Large-size cylinder anti-deformation longitudinal joint milling and welding supporting device

A supporting device and anti-deformation technology, applied in positioning devices, welding equipment, supports, etc., can solve problems such as limited welding forms, complex external structure, and inconvenient operation, so as to improve welding quality, facilitate docking and fixing, and improve welding quality. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

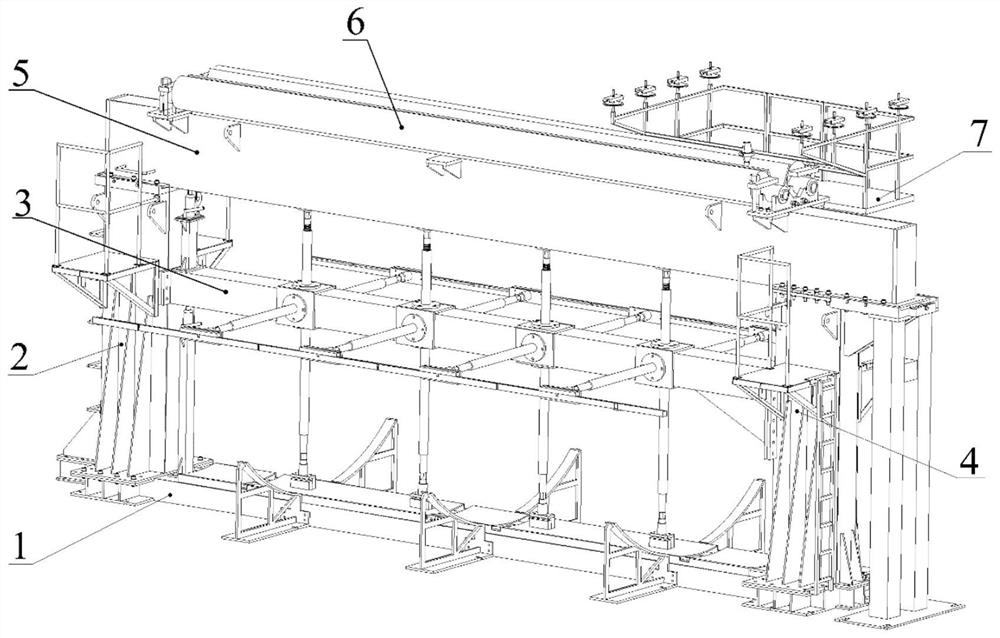

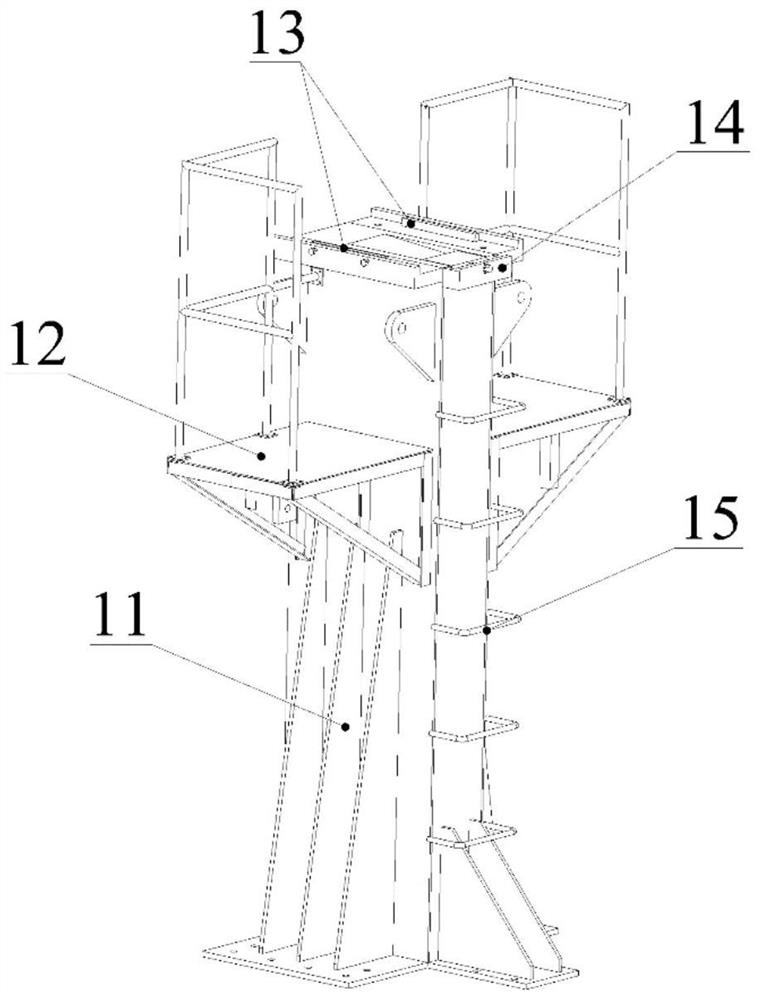

[0028] Such as Figure 1 to Figure 9 The shown large-size cylindrical anti-deformation longitudinal seam milling and welding support device includes a head frame 4 and a tail frame 2; Fixed on the top of the tailstock 2 and the headstock 4, the tailstock 2 and the headstock 4 are equipped with a left and right centering adjustment mechanism 13 and an up and down leveling wedge mechanism 14 for adjusting the relative position between the top and the bottom; the support beam A detachable clamp beam 6 is installed on the 5.

Embodiment 2

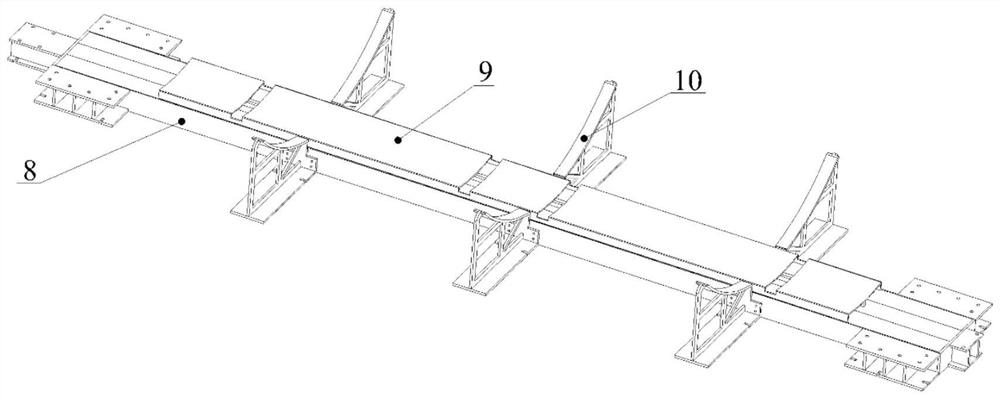

[0030] Based on Embodiment 1, the support beam 5 is composed of a support beam main body 35 , a backing plate 36 is installed on the top surface of the support beam main body 35 , and a detachable spacer 37 is installed on the backing plate 36 .

Embodiment 3

[0032] Based on Embodiment 1, there are two kinds of pads 37 , namely pads for welding without grooves and pads for milling with grooves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com