Water-based polyurethane superfine fiber synthetic leather and preparation method thereof

A water-based polyurethane and ultra-fine fiber technology, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., to achieve the effect of reducing cost and energy waste, reducing investment and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

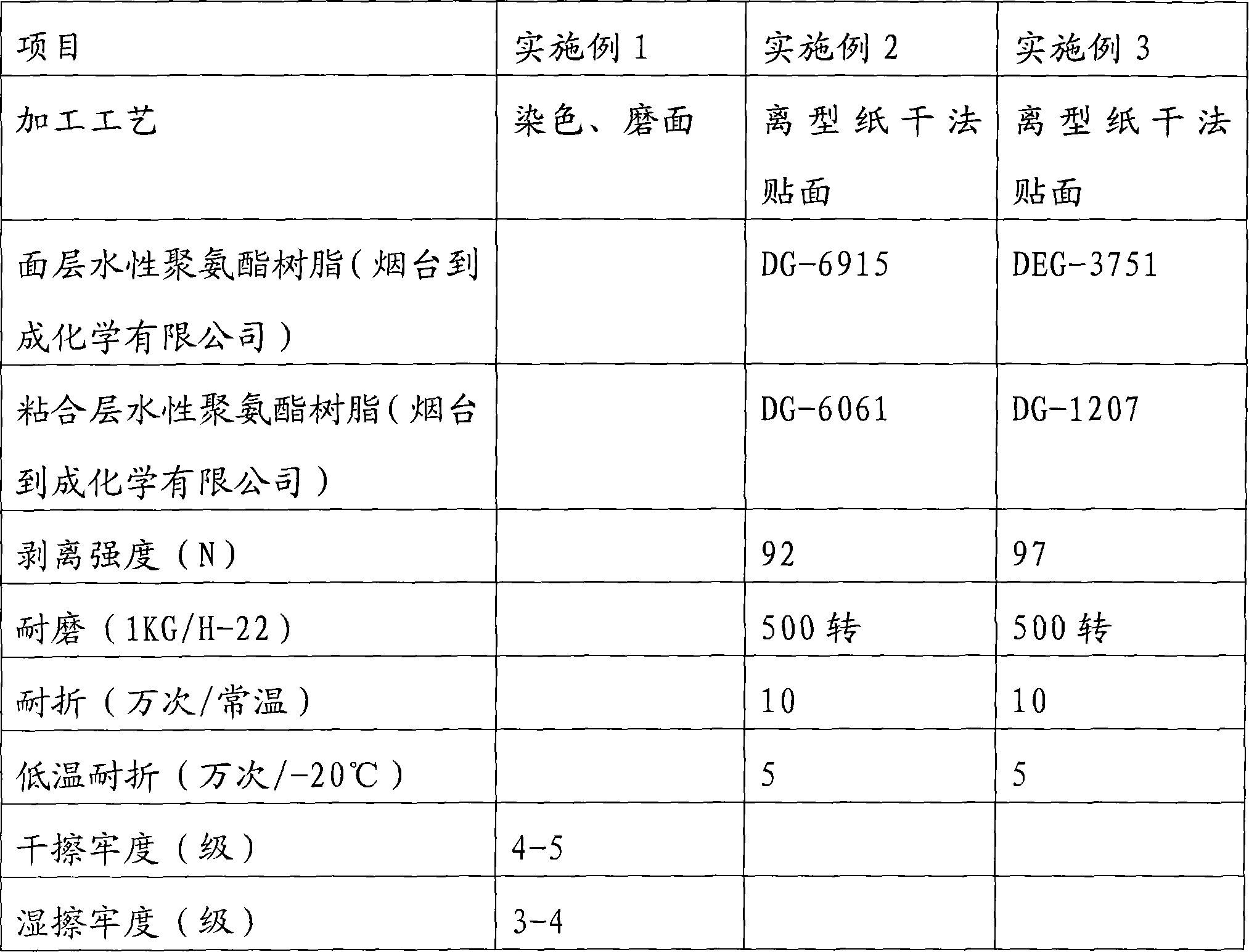

Examples

Embodiment 1

[0017] PA / COPET type fixed island non-woven fabric, its unit weight is 240g / m 2 , its apparent density is 0.30g / m 3 ; 120 parts of water-based polyurethane slurry, the water-based polyurethane slurry is DG-3020, and its dry film 120% modulus is 20KG / cm 2 , solid content 20% by weight, its viscosity is 6Pa.s, 3 parts of sodium dodecylbenzenesulfonate, 2 parts of stearic acid amine and 50 parts of water, stir with high-speed mixer, make the density of mixed slurry be 300g / L; impregnate the non-woven fabric with the mixed slurry in the impregnation tank, the impregnation amount is 400-550g / m 2 , keeping 40-85% of the cells; then in the coagulation tank, the pH value is 5, and the temperature is 20 ℃ aqueous coagulation liquid coagulation, washed in the water washing tank, and dried in an infrared drying oven to obtain the base cloth; and then The dried base fabric is subjected to an alkali weight reduction process in a continuous or batch type alkali weight reduction machine. ...

Embodiment 2

[0020] PA / COPET type fixed island non-woven fabric, its unit weight is 300g / m 2 , its apparent density is 0.33g / m 3 ; 120 parts of water-based polyurethane slurry, the water-based polyurethane slurry is DG-3050, and its dry film 120% modulus is 50KG / cm 2 , the solid content is 25% by weight, and its viscosity is 10Pa.s, 5 parts of sulfonated ammonium succinate foaming agents, 3 parts of foam stabilizer stearic acid amines and 120 parts of water, and the high-speed mixer stirs evenly to make the mixed slurry The density is 500g / L; in the impregnation tank, impregnate the non-woven fabric with the mixed slurry, and the impregnation amount is 600-660g / m 2 , keeping 40-85% of the cells; then in the coagulation tank, the pH value is 4, the temperature is 25 ℃ aqueous coagulation liquid solidification, washed in the water washing tank, and dried in an infrared drying oven to obtain the base cloth; and then The dried base fabric is subjected to an alkali reduction process in a cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com