Preparation method of high-strength biological zinc-magnesium alloy composite material

A technology of zinc-magnesium alloy and composite materials, which is applied in the field of medical materials, can solve the problems of zinc-magnesium alloy coatings not being able to effectively exert tightness, corrosion fatigue, and toxic ions, so as to improve biological activity and compatibility, and improve corrosion resistance ability, the effect of matching mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

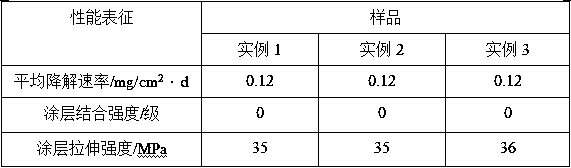

[0016] According to the mass ratio of 1:1, mix 200 mesh zinc powder and 200 mesh magnesium powder and place them in a crucible, place the crucible in a tube-type atmosphere furnace, and feed a mixed gas of sulfur hexafluoride and carbon dioxide in an equal volume ratio , remove the air, control the mixed gas flow rate to 45-50mL / min, then raise the temperature to 750-800°C at 5°C / min, heat-preserve and melt for 10-15min and pour into the mold, let it stand and cool to room temperature, demould and collect The alloy matrix is obtained; according to the molar ratio of 1:8:100, silicon dioxide, sodium oxide and 10% aqueous solution of tetrapropylammonium hydroxide are stirred and mixed, and placed at 75-85°C for 3-5 hours, and the reaction is obtained. Add the alloy matrix to the reaction solution at a mass ratio of 1:10, and place it at 180-200°C for heat preservation and crystallization treatment. After the crystallization is completed, collect the crystallization-coated matri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com