A2B2O7 type rare earth tantalate ceramic and preparation method thereof

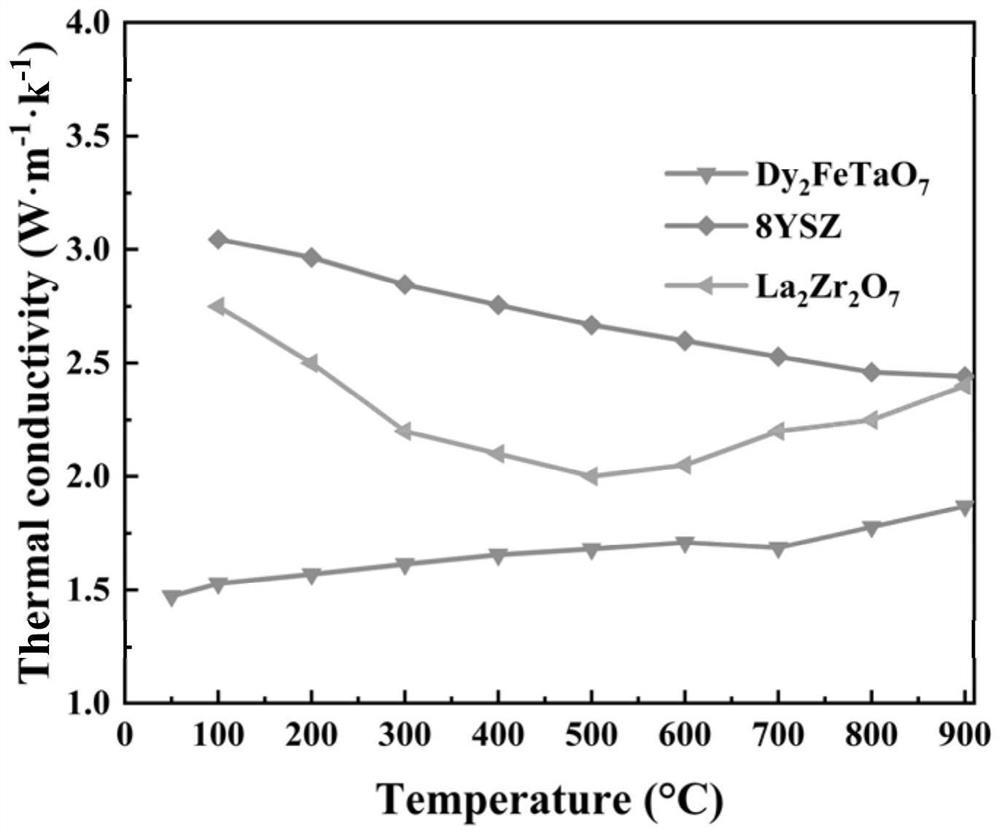

A technology of A2B2O7 and tantalate, applied in the field of thermal barrier coating, can solve the problem of lack of B-site regulation performance, and achieve the effect of reducing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

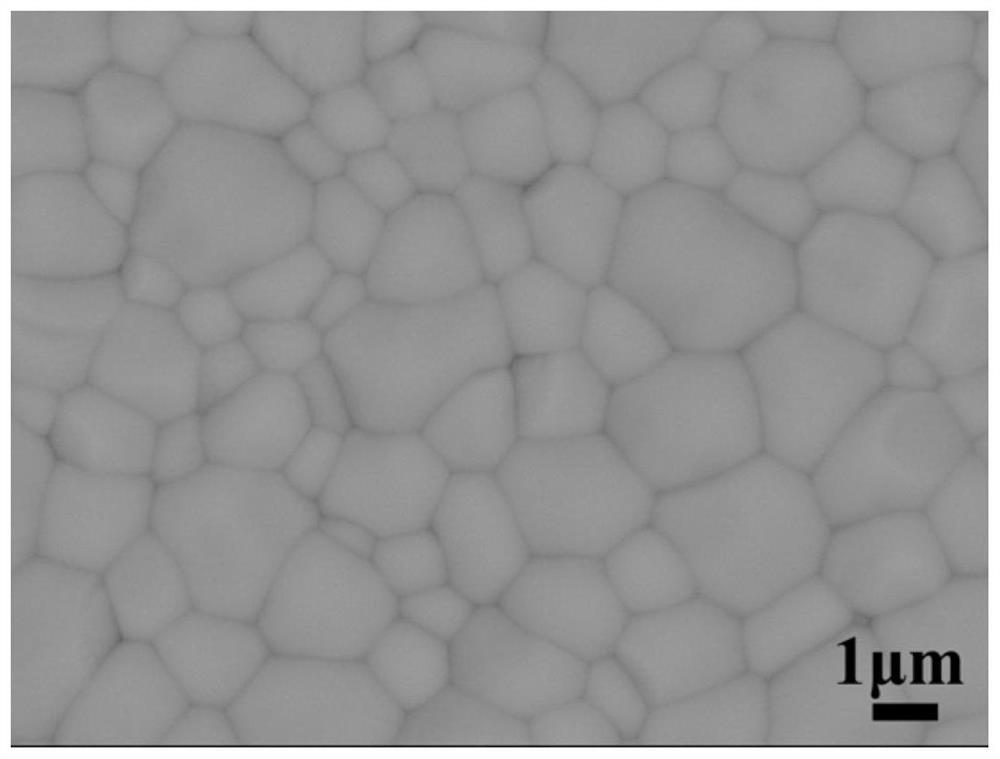

Image

Examples

Embodiment 1

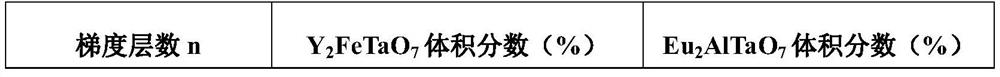

[0034] A kind of A2B2O7 type rare earth tantalate ceramics, the structure formula of this ceramics is Y 2 FeTaO 7 , the preparation method of the ceramics comprises the following steps:

[0035] Step 1: Follow Y 2 FeTaO 7 The structural formula will be the appropriate amount of Y 2 o 3 and Fe 2 o 3 respectively dissolved in concentrated nitric acid for reaction, and the pH was adjusted to about 1, and then the prepared TaOCl 3Add the solution drop by drop (the dropping speed is 200mL / min), keep stirring, and at the same time add ammonia water to stabilize the pH of the system at 9-10, after stirring for 1 hour, continue stirring for 30 minutes in a water bath environment at 100°C, and then use Wash the precipitate with ionic water until PH = 7, put the obtained filter cake in an oven and dry it at 120°C for 5 hours, then pass through a 500-mesh sieve and sinter at 900°C for 5 hours, and pass the sintered powder through a 500-mesh sieve again spare.

[0036] Step 2: Pu...

Embodiment 2

[0039] The difference from Example 1 is that the ceramic structural formula of Example 2 is Dy 2 FeTaO 7 , the preparation method of the ceramics is the same as in Example 1.

Embodiment 3

[0041] The difference from Example 1 is that the ceramic structural formula in Example 3 is Eu 2 AlTaO 7 , the preparation method of the ceramics is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com