Wind energy collecting device and wind power generation system thereof

A technology of wind power generation system and collection device, which is applied to wind power generation, wind turbines that are consistent with the wind direction, wind turbines, etc., can solve the problems of waste of installed resources, fatigue damage of parts, increased energy consumption, etc. The effect of improving service life and reducing configuration costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

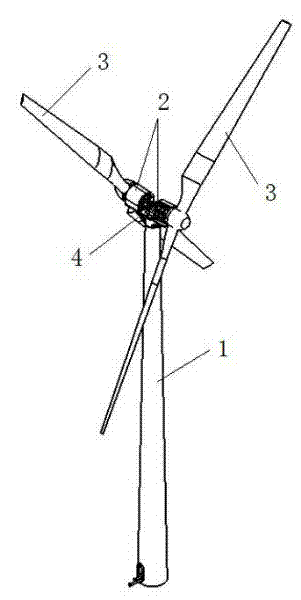

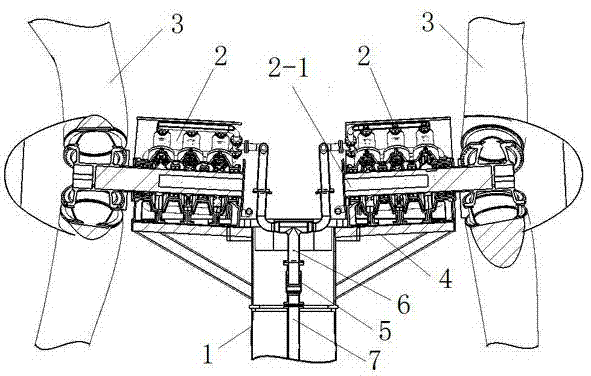

[0035] The wind energy collection device of the present invention includes a cylindrical or frame-mounted tower body 1 standing on the ground, and is characterized in that: two independently operating water pumps 2 are installed on the top of the tower body 1 back to back, and the two water pumps 2 One wind turbine 3 is mounted at each end of the drive shaft, and the rotation directions of the two wind turbines 3 are opposite (the angles of attack of the blades are opposite).

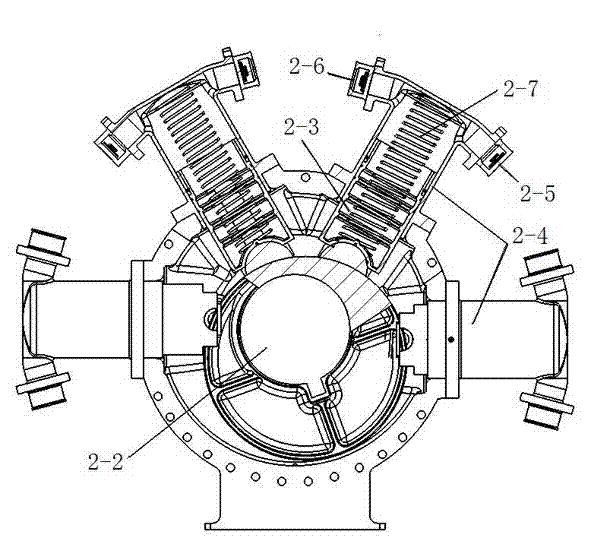

[0036] The above-mentioned water pump 2 is a low-speed plunger pump, which includes a drive shaft 2-1, a cam 2-2 mounted on the drive shaft, and several plungers 2 arranged axially and radially along the drive shaft. -3, the plunger 2-3 is driven by the cam 2-2, so that it can make a rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com