Patents

Literature

37results about How to "Rigid foot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

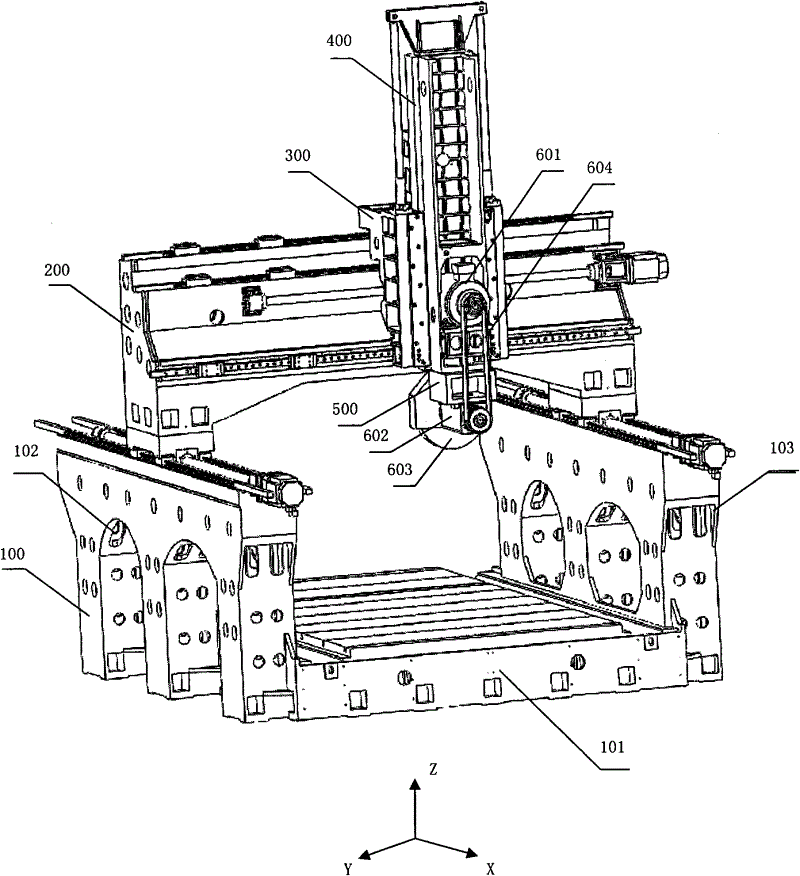

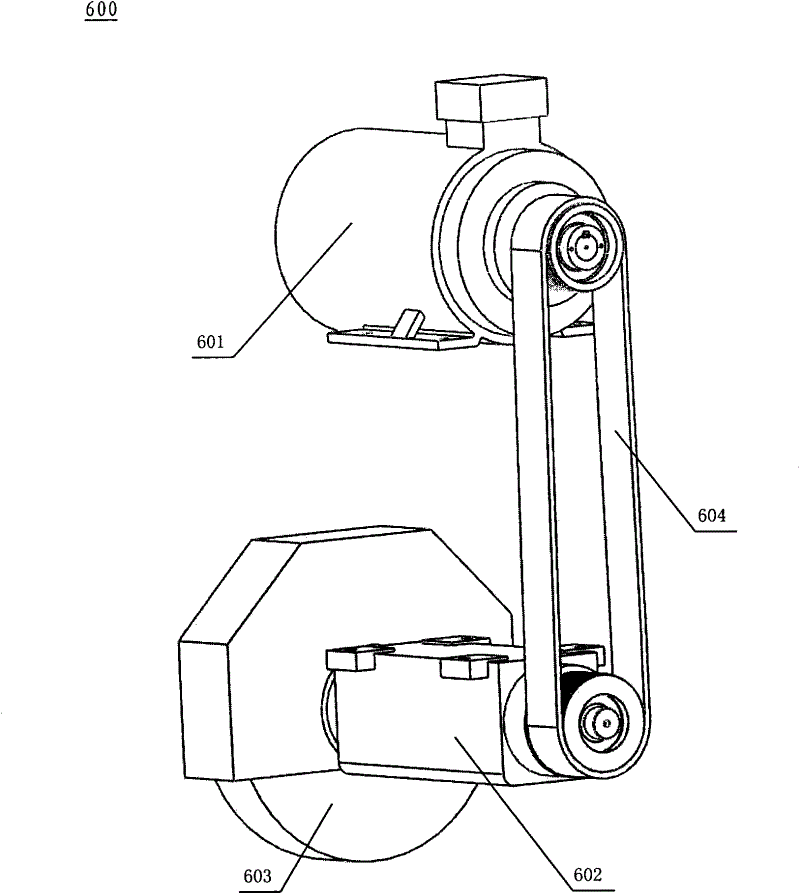

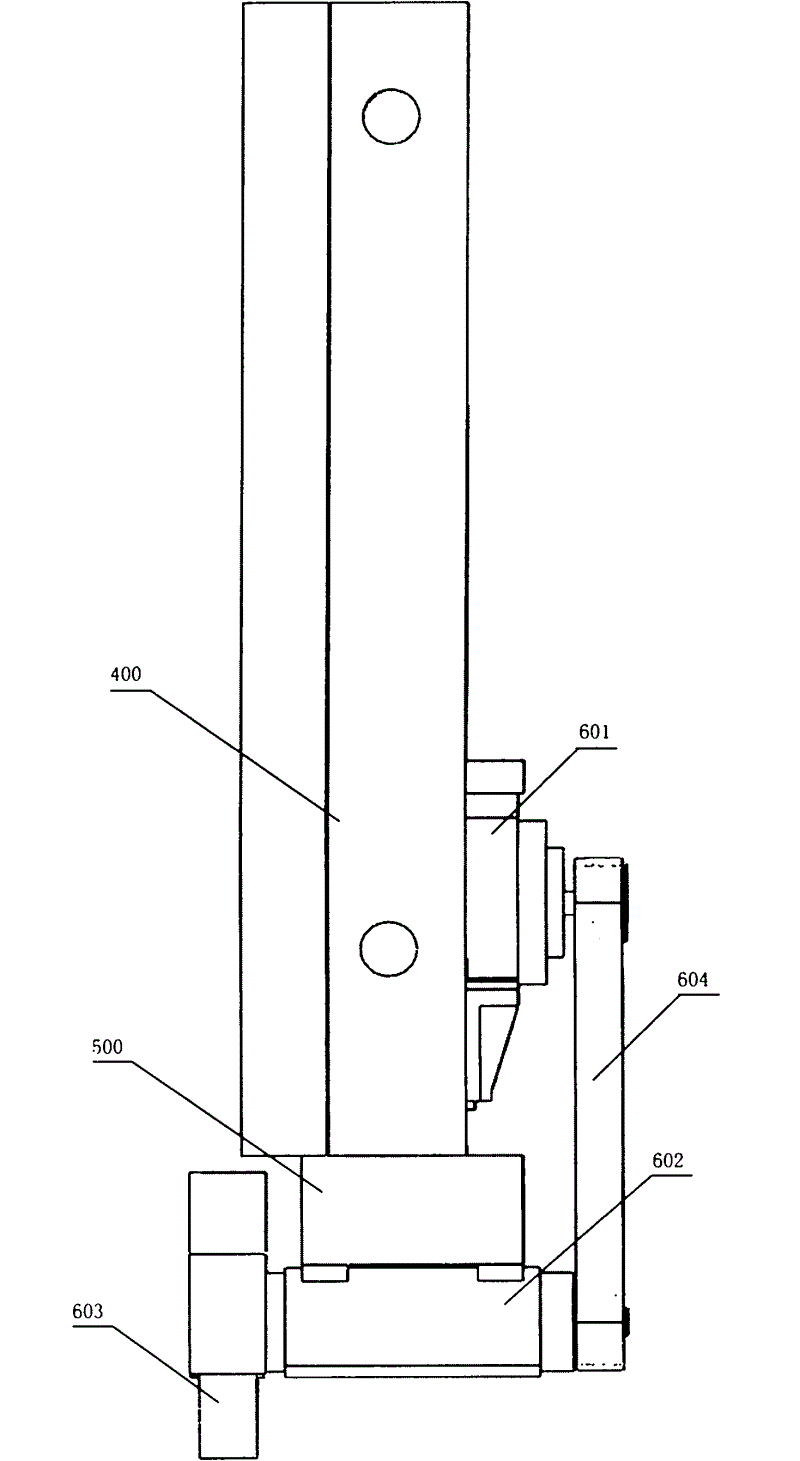

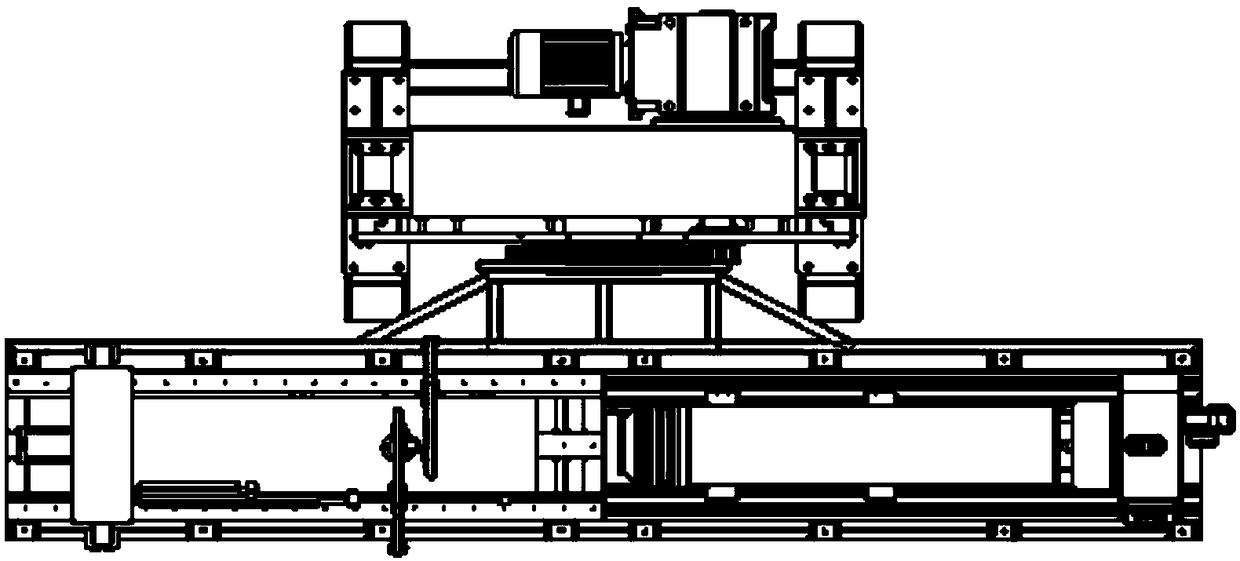

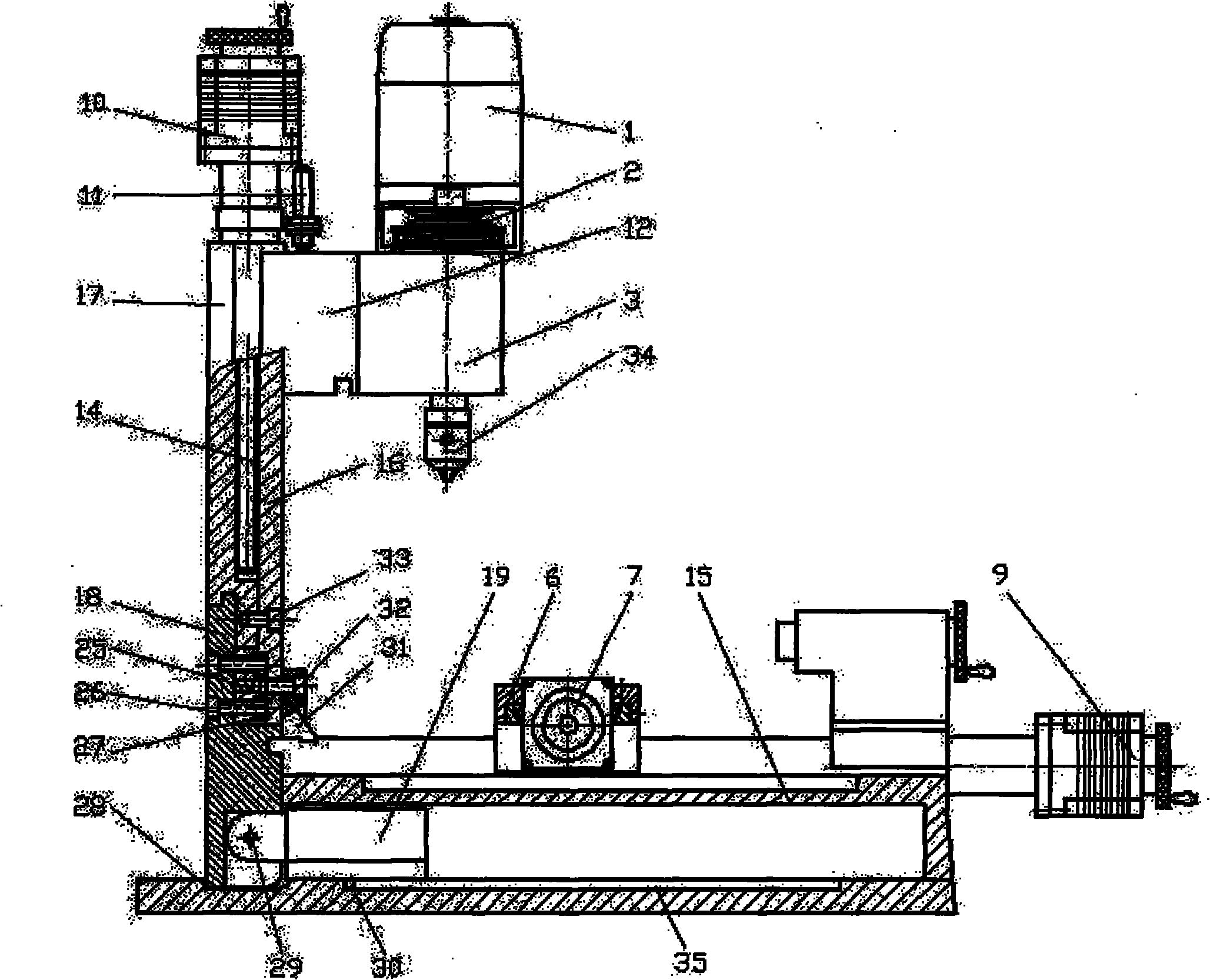

Bridge type numerical control planogrinder structure

The invention relates to a bridge type numerical control planogrinder structure, which comprises a base, a beam, a sliding saddle, a ram, a grinding head box body and a dynamic-static grinding head assembly, wherein a workbench is arranged in the base, the beam is arranged on the base, the sliding saddle is arranged on the beam in sliding mode, and a guide rail and a lead screw pair are arranged in the direction that the sliding saddle is perpendicular to the workbench. The ram is arranged on the sliding saddle and in sliding connection with the guide rail of the sliding saddle in mutual matching mode. The grinding head box body is fixedly arranged at the lower end of the ram, and the dynamic-static grinding head assembly is arranged on the grinding head box body. The dynamic-static grinding head assembly comprises a grinding head motor, a dynamic-static grinding head spindle, a grinding wheel and a multi-wedge pulley, wherein the grinding wheel is arranged at one end of the dynamic-static grinding head spindle, the dynamic-static grinding head spindle is arranged below the grinding head box body, the grinding head motor is arranged in the ram, and the multi-wedge pulley is connected an output shaft of the grinding head motor and the other end of the dynamic-static grinding head spindle. Therefore, the bridge type numerical control planogrinder structure is simple and convenient to process, reliable in work and capable of improving processing precision and working efficiency.

Owner:深圳市盛德丰精密机床有限公司

High-strength corrosion resistance distribution box used for electric power

The invention relates to a distribution box, which includes a box body, a box cover, and a fastening mechanism for movably connecting the box body and the box cover. The raw material components of the box body and the box cover are as follows, all in parts by weight: polyethylene resin 40-60 20-30 parts of phenolic resin, 2-10 parts of elastomer, 0.1-15 parts of graphene, 3-7 parts of silicon carbide, 1-10 parts of silane coupling agent, 12-15 parts of semi-reinforced furnace black, calcined 10-12 parts of pottery clay, 6-12 parts of surface-treated Kevlar chopped fibers, 5-7 parts of nanomolybdenum disulfide (MoS2), 0.5-3 parts of aluminum oxide, 3 parts of polydimethylsiloxane ‑5 parts, 0.5‑2.5 parts of flame retardant, 1‑3 parts of dispersant. In the preparation process of the distribution box body and the box cover of the present invention, the raw materials and the proportions, together with the processing technology, make the distribution box box and the box cover of the present invention have excellent flexibility, mechanical properties and corrosion resistance, and at the same time It has good thermal conductivity, improves the performance of the distribution box as a whole, is not easy to age, has sufficient rigidity, and has a long service life, reducing maintenance costs.

Owner:DONGA POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

Weather resistant polyethylene composite for manufacturing casing of outdoor equipment of household appliances

The invention relates to a weather resistant polyethylene composite used for manufacturing casings of outdoor equipment of the household appliances, which is characterized in that the polyethylene composite comprises the following ingredients by the weight percentage: 60% to 85% of polyethylene resin; 10% to 40% of mineral reinforcing agent; 3% to 5% of toughening modifiers; 0.1% to 0.2% of antioxidant; 0.1% to 0.4% of composite light stabilizer; 0.1% to 0.2% of colorant; 0.1% to 0.6% of coupling agent; and 0.2% to 0.5% of processing aid. The invention has the advantages that the casings of outdoor equipment of household appliances made of the polyethylene composite are not easily aged, the rigidity is sufficient, and the service life is long.

Owner:MIDEA GRP CO LTD

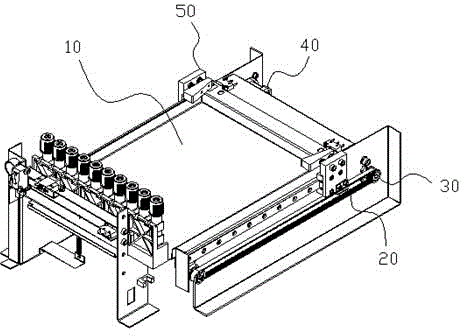

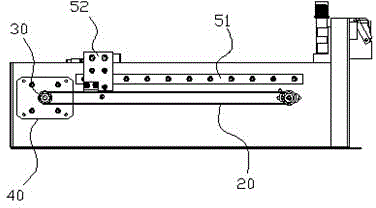

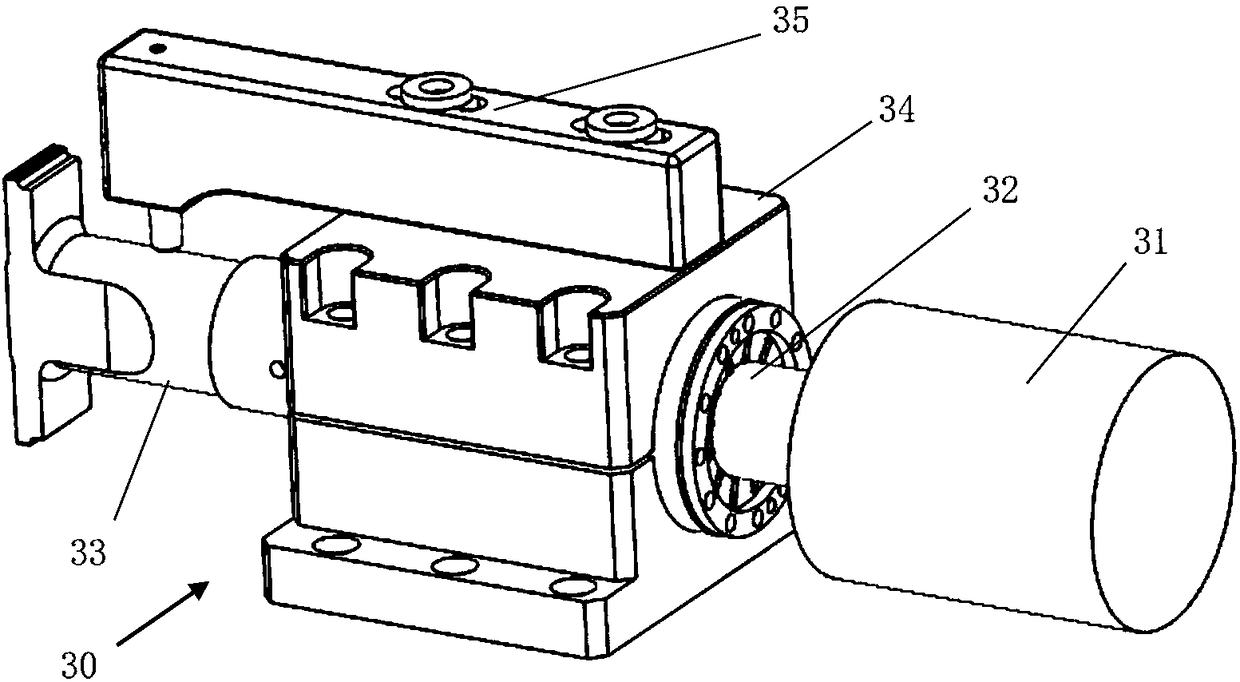

Sample introduction device of blood cell analyzer

ActiveCN104991080AHigh precisionEasy loadingMaterial analysisReciprocating motionBlood cell analysis

The invention relates to the technical field of medical and health apparatuses, particularly to a sample introduction device of a blood cell analyzer. The sample introduction device includes a test tube sample holder loading disc, a synchronous belt, synchronous pulleys driving the synchronous belt to do reciprocating motion, a motor driving the synchronous pulleys to rotate and a guide mechanism. The guide mechanism includes linear slide rails parallel to the synchronous belt and a sliding block able to slide on the linear slide rails. The sliding block is in fixed connection with the synchronous belt and is driven by the motor to move. The sample introduction device also includes a push block that is fixed on the sliding block and does reciprocating motion along with the synchronous belt. Under the driving of the push block, the test tube loaded test tube sample holder is conveyed to a specific location along the guide mechanism. The device provided by the invention employs the linear guide rails to replace existing linear bearings to serve as the guide transmission mechanism, the load is large, the stability is stronger, and the rigidity is enough.

Owner:ZHONGSHAN CHUANGYI BIOCHEM ENG

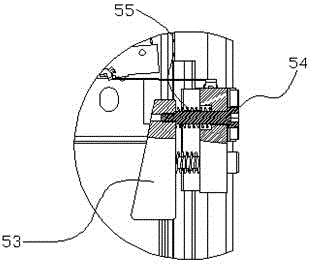

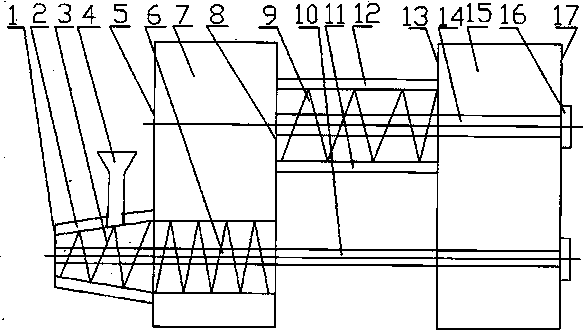

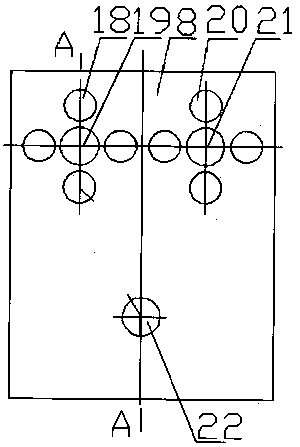

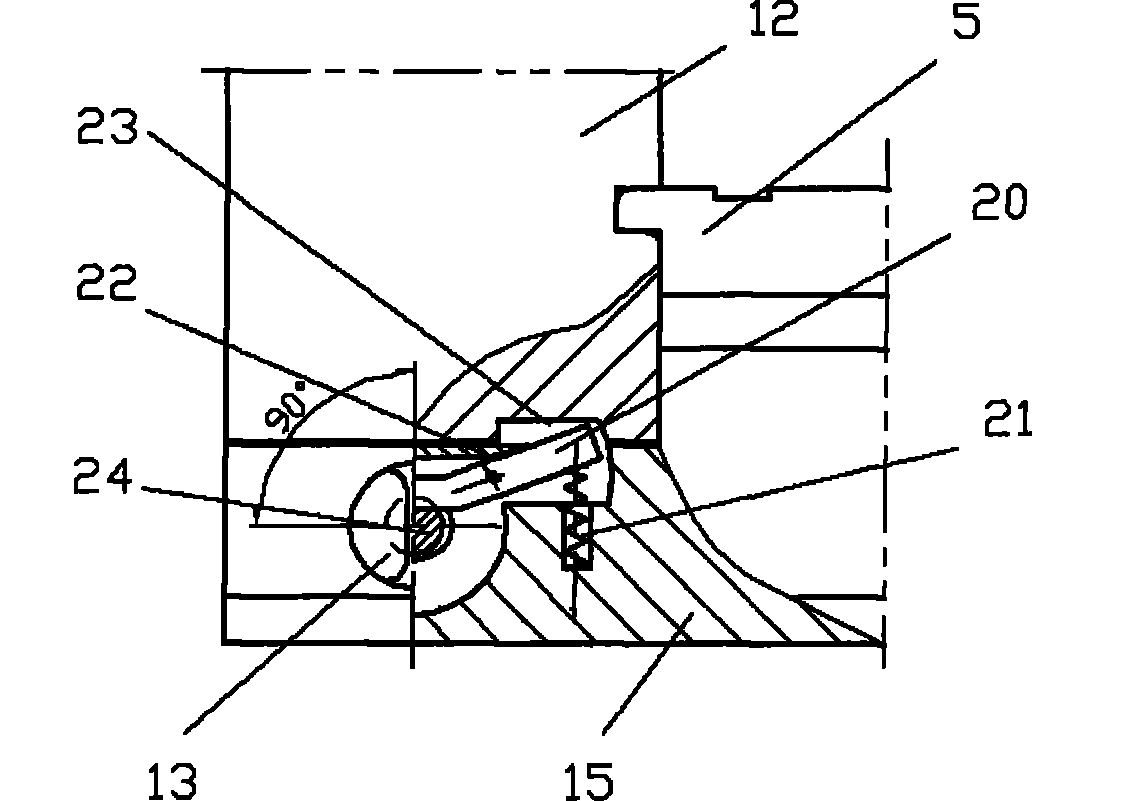

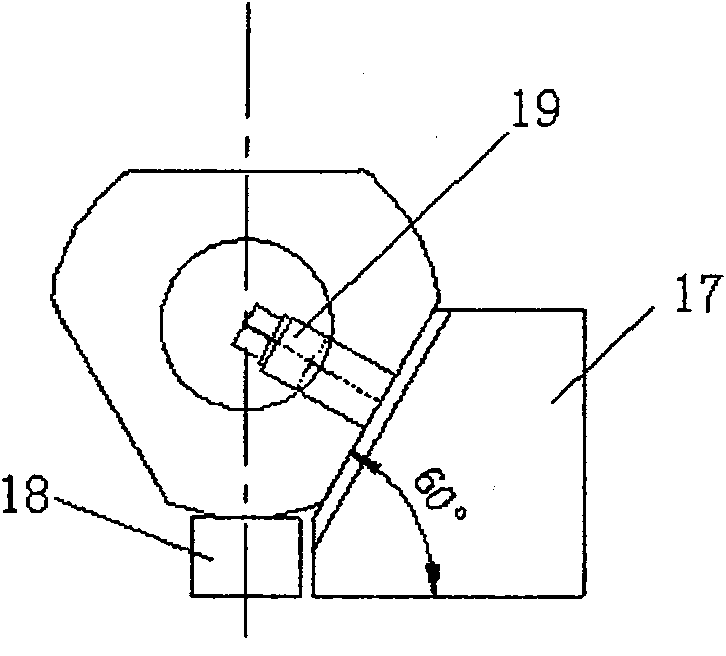

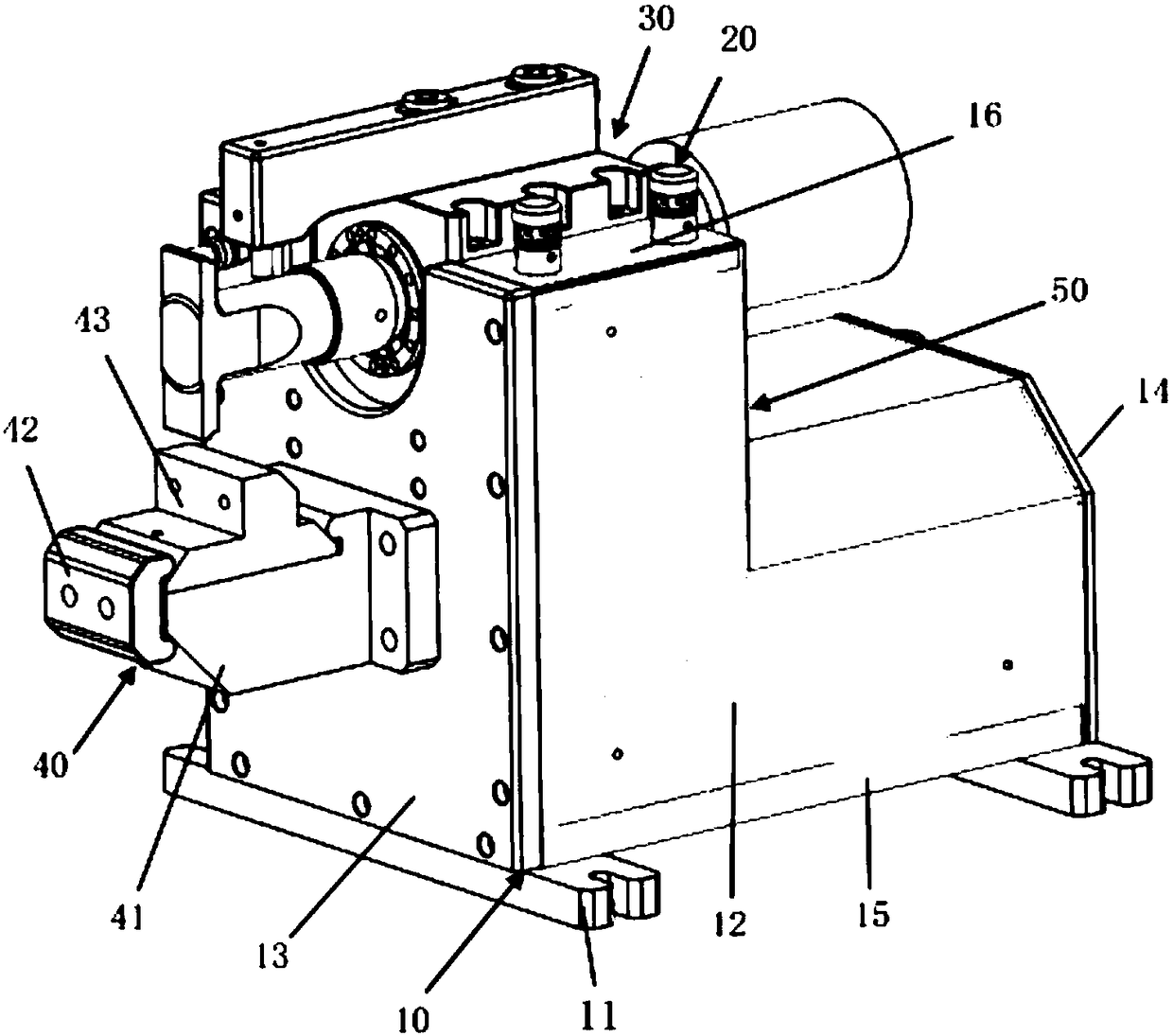

Rolling guide and guard

InactiveCN101480667AImprove stabilityAchieve regulationGuiding/positioning/aligning arrangementsPulleyWedge shape

The invention relates to a device for guiding the wire-shaped working materials and the bar-shaped working materials, in particular to a roller guide and guard unit which comprises a guide and guard case body, a cover plate and a base. The rear ends of a left idler pulley arm and a right idler pulley arm are provided with opening regulating mechanisms, each opening regulating mechanism comprises a wedge-shaped regulating block fixed on the guide and guard case body, and both lateral wedge surfaces of the wedge-shaped regulating block are respectively attached to the lateral surfaces inside the rear ends of the left idler pulley arm and the right idler pulley arm. With the technical scheme, both sides of the roller guide and guard unit are limited in a rolling way by a front guide roller group and a rear guide roller group after the wire-shaped working materials and the bar-shaped working materials enter the roller guide and guard unit, and the wire-shaped working materials and the bar-shaped working materials can be smoothly guided to pass through. Furthermore, because the rear ends of the left idler pulley arm and the right idler pulley arm are provided with opened regulating mechanisms, and each opened regulating mechanism adopts the wedge-shaped regulating block, the left idler pulley arm and the right idler pulley arm are driven by the wedge-shaped regulating blocks moving front and back to rotate, thereby the invention realizes the regulation of the opening degree of the guide rollers. In addition, because the processing difficulty of the wedge-shaped regulating blocks is low, the guide and guard cost is reduced, and because the rigidity of the wedge-shaped regulating blocks is high, the guide and guard stability is good.

Owner:HEFEI BAISHENG SCI & TECH

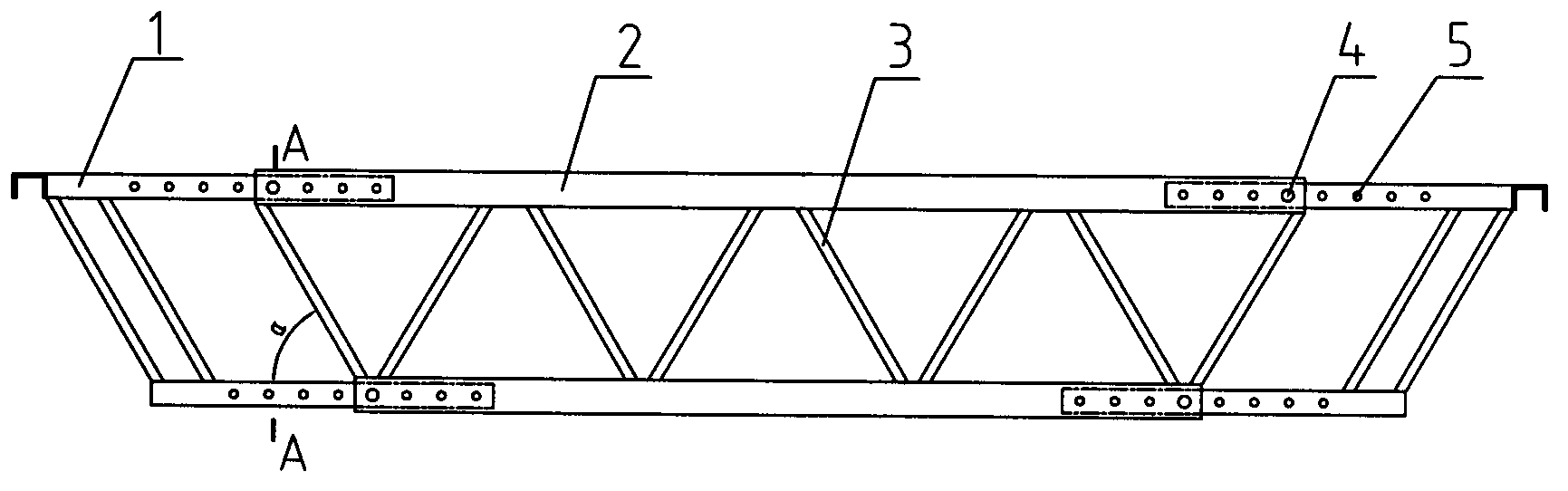

Telescopic formwork support beam

InactiveCN102704677ALess materialEasy to manufactureForms/shuttering/falseworksUltimate tensile strengthBuilding construction

The invention discloses a telescopic formwork support beam. The telescopic formwork support beam comprises a sub beam, a main beam, ribs, pin bolts and pin holes, wherein the main beam is a ladder-shaped strip truss, upper and lower edges of the main beam are steel pipes, and the two steel pipes are fixedly connected by the ribs, and the tilting angles of the ribs on the two ends are equal; 6-10 axial equally-spaced pin holes are respectively arranged on the two ends of the upper and lower edges of the main beam, the sub beam is an open shaped frame, the upper and lower edges of the sub beam are steel pipes, and the outer end of the sub beam is fixedly connected by two tilting ribs along the same direction; the tilting angles of the ribs connected with the sub beam are equal to that of the ribs connected with two ends of the main beam; and the upper and lower edges of the open end of the sub beam are respectively axially inserted into pipes on the two ends of the main beam to form a nesting structure, and the sub beam is positioned relatively to the axial mounting position of the main beam by making the pin bolt traverse the pin hole. The telescopic formwork support beam is in a truss structure, the length of the beam is adjustable, and the structure strength is good; and during the mounting process, the mated vertical top brace is less, thus the auxiliary materials are saved, and the traffic space of the construction site is improved; and more importantly, the telescopic formwork support beam can be repeatedly used and the use cost can be saved.

Owner:JIANGSU ZHENGWEI CONSTR

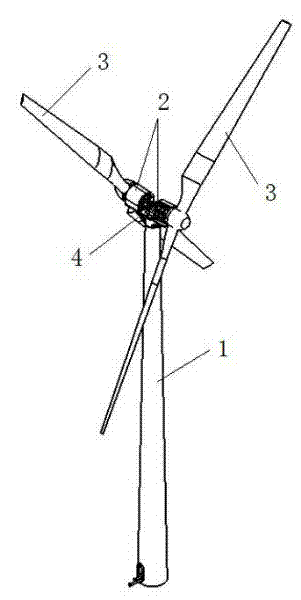

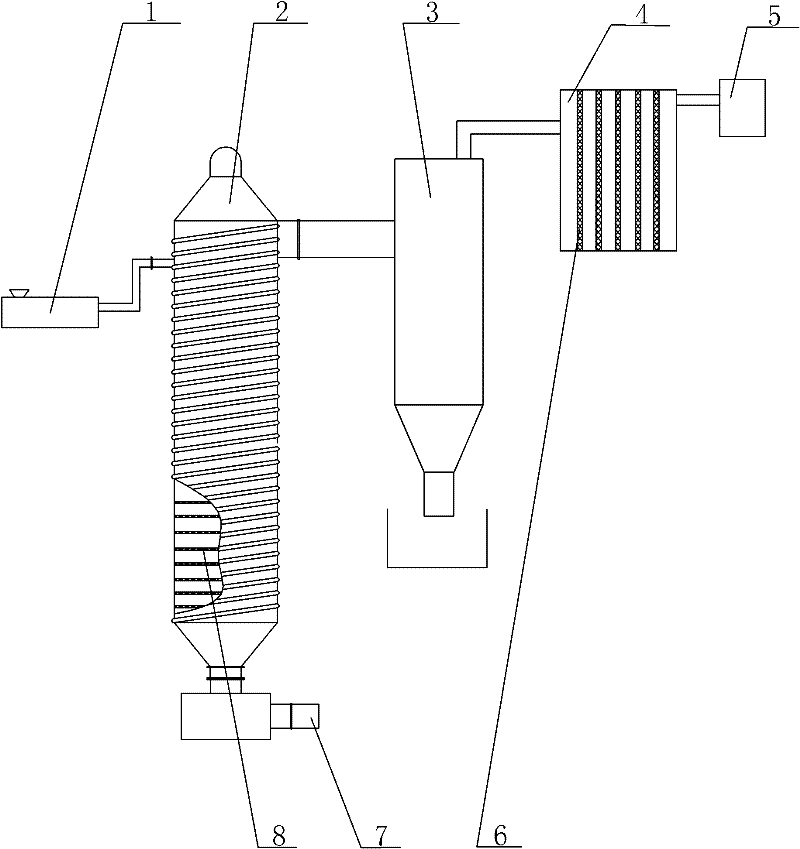

Wind energy collecting device and wind power generation system thereof

InactiveCN102384035AImprove wind energy conversion efficiencyReduce configuration costsEngine fuctionsWorking fluid for enginesEngineeringHigh pressure water

The invention relates to a wind energy collecting device and a wind power generation system thereof. The wind energy collecting device comprises a cylinder or title frame type tower body standing on the ground, the collecting device is characterized in that the top of the tower body is provided with two independent operative water pumps in a back to back manner, the tail ends of driving rotor shafts of the two water pumps are respectively provided with a wind turbine, the rotation directions of the two wind turbines are reverse, high-pressure water outlet pipes of the two water pumps are connected in a high-pressure water-delivery main pipe after confluence; and the tail end of the high-pressure water-delivery main pipe is provided with a ration nozzle, high-velocity waterflow jetted by the nozzle is used for driving each water turbine to rotate, and each water turbine drives the generator to generate electrical energy. The wind energy collecting device provided by the invention has the advantages that the design is reasonable, the structure is simple, and the wind energy utilization rate is improved; the volume of each water pump of the wind power generation system and the nozzle of each water turbine are quantitative, thereby ensuring the constant total drag coefficient of a whole waterpower drive system, the ratio of the rotation rate to wind speed of each driving rotor shaft of each water pump is constant, namely the blade tip speed ratio of a blade is constant; and the conversion efficiency of each wind turbine to the wind energy corresponding to different wind speeds can reach the maximum value.

Owner:朱永波

Metal additive material manufacturing support method and device based on shape following base plate

ActiveCN110421164ASpeed up design timeExtended production timeAdditive manufacturing apparatusIncreasing energy efficiencyRemoval DifficultiesEngineering

A metal additive material manufacturing support method based on a shape following base plate is used for reducing the distance between a supporting point and a base plate, various generated support areas serve as a base, the shape following base plate related to the surface of a formed component is downwards established, a new support is generated on the shape following base plate, and accordinglythe support height is lowered. The shape following base plate can guarantee the generated support forming quality along with constant changes of the height, the shape and the thickness of the formedface. A metal additive material manufacturing support device based on the shape following base plate is provided. When formed components are complex in shape and structure and the support areas are high, on one hand, a conical support can be continuously utilized, materials are saved, and the removal difficulty is lowered; and on the other hand, the height of the support, making contact with the formed bottom face, of the base plate can be effectively reduced, and the component bottom face and structure forming quality is improved.

Owner:ZHEJIANG UNIV OF TECH

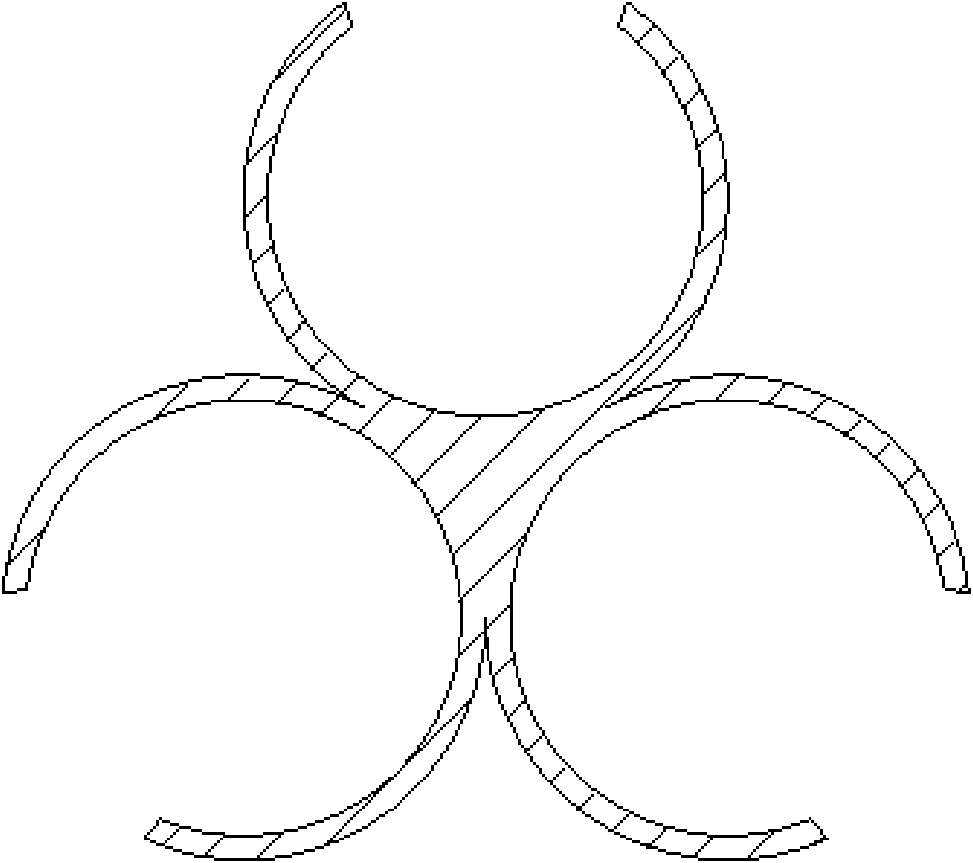

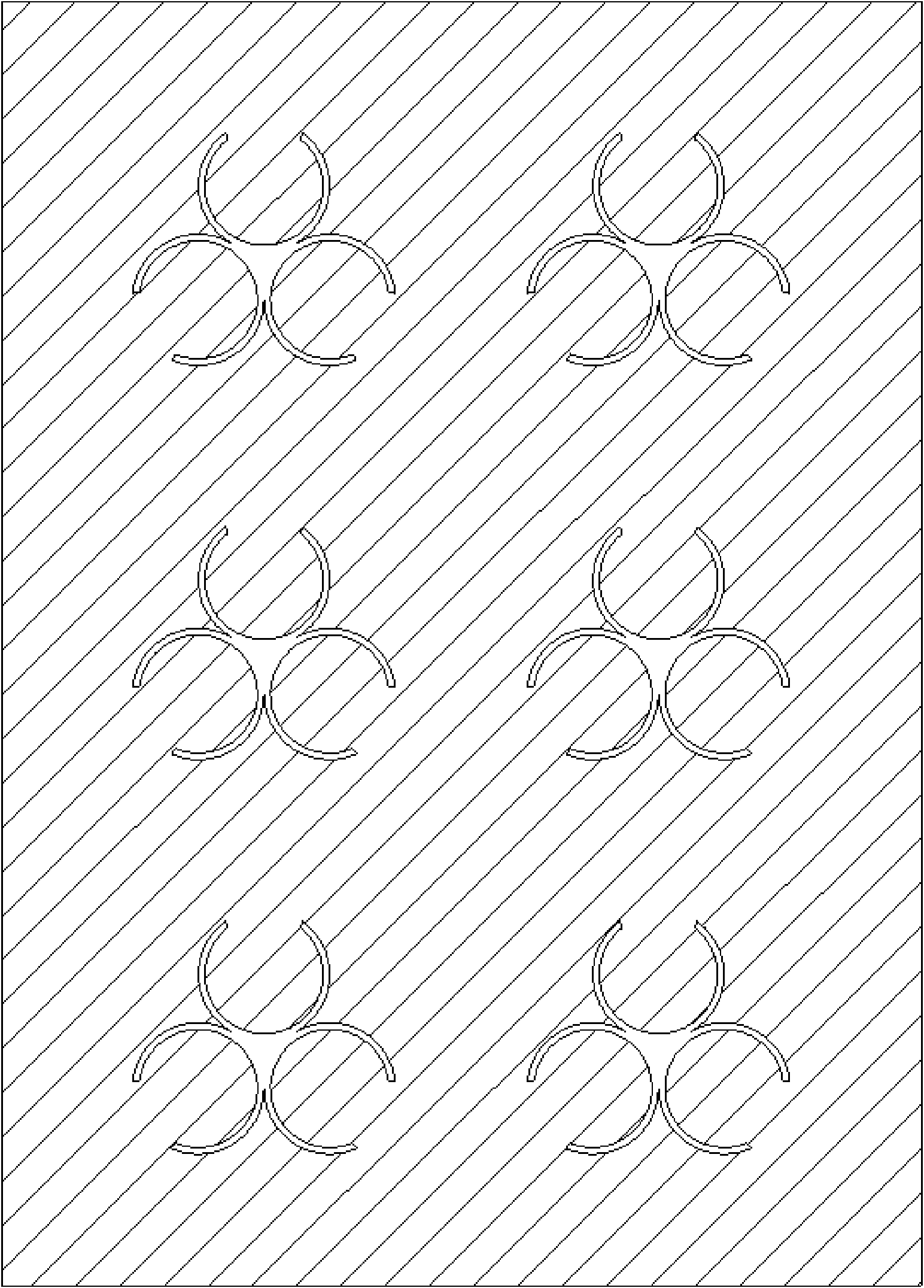

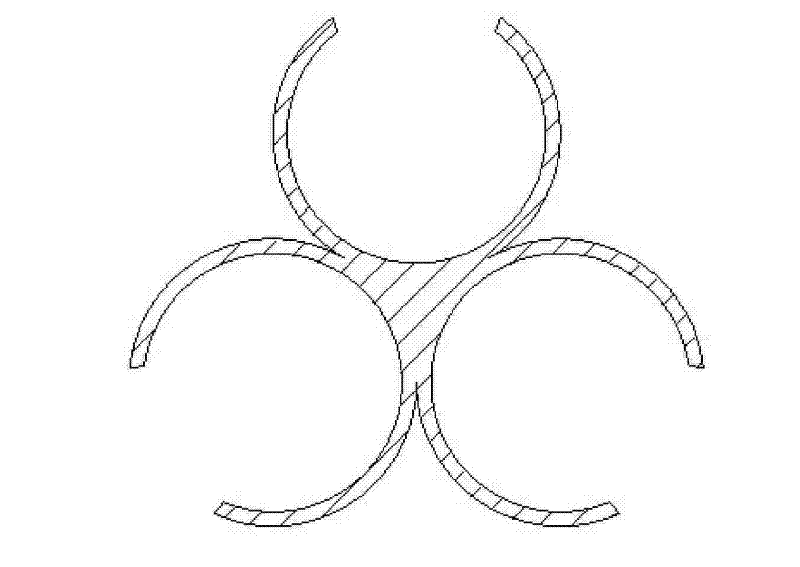

Breathable multifunctional pillow inner with moisture penetrability

ActiveCN101627869ABreathable, moisture-permeable and sweat-conducting effect is goodHigh loosenessPillowsFiberPolyethylene terephthalate

The invention discloses a breathable multifunctional pillow inner with moisture penetrability filled with fibers. The fibers consist of three hollow fibers with circular arc cross sections. The circular arcs are connected in such a way that every two are externally tangent with each other, and a connected closed region is an entity. The hollow fibers are made from polyethylene terephthalate with the intrinsic viscosity of 0.65-0.66, the melting point of 266 DEG C, the carboxyl content of more than zero and less than or equal to 25 equivalent / g * 10<6>, and the ash content of more than zero and less than 0.04 percent. The breathable multifunctional pillow inner with moisture penetrability is made of fibers which are three-hole hollow fibers with three outward openings, thereby the pillow inner is breathable and has moisture penetrability. In hot rolling process, a shape with six interlaced holes can be formed between the adjacent fibers and the fibers have openings, thus the pillow inner made from the fibers has excellent moisture penetrability.

Owner:BEIJING GUANGHUA TEXTILE GRP +1

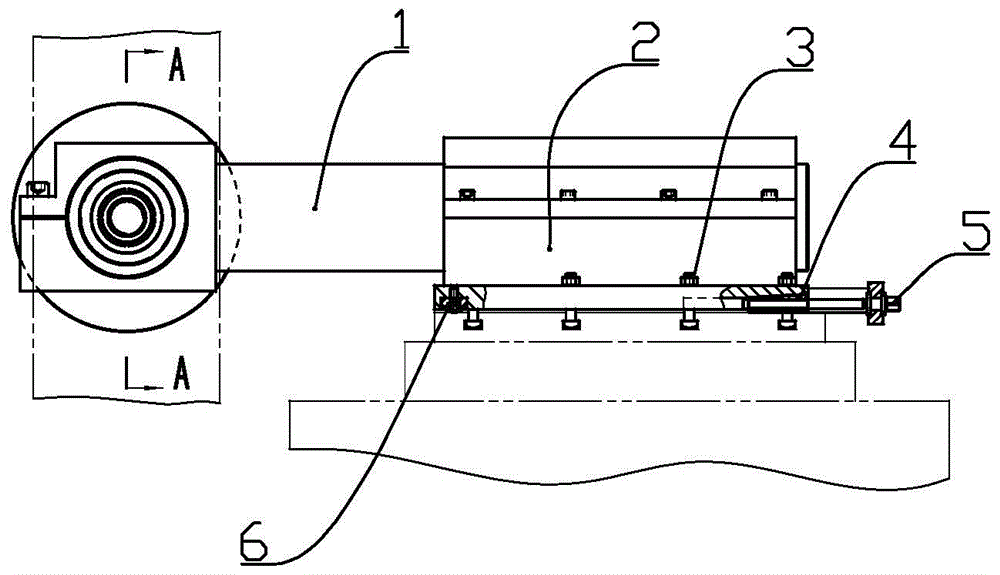

Leveling lifting device for parking equipment trolley

The invention discloses a leveling lifting device for a parking equipment trolley, and relates to the field of parking equipment. The leveling lifting device comprises power detection components, turning plates, a leveling component, supporting components, transmission shafts and bearings; the two supporting components are located on the left side and the right side of the leveling component correspondingly, the bearings are arranged at the two ends of the opposite sides of the two supporting components through bolts, the transmission shaft is arranged between the two bearings on each supporting component, and the turning plates are arranged on the transmission shafts; and the two ends of the supporting components are connected with one ends of the power detection components, and the turning plates are hinged to the other ends of the power detection components through hinge pins. The device not only solves the problem of low precision caused by electric appliance stop control in the moving process of a moving component, but also can avoid equipment faults caused by loosening and breaking of a chain or a steel wire rope, and can be widely applied to vertical lifting parking equipment.

Owner:QINGDAO DESHENGLI THREE DIMENSIONAL PARKING EQUIP

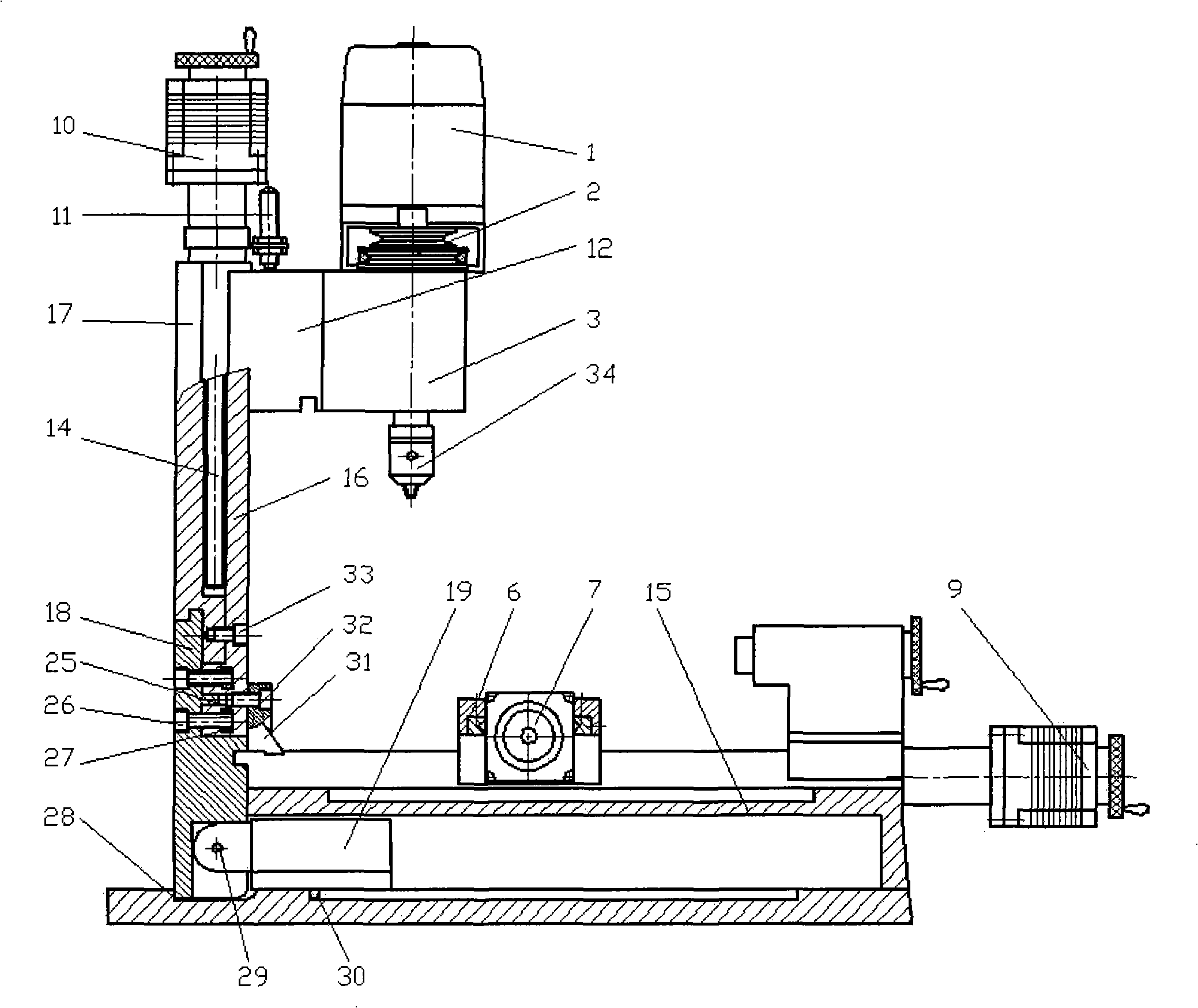

Changeable minisize multifunctional numerically-controlled machine tool

InactiveCN101259587AEnhance perceptual knowledgeImprove learning enthusiasmOther manufacturing equipments/toolsLarge fixed membersNumerical controlDrive wheel

The invention relates to an indexable type micro multifunctional numerical control machine; wherein, a main motor, a driving wheel, a main spindle box and a chuck are sequentially connected; the main spindle box and a main spindle box base are fixedly connected; a sliding upright column, a round rotary table, a spacing guiding sliding block and a sliding guiding rail are arranged in inner cavity of a horizontal type bed body and can be translated from left to right; an end of the round rotary table is articulated with the spacing guiding sliding block and the other end is connected with the sliding upright column which is externally fixedly connected with the sliding guiding rail; the main spindle box base is fixedly connected with the upper surface of the sliding guiding rail; the sliding upright column is internally provided with a lead screw which is connected with a lead screw feed motor; a locking block is arranged along left end of the guiding rail of the bed body and a limit switch is arranged at the left end part of the guiding rail of the bed body; a bed body step is equipped at the bottom of the bed body at the left end; an inner cavity locating groove is arranged at the bottom of the horizontal type bed body; the horizontal type vehicle main spindle box base is locked with a horizontal vehicle body by a locking device; the spacing guiding sliding block, etc. are translated to the left along the inner cavity of the horizontal type bed body and rotate clockwise with 90 degrees around an articulated pivot of the round rotary table and the spacing guiding sliding block, thus showing a vertical milling numerical control machine. The indexable type micro multifunctional numerical control machine has the advantages of small volume and wide use.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Multi-color pug production equipment

ActiveCN103934884AImprove the finishKnead enoughCeramic shaping apparatusClay processing apparatusMixed materialsMechanical engineering

The invention discloses multi-color pug production equipment. The multi-color pug production equipment is characterized in that a forming auger is installed in front of a pug kneading auger, a multi-color pug auger is installed in front of the forming auger, pug of multiple colors is added outside the multi-color pug auger through a multi-color pug feeding device, the pug of multiple colors and formed pug of the forming auger are mixed, stirred and extruded to obtain multi-color pug, and the multi-color pug is used for making multi-color ceramic products. The pug kneading auger stirs blank pug, the blank pug enters the forming auger and the multi-color pug auger, the multi-color pug feeding device is arranged at the forming auger, and mixed materials of different colors can be obtained after mixing, stirring and extruding. The multi-color pug feeding device is tubular, the multi-color pug can also be obtained after mixing, stirring and extruding by installing an auger, the multi-color pug is used for manufacturing the ceramic products, the structural density of the pug is high, the degree of finish of patterns is high, the products are delicate and pleasant, the colors are natural, and people can feel comfortable and are attracted. The structure is simple, manufacturing is easy, use is convenient, cost is low, and the products are varied.

Owner:GUANGXI NANSHAN PORCELAIN

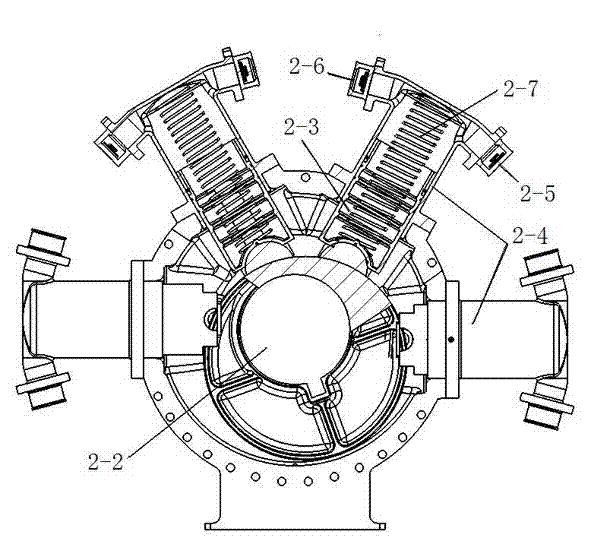

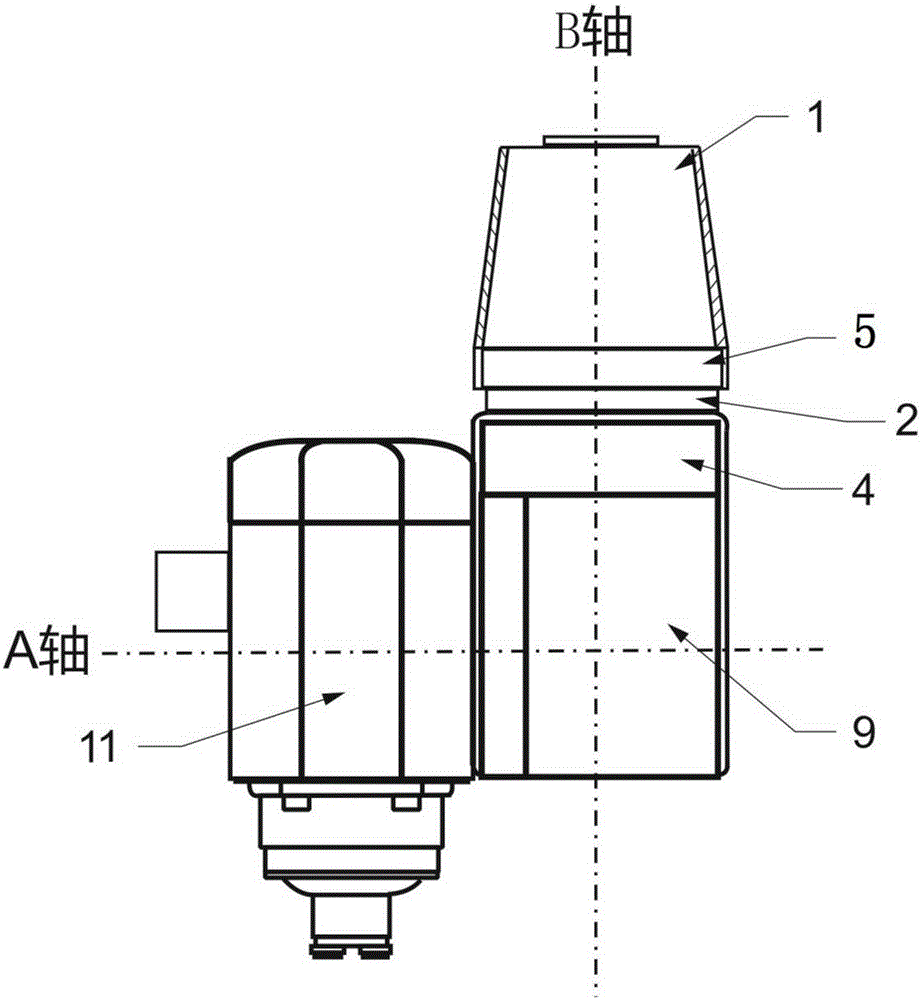

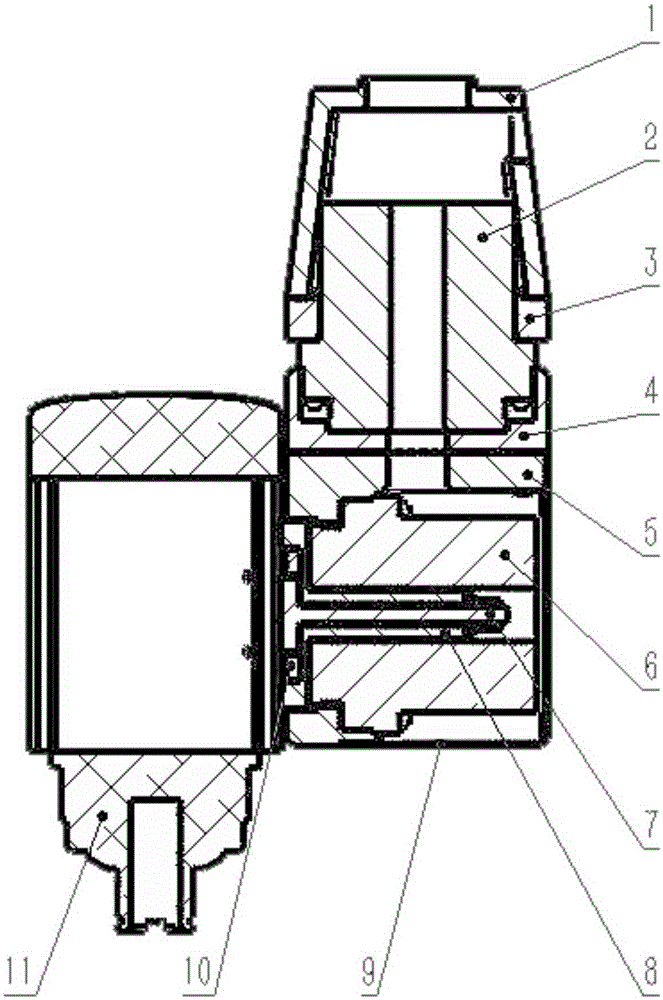

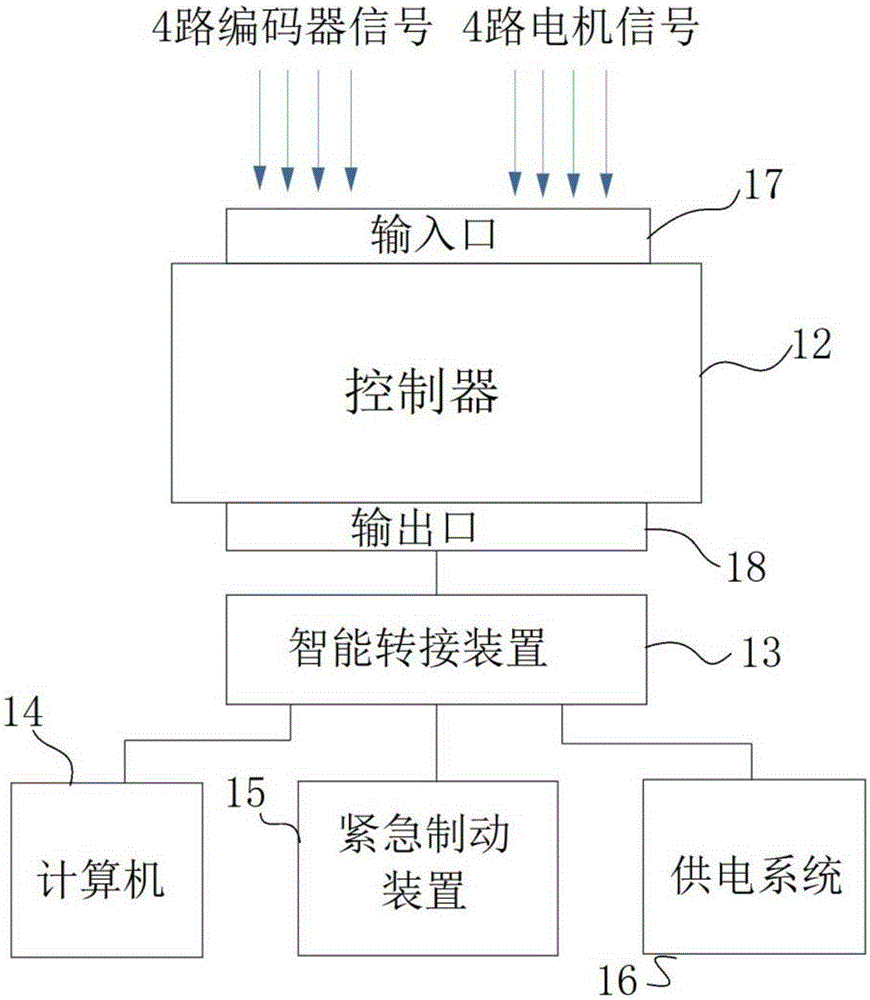

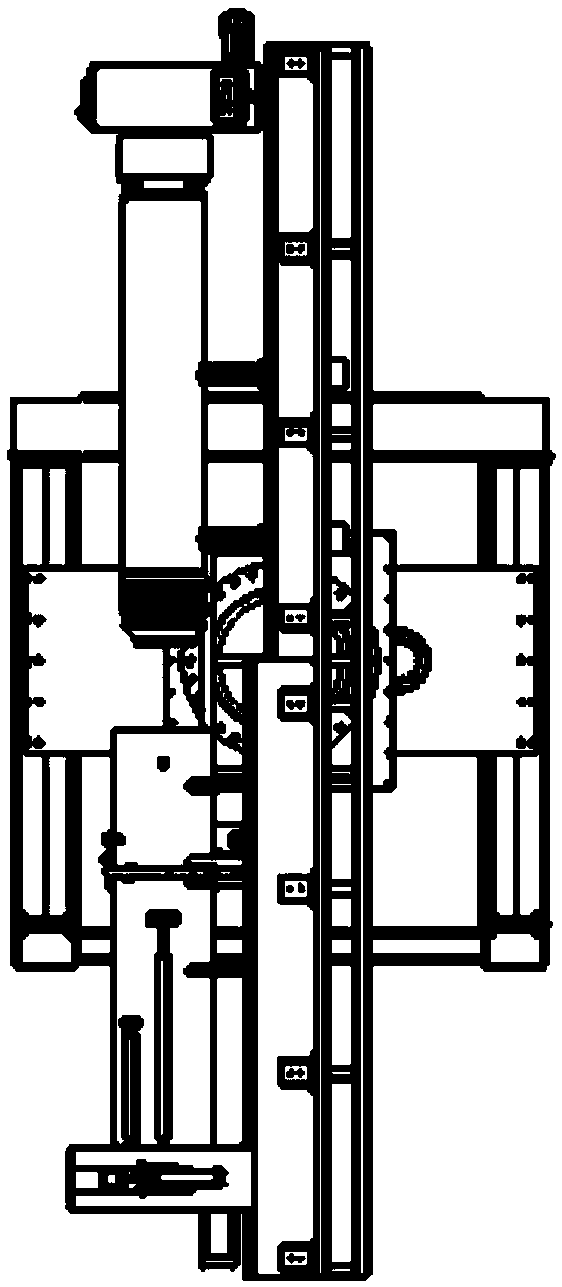

Automatic double-rotation milling head

InactiveCN105196096ACompact structureReduce weightFeeding apparatusMilling equipment detailsEngineeringDouble rotation

The invention provides an automatic double-rotation milling head comprising a B shaft power and position module, an A shaft power and position module, a processing main shaft, a main shaft connection seat, a structure part, and an installation seat, wherein the B shaft power and position module and the A shaft power and position module are vertical to each other; the A shaft power and position module can rotate with any angle in a range being + / -360 degrees around the B shaft power and position module; the main shaft connection seat is arranged at the side part of the A shaft power and position module; the connection end of the processing main shaft and the main shaft connection seat can be fixed by a bolt; the processing main shaft is arranged at the rotation part of the A shaft power and position module; the rotation part can drive the processing main shaft to rotate with any angle in a range being + / -360 degrees around the A shaft power and position module; the structure part is in a double-layer structure main body, is arranged between the B shaft power and position module and the A shaft power and position module and can be used as a fixing part for the B shaft power and position module and the A shaft power and position module; the installation seat is arranged above the B shaft power and position module; an adaptor seat is connected onto the installation seat or the installation seat is connected onto a device by an adaptor plate.

Owner:XIAN HIGH TECH AEH INDAL METROLOGY

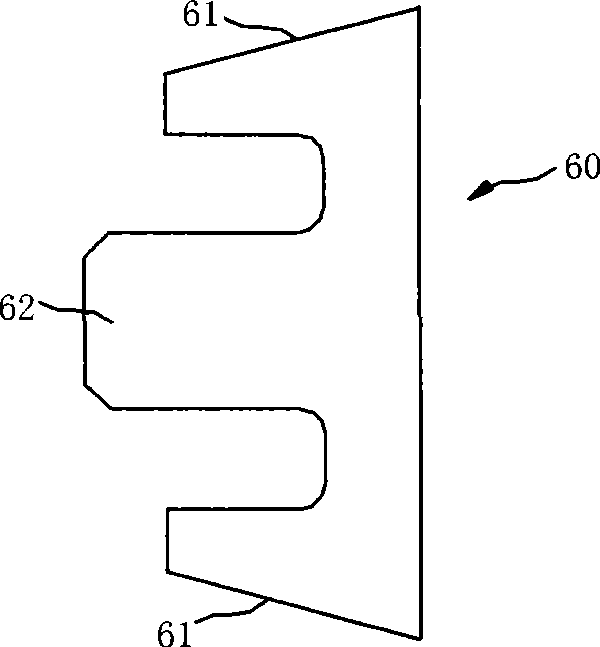

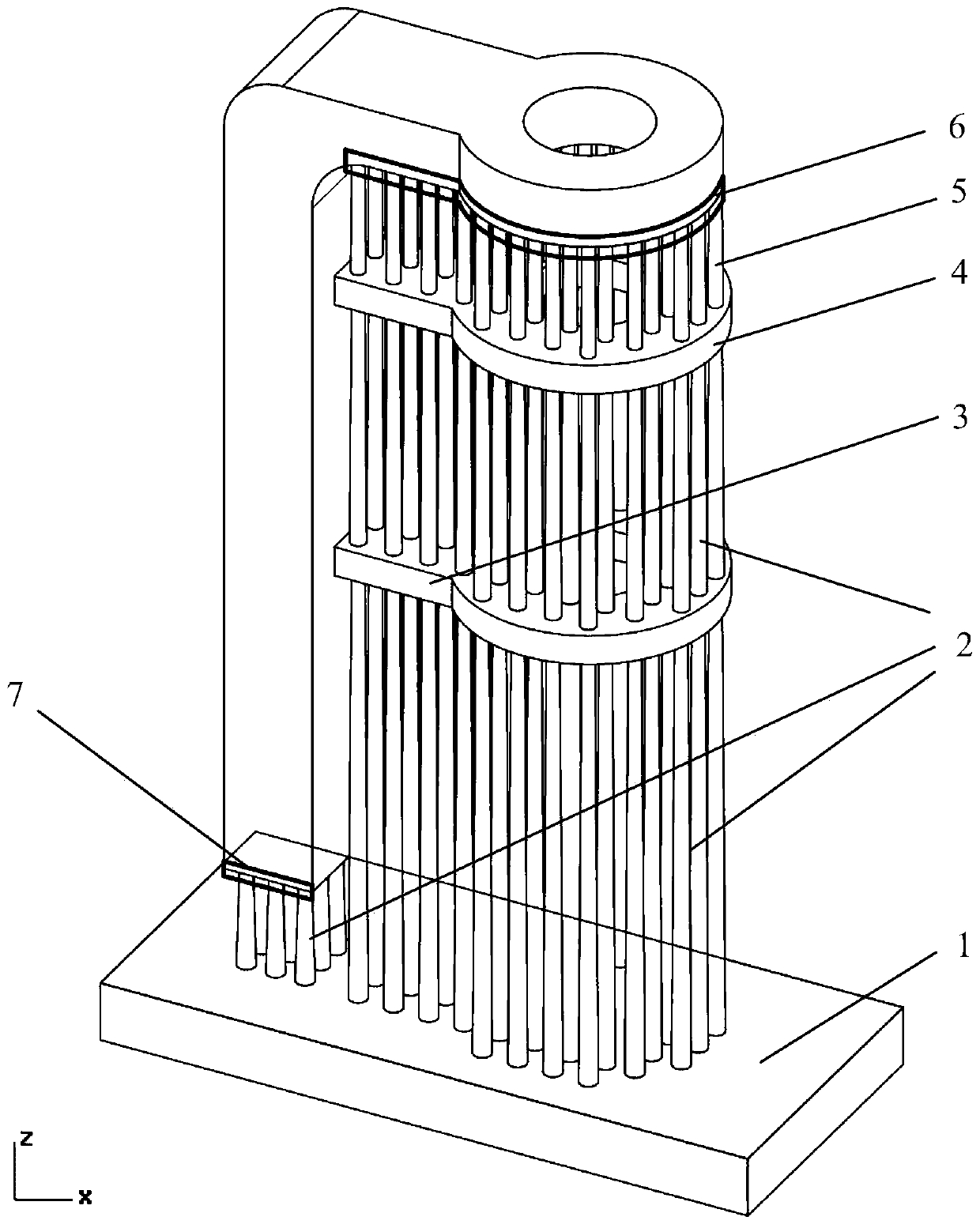

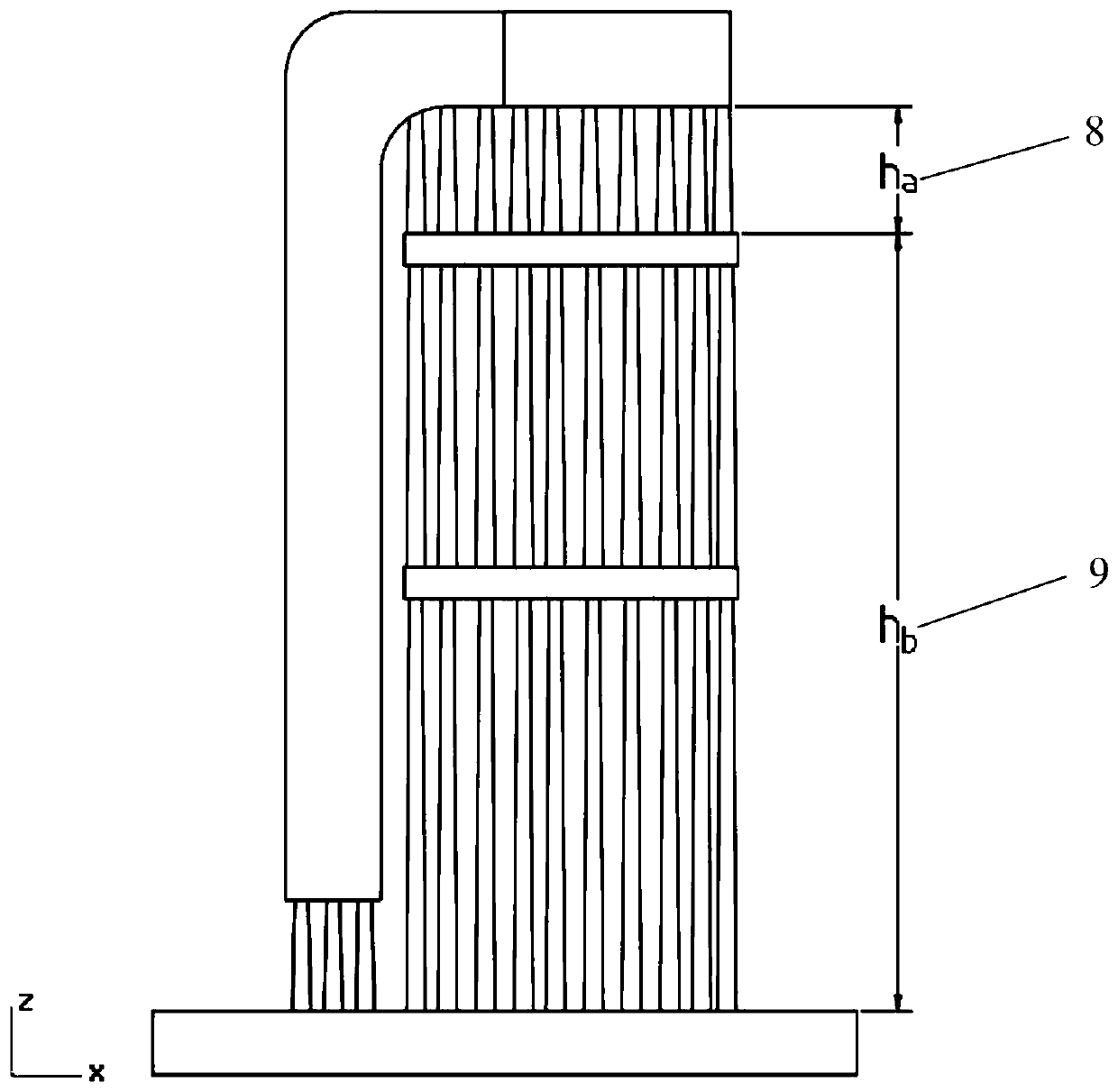

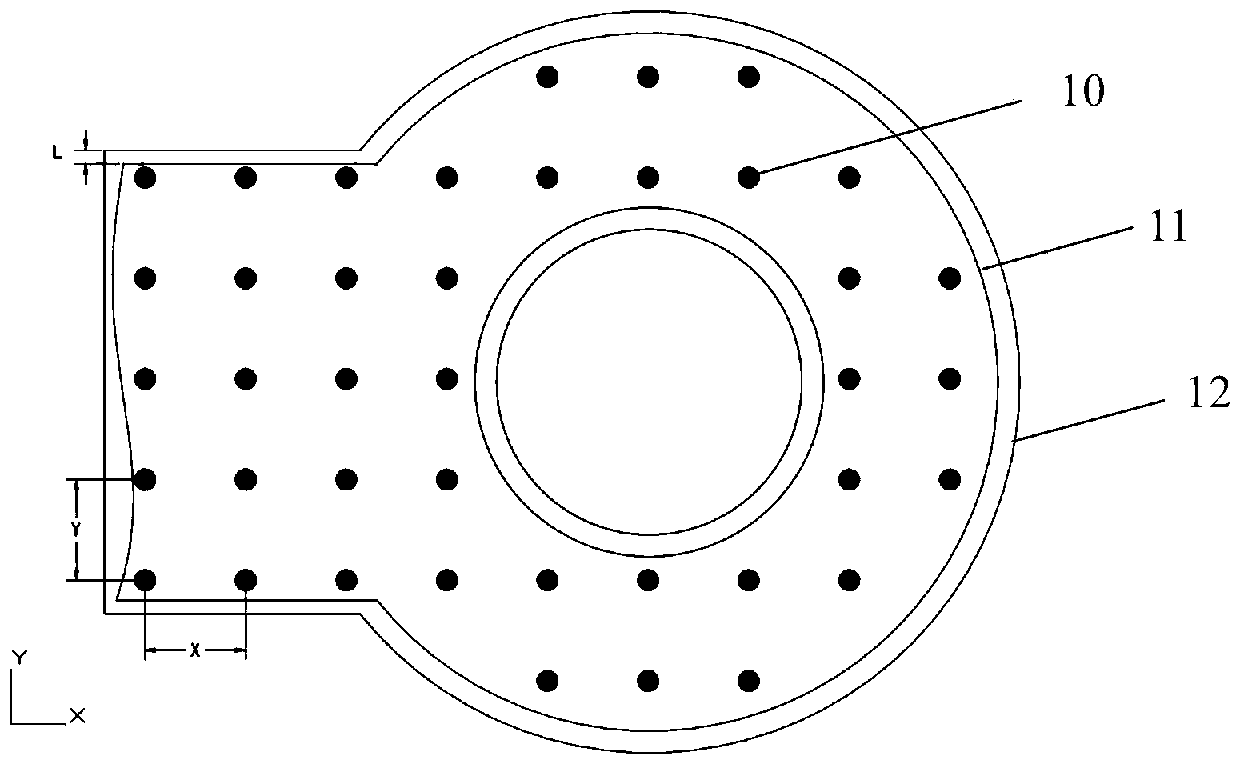

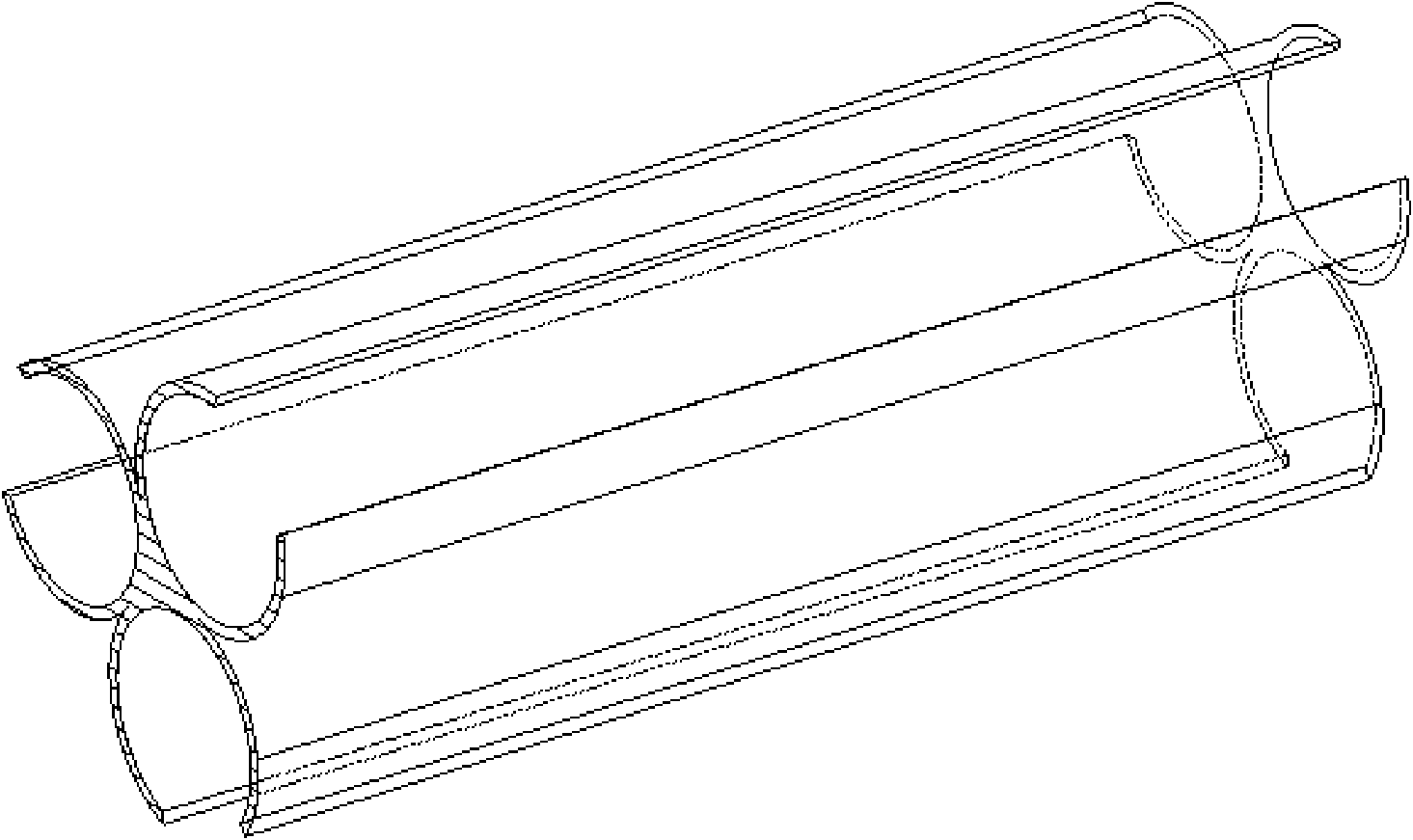

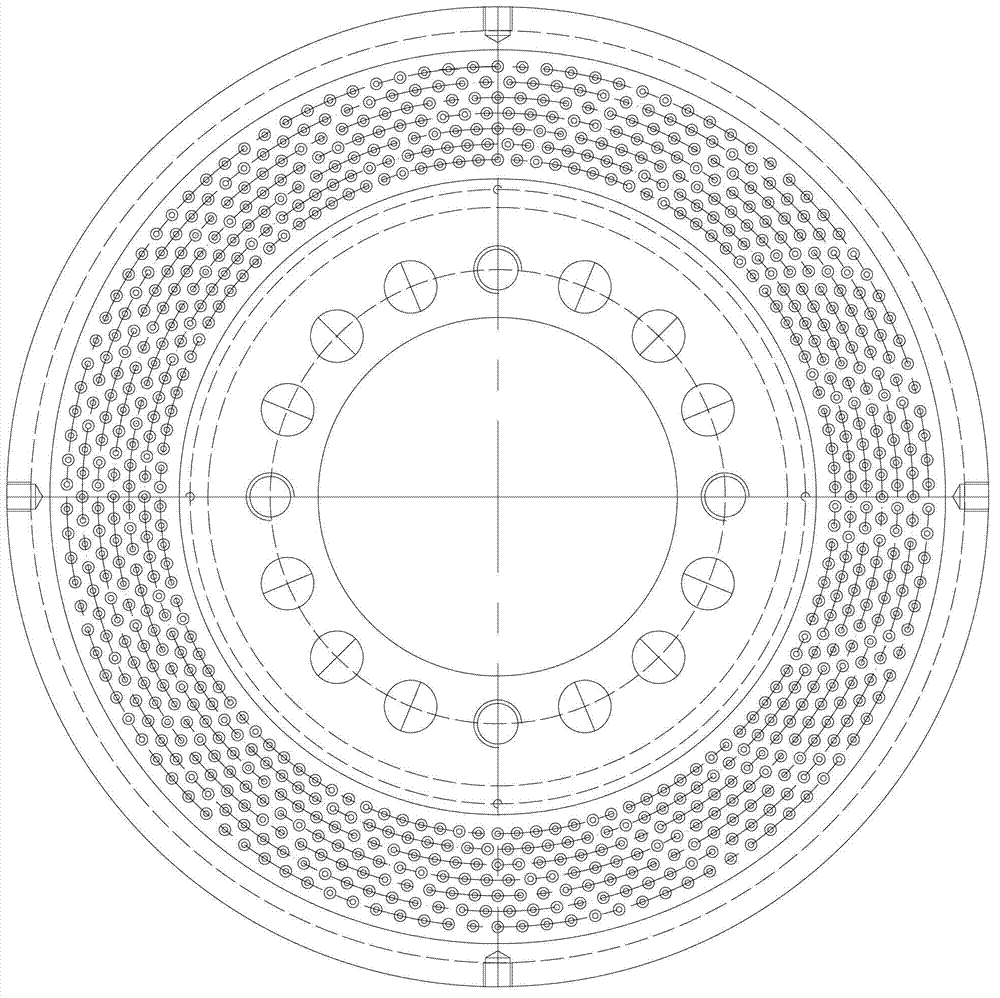

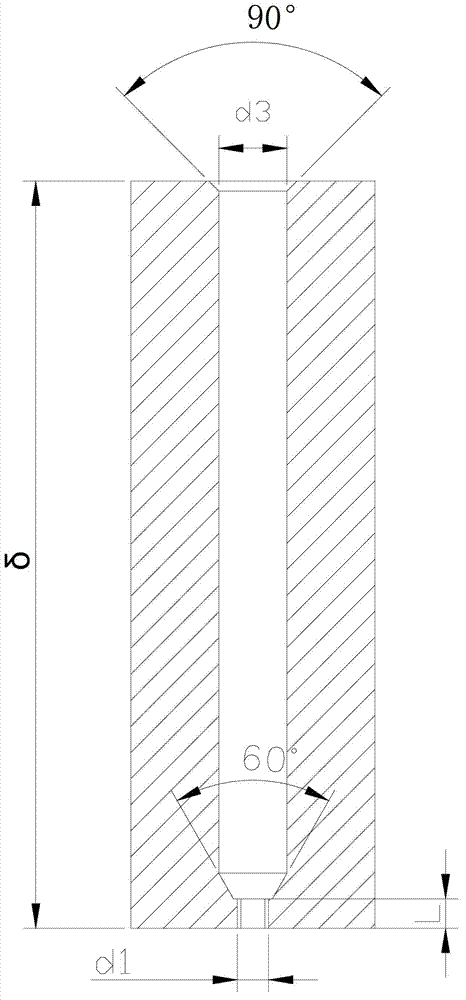

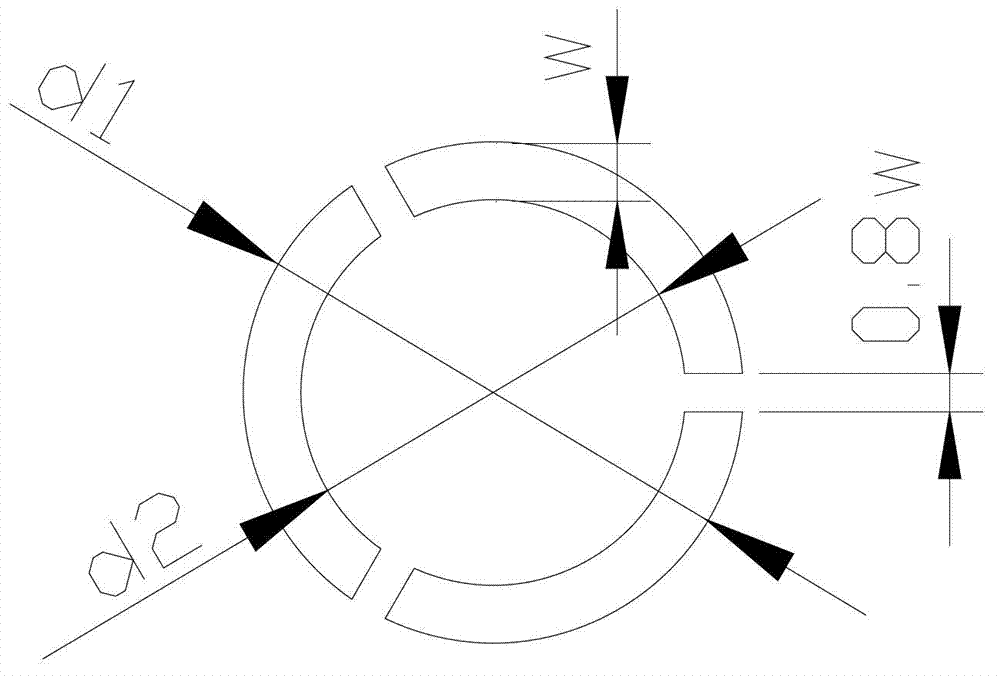

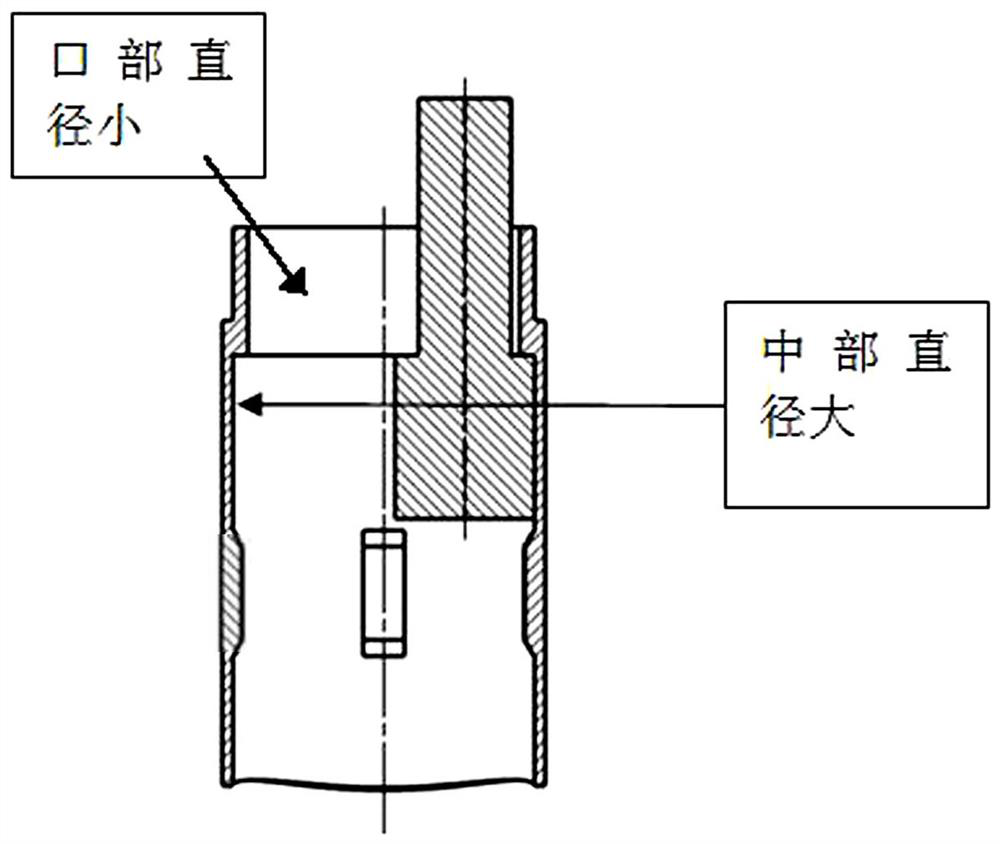

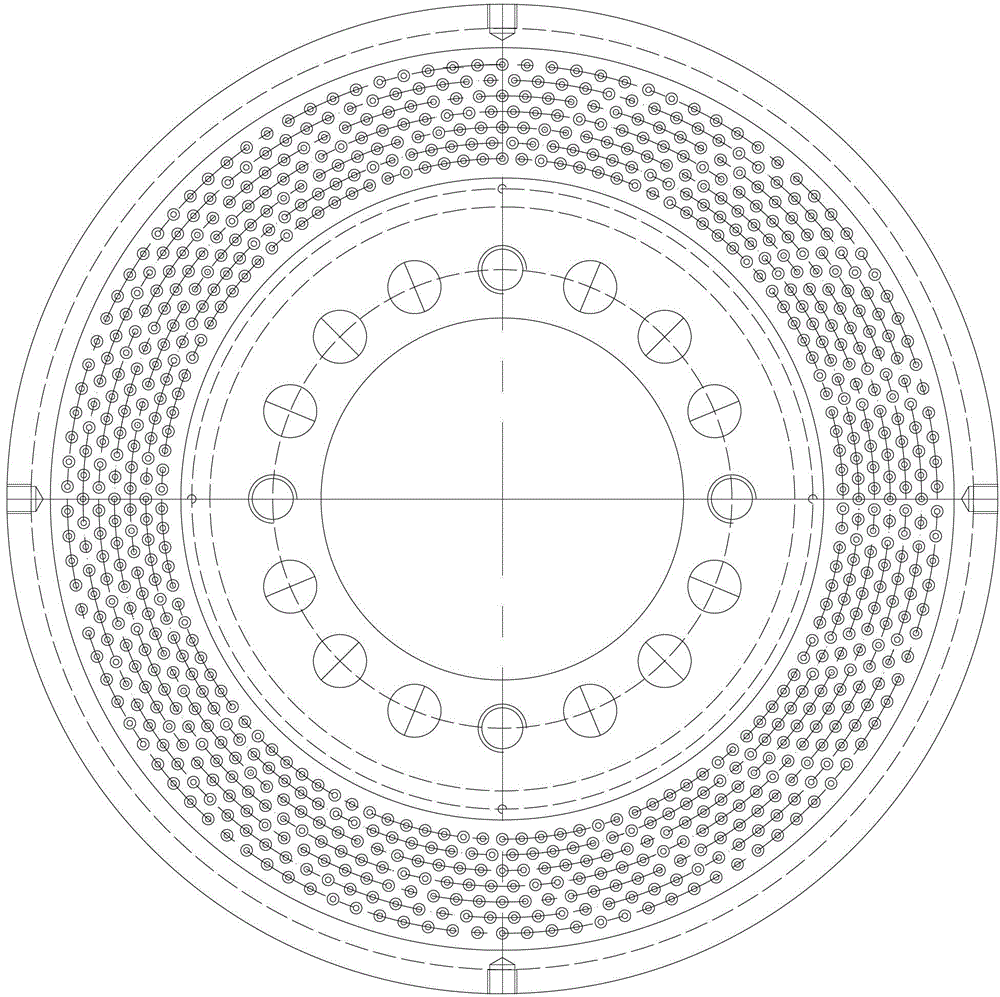

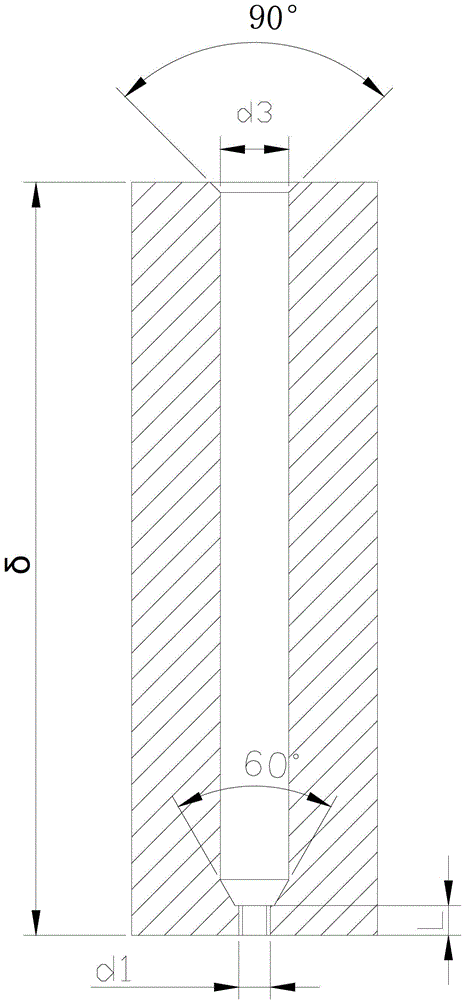

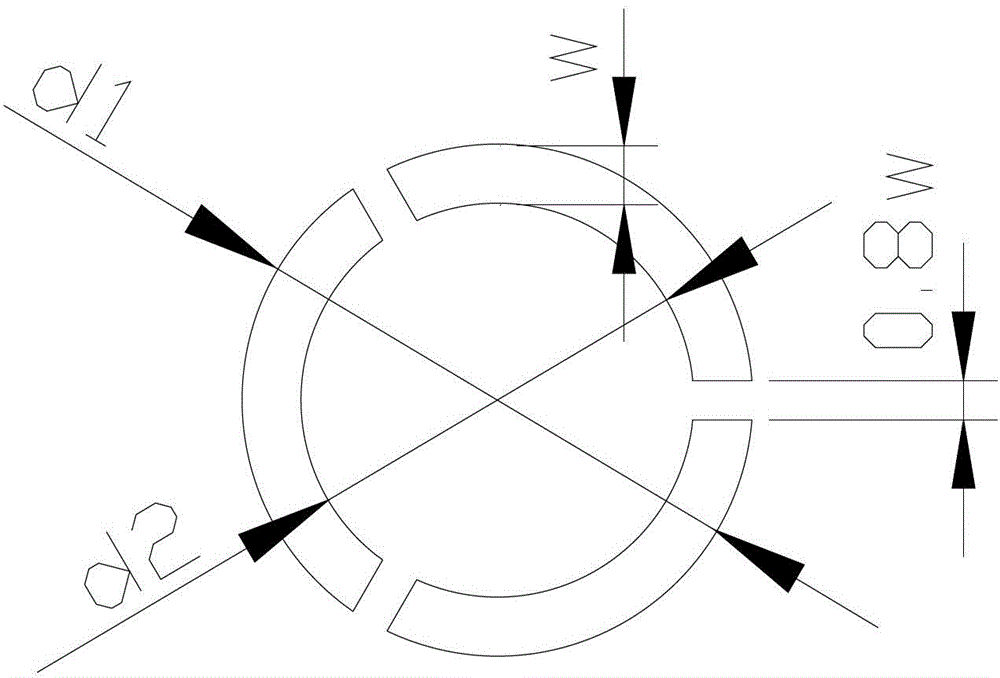

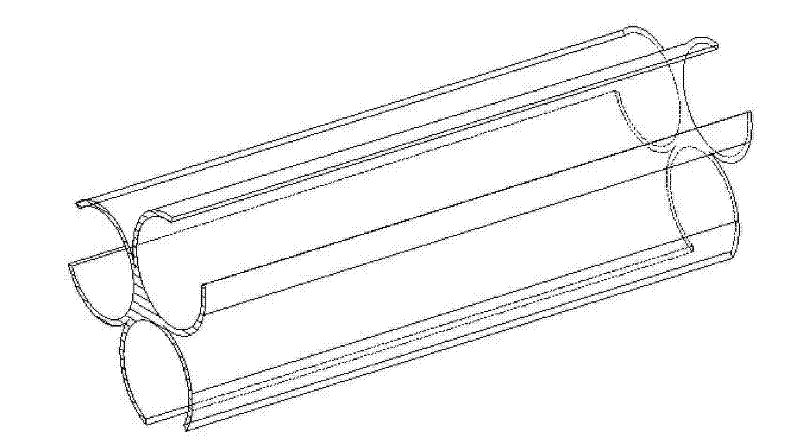

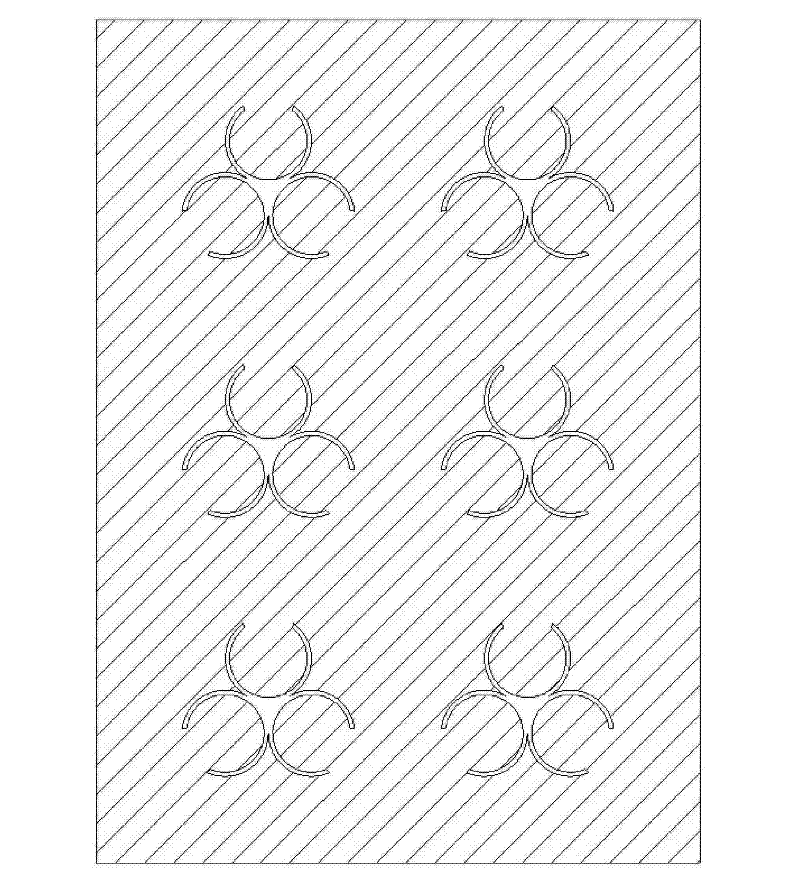

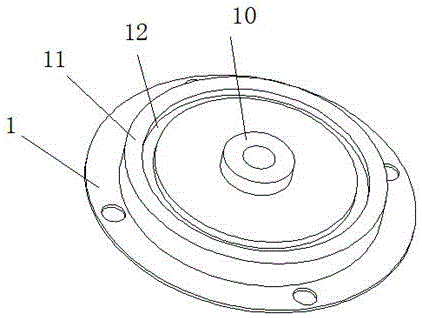

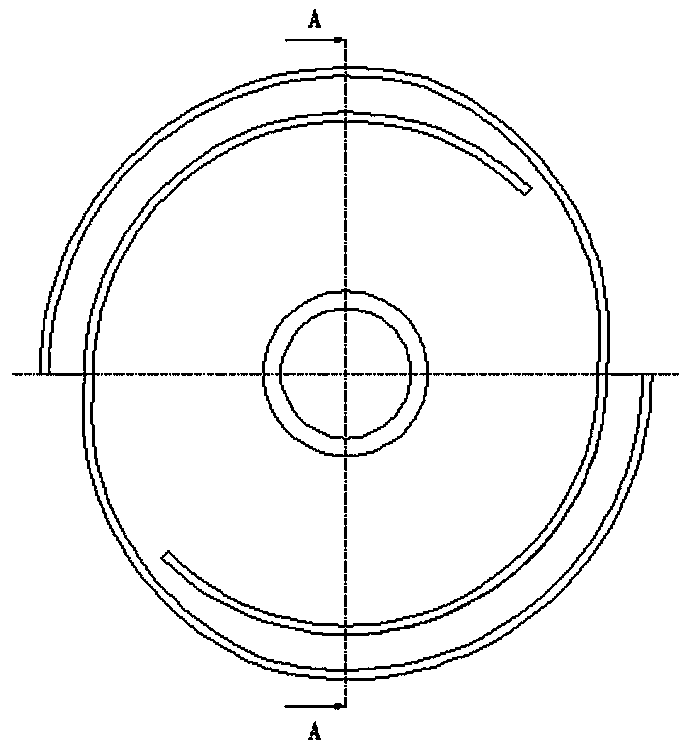

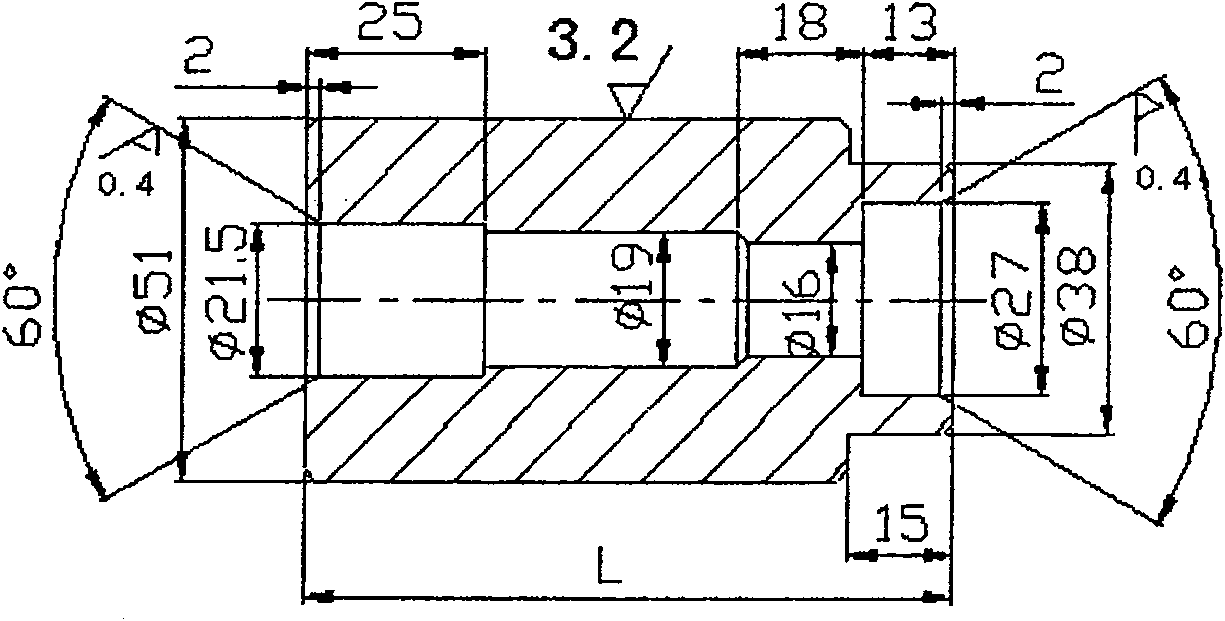

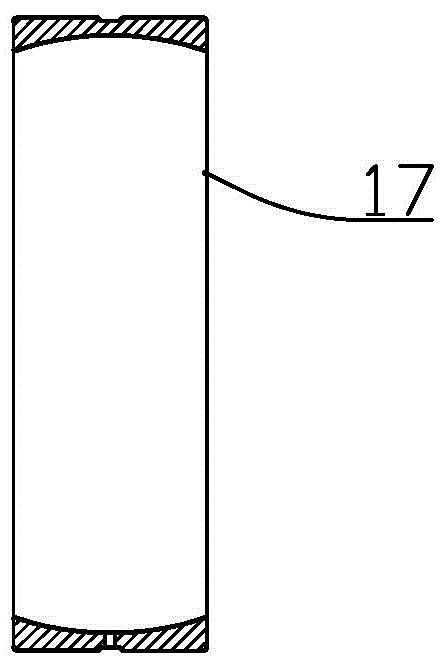

High-viscosity melt spinning spinneret plate

InactiveCN102926004AGuaranteed spinnabilityGood compatibilityHollow filament manufactureEngineeringMelt spinning

The invention relates to a spinneret plate and particularly relates to a high-viscosity polyester melt spinning spinneret plate with the intrinsic viscosity ranging between 0.74dL / g-0.78dL / g. The overall shape of the spinneret plate is in a cylindrical shape, a plurality of spinneret orifices are arranged evenly on the spinneret plate in a circular mode, each of the spinneret orifice comprises a guide hole and a micro hole, the guide hole is connected with the micro hole, the shape of a cross section of the micro hole is a circular ring with three openings, the three openings are distributed on the circular ring evenly, the outer diameter d1of the circular ring ranges between 2.25mm and 2.45mm, the inner diameter d2 ranges between 1.5mm and 2.0mm, the width of the openings is 0.70-0.90 time of the width w of the circular ring, the length L of the micro hole ranges between 1.5mm and 2.0mm, the diameter d3 of the guide hole ranges between 4.0mm and 5.5mm, and the thickness Delta of the spinneret plate ranges between 35mm and 40mm. The spinneret plate has the advantages that coarse denier three-dimensional crimp polyester produced by the spinneret plate is low in spinning speed, good in spinnability, high in filling power, sufficient in stiffness and good in compression elasticity.

Owner:NINGBO DAFA CHEM FIBER

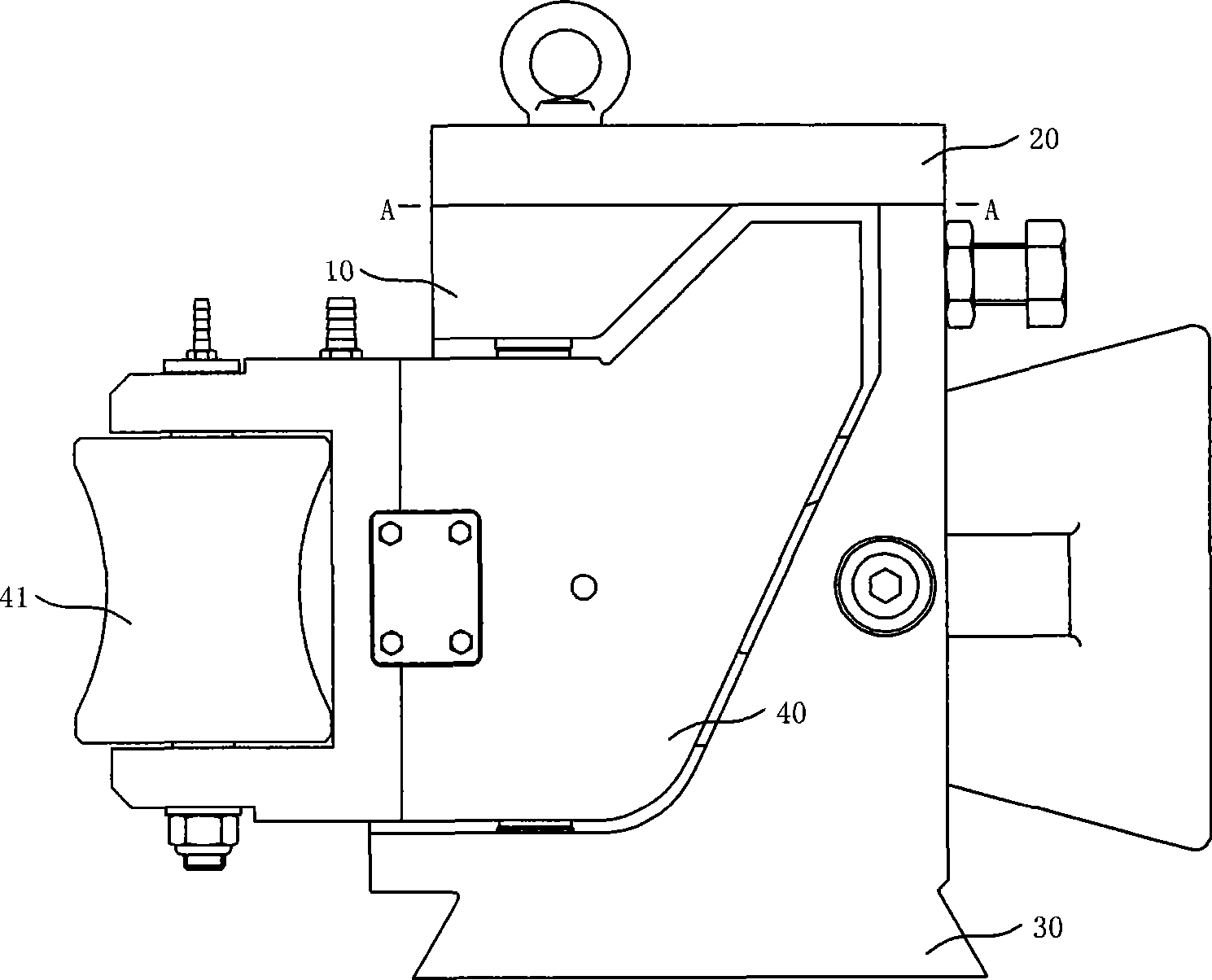

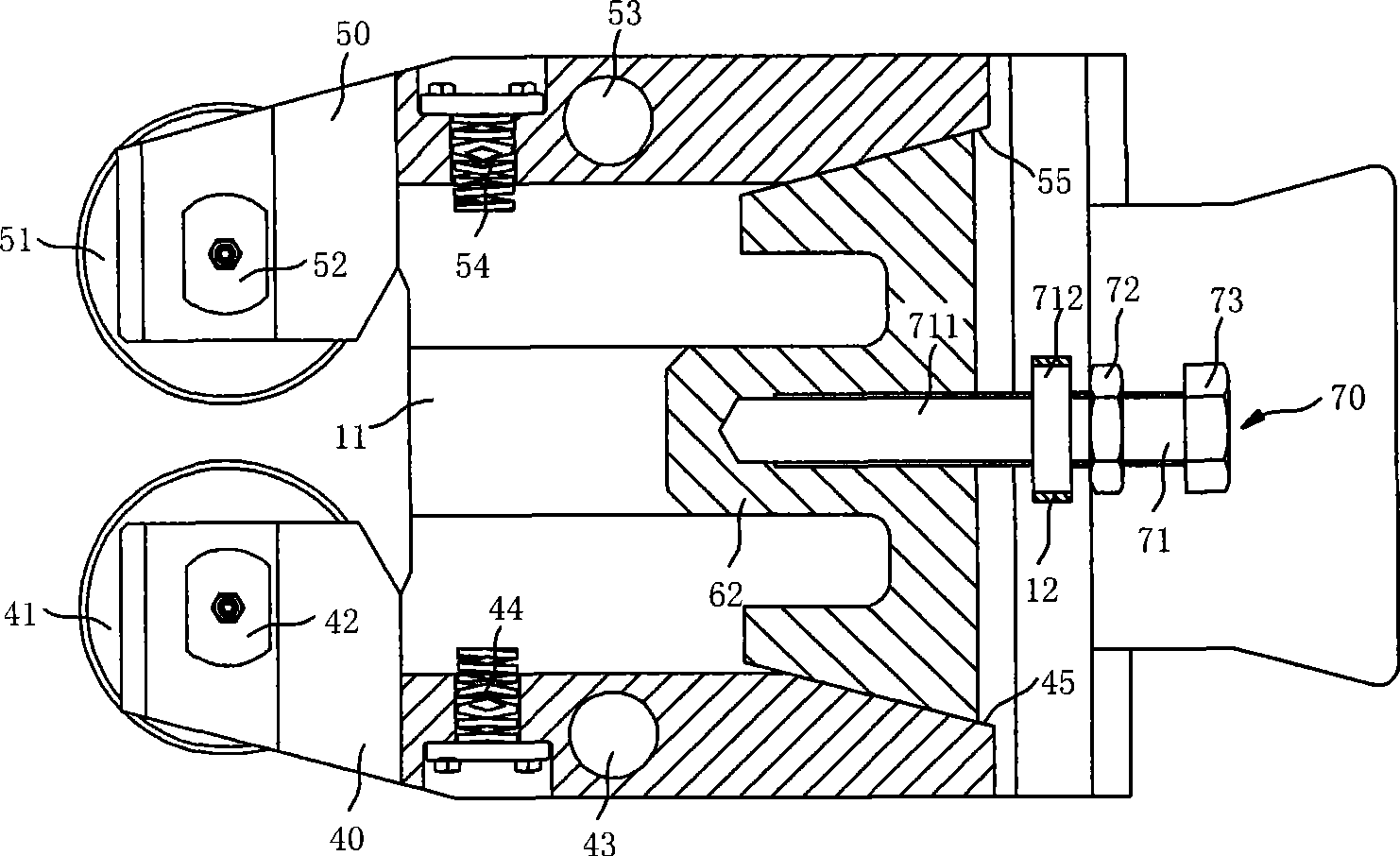

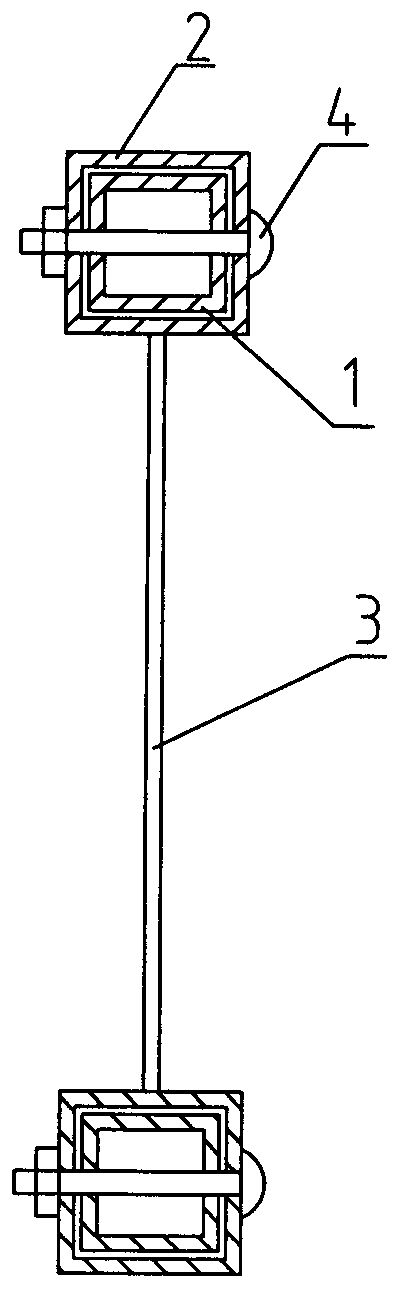

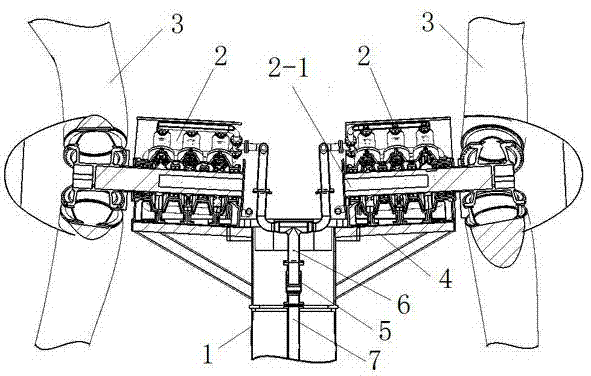

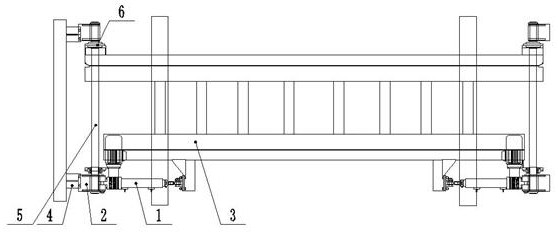

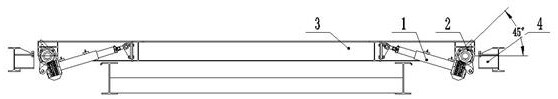

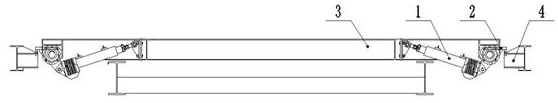

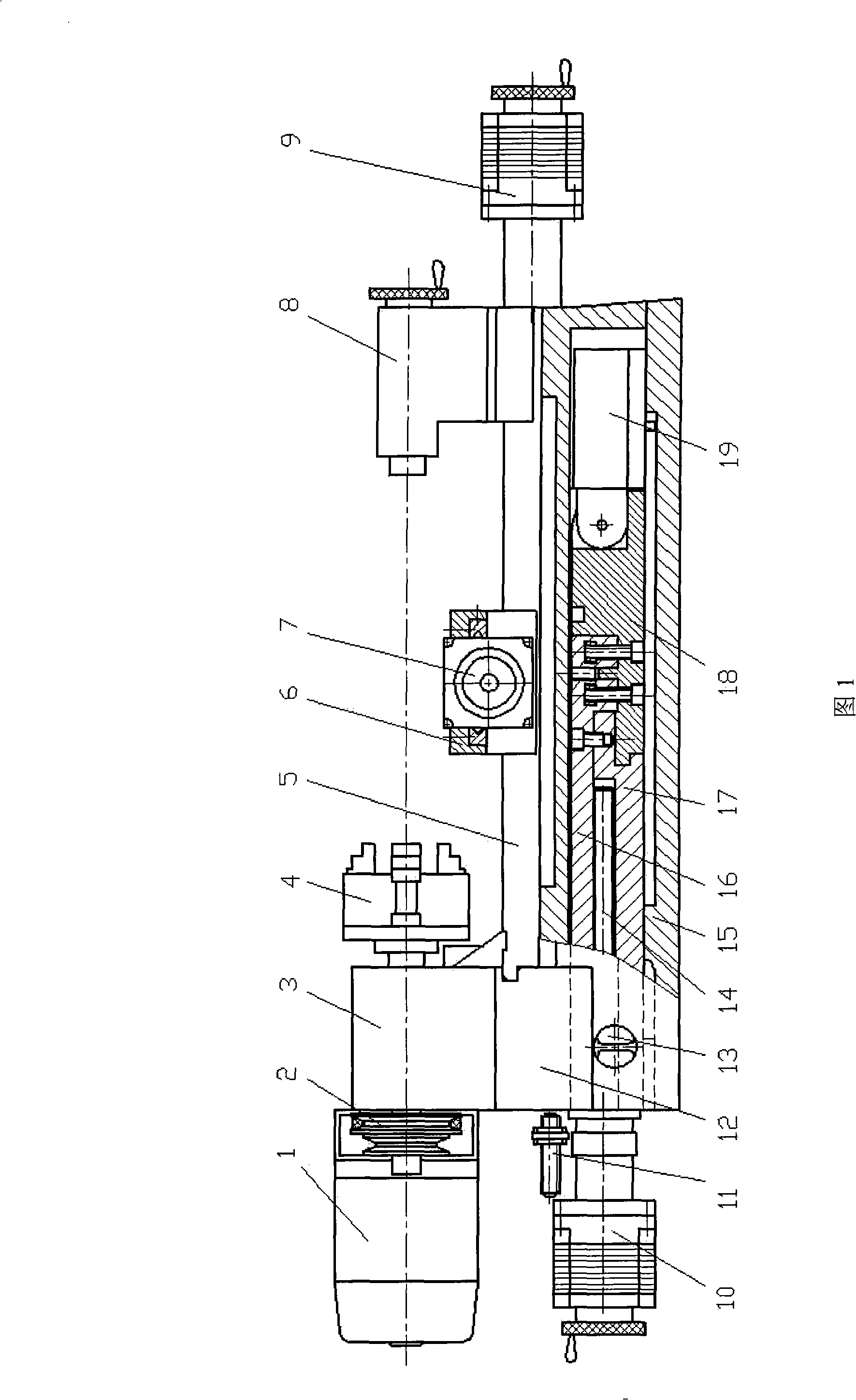

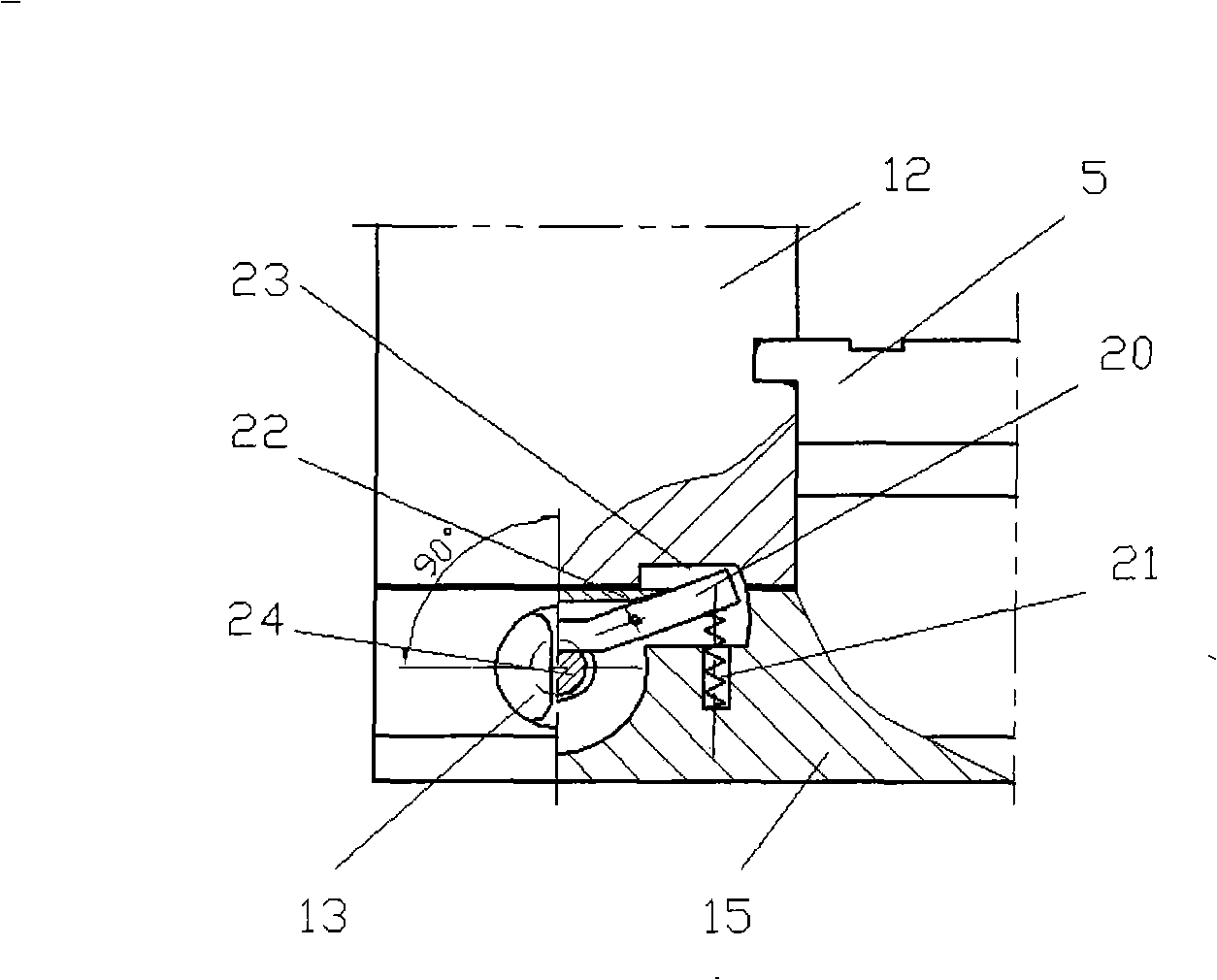

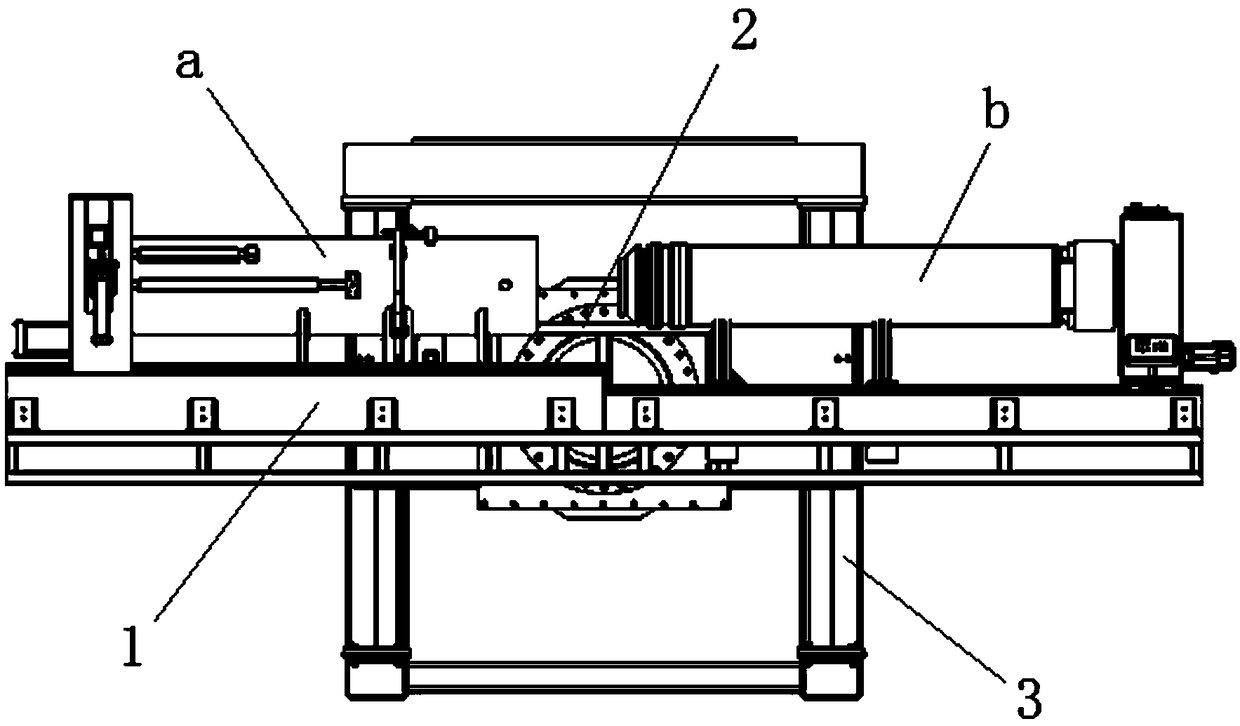

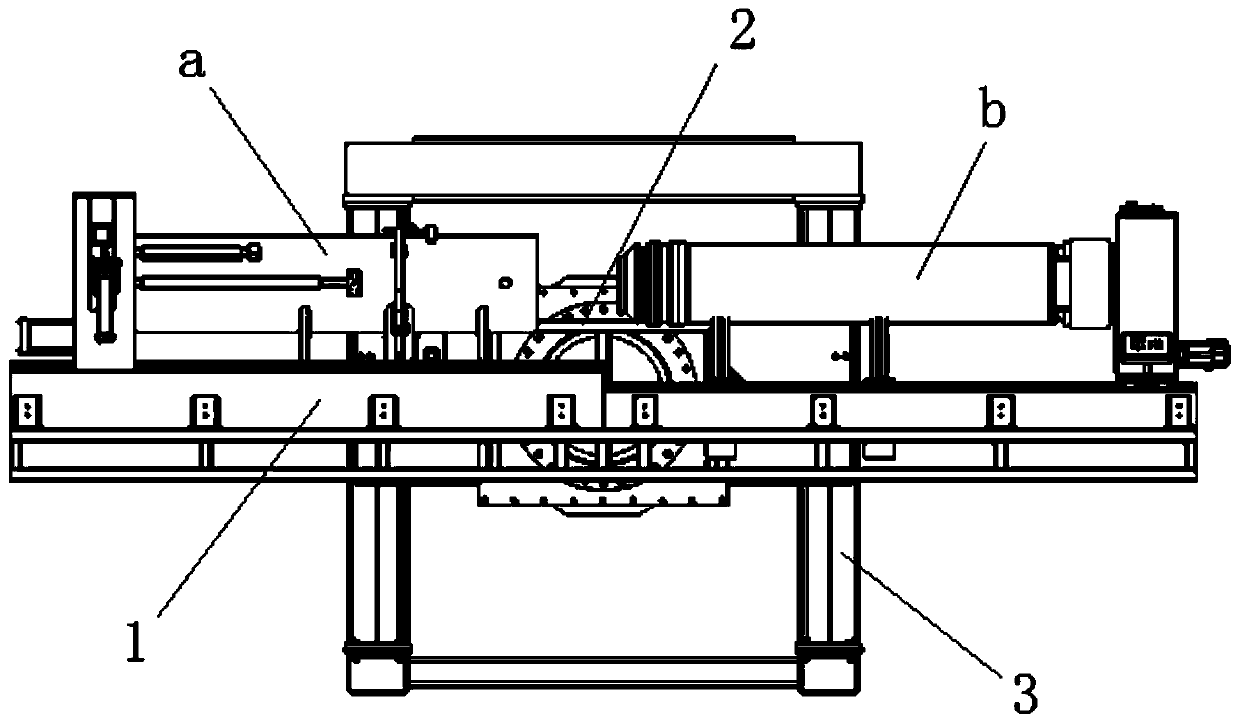

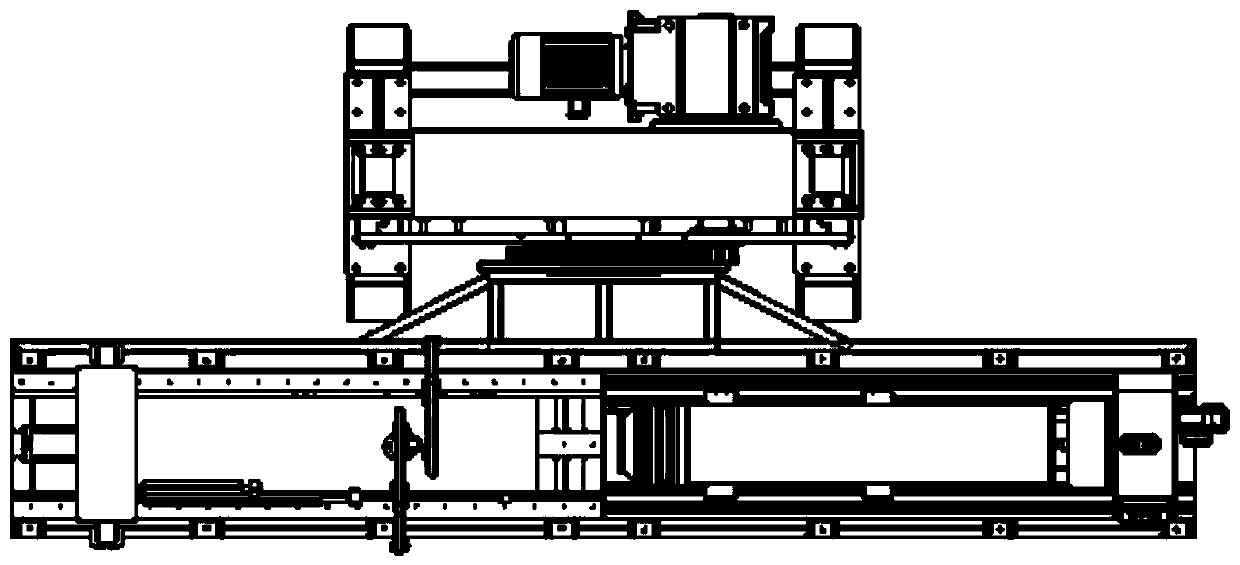

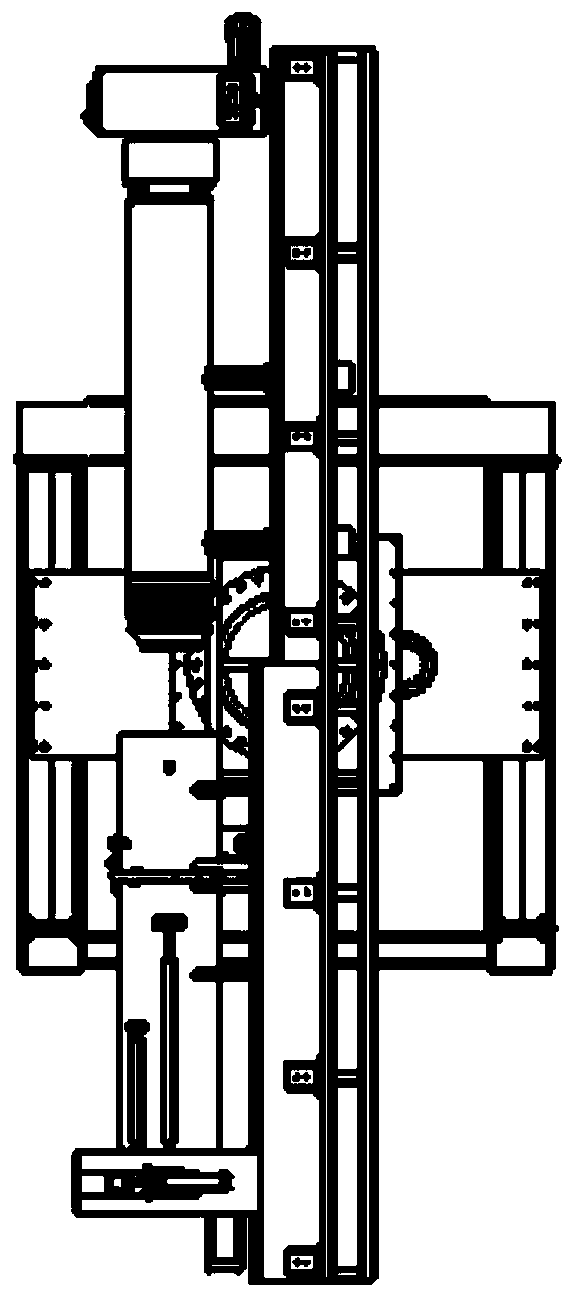

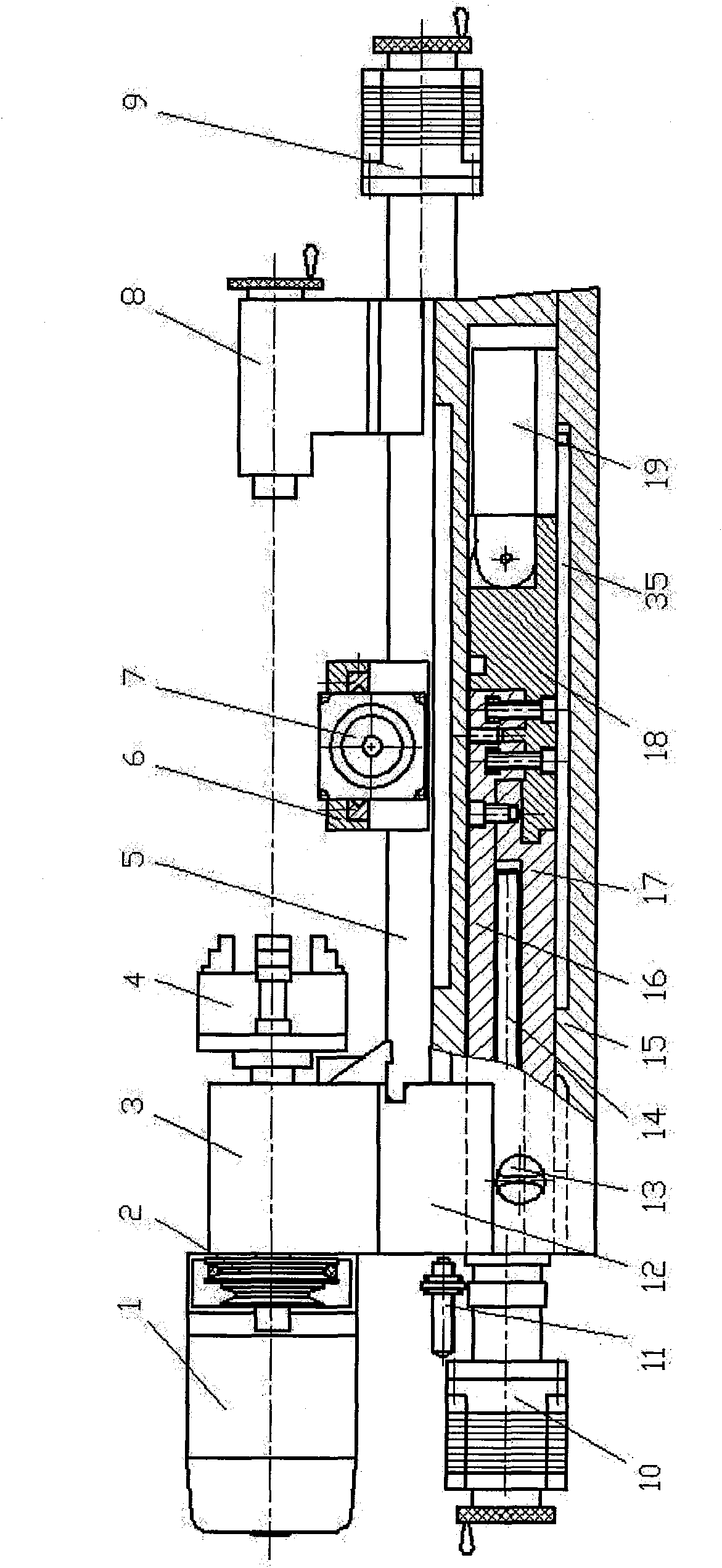

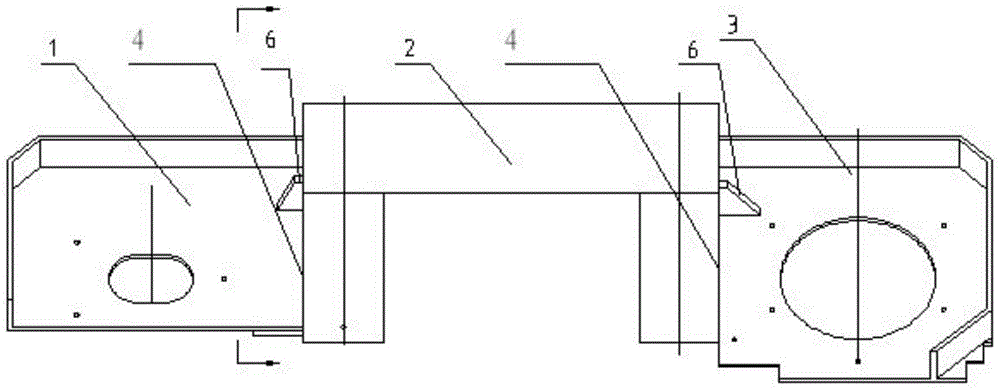

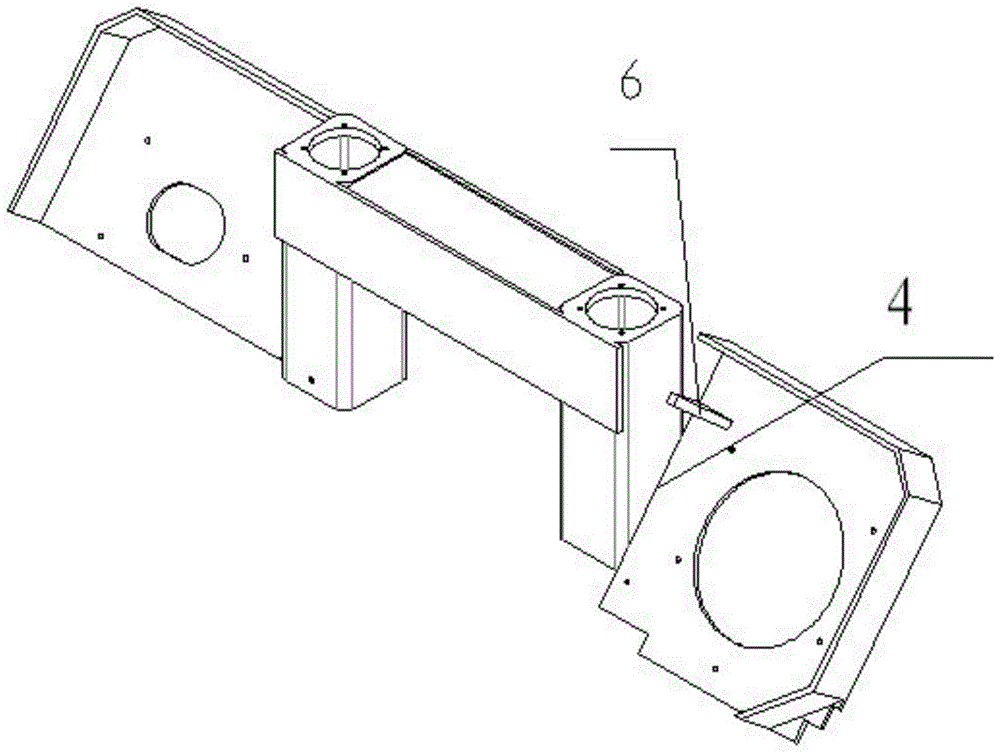

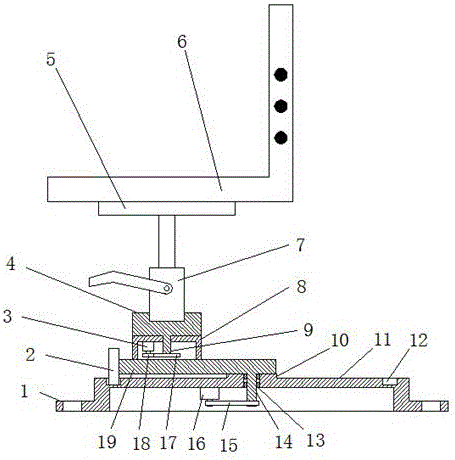

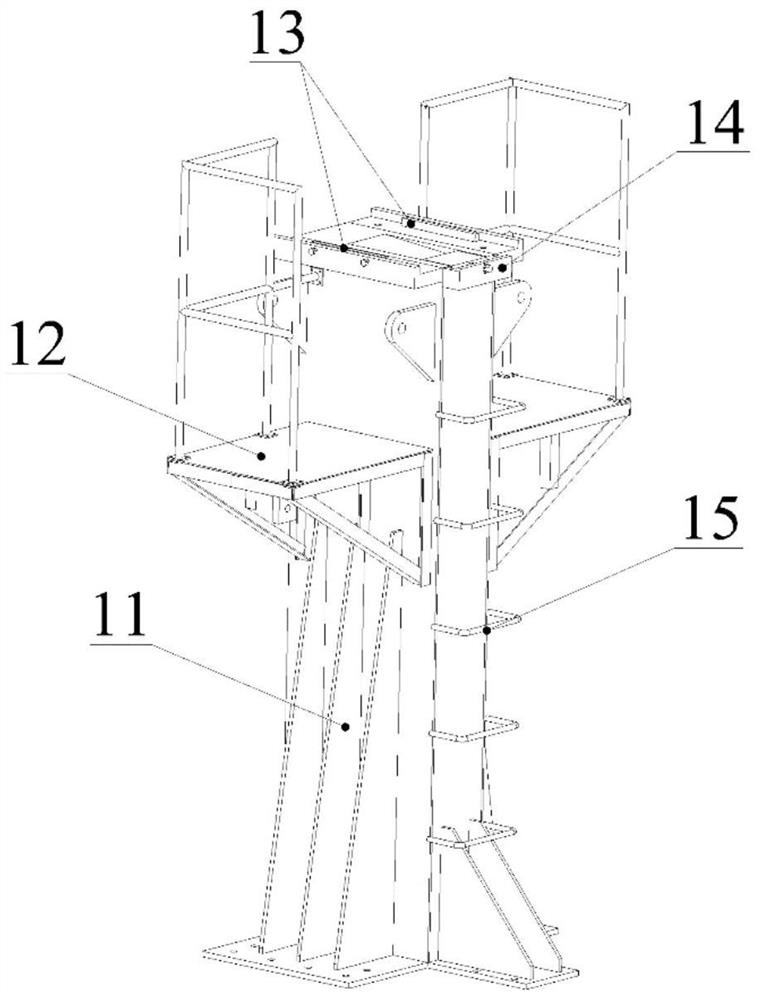

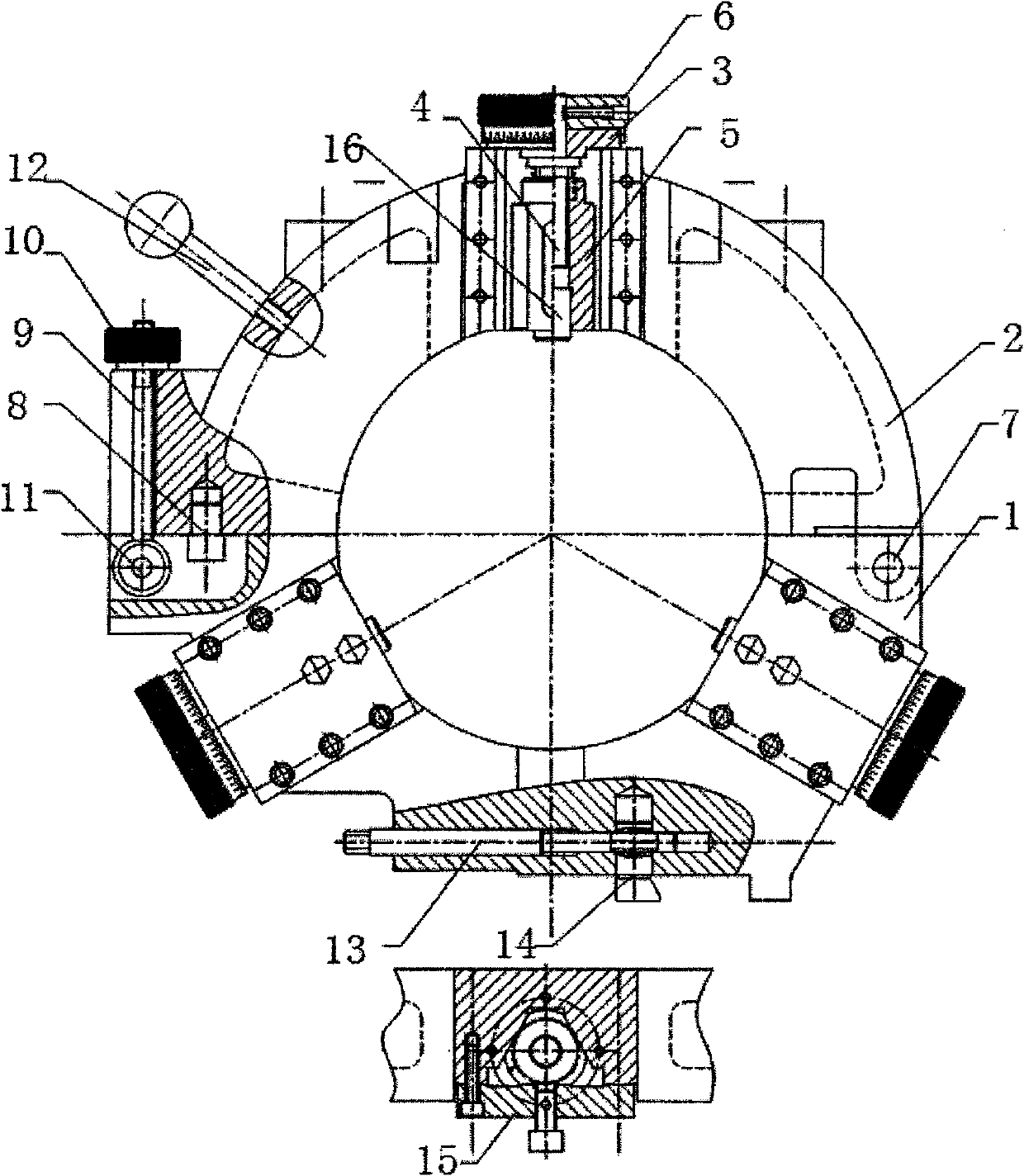

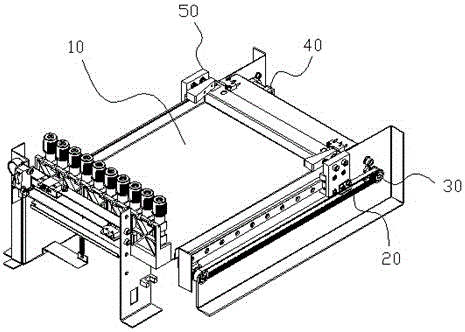

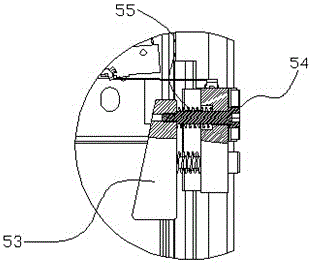

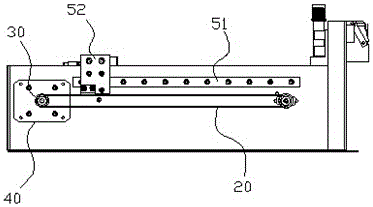

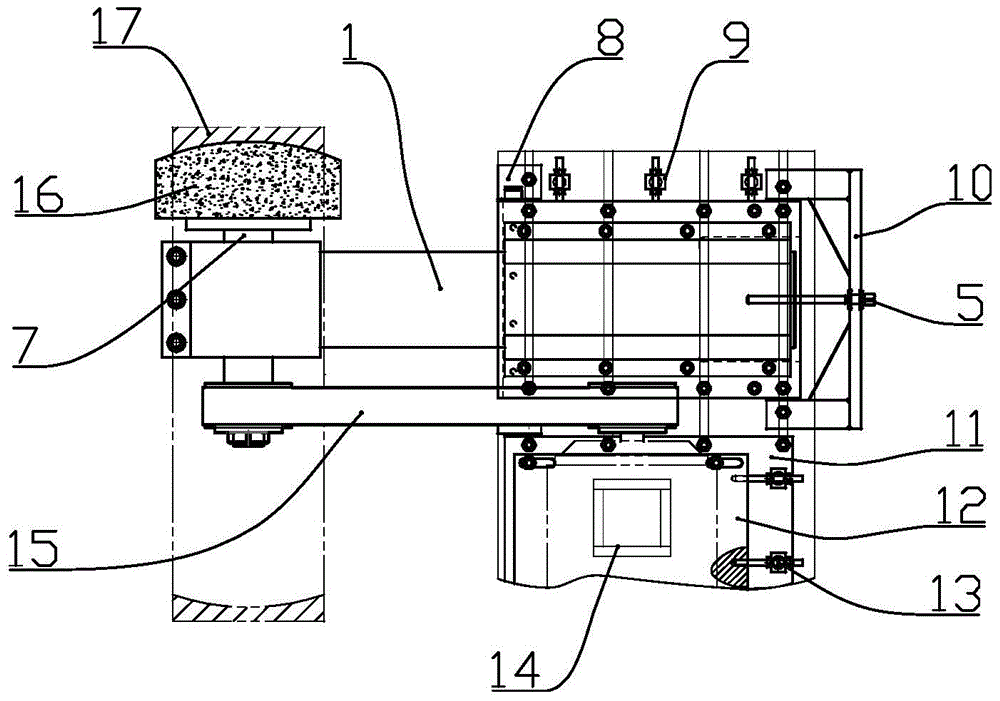

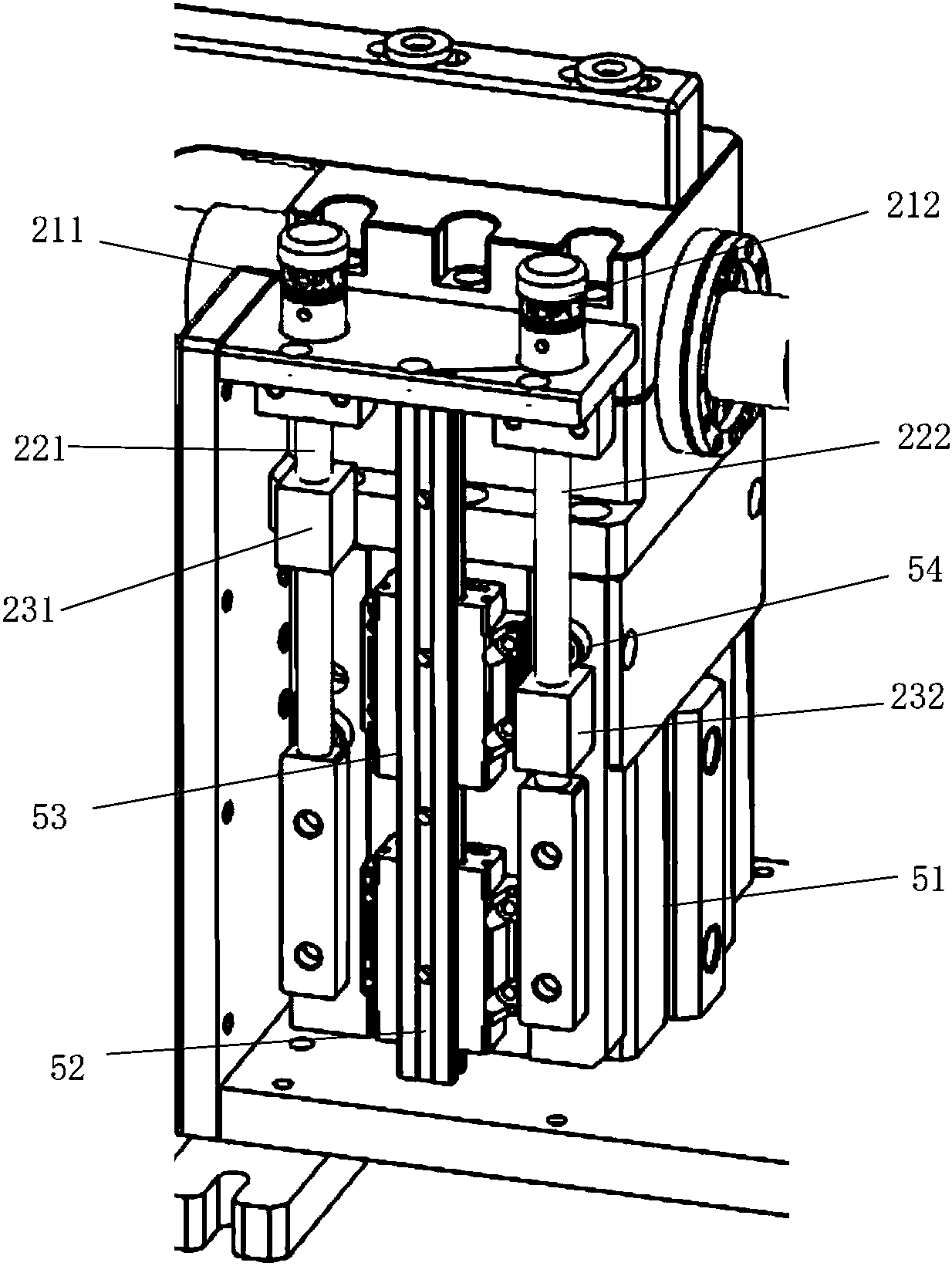

Automatic assembling machine of column oil cylinder

ActiveCN109175950AImprove assembly efficiencyRigid footMetal working apparatusPlungerPetroleum engineering

The invention discloses an automatic assembling machine of a column oil cylinder and belongs to the technical field of automatic devices. An assembly module is fixedly connected with a rotating modulethrough a connection tool. The automatic assembling machine of the column oil cylinder comprises the rotating module and a column oil cylinder assembling module. The rotating module is composed of aportal frame and a rotating transmission mechanism. The column oil cylinder assembling module is connected with the rotating module. The assembling module fastens a middle cylinder and an outer cylinder which are conveyed by a truss, then the rotating module rotates by 90 degrees, the assembling module is driven to rotate by 90 degrees to be in the vertical state, and then the assembling module installs the middle cylinder into the outer cylinder; the rotating module overturns by 90 degrees, the assembling module is driven to be in the horizontal state, the truss places a plunger into the assembling module, and the assembling module and the rotating module cooperate to install the plunger into the middle cylinder in the same way. The automatic assembling machine of the column oil cylinderhas the advantages of being high in assembling efficiency, enough in rigidity, high in universality and the like.

Owner:无锡恒久安泰智能制造有限公司

A kind of washable silk quilt and its production process

The invention discloses a washable silk quilt, which comprises a quilt core and a quilt core cover outside the quilt core. The quilt core is composed of raw materials in the following weight ratio: 80-85% hollow silicon-added polyester fiber, Hot-melt fiber 15-20%. Its production process is also disclosed. The beneficial effects of the present invention are: when the hollow silicon-added polyester fiber is heated and fused with the hot-melt fiber, cross-linking and bonding occur to each other, thereby forming a fiber core structure with soft texture, good air permeability, high strength and high elasticity , high heat retention coefficient, soft and refreshing feel, good resilience, long-term use will not collapse, repeated washing will not cause fiber damage, no hardening, and easy to wash and dry, increasing the service life.

Owner:眉山宽庭环保家居用品有限公司

Preparation method of deoiled hard short fibers

InactiveCN102154728BHigh viscosityHigh densityMonocomponent polyesters artificial filamentSynthetic polymer filament chemical after-treatmentYarnPolyethylene terephthalate

Owner:NINGBO DAFA CHEM FIBER

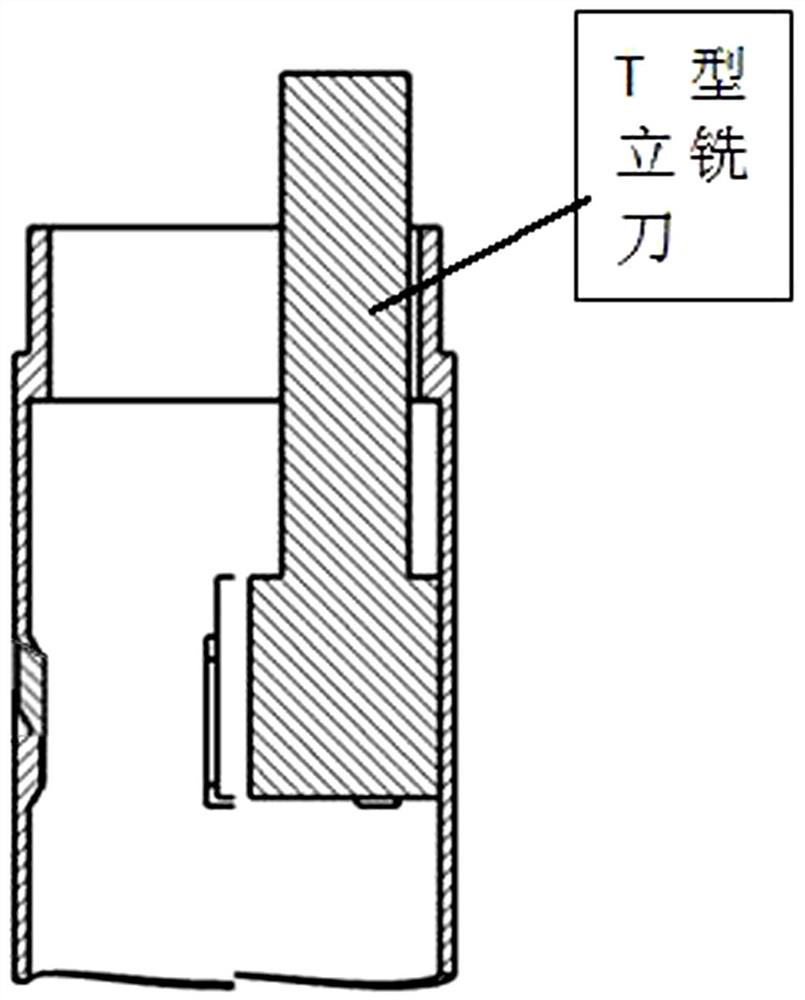

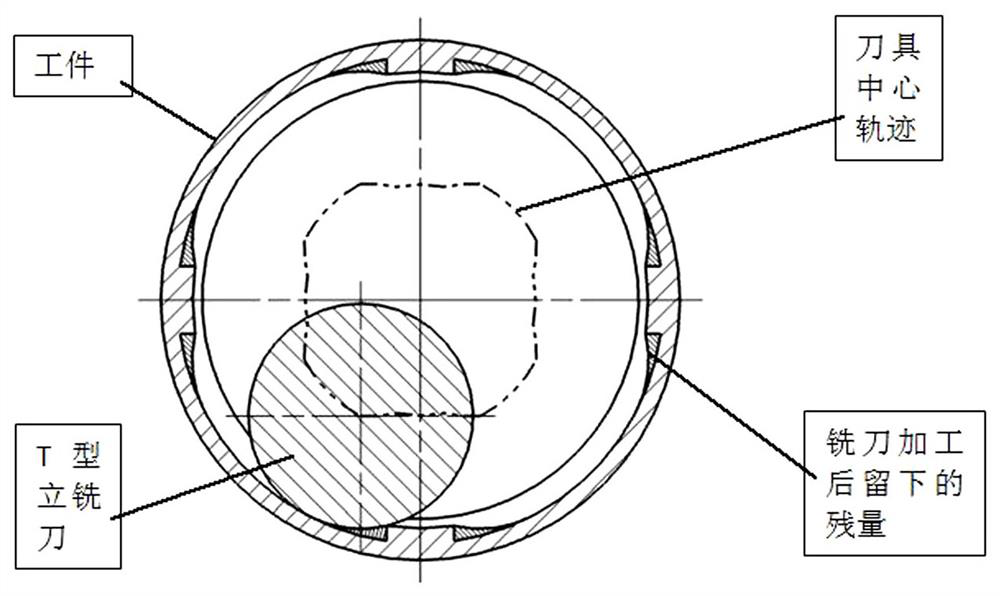

Machining process for thin-wall cylindrical part with boss in inner hole

The invention discloses a machining technology for a thin-wall cylindrical part with a boss in an inner hole. The machining process comprises the following steps: step 1, completing rough turning of the inner shape, rough turning of the outer shape and semi-turning of the outer circle datum of a pipe body on a common numerical control lathe; and step 2, selecting four-axis machining equipment with a rotary table or a dividing head, and wrapping the semi-turning outer circle part of the pipe body workpiece with a self-made special clamp. The machining process effectively solves the problems that: the two ends of the inner shape of a pipe body workpiece are subjected to multi-pass finish turning machining through a common numerical control lathe, due to the influence of multiple clamping errors and machining and clamping deformation factors,the machining precision is poor, scrap iron discharging is difficult, the cutting state is poor, a slotting machining face and a turning machining face do not coincide, and shutdown measurement, deviation value judgment, coordinate system center adjustment, program modification, relatively large machining allowance and a lot of time for roughly interpolating the allowance are caused by semi-finish machining allowance in actual machining.

Owner:HENAN NORTHERN HONGYANG ELECTROMECHANICAL CO LTD

High-viscosity melt spinning spinneret plate

InactiveCN102926004BGuaranteed spinnabilityGood compatibilityHollow filament manufacturePolyesterEngineering

The invention relates to a spinneret plate and particularly relates to a high-viscosity polyester melt spinning spinneret plate with the intrinsic viscosity ranging between 0.74dL / g-0.78dL / g. The overall shape of the spinneret plate is in a cylindrical shape, a plurality of spinneret orifices are arranged evenly on the spinneret plate in a circular mode, each of the spinneret orifice comprises a guide hole and a micro hole, the guide hole is connected with the micro hole, the shape of a cross section of the micro hole is a circular ring with three openings, the three openings are distributed on the circular ring evenly, the outer diameter d1of the circular ring ranges between 2.25mm and 2.45mm, the inner diameter d2 ranges between 1.5mm and 2.0mm, the width of the openings is 0.70-0.90 time of the width w of the circular ring, the length L of the micro hole ranges between 1.5mm and 2.0mm, the diameter d3 of the guide hole ranges between 4.0mm and 5.5mm, and the thickness Delta of the spinneret plate ranges between 35mm and 40mm. The spinneret plate has the advantages that coarse denier three-dimensional crimp polyester produced by the spinneret plate is low in spinning speed, good in spinnability, high in filling power, sufficient in stiffness and good in compression elasticity.

Owner:NINGBO DAFA CHEM FIBER

Breathable multifunctional pillow inner with moisture penetrability

ActiveCN101627869BBreathable, moisture-permeable and sweat-conducting effect is goodHigh loosenessPillowsFiberPolyethylene terephthalate

The invention discloses a breathable multifunctional pillow inner with moisture penetrability filled with fibers. The fibers consist of three hollow fibers with circular arc cross sections. The circular arcs are connected in such a way that every two are externally tangent with each other, and a connected closed region is an entity. The hollow fibers are made from polyethylene terephthalate with the intrinsic viscosity of 0.65-0.66, the melting point of 266 DEG C, the carboxyl content of more than zero and less than or equal to 25 equivalent / g * 10<6>, and the ash content of more than zero and less than 0.04 percent. The breathable multifunctional pillow inner with moisture penetrability is made of fibers which are three-hole hollow fibers with three outward openings, thereby the pillow inner is breathable and has moisture penetrability. In hot rolling process, a shape with six interlaced holes can be formed between the adjacent fibers and the fibers have openings, thus the pillow inner made from the fibers has excellent moisture penetrability.

Owner:BEIJING GUANGHUA TEXTILE GRP +1

A column oil cylinder automatic assembly machine

ActiveCN109175950BImprove assembly efficiencyRigid footMetal working apparatusStructural engineeringMachine

The invention discloses an automatic assembling machine of a column oil cylinder and belongs to the technical field of automatic devices. An assembly module is fixedly connected with a rotating modulethrough a connection tool. The automatic assembling machine of the column oil cylinder comprises the rotating module and a column oil cylinder assembling module. The rotating module is composed of aportal frame and a rotating transmission mechanism. The column oil cylinder assembling module is connected with the rotating module. The assembling module fastens a middle cylinder and an outer cylinder which are conveyed by a truss, then the rotating module rotates by 90 degrees, the assembling module is driven to rotate by 90 degrees to be in the vertical state, and then the assembling module installs the middle cylinder into the outer cylinder; the rotating module overturns by 90 degrees, the assembling module is driven to be in the horizontal state, the truss places a plunger into the assembling module, and the assembling module and the rotating module cooperate to install the plunger into the middle cylinder in the same way. The automatic assembling machine of the column oil cylinderhas the advantages of being high in assembling efficiency, enough in rigidity, high in universality and the like.

Owner:无锡恒久安泰智能制造有限公司

Changeable minisize multifunctional numerically-controlled machine tool

InactiveCN101259587BEnhance perceptual knowledgeImprove learning enthusiasmOther manufacturing equipments/toolsLarge fixed membersNumerical controlDrive wheel

The invention relates to an indexable type micro multifunctional numerical control machine; wherein, a main motor, a driving wheel, a main spindle box and a chuck are sequentially connected; the main spindle box and a main spindle box base are fixedly connected; a sliding upright column, a round rotary table, a spacing guiding sliding block and a sliding guiding rail are arranged in inner cavity of a horizontal type bed body and can be translated from left to right; an end of the round rotary table is articulated with the spacing guiding sliding block and the other end is connected with the sliding upright column which is externally fixedly connected with the sliding guiding rail; the main spindle box base is fixedly connected with the upper surface of the sliding guiding rail; the sliding upright column is internally provided with a lead screw which is connected with a lead screw feed motor; a locking block is arranged along left end of the guiding rail of the bed body and a limit switch is arranged at the left end part of the guiding rail of the bed body; a bed body step is equipped at the bottom of the bed body at the left end; an inner cavity locating groove is arranged at thebottom of the horizontal type bed body; the horizontal type vehicle main spindle box base is locked with a horizontal vehicle body by a locking device; the spacing guiding sliding block, etc. are translated to the left along the inner cavity of the horizontal type bed body and rotate clockwise with 90 degrees around an articulated pivot of the round rotary table and the spacing guiding sliding block, thus showing a vertical milling numerical control machine. The indexable type micro multifunctional numerical control machine has the advantages of small volume and wide use.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

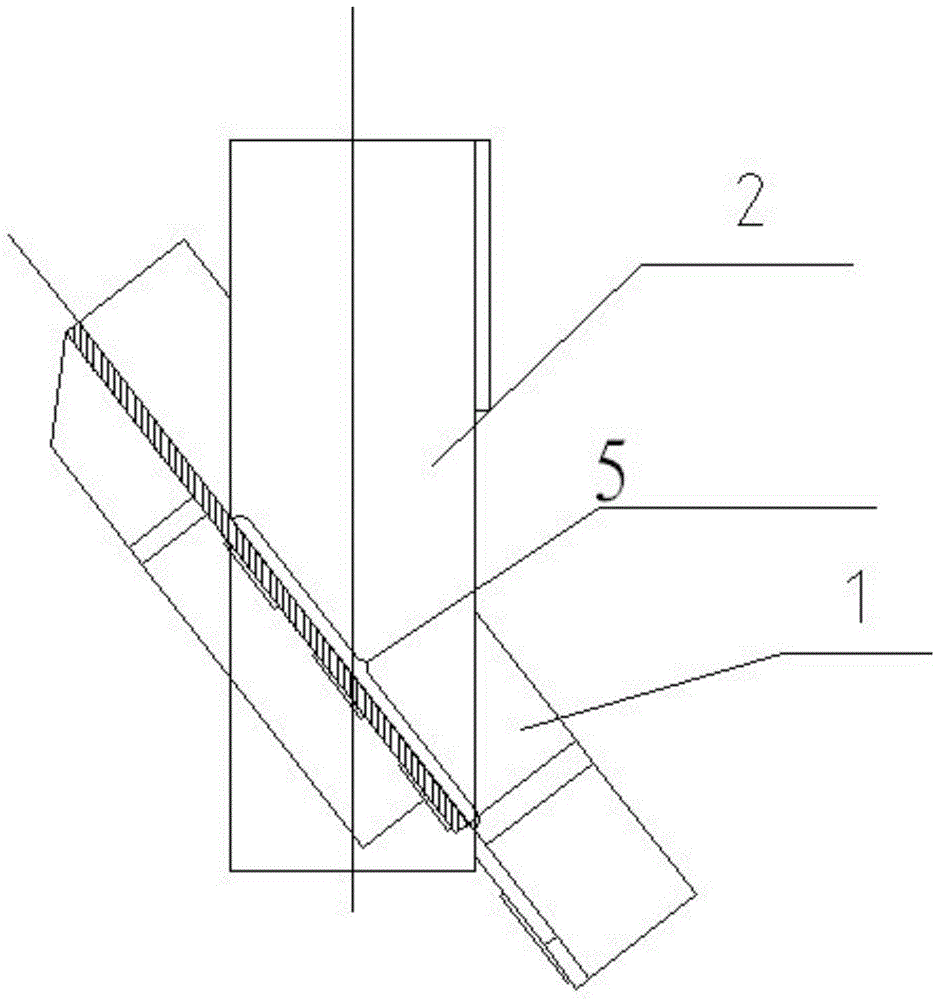

New girder for sawing machine

The invention discloses a novel cross beam of a sawing machine. The novel cross beam comprises a column sleeve and beam plates. The beam plates comprise the left beam plate and the right beam plate. The left beam plate and the right beam plate are directly welded to the two sides of the column sleeve respectively. An ultra-long welded position exists between the column sleeve and each beam plate, and extends in a straight line from one crossed end of the column sleeve and corresponding beam plate to the other crossed end of the column sleeve and the corresponding beam plate. According to the novel cross beam of the sawing machine, the left beam plate and the right beam plate are directly welded to the two sides of the column sleeve to form a whole, and the traditional sawing machine cross beam screw connection way is changed, so that the cross beam of the sawing machine is higher in rigidity, small in deformation and better applicable to hard material sawing.

Owner:浙江仁工机械有限公司

Turning regulating mechanism of children's amusement chair

Owner:济宁高新科达科技项目服务有限公司

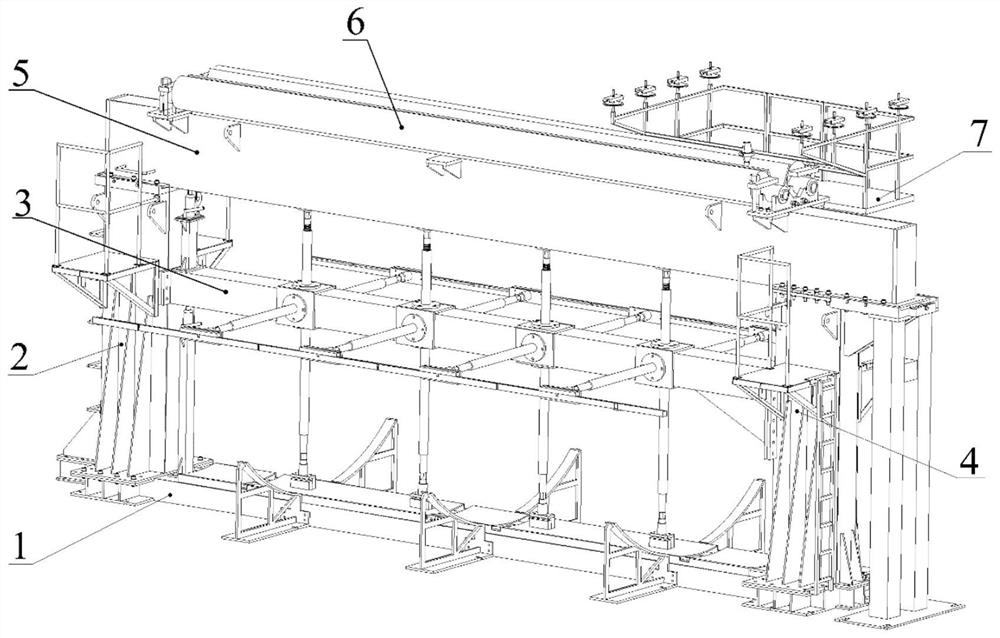

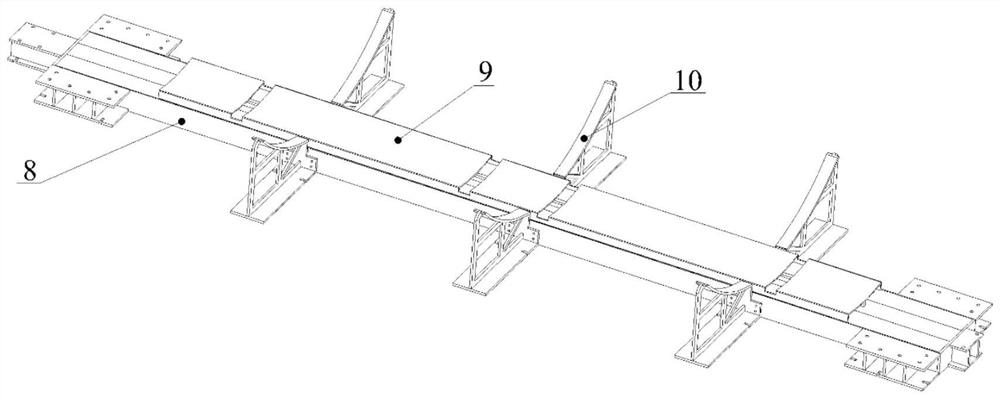

Large-size cylinder anti-deformation longitudinal joint milling and welding supporting device

ActiveCN114161160AAchieve arc controlAchieve levelingOther manufacturing equipments/toolsMilling equipment detailsHeadframeButt joint

The invention provides an anti-deformation longitudinal joint milling and welding support device for a large-size cylinder. The anti-deformation longitudinal joint milling and welding support device comprises a headstock and a tailstock, the headstock and the tailstock are fixed at two ends of the base, a support beam is fixed across the tops of the tailstock and the headstock, and the tailstock and the headstock are respectively provided with a left-right centering adjusting mechanism and an up-down leveling wedge block mechanism which are used for adjusting the relative position between the top and the bottom; a detachable clamp beam is installed on the supporting beam. On the basis of an integral external embracing clamp structure, a strong-rigidity pressing function can be realized, and compared with other external embracing modes such as a piano key type, the external embracing clamp is more sufficient in rigidity, simpler to operate and more cost-saving, and the longitudinal seam welding efficiency is improved; arc-shaped control of a barrel product can be achieved, and butt joint and fixation of longitudinal seams are facilitated; the roundness of the barrel can be corrected through a bidirectional left-hand thread telescopic mechanism at the lower end of the auxiliary support, and practicability is high; and milling and welding of products can be achieved respectively, and the welding efficiency is improved.

Owner:浙江蓝箭航天空间科技有限公司

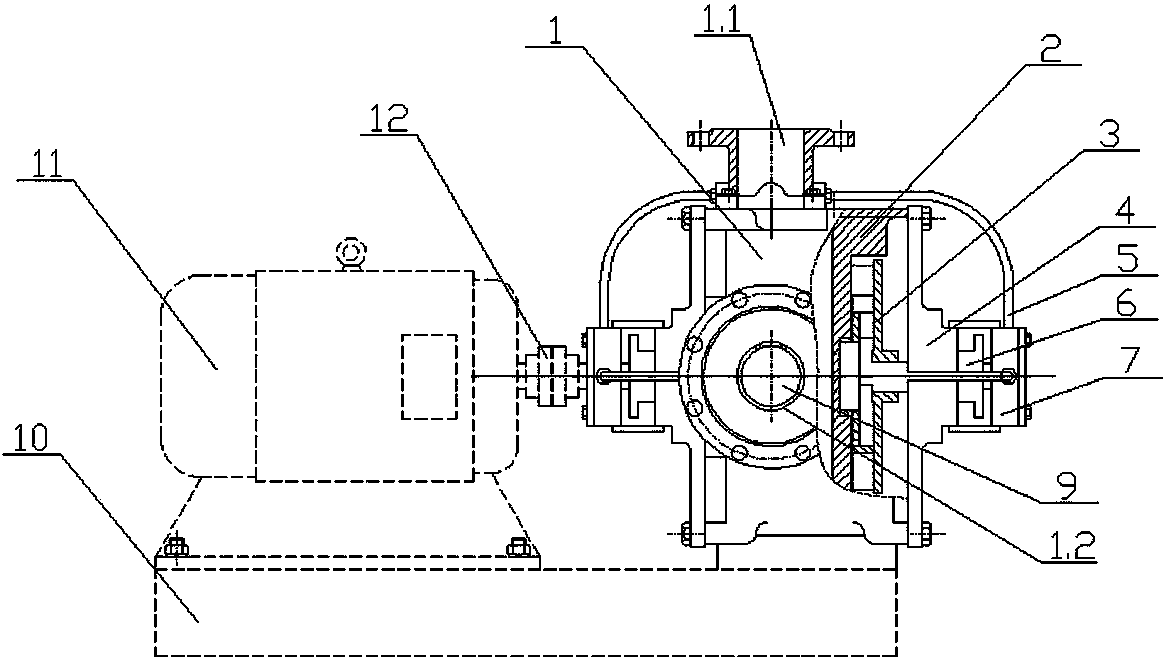

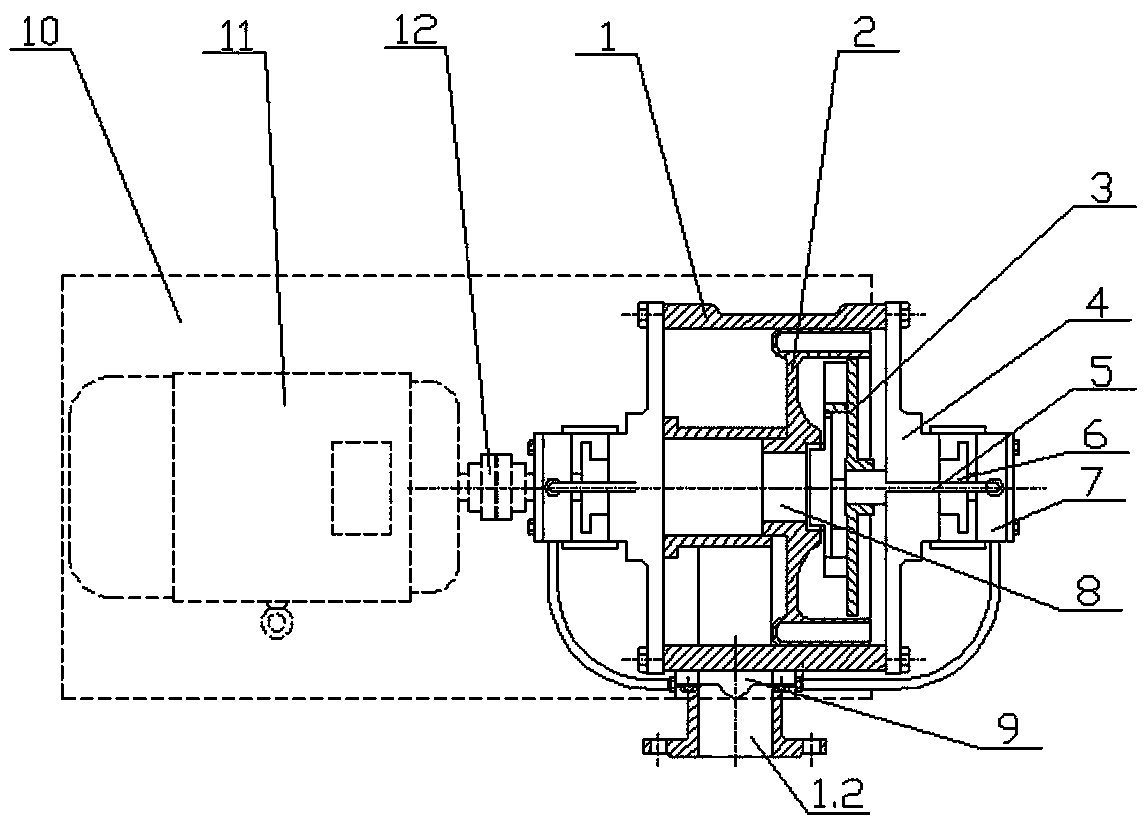

Volute changeable type marine self-priming centrifugal pump

InactiveCN103994078ARigid footReduce distortionPump componentsPriming pumpCentrifugal pumpEngineering

The invention discloses a volute changeable type marine self-priming centrifugal pump. The changeable type marine self-priming centrifugal pump comprises a pump body, a volute, an impeller, pump covers, a water pipe, a shaft seal, a shaft base, a pump shaft and a valve plate. The pump body is a horizontal shell, the two ends of a pump body through hole are provided with the pump covers, the top of the pump body is provided with an upward pump outlet, and a pump inlet is formed in the left side of the pump body, wherein the included angle between the plane where the pump inlet is located and the plane where the pump outlet is located is 90 degrees. The volute is axially positioned and installed in an inner cavity in the right side of the pump body, one face, facing rightwards and provided with a volute channel, of the volute is provided with the impeller, the pump shaft axially penetrating through an impeller inner hole is exposed out of the pump covers at the two ends, and the exposed shaft ends of the pump shaft are sleeved with the shaft seal and the shaft base from interior to exterior respectively to form a double-bearing and double-sealing integrated structure in which the impeller rotates relative to the volute. On the premise that the specification is determined, volutes or impellers with different sizes can be independently exchanged, the volutes and the impellers with the different sizes can be exchanged at the same time, the optimal hydraulic performance matching can be achieved through combination, the pump can operate under the most economical work condition, and the volute changeable type marine self-priming centrifugal pump is especially suitable for vessel mating.

Owner:JIANGSU DEHUA PUMP MFG CO LTD

Method for processing center frame of equal height triangle sleeve barrel structure and triangle sleeve barrel

InactiveCN100588497CHigh guiding precisionLarge contact surfaceLarge fixed membersWear resistantCylindrical grinder

Owner:北京机电院机床有限公司

A sampling device for a hematology analyzer

The invention relates to the technical field of medical and health equipment, in particular to a sample feeding device for a blood cell analyzer, which includes a test tube sample rack loading tray, a timing belt, a timing pulley that drives the reciprocating motion of the timing belt, and a timing pulley that drives the timing belt A rotating motor and a guide mechanism; the guide mechanism includes a linear slide rail parallel to the synchronous belt and a slide block that can slide on the linear slide rail; the slide block is fixedly connected to the synchronous belt, and is controlled by The motor is driven to move; it also includes a push block fixed on the slide block and moves reciprocatingly with the synchronous belt; the test tube sample rack is pushed by the push block along the guide mechanism to move the test tube The test tube sample rack is transported to the designated position. The present invention adopts the linear guide rail instead of the existing linear bearing as the guiding transmission mechanism, which has large load, stronger stability and sufficient rigidity.

Owner:ZHONGSHAN CHUANGYI BIOCHEM ENG

A wind power main shaft bearing outer ring roller grinding device

ActiveCN105014506BEasy to processGuaranteed machining accuracyGrinding drivesGrinding machinesEngineeringGrinding wheel

Owner:DEQING TIANMA BEARING CO LTD

An ultrasonic welding device

Owner:SBT ULTRASONIC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com