Telescopic formwork support beam

A formwork support and telescopic technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of restricting construction progress, non-adjustable length, and many supporting beam materials, to achieve The effect of saving support materials, strong versatility, and stable support quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and structural embodiments.

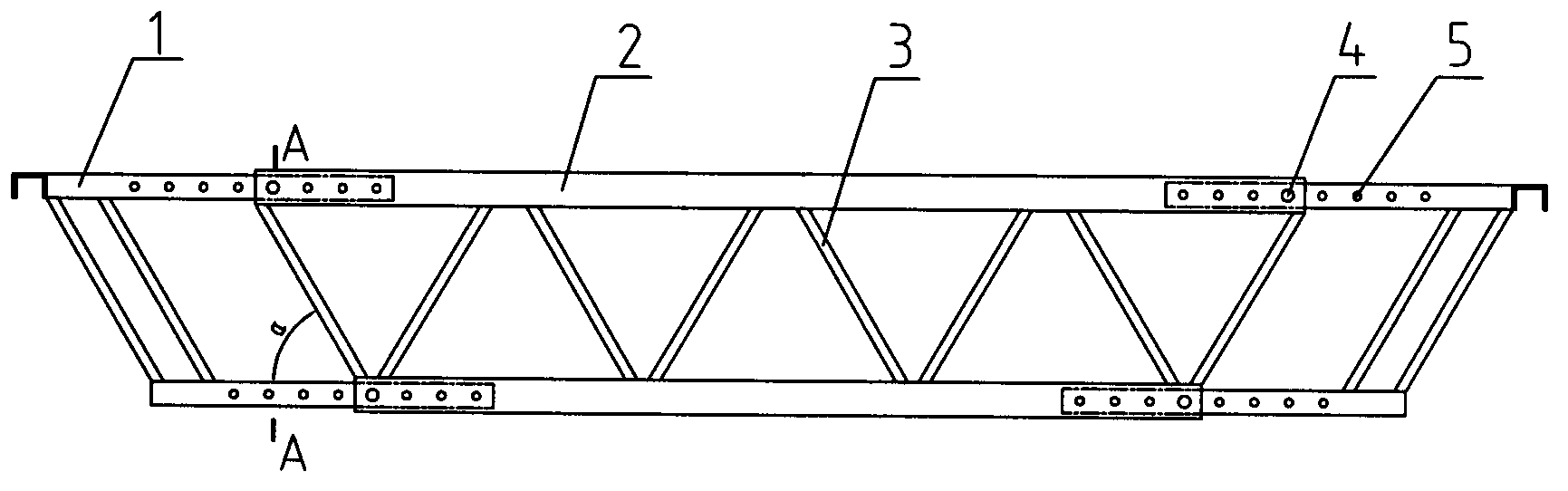

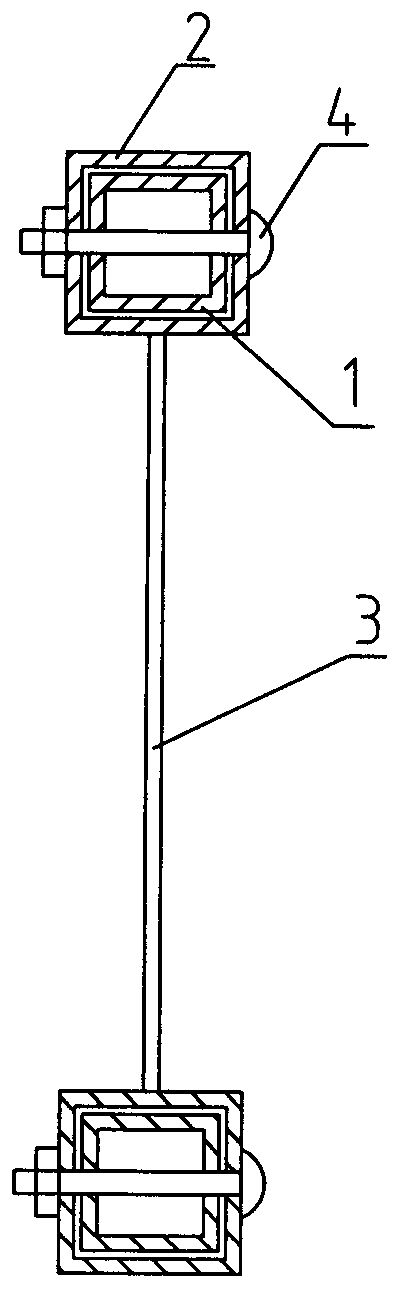

[0016] figure 1 The telescopic formwork supporting beam embodiment shown includes a subbeam 1 , a main beam 2 , ribs 3 , pins 4 and pin holes 5 . The shape of the front of the main beam 2 is an isosceles trapezoidal long truss with a large top and a small bottom. The oblique angle of the two ends of the main beam 2 is 60°, and the upper and lower sides parallel to each other are square steel pipes. The ribs 3 are fixedly connected, and the ends of the two pipes are provided with 8 pin holes 5 arranged at equal intervals of 50mm in the axial direction. The subbeam 1 is an open frame, and the upper and lower sides parallel to each other are also square steel pipes. The outer ends of the two pipes are fixedly connected by two oblique ribs 3 in the same direction. The oblique angle α between the ribs 3 and the lower pipe is the same as that of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com