Injectable hyaluronic acid microsphere as well as preparation method and application thereof

A technology of hyaluronic acid and microspheres, applied in the field of A61L, can solve the problems of complex preparation, uneven particle size, poor plumpness and compression elasticity of microspheres, etc., and achieves wide application prospects, simple preparation method, and biocompatibility. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

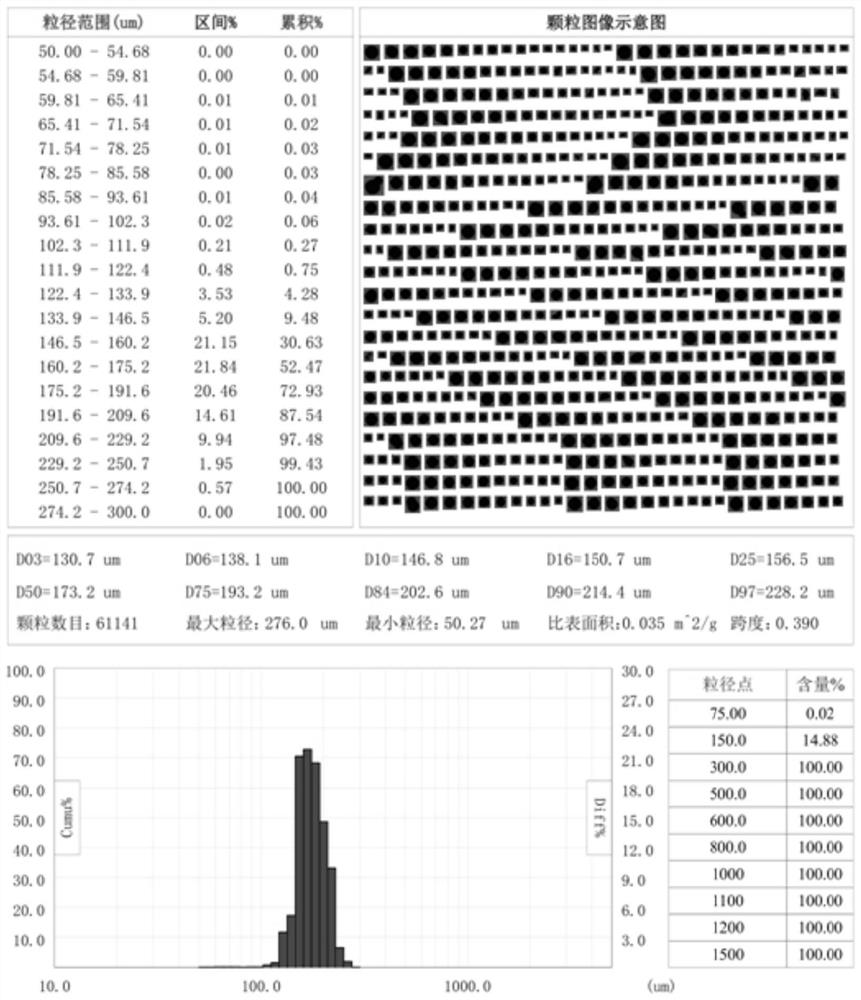

Embodiment 1

[0040] This example provides a preparation method of hyaluronic acid microspheres, including: dissolving hyaluronic acid in 2mol / L NaCl, stirring evenly, the concentration of hyaluronic acid is 8% wt, until the hyaluronic acid is completely dissolved, adjusting the pH value to about 4, Weigh EDC (0.005 mol per gram of hyaluronic acid) and dissolve it in deionized water, add it into the hyaluronic acid solution under ice bath, and stir evenly. Weigh NHS (add 0.005mol per gram of hyaluronic acid) and dissolve it in deionized water, add it to the hyaluronic acid solution, stir well, seal with plastic wrap and transfer to 4°C refrigerator for activation overnight; dissolve chitosan with 1wt% acetic acid , to obtain a chitosan solution with a chitosan mass concentration of 2wt%, mix and stir the activated hyaluronic acid and chitosan solution (amount of 5wt% hyaluronic acid solids), and get butyl acetate in addition, add cellulose acetate element (concentration 7wt%) to form a reac...

Embodiment 2

[0042] This example provides a preparation method of hyaluronic acid microspheres, including: dissolving hyaluronic acid in 2mol / L NaCl, stirring evenly, until the hyaluronic acid concentration is 8wt%, until the hyaluronic acid is completely dissolved, adjusting the pH value to about 6, Weigh EDC (0.005 mol per gram of hyaluronic acid) and dissolve it in deionized water, add it into the hyaluronic acid solution under ice bath, and stir evenly. Weigh NHS (add 0.005mol per gram of hyaluronic acid) and dissolve it in deionized water, add it to the hyaluronic acid solution, stir well, seal with plastic wrap and transfer to 4°C refrigerator for activation overnight; dissolve chitosan with 1wt% acetic acid , to obtain a chitosan solution with a chitosan mass concentration of 2wt%, mix and stir the activated hyaluronic acid and chitosan solution (amount of 5wt% hyaluronic acid solids), and get butyl acetate in addition, add cellulose acetate element (concentration 7wt%) to form a re...

Embodiment 3

[0044] This example provides a preparation method of hyaluronic acid microspheres, which includes: dissolving hyaluronic acid in 2mol / L NaCl, stirring evenly, the concentration of hyaluronic acid is 10wt%, until the hyaluronic acid is completely dissolved, and adjusting the pH value to about 4, Weigh EDC (0.005 mol per gram of hyaluronic acid) and dissolve it in deionized water, add it into the hyaluronic acid solution under ice bath, and stir evenly. Weigh NHS (add 0.005mol per gram of hyaluronic acid) and dissolve it in deionized water, add it to the hyaluronic acid solution, stir well, seal with plastic wrap and transfer to 4°C refrigerator for activation overnight; dissolve chitosan with 1wt% acetic acid , to obtain a chitosan solution with a chitosan mass concentration of 5wt%, mix and stir the activated hyaluronic acid and chitosan solution (amount of 7wt% hyaluronic acid solids), and get butyl acetate in addition, add cellulose acetate element (concentration 7wt%) to fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com