Lift-to-drag blending wing plate type vertical axis wind wheel

A vertical axis and wind wheel technology, applied in the field of wing-plate vertical axis wind wheels, can solve the problems of unfavorable wind flow, damage to the overall shape of the blade structure, and manufacturing difficulties, so as to improve the efficiency of wind energy conversion and improve the low operating speed. , Improve the effect of wind energy utilization characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

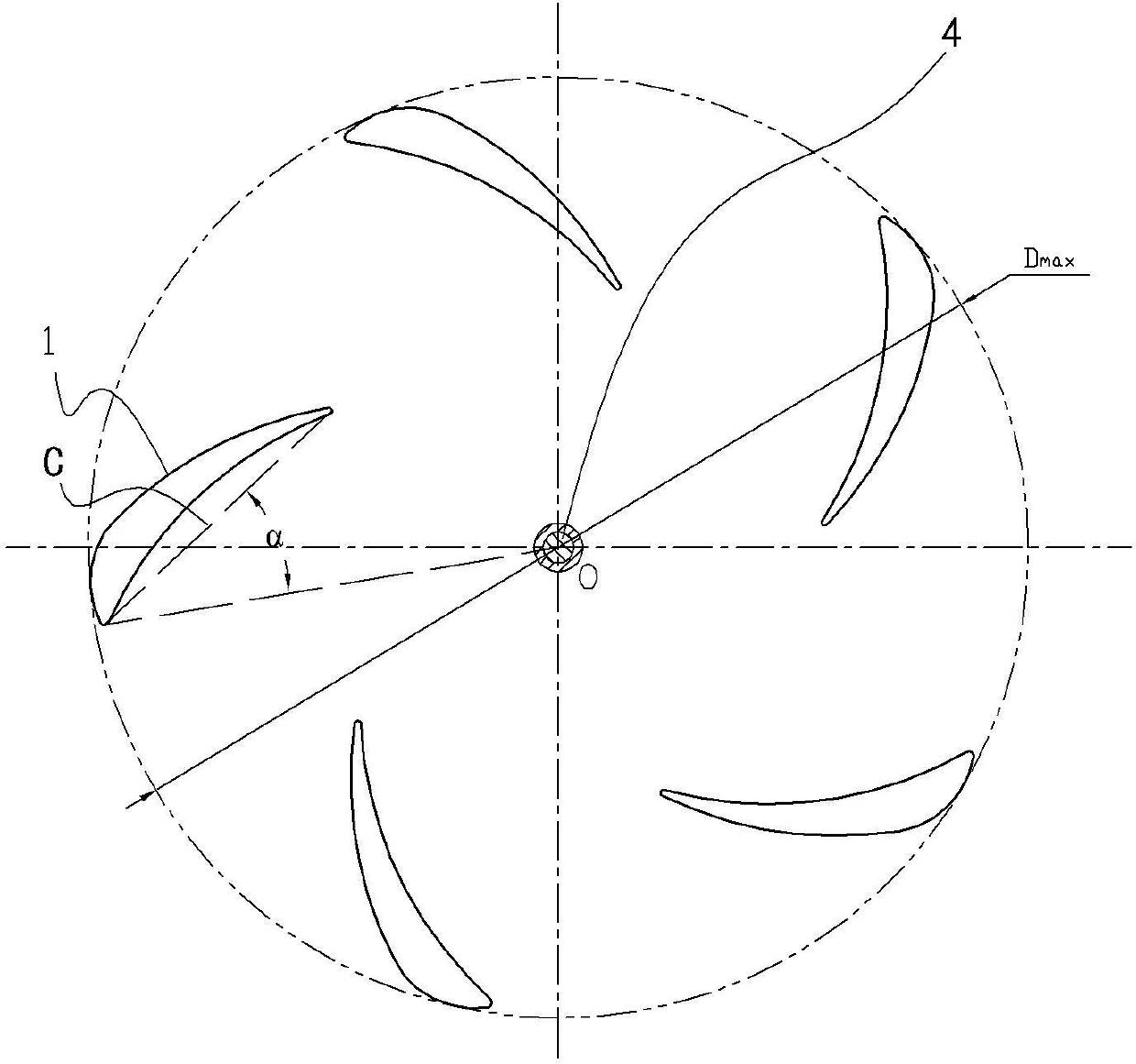

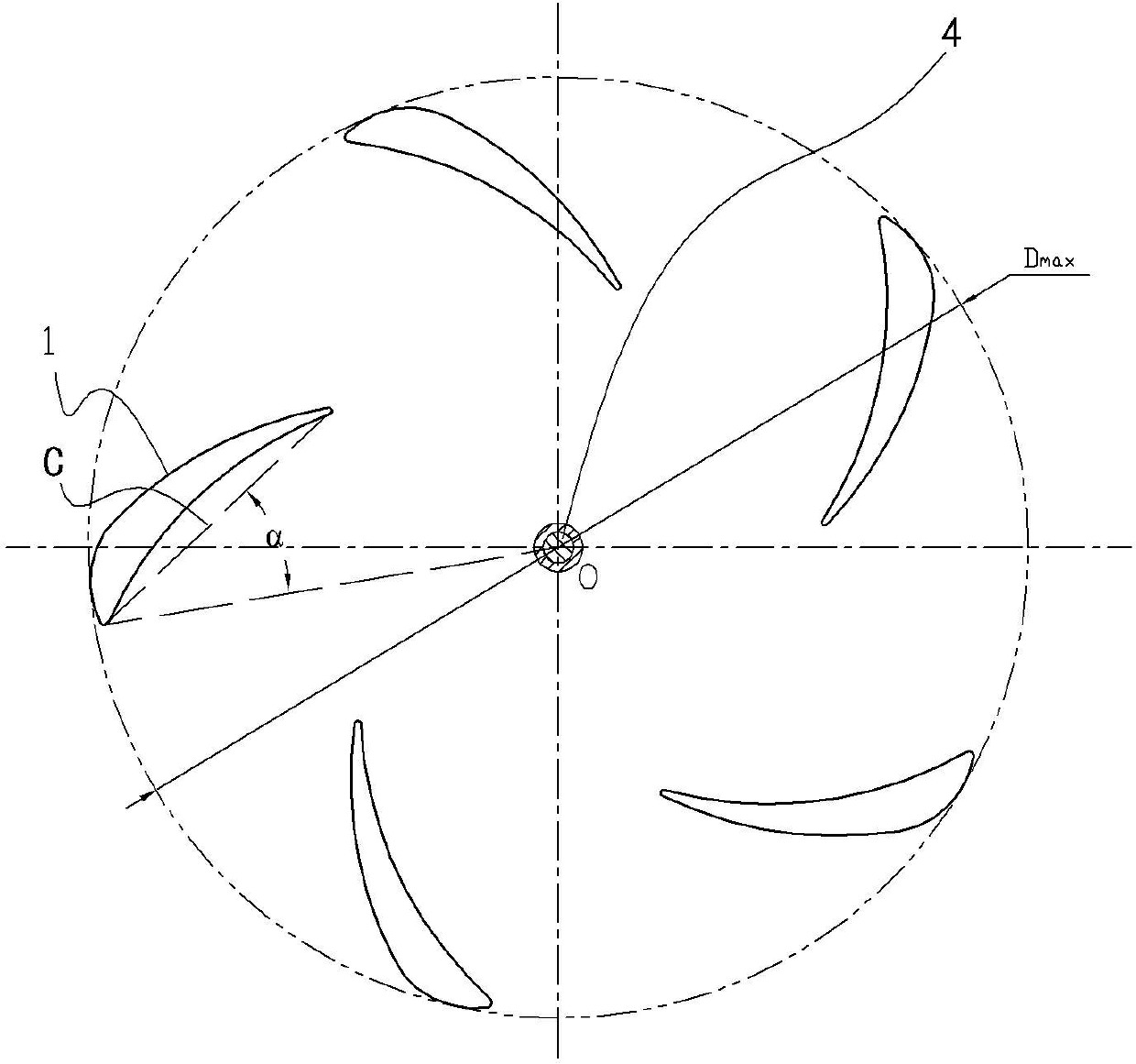

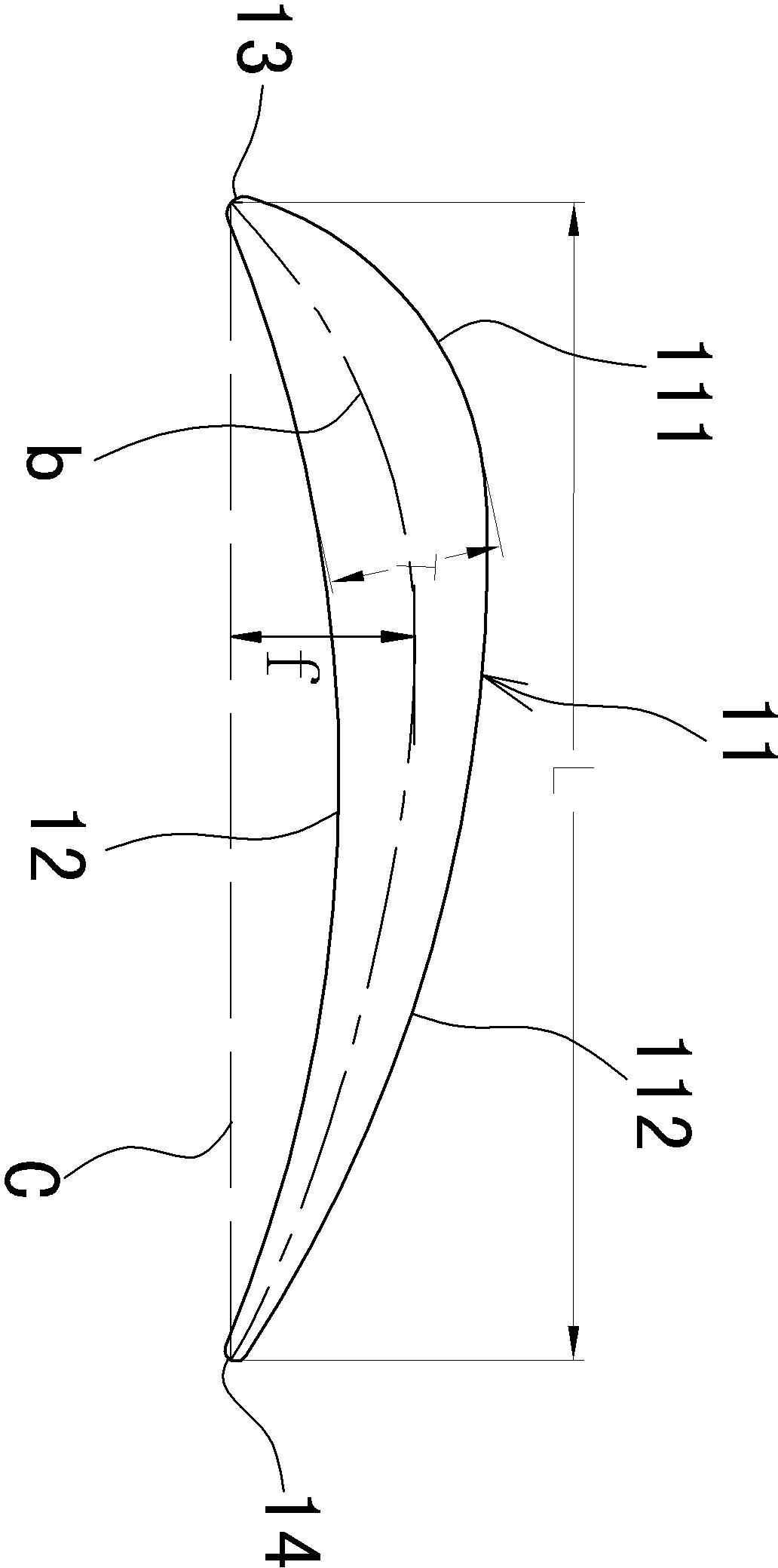

[0015] Such as Figure 1~3 As shown, the specific embodiment of the vertical axis wind wheel of the present invention includes a rotating shaft 4 and five blades 1 distributed along the circumference with the rotating shaft 4 as the center. On the upper cover plate 2 and the lower base plate 5 intersecting and fixedly arranged, the upper and lower ends of each blade 1 are fixed on the corresponding upper cover plate 2 and lower base plate 5 by bolts, and the wind force received by the blade 1 passes through the upper cover plate 2 And the lower base plate 5 is transmitted to the rotating shaft 4 . Each blade 1 is an airfoil-shaped lift-drag fusion wing plate whose height extension direction of the surrounding side is consistent with the axis of the rotating shaft 4 and whose cross-section is perpendicular to the rotating shaft 4. The surrounding side of the blade 1 is formed by a lift convex surface Cylinder 11, resistance concave cylinder 12, front transition arc cylinder 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com