Double-rare-earth zirconate thermal barrier coating material and preparation method thereof

A technology of thermal barrier coating and zirconate, which is applied in the direction of sustainable transportation, climate sustainability, air transportation, etc., can solve the problems of low thermal expansion coefficient, unfavorable bonding layer matching, large internal stress of materials, etc., and achieve impurity The effect of low content, reduced thermal mismatch stress, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing the double rare earth zirconate thermal barrier coating material, comprising the following steps:

[0035] (1) The Nd 2 O 3 , Dy 2 O 3 , ZrO 2 calcined to obtain calcined Nd 2 O 3 , Dy 2 O 3 , ZrO 2 ;

[0036] (2) The calcined Nd 2 O 3 , Dy 2 O 3 , ZrO 2 Mixed with solvent, and then ball-milled to obtain mixed slurry;

[0037] (3) the mixed slurry is evaporated to dryness, calcined, and ground to obtain the mixture after primary grinding, and then the mixture after primary grinding is ball-milled, evaporated to dryness, and sieved to obtain mixed powder;

[0038] (4) pre-compressing the mixed powder into a block, and cold isostatic pressing to obtain a shaped block;

[0039] (5) Sintering the shaped block to obtain dense (Nd 1-x Dy x ) 2 Zr 2 O 7 ceramics.

[0040] In the present invention, in the step (1), the calcination temperature is preferably 900-1100°C, more preferably 1000°C; the ca...

Embodiment 1

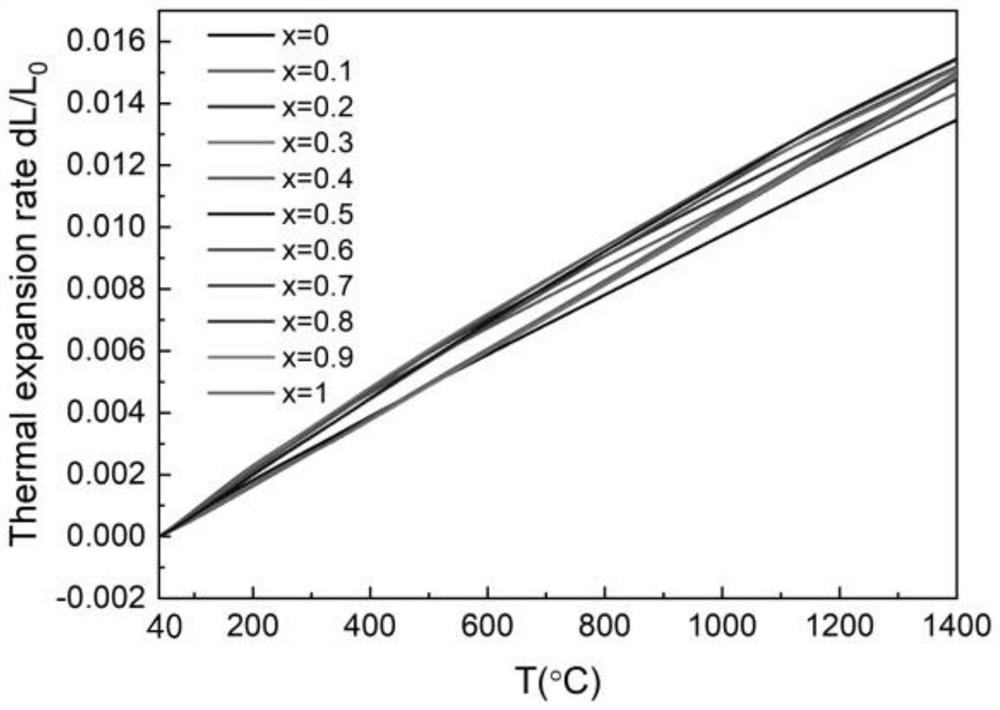

[0052] High temperature and high thermal expansion coefficient (Nd 0.9 Dy 0.1 ) 2 Zr 2 O 7 Preparation of ceramic materials:

[0053] (1) The Nd 2 O 3 , Dy 2 O 3 , ZrO 2 After calcining at 1000℃ for 5h, after cooling to room temperature, Nd was weighed in molar ratio. 2 O 3 , Dy 2 O 3 , ZrO 2 A total of 15 g of the powder was mixed in 100 mL of anhydrous ethanol, and then placed in a planetary ball mill for ball milling (the speed of the ball mill was 250 r / min, and the ball milling time was 4 h). 1200 ℃ calcined for 5h.

[0054] (2) After calcination, grind the mixed powder evenly, and place it in a planetary ball mill for ball milling (the speed of the ball mill is 250r / min, and the ball milling time is 10h); the ball milled powder is dried by rotary evaporation and passed through a 200-mesh sieve to obtain fine powder Then press hydraulic pressure into cylinder blocks of Φ15mm*1.5mm, and cuboid blocks of 55mm*6mm*4mm (the holding pressure of the cylindrical b...

Embodiment 2

[0058] High temperature and high thermal expansion coefficient (Nd 0.8 Dy 0.2 ) 2 Zr 2 O 7 Preparation of ceramic materials:

[0059] (1) The Nd 2 O 3 , Dy 2 O 3 , ZrO 2 After calcining at 1000℃ for 5h, after cooling to room temperature, Nd was weighed in molar ratio. 2 O 3 , Dy 2 O 3 , ZrO 2 A total of 15 g of the powder was mixed in 100 mL of anhydrous ethanol, and then placed in a planetary ball mill for ball milling (the speed of the ball mill was 250 r / min, and the ball milling time was 4 h). 1200 ℃ calcined for 5h.

[0060] (2) After calcination, grind the mixed powder evenly, and place it in a planetary ball mill for ball milling (the speed of the ball mill is 250r / min, and the ball milling time is 10h); the ball milled powder is dried by rotary evaporation and passed through a 200-mesh sieve to obtain fine powder Then press hydraulic pressure into cylinder blocks of Φ15mm*1.5mm, and cuboid blocks of 55mm*6mm*4mm (the holding pressure of the cylindrical b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com