Preparation method of deoiled hard short fibers

A short fiber and hard technology, applied in the field of preparation of deoiled hard short fibers, can solve the problems of limited application surface, moisture, weak strength, etc., and achieve the effect of increasing linear density, increasing viscosity, and sufficient fiber rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

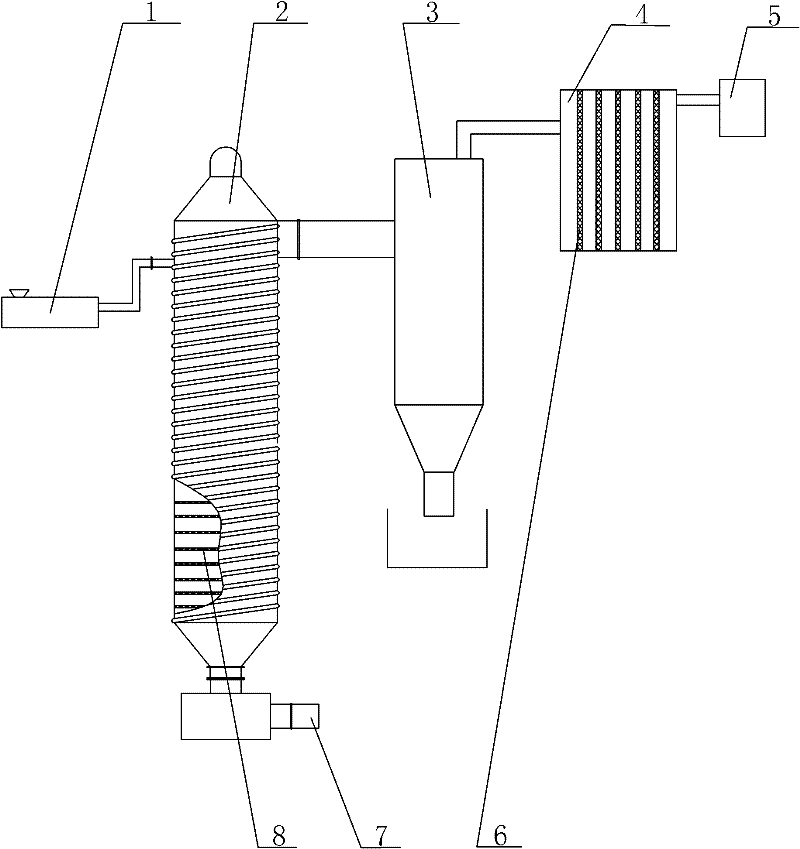

[0016] Below in conjunction with accompanying drawing, the preferred embodiment of the preparation method of a kind of deoiled rigid staple fiber of the present invention is described in detail:

[0017] Such as figure 1 As shown, take the washed and dried polyethylene terephthalate (PET) waste fragments, and prepare polyester staple fibers according to the following steps:

[0018] ① Melt the treated PET waste in the screw extruder 1, the melting temperature is 275°C, and the time is 3 minutes; There are 20 layers of perforated plates 8, and a plurality of cylindrical through holes are arranged perpendicular to the plate surface on the perforated plates 8, and the diameter of the through holes is 10mm. The inside of the polycondensation reaction kettle 2 is kept in a vacuum state, and is controlled by the heat medium pipeline on the wall of the kettle. The temperature in the kettle was 285°C. After the melted melt is fed into the polycondensation reactor 2, polycondensation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com