High-temperature-resistant CMAS-corrosion-resistant rare earth silicate ceramic and preparation method thereof

A rare earth silicate and rare earth monosilicate technology, applied in the direction of high-efficiency propulsion technology, sustainable transportation, climate sustainability, etc., can solve the problems of limiting the application of EBCs, unable to meet the use requirements, poor corrosion ability, etc. The effect of improving the corrosion resistance of high temperature CMAS, improving the corrosion resistance of high temperature CMAS, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, Y and Yb elements are selected to prepare two-component high-entropy (2RE) 1 / 2 ) 2 Si 2 O 7 / (2RE 1 / 2 ) 2 SiO 5 Multiphase ceramics, including the following steps:

[0026] Step 1, preparation of high-entropy rare earth mono- and di-silicate powder: the RE 2 O 3 (RE is rare earth element), SiO 2 Mix in 1:1 and 1:2 molar ratios, respectively. The mixed powder was wet ball milled in a ball mill for 24 h, and then the obtained slurry was placed in an oven, dried at 80 °C for 10 h, and then the dried powder was calcined at 1450 °C for 2 h, and then ball-milled for 10 h. , respectively, to synthesize single-phase high-entropy rare earth monosilicate (2RE 1 / 2 ) 2 SiO 5 Powder and single-phase high-entropy rare earth disilicate (2RE) 1 / 2 ) 2 Si 2 O 7 powder.

[0027] Step 2, (2RE 1 / 2 ) 2 Si 2 O 7 / (2RE 1 / 2 ) 2 SiO 5 Preparation of multi-phase powder: the single-phase powder prepared in step 1, press (2RE 1 / 2 ) 2 SiO 5 :(2RE 1 / 2 )...

Embodiment 2

[0031] In this embodiment, Y, Yb, Er elements are selected to prepare three-component high-entropy (3RE 1 / 3 ) 2 Si 2 O 7 / (3RE 1 / 3 ) 2 SiO 5 Multiphase ceramics, including the following steps:

[0032] Step 1, preparation of high-entropy rare earth mono- and di-silicate powder: the RE 2 O 3 (RE is rare earth element), SiO 2 Mix in 1:1 and 1:2 molar ratios, respectively. The mixed powder was wet ball milled and mixed in a ball mill for 24 h, and then the obtained slurry was placed in an oven, dried at 80 °C for 10 h, and then the dried powder was kept at 1500 °C for 2 h, and then ball-milled for 10 h. , respectively, to synthesize single-phase high-entropy rare earth monosilicate (3RE 1 / 3 ) 2 SiO 5 Powder and single-phase high-entropy rare earth disilicates (3RE 1 / 3 ) 2 Si 2 O 7 powder.

[0033] Step 2, (3RE 1 / 3 ) 2 Si 2 O 7 / (3RE 1 / 3 ) 2 SiO 5 Preparation of multi-phase powder: the single-phase powder prepared in step 1, press (3RE 1 / 3 ) 2 SiO 5 :(3R...

Embodiment 3

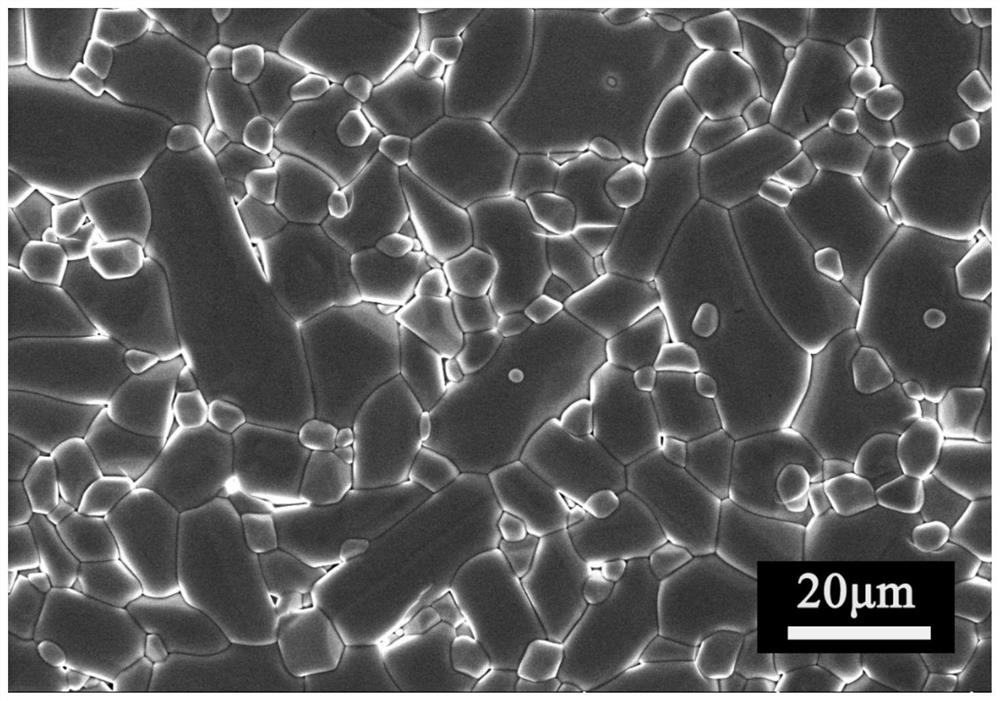

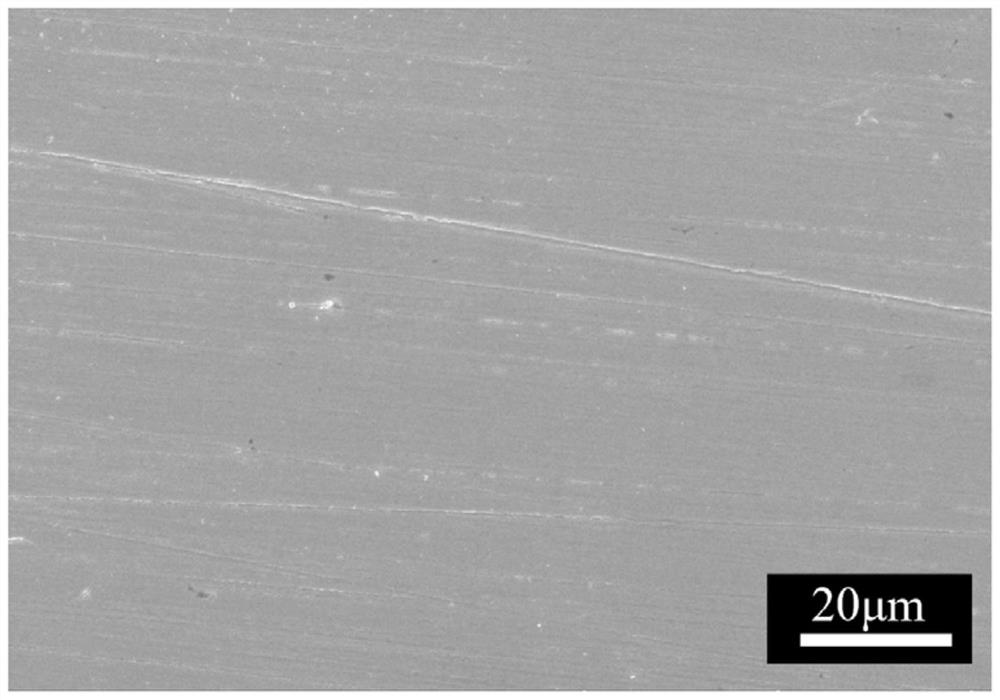

[0037] combine Figure 1-2 , the present embodiment selects Y, Yb, Er, Sc elements to prepare four-component high-entropy (4RE 1 / 4 ) 2 Si 2 O 7 / (4RE 1 / 4 ) 2 SiO 5 Multiphase ceramics, including the following steps:

[0038] Step 1, preparation of high-entropy rare earth mono- and di-silicate powder: the RE 2 O 3 (RE is rare earth element), SiO 2 Mix in 1:1 and 1:2 molar ratios, respectively. The mixed powder was wet ball milled and mixed in a ball mill for 24 h, and then the obtained slurry was placed in an oven, dried at 80 °C for 10 h, and then the dried powder was kept at 1500 °C for 2 h, and then ball-milled for 10 h. , respectively, to synthesize single-phase high-entropy rare earth monosilicate (4RE 1 / 4 ) 2 SiO 5 Powder and single-phase high-entropy rare earth disilicate (4RE) 1 / 4 ) 2 Si 2 O 7 powder.

[0039] Step 2, (4RE 1 / 4 ) 2 Si 2 O 7 / (4RE 1 / 4 ) 2 SiO 5 Preparation of multi-phase powder: the single-phase powder prepared in step 1, press (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com