A kind of three-dimensional printing composite aerogel to construct a simulated gas pipe and its preparation method

A composite aerogel, three-dimensional printing technology, applied in tissue regeneration, pharmaceutical formulations, prostheses, etc., can solve problems such as high cost and cumbersome processing methods, and achieve simple technology, good repeatability, and excellent personalized customization performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

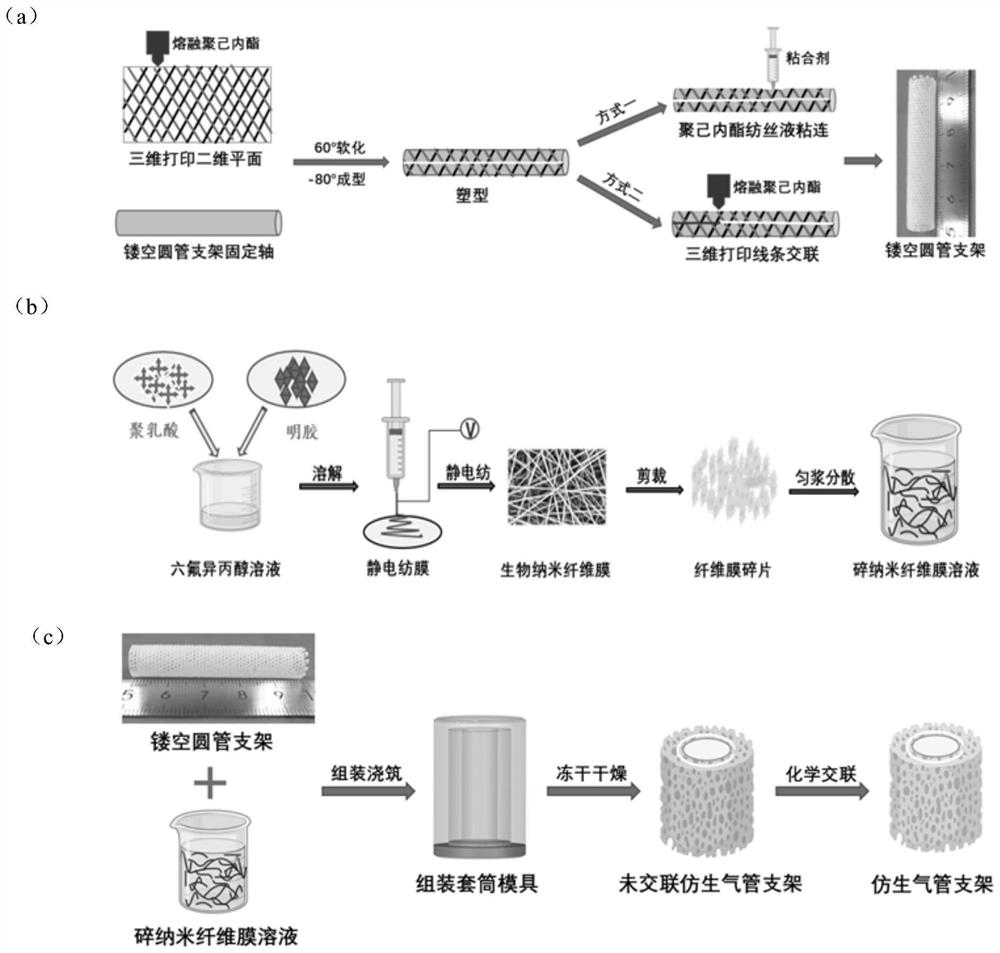

Method used

Image

Examples

Embodiment 1

[0054] (1) Prepare polylactic acid (molecular weight 300000, Guangzhou Maipu Regenerative Medicine Co., Ltd.) / gelatin (Beijing Innochem, innochem, B76801) spinning solution: mix 0.2g gelatin and 0.8g polylactic acid (mass ratio is 1:4 ) was dissolved in 10 mL of hexafluoroisopropanol (>99%, Shanghai Darui Chemical Co., Ltd.) with a mass fraction of 10%.

[0055] (2) Preparation of biological nanofiber membrane by electrospinning: suck the polylactic acid / gelatin spinning solution into the syringe, control the advancing rate of the micro-injection pump to 2.0mL / h, connect the 12.5KV high-voltage power supply to the needle of the syringe, and receive it with aluminum foil , the receiving distance was 13 cm, and the gelatin / polylactic acid nanofiber membrane was obtained by electrospinning. The nanofiber membrane needs to be vacuum dried for 24h under the condition of vacuum degree of -25KPa and drying temperature of 25℃.

[0056] (3) Homogenization and pulverization of the biol...

Embodiment 2

[0071] (1) Prepare polylactic acid (molecular weight 300000, Guangzhou Maipu Regenerative Medicine Co., Ltd.) / gelatin (Beijing Innochem, innochem, B76801) spinning solution: mix 0.2g gelatin and 0.8g polylactic acid (mass ratio is 1:4 ) was dissolved in 10 mL of hexafluoroisopropanol (>99%, Shanghai Darui Chemical Co., Ltd.) with a mass fraction of 10%.

[0072] (2) Preparation of biological nanofiber membrane by electrospinning: suck the polylactic acid / gelatin spinning solution into the syringe, control the advancing rate of the micro-injection pump to 2.0mL / h, connect the 12.5KV high-voltage power supply to the needle of the syringe, and receive it with aluminum foil , the receiving distance was 13 cm, and the gelatin / polylactic acid nanofiber membrane was obtained by electrospinning. The nanofiber membrane needs to be vacuum dried for 24h under the condition of vacuum degree of -25KPa and drying temperature of 25℃.

[0073] (3) Homogenization and pulverization of the biol...

Embodiment 3

[0090] (1) Prepare polylactic acid (molecular weight 300000, Guangzhou Maipu Regenerative Medicine Co., Ltd.) / gelatin (Beijing Innochem, innochem, B76801) spinning solution: mix 0.2g gelatin and 0.8g polylactic acid (mass ratio is 1:4 ) was dissolved in 10 mL of hexafluoroisopropanol (>99%, Shanghai Darui Chemical Co., Ltd.) with a mass fraction of 10%.

[0091] (2) Preparation of biological nanofiber membrane by electrospinning: suck the polylactic acid / gelatin spinning solution into the syringe, control the advancing rate of the micro-injection pump to 2.0mL / h, connect the 12.5KV high-voltage power supply to the needle of the syringe, and receive it with aluminum foil , the receiving distance was 13 cm, and the gelatin / polylactic acid nanofiber membrane was obtained by electrospinning. The nanofiber membrane needs to be vacuum dried for 24h under the condition of vacuum degree of -25KPa and drying temperature of 25℃.

[0092] (3) Homogenization and pulverization of the biol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com