An ultrasonic welding device

A technology of ultrasonic welding and ultrasonic vibration, applied in the field of ultrasonic welding, can solve the problems of fragile workpiece damage, occupying a large space, reducing the rigidity of the tool, etc., and achieve the effect of improving the rigidity of the system and the compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

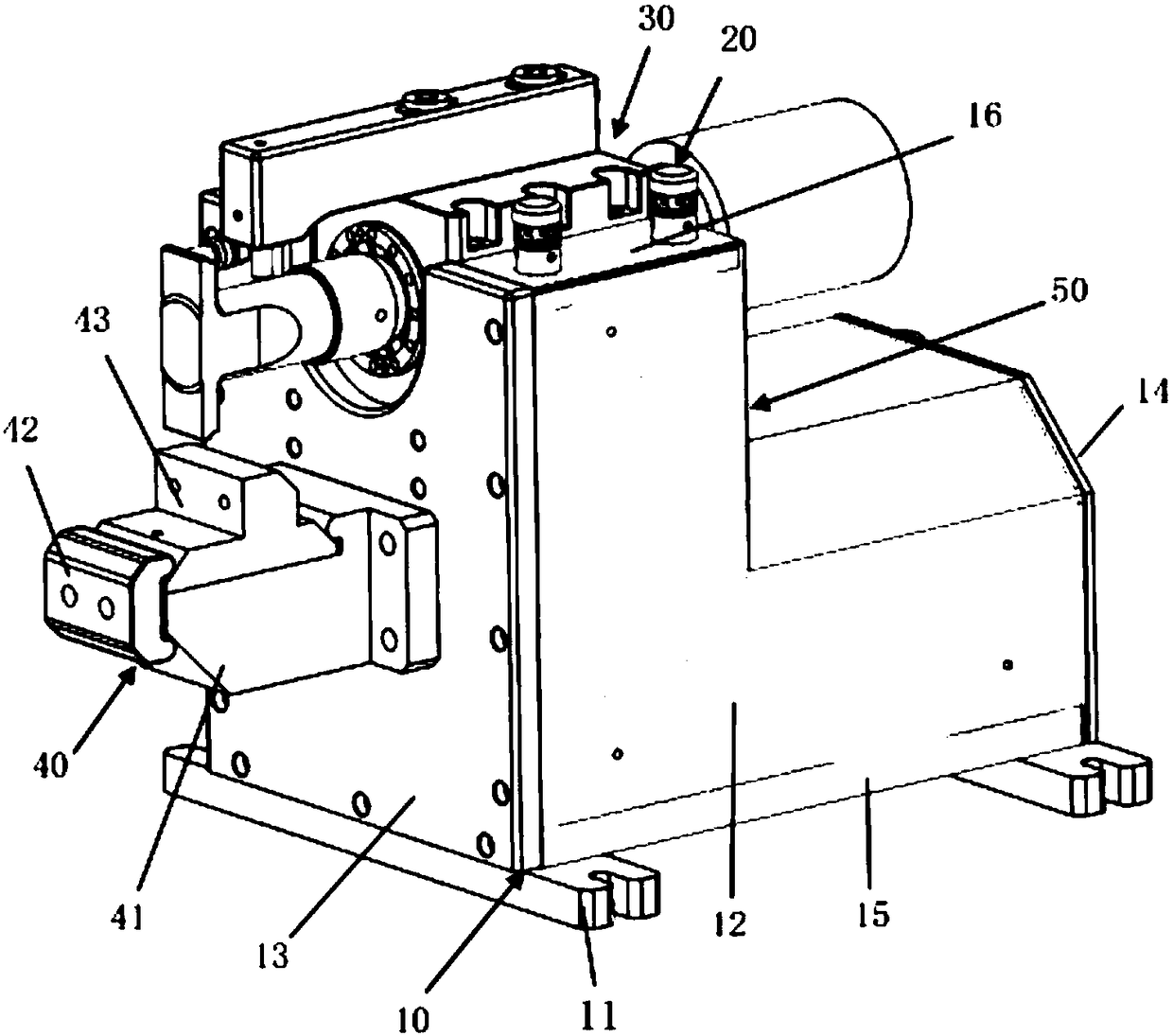

[0022] The ultrasonic welding device of the present invention is compact in structure, sufficiently rigid and easy to operate, and can realize ultrasonic welding of plastic parts. The specific structure is as follows:

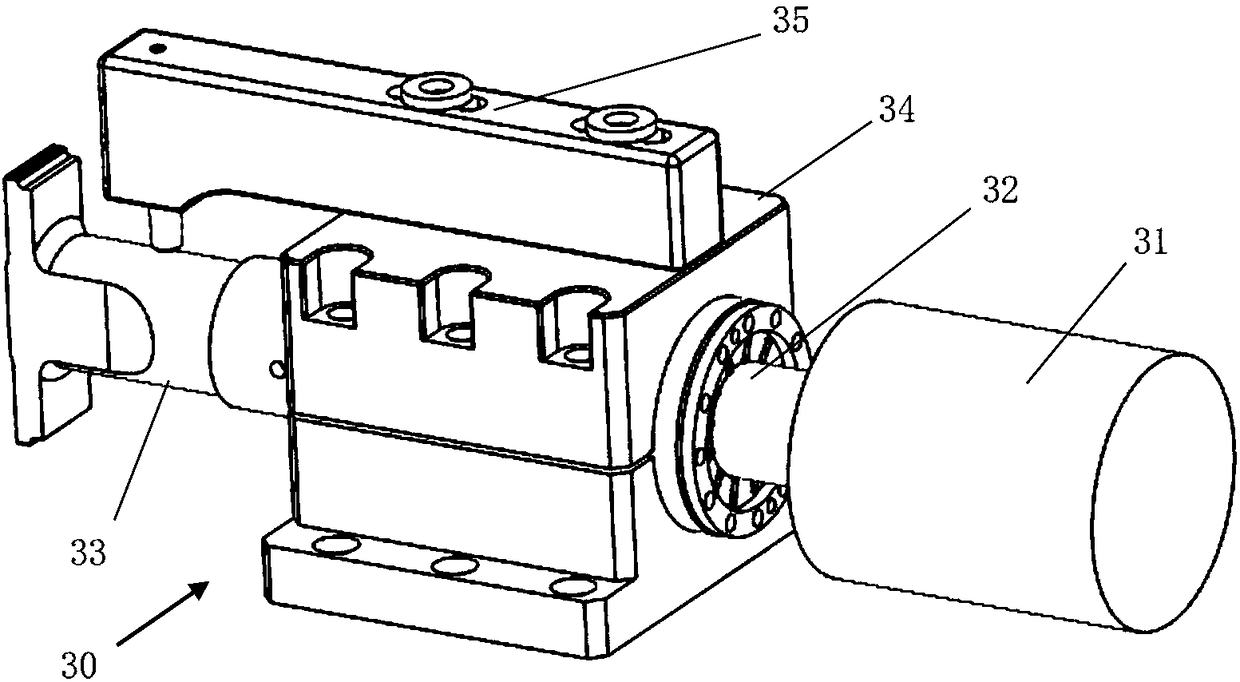

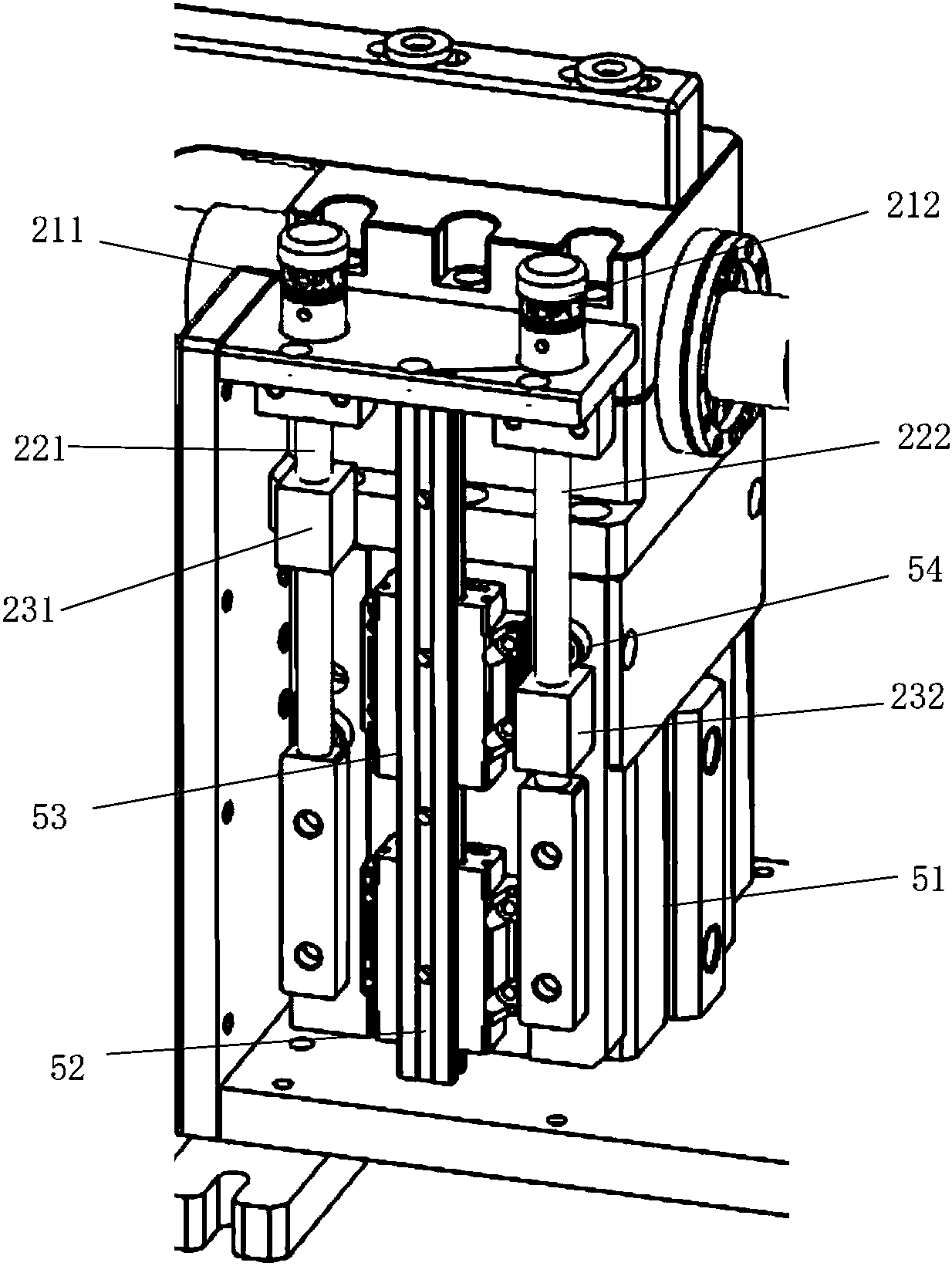

[0023] figure 1 It is a structural diagram of the ultrasonic welding device of the present invention, and the ultrasonic welding device includes a base 10 , a stroke adjustment system 20 , an ultrasonic vibration device 30 , a bottom mold part 40 and a power drive system 50 . The base 10 includes an anchor 11 , a side panel 12 , a front panel 13 , a rear panel 14 , a bottom panel 15 and an upper panel 16 . Stroke adjustment system 20 (see image 3 ) includes an upper limit adjustment knob 211, a lower limit adjustment knob 212, an upper limit screw 221, a lower limit screw 222, an upper limit block 231 and a lower limit block 232; the ultrasonic vibration device 30 (see figure 2 ) includes transducer 31, horn 32, cutter 33, tool holder 34 and rigid auxiliary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com