Multi-color pug production equipment

A kind of production equipment and mud refining technology, which is applied in the field of ceramics, to achieve the effect of sufficient kneading, tight and tender mud texture, and pleasant color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

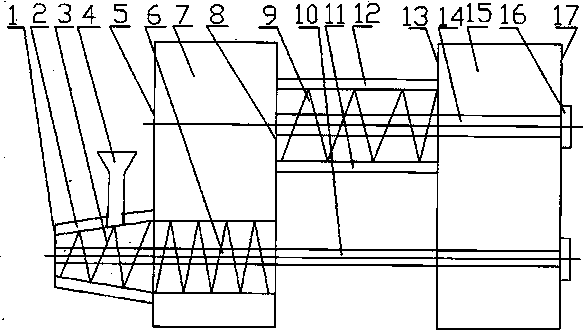

[0030]Embodiment 1, the kneading mud auger (9) is installed between the installation box (15) and the kneading mud chamber (7), and the front of the kneading mud chamber (7) is a multi-color mud molding extrusion chamber (24), and the multi-color mud molding A multi-color mud auger (3) is installed inside the extrusion chamber (24), and the ring surface of the multi-color mud auger (3) is covered with a conical end cover (2), and the conical end cover (2) is equipped with a multi-color mud feeder Device (4), multicolor mud feeding device (4) communicates with multicolor mud auger (3), multicolor mud feeding device (4) communicates with multicolor mud auger (3), multicolor mud feeding device (4) ) can also pressurize the mud of different colors into the multi-color mud auger (3) by installing the auger, so that it can be mixed with the mud from the color of the multi-color mud auger (3) to form multi-color mud , and after being stirred and extruded by the multi-color mud auger ...

Embodiment 2

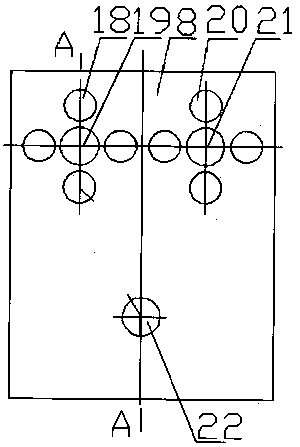

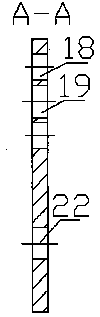

[0031] Embodiment 2, a kind of colorful mud refining production equipment, including outlet, conical end cover, multi-color mud auger, multi-color mud feeding device, forming mud through-hole plate, forming mud auger, kneading mud chamber, kneading mud over Orifice plate, kneading auger, central shaft of forming auger, kneading box plate, top plate of kneading box plate, installation box plate, central shaft of kneading auger, installation box, shaft cover, installation box outer plate, first kneading Mud through hole, first shaft hole, second kneading mud through hole, second shaft hole, forming mud auger shaft hole, forming mud through hole, forming mud auger shaft hole, multi-color mud forming extrusion cavity, its characteristics The forming mud auger (6) is installed at the bottom of the mud kneading chamber (7), the front end of the forming mud auger (6) is a multi-color mud auger (3), and the multi-color mud auger (3) has a tapered end cover on the outside (2), the con...

Embodiment 3

[0032] Embodiment 3, with reference to the basic part of Example 1 remains unchanged, but the multi-color mud auger (3) and the forming mud auger (6) can be connected into one auger for installation, and the rear end can also be installed separately. The auger central shaft (10) is connected to the motor transmission shaft or transmission gear at the rear section of the forming auger central shaft (10) to obtain power to rotate, stir and extrude the slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com