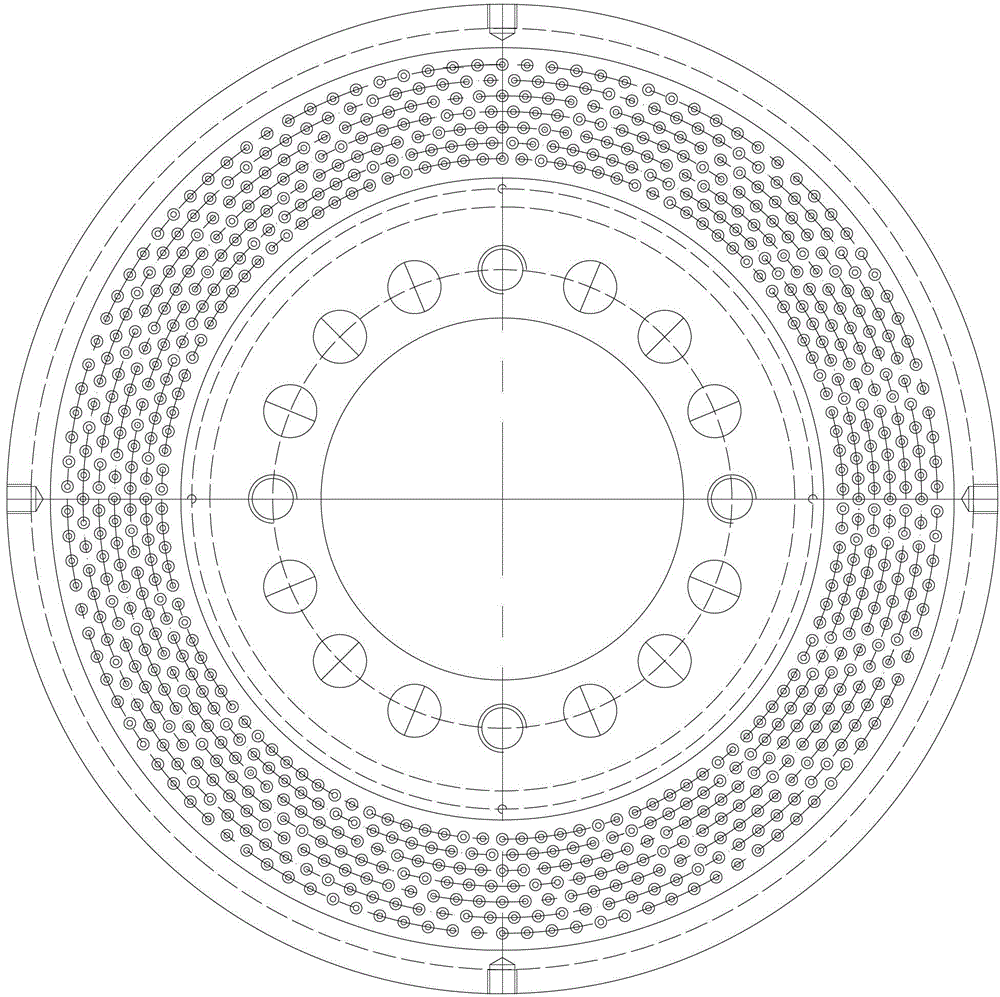

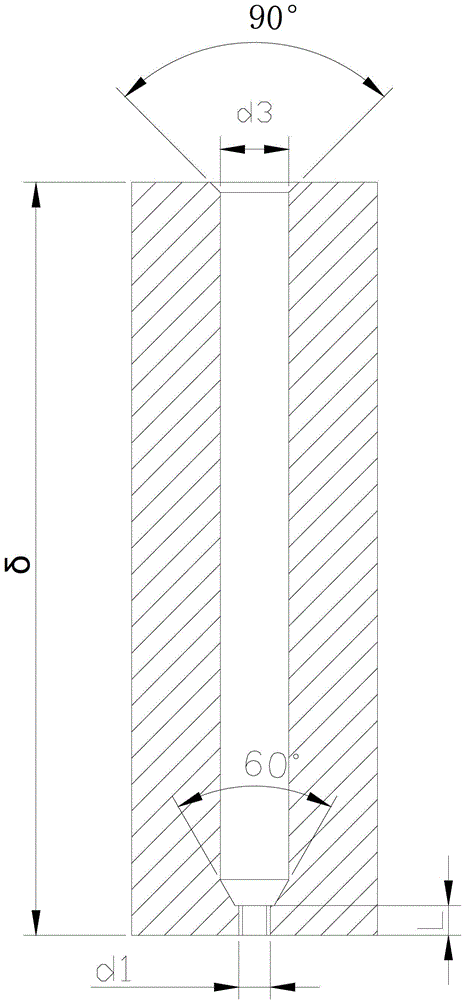

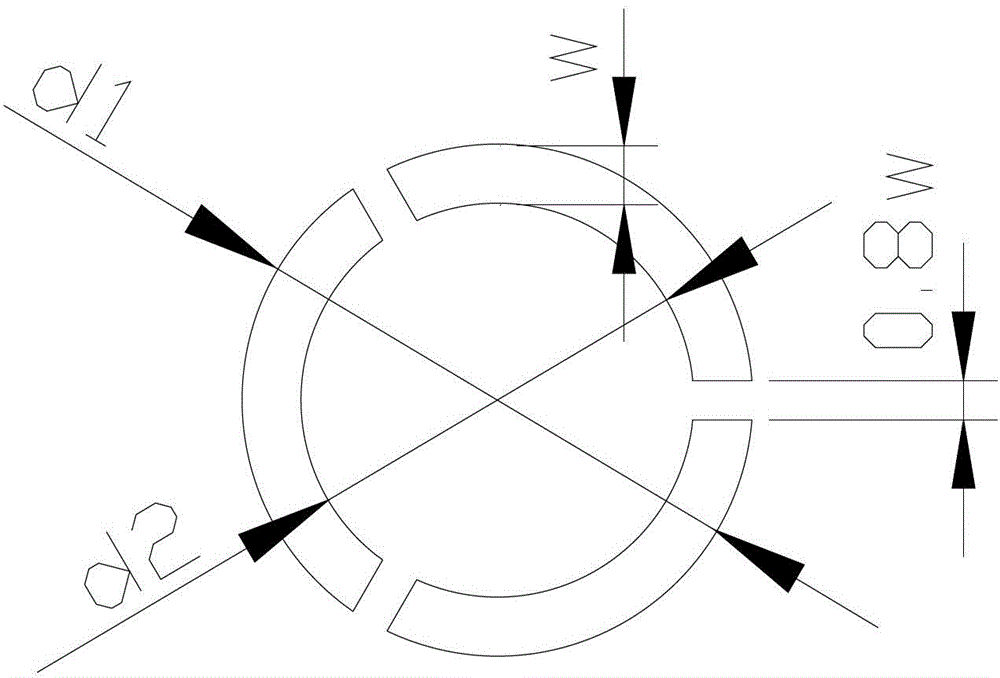

[0016] A high-viscosity melt spinning spinneret. The overall shape of the spinneret is cylindrical. There are 728 spinneret holes evenly distributed on the spinneret. The spinneret holes are divided into two parts: guide holes and micro holes. Connected, the cross-sectional shape of the microholes is designed as 3 "C" shapes, one of the opening directions faces the direction of the center of the plate, the outer diameter d1 of the spinneret microholes: 2.26mm, the inner diameter d2: 1.60mm, and the opening width is 0.530mm; Microhole height L: 1.6mm, microhole cone angle is 60°, guide hole diameter is d3: 5mm; spinneret thickness δ: 38mm. The deflection angle of the initial holes is 1.636°, the distance between spinneret hole circles is 13 mm, and each circle has 104 holes.

[0017] Spinning process parameters (27.8dte×51mm as a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com