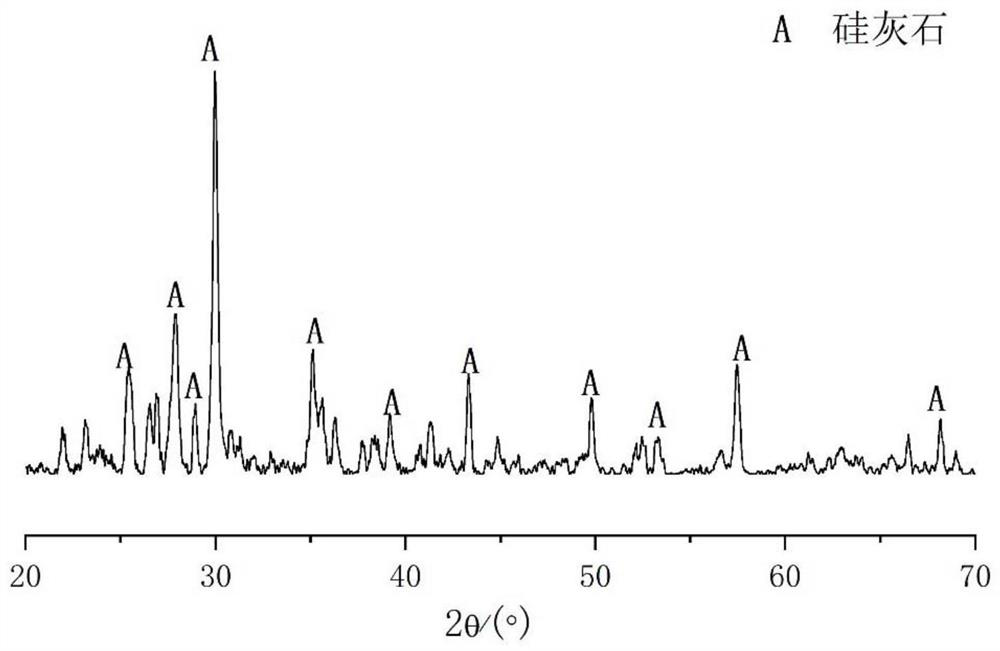

Method for preparing porous wollastonite ceramic membrane for membrane distillation desalination through dry pressing by taking blast furnace slag as main raw material

A main raw material, dry pressing technology, applied in the field of desalination, can solve the problem of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

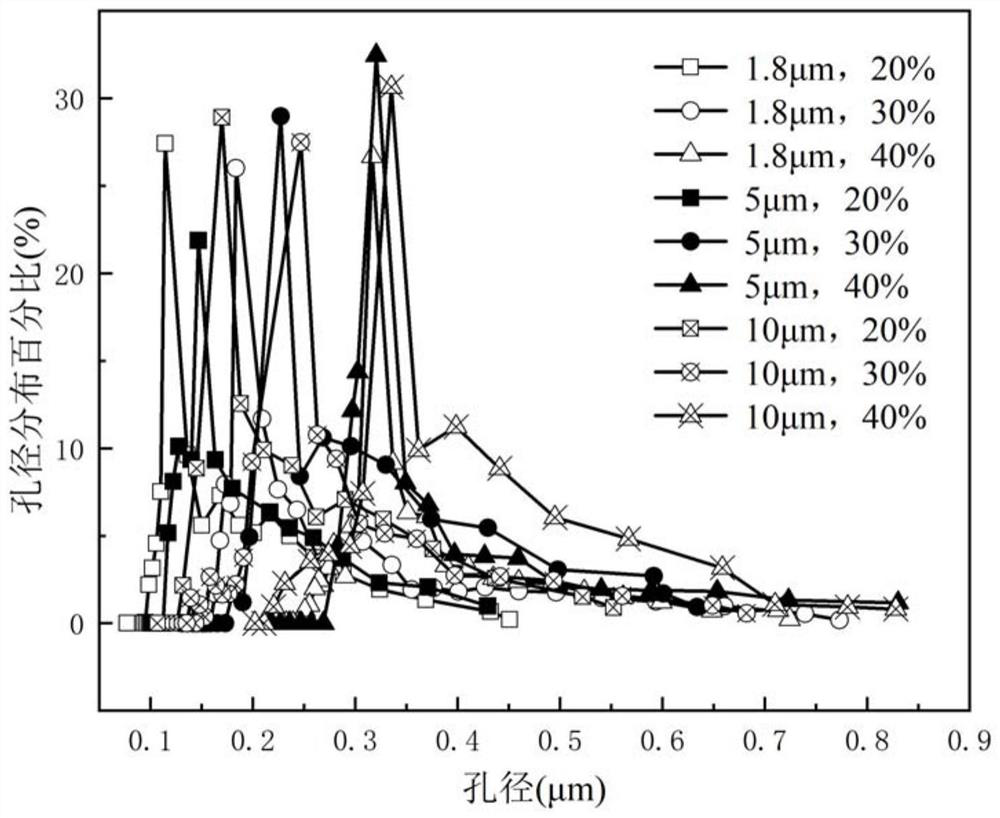

Embodiment 1

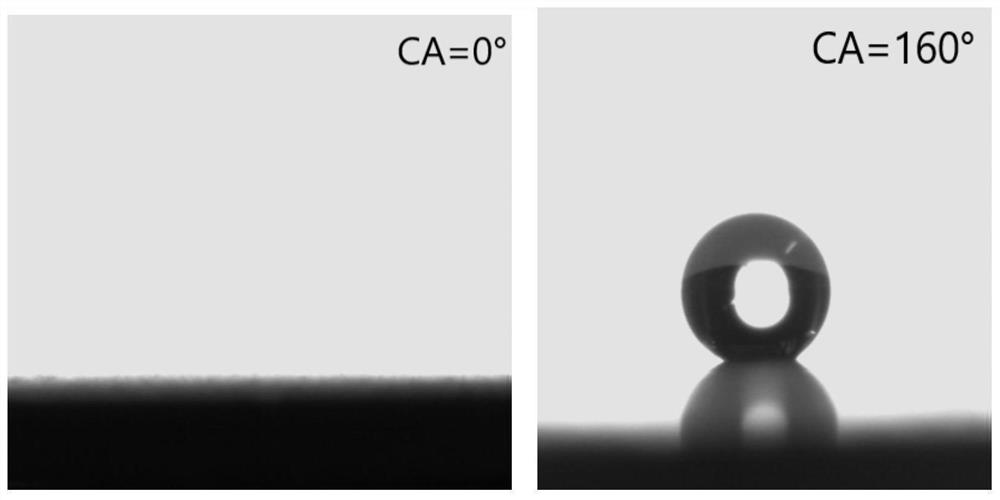

[0026] Weigh 42g of blast furnace slag and 13.22g of SiO 2 , 4.78g CaO, and 40g of PMMA powder with a particle size of 10μm was weighed and added to the ball milling jar together. The addition amount of the two symmetrical ball milling jars was the same. Add 150ml of absolute ethanol to each ball milling jar and mill for 5 hours. Then transfer the ball-milled slurry to a beaker, put it in a drying oven at 80° C. for 12 hours, grind the dried sample, and pass through a 200-mesh standard sieve. Weigh 1.2 g of the sieved powder and put it into a circular abrasive tool, hold the pressure at 20 MPa for 1 min, and press it into a tablet. After room temperature, take it out and wash it alternately with deionized water and ethanol, and dry it at 100°C for 24 hours. Take 10g of polymethylhydrogensiloxane and dissolve it in 90g of n-hexane to form polymethylhydrosiloxane with a mass fraction of 10% (too low the concentration of the modifier will make the surface of the ceramic membrane...

Embodiment 2

[0028] Weigh 49g of blast furnace slag and 15.42g of SiO 2 , 5.58g CaO, and weigh 30g of PMMA powder with a particle size of 10μm and add them to the ball milling jar together. The two symmetrical ball milling jars have the same amount of addition. Add 150ml of absolute ethanol to each ball milling jar and mill for 5 hours. Then transfer the ball-milled slurry to a beaker, put it in a drying oven at 80° C. for 12 hours, grind the dried sample, and pass through a 200-mesh standard sieve. Weigh 1.2 g of the sieved powder and put it into a circular abrasive tool, hold the pressure at 20 MPa for 1 min, and press it into a tablet. After room temperature, take it out and wash it alternately with deionized water and ethanol, and dry it at 100°C for 24 hours. Get 10g of polymethylhydrogensiloxane and dissolve it in 90g of n-hexane to form a polymethylhydrogensiloxane organic solution with a mass fraction of 10%, transfer the dried ceramic sheet to a porcelain boat, add the above solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com