Spunlace jacquard non-woven fabric and production method thereof

A technology of non-woven fabrics and spunlace, applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve the problems of jacquard texture deformation, etc., and achieve the effect of increasing entanglement, not easy to deform, and large radius of curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] According to one aspect of the present invention, a kind of preparation method of spunlace jacquard non-woven fabric, described preparation method comprises the following steps:

[0038]First, the three-dimensional hollow crimped fiber and ordinary polyester staple fiber are mixed and then opened, carded, laid and drawn in sequence to obtain a fiber web, and the polypropylene fiber is separately prepared to produce a polypropylene spunbonded fabric; then the fiber web and polypropylene The spunbond fabric is compounded to obtain a double-layer composite material; then the double-layer composite material is subjected to pre-wet spunlace, spunlace entangling, spunlace jacquard, dehydration, drying and winding to obtain a spunlace jacquard non-woven fabric .

[0039] The preparation method of the spunlace jacquard non-woven fabric provided by the present invention first mixes the three-dimensional hollow crimped fiber and ordinary polyester staple fiber to obtain a fiber m...

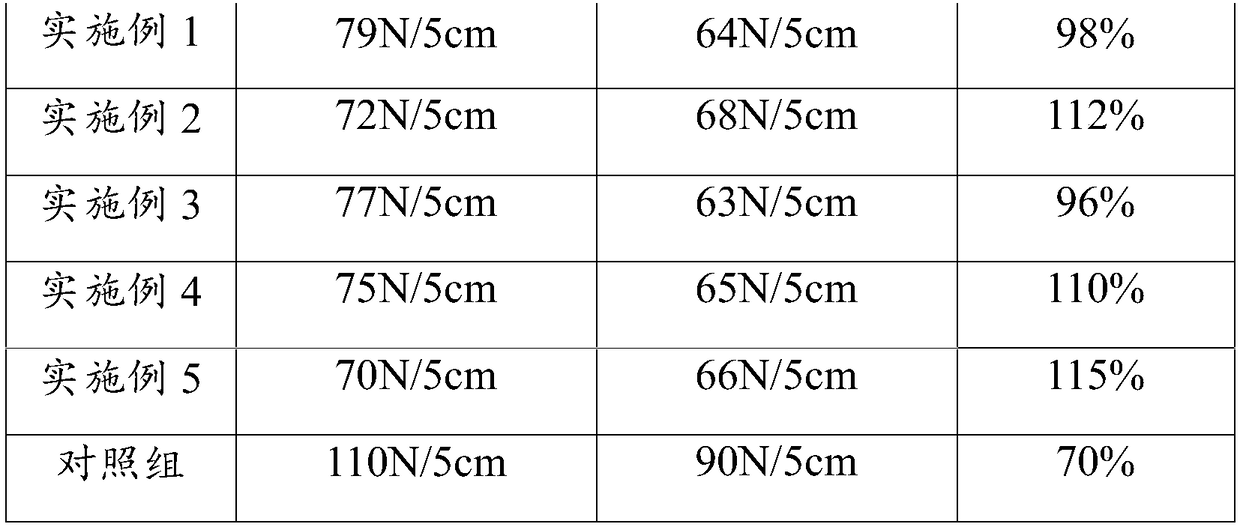

Embodiment 1

[0059] A spunlace jacquard nonwoven fabric, in terms of parts by mass, said spunlace jacquard nonwoven fabric is mainly made of the following raw materials: 30 parts of three-dimensional hollow crimped fiber, 15 parts of polypropylene fiber and 45 parts of ordinary polyester staple fiber;

[0060] The preparation method of above-mentioned spunlace jacquard non-woven fabric comprises the following steps:

[0061] First, the three-dimensional hollow crimped fiber and ordinary polyester staple fiber are mixed and then opened, carded, laid and drawn in sequence to obtain a fiber web, and the polypropylene fiber is separately prepared to produce a polypropylene spunbonded fabric; then the fiber web and polypropylene The spunbond fabric is compounded to obtain a double-layer composite material; then the double-layer composite material is subjected to pre-wet spunlace, spunlace entangling, spunlace jacquard, dehydration, drying and winding to obtain a spunlace jacquard non-woven fabri...

Embodiment 2

[0068] A spunlace jacquard non-woven fabric, in parts by mass, said spunlace jacquard nonwoven fabric is mainly made of the following raw materials: 45 parts of three-dimensional hollow crimped fiber, 20 parts of polypropylene fiber and 55 parts of ordinary polyester staple fiber;

[0069] The preparation method of above-mentioned spunlace jacquard non-woven fabric comprises the following steps:

[0070] First, the three-dimensional hollow crimped fiber and ordinary polyester staple fiber are mixed and then opened, carded, laid and drawn in sequence to obtain a fiber web, and the polypropylene fiber is separately prepared to produce a polypropylene spunbonded fabric; then the fiber web and polypropylene The spunbond fabric is compounded to obtain a double-layer composite material; then the double-layer composite material is subjected to pre-wet spunlace, spunlace entangling, spunlace jacquard, dehydration, drying and winding to obtain a spunlace jacquard non-woven fabric ;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com