Automatic double-rotation milling head

A dual-rotation, milling head technology, applied in the driving device, milling machine equipment, details of milling machine equipment, etc., can solve the problem of rising processing cost, and achieve the effect of good positioning accuracy, compact overall structure, and rapid tool change structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

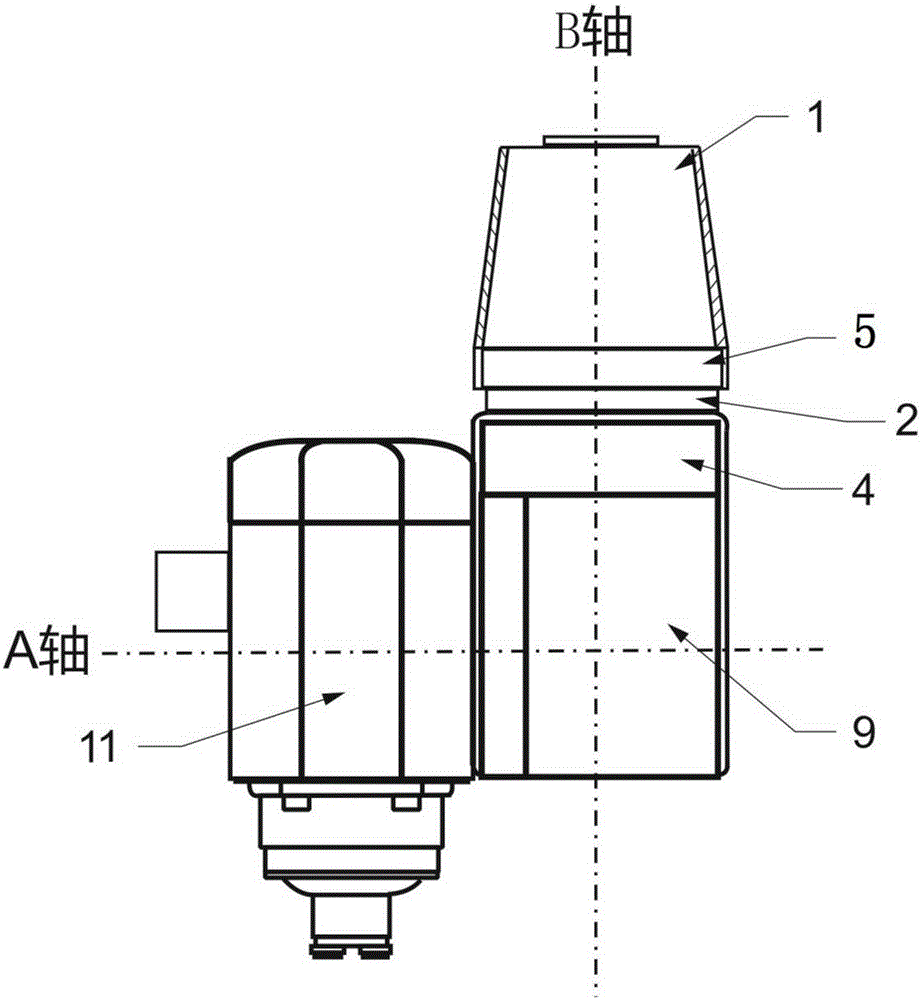

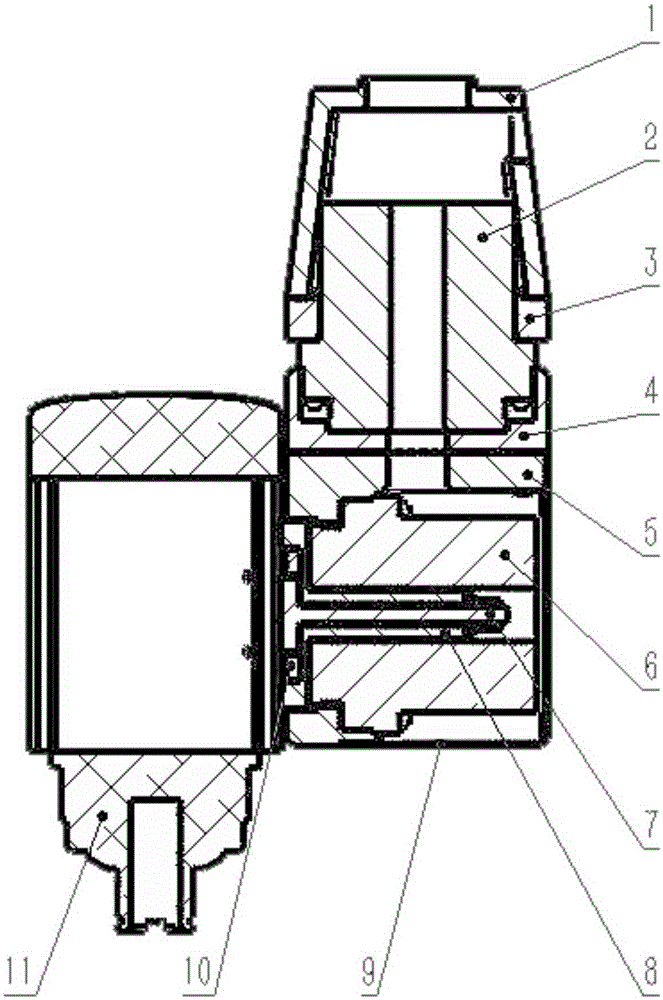

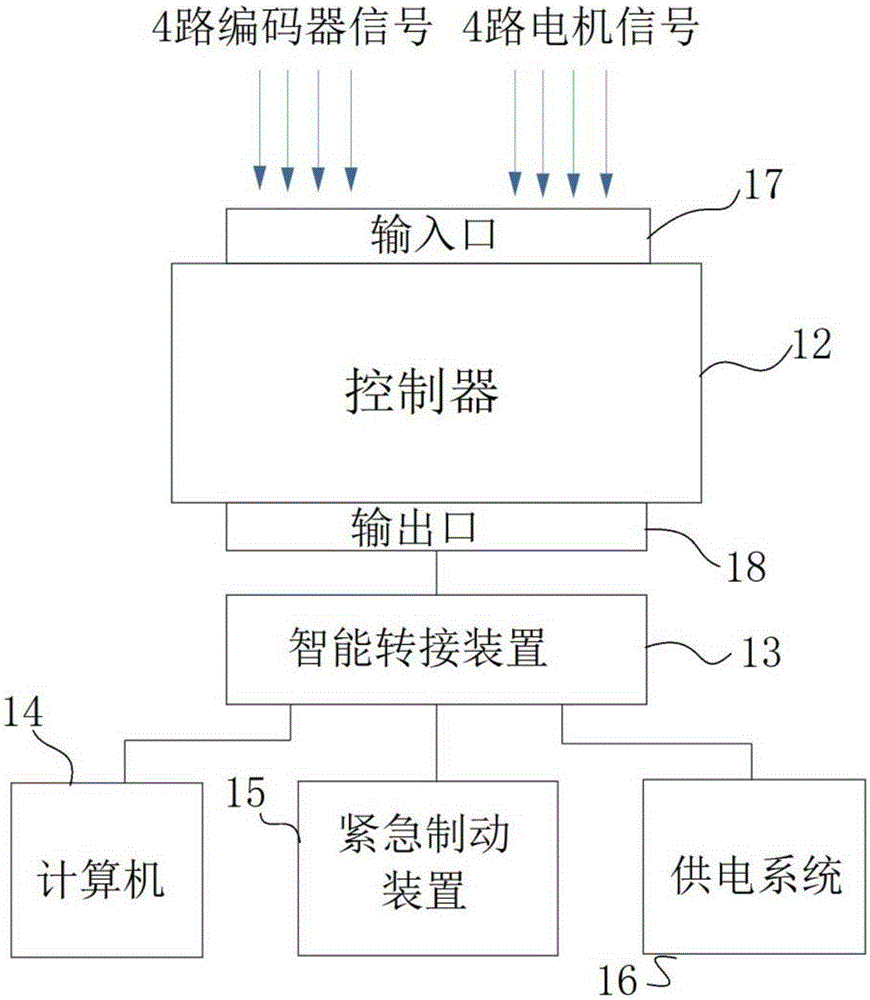

[0024] refer to figure 1 , figure 2 as well as image 3 , the names and marks of each component are as follows: Adapter seat 1, B-axis power and position module 2, connecting plate 3, structural components 4, mounting seat 5, A-axis power and position module 6, spindle connection seat 7, rotary Connecting plate 8, outer casing 9, key 10, processing spindle 11, controller 12, intelligent switching device 13, computer 14, emergency braking device 15, power supply system 16, input port 17 and output port 18.

[0025] see figure 1 with figure 2 , the technical solution adopted is: an automatic double-rotation milling head, including B-axis power and position module 2, A-axis power and position module 6 and processing spindle 11, the B-axis power and position module 2 and A Axis power and position module 6 is installed vertically, and A-axis power and position modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com