Preparation method of carbon aerogel

A carbon aerogel, carbon nanosphere technology, applied in the preparation/purification of carbon, chemical instruments and methods, other chemical processes, etc., can solve problems such as complex energy consumption, achieve wide practicability, good adsorption performance, cycle Good regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

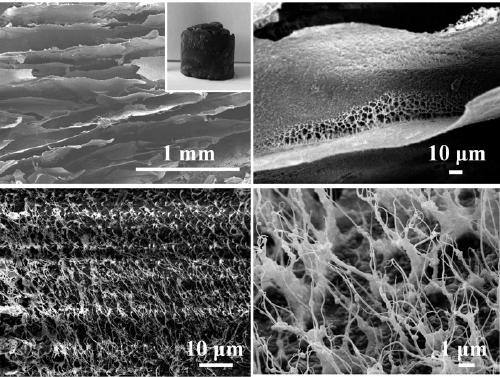

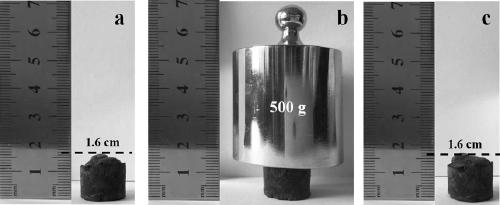

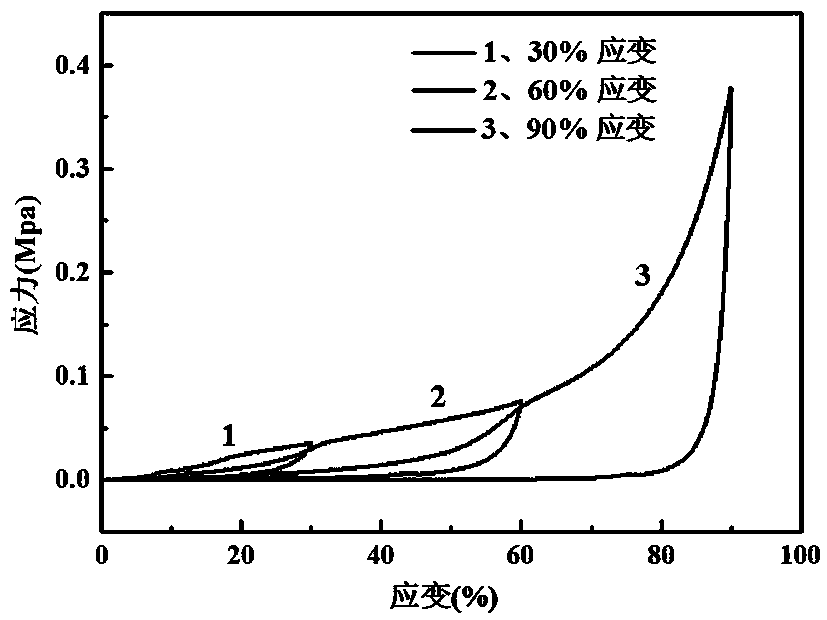

[0030] Weigh 3.168g of glucose, add it into a polytetrafluoroethylene container, then add 40mL of deionized water, and dissolve it evenly by ultrasonication for 15min. Put the polytetrafluoroethylene container containing the solution into the reaction kettle, seal the reaction kettle, place it in an electric blast drying oven, and raise the temperature to 180°C for hydrothermal reaction for 12 hours. After the reaction, the solution was cooled to room temperature, and the precipitate was successively centrifuged and washed with absolute ethanol and deionized water, and then dried in an oven at 50°C. After drying, the product was calcined at 700° C. for 2 h under Ar atmosphere to prepare carbon nanospheres.

[0031] Add 0.2g of carbon nanospheres and 0.1g of polyvinyl alcohol (alcoholysis degree 72.5-74.5mol%, viscosity 4.2-5.0mPa·S) into 5mL deionized water, stir in a constant temperature water bath at 90°C for 60min to disperse evenly. Then add 0.02g of borax and continue to...

Embodiment 2

[0041] Ar gas was introduced into the resistance furnace at a flow rate of 200 mL / min. Raise the temperature of the resistance furnace to 950°C, adjust the flow rate of Ar gas to 700mL / min, and at the same time flow acetylene gas at a flow rate of 80mL / min for 2h. Stop heating and turn off the acetylene gas, adjust the Ar gas flow rate to 200mL / min, wait until the temperature in the furnace drops below 100°C, turn off the Ar gas, collect the product, and obtain carbon nanospheres.

[0042] Add 0.1 g of carbon nanospheres and 0.1 g of polyvinyl alcohol into 10 mL of deionized water, stir at 90 °C for 60 min, add 0.02 g of borax, and continue stirring at 90 °C for 15 min.

[0043] After the reaction, the mixed solution was transferred to a sample bottle, cooled to room temperature, and then the sample bottle was placed in a -78°C ultra-low temperature freezer for 30 minutes. Take out the sample vial, thaw it for 20 minutes, and place the sample vial in a -78°C ultra-low tempera...

Embodiment 3

[0046] Weigh 0.1g of 1,5-dihydroxynaphthalene, 0.5g of PF127, and 0.3g of ferrocene into a polytetrafluoroethylene container, then add 20mL of absolute ethanol and 1mL of 30wt% hydrogen peroxide, and mix well to obtain a mixed solution. Put the polytetrafluoroethylene container containing the mixed solution into the reaction kettle, seal the reaction kettle, place it in a heating furnace, raise the temperature to 220°C and heat for 24 hours. After the reaction, the solution was cooled to room temperature, and the precipitate was successively centrifuged and washed with absolute ethanol and deionized water, and then dried in an oven at 50° C. to prepare magnetic carbon nanospheres.

[0047] Add 0.05g of magnetic carbon nanospheres and 0.1g of polyvinyl alcohol into 7.5mL of deionized water, stir at a constant temperature of 90°C for 60min, then add 0.02g of borax, and continue stirring at 90°C for 17min.

[0048] After the reaction, the mixed solution was transferred to a sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com