Rolling guide and guard

A guide device and guide roller technology, applied in the field of material-oriented devices, can solve the problems of decreased stability of the guide device, high processing difficulty, limited adjustment range, etc., and achieve reduced guide cost, low processing difficulty, and stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing:

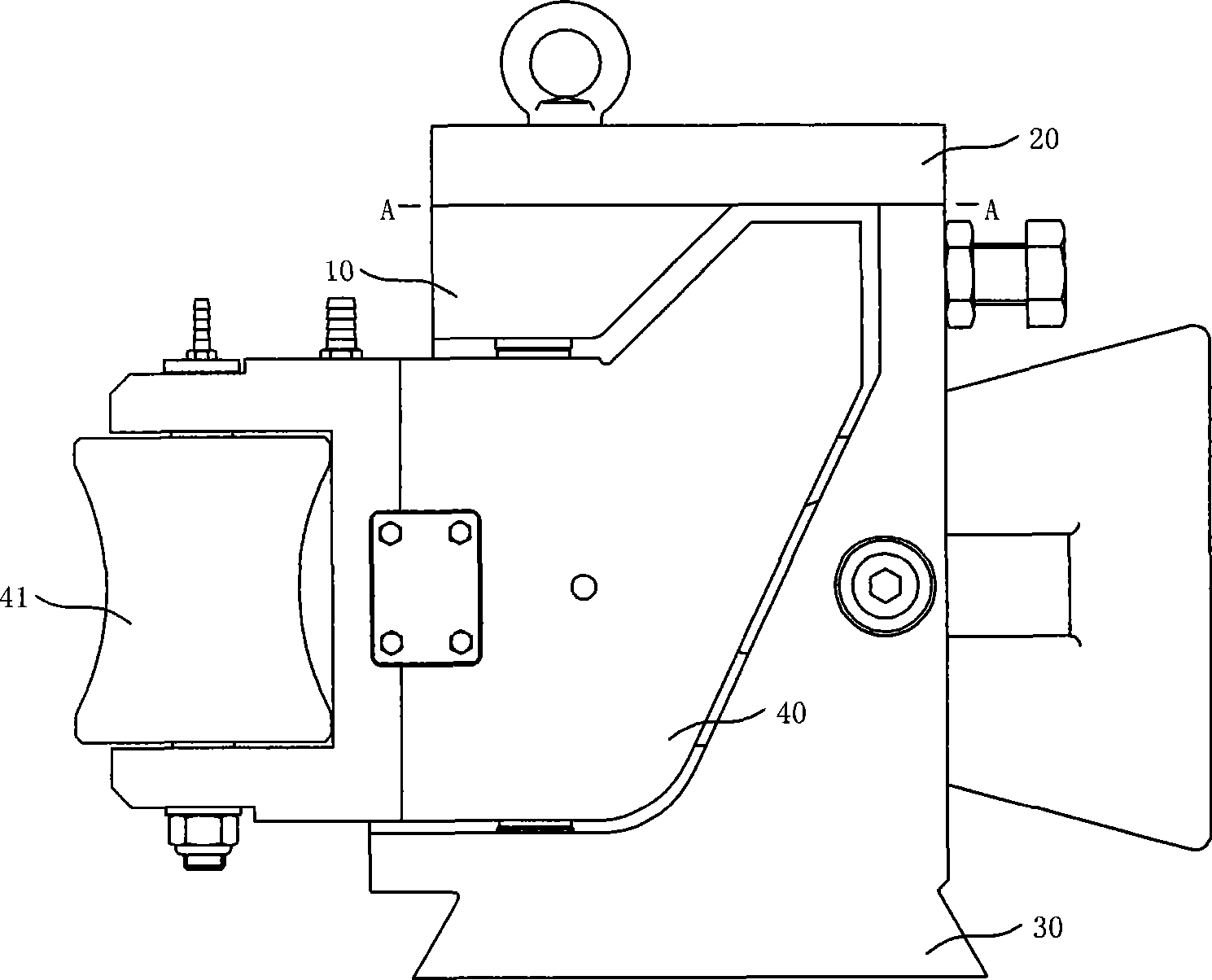

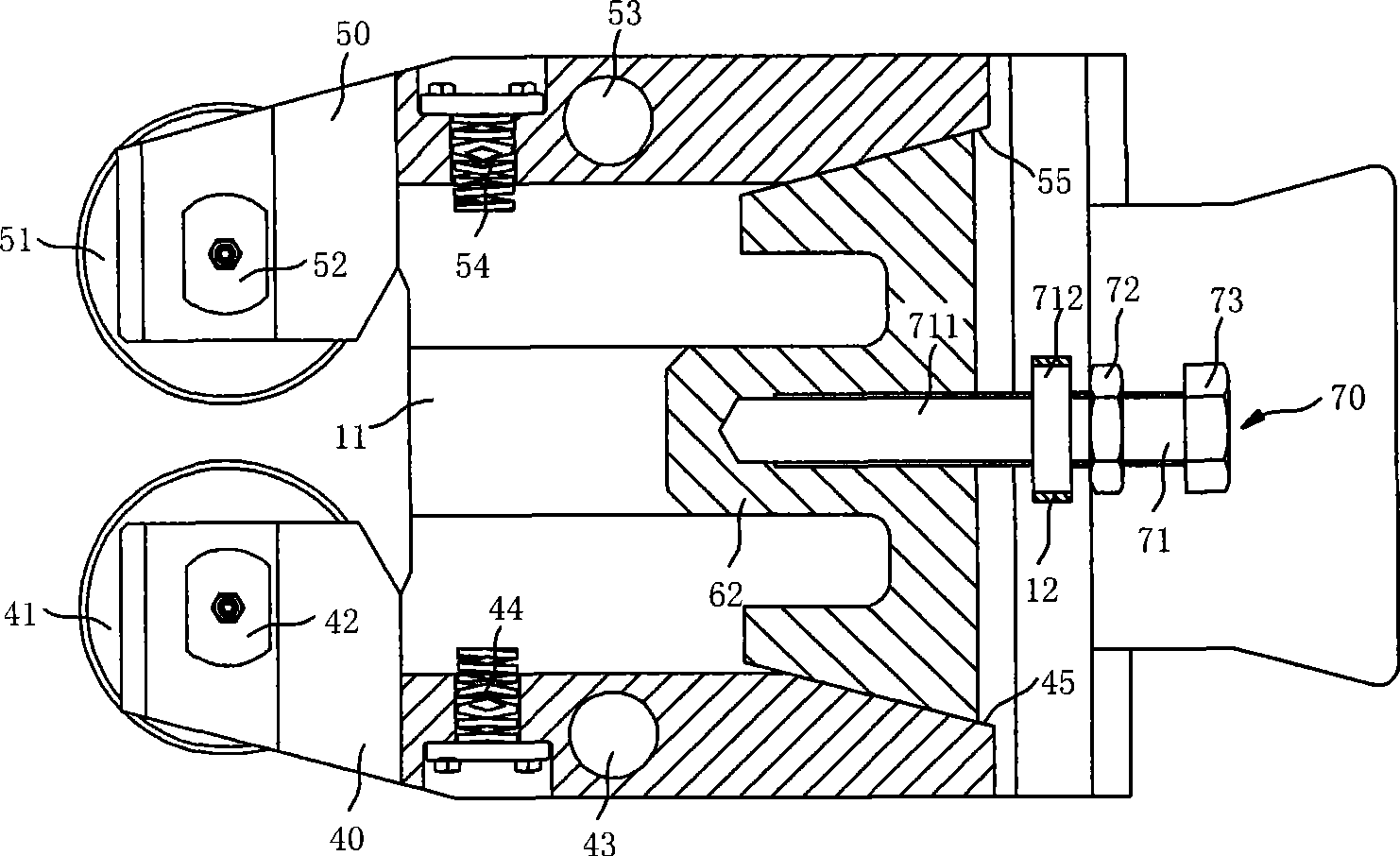

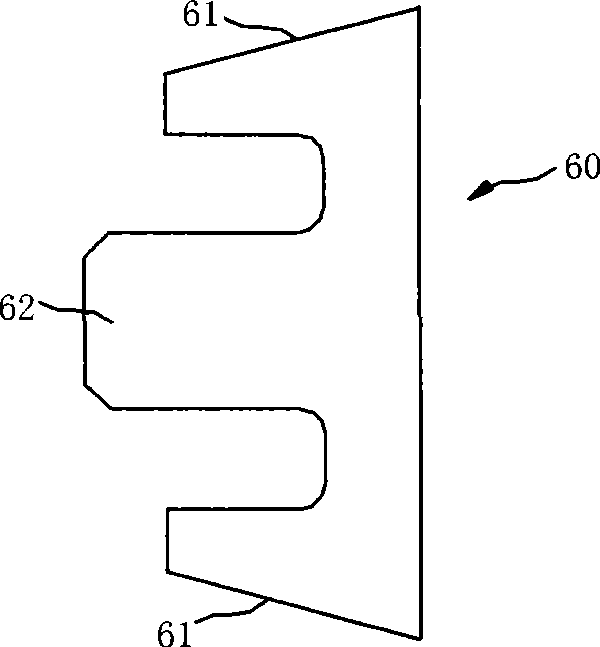

[0010] Such as figure 1 , figure 2 The shown rolling guide device includes a guide box 10 with a cover plate 20 on its upper part and a base 30 on its lower part. A channel for blanks or finished products to pass is formed between the cover plate 20 and the base 30. The cover plate 20 and the base 30 both sides are provided with left and right guide wheel arms 40,50 arranged in the front and rear direction, the front ends of the left and right guide wheel arms are provided with guide rollers 41,51, and the rotary shafts of guide rollers 41,51 42,52 center is positioned at vertical direction, and left and right guide wheel arm 40,50 is hinged between cover plate 20 and base 30 by rotating shaft 43,53, and rotating shaft 43,53 and the rotating shaft 42,52 of guide roller 41,51 parallel. The front ends of the left and right guide wheel arms 40, 50 are respectively provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com