Polyoxometallic acid lithium salt ceramic membrane for lithium-ion battery

A lithium polyoxometalate, lithium ion battery technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as hindering the normal migration of lithium ions and poor ion conductivity, and achieve simple operation and environmental protection in the production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

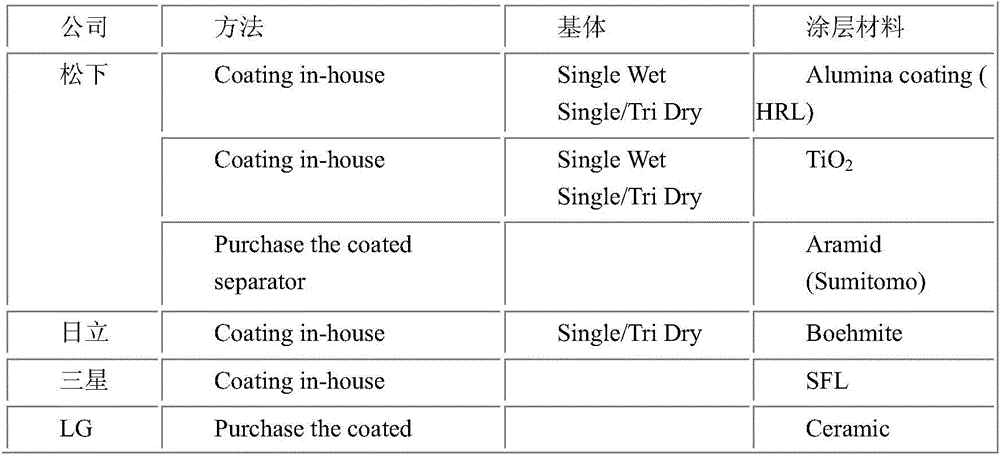

[0073] Will Al 2 o 3 Ceramic powder, Li 3 PMo 12 o 40 , Water-soluble modified polyvinylidene fluoride and water are weighed according to the mass ratio of 10:1:0.5:10, mixed and stirred evenly, configured into a slurry, and then transferred to the base of the diaphragm on the coating machine On the surface, a 1 μm coating was formed, dried in a coater oven at 75°C, and rolled.

Embodiment 2

[0075] Will Al 2 o 3 Ceramic powder, Li 3 PMo 12 o 40 , styrene-butadiene rubber and water are weighed at a mass ratio of 10:5:0.5:10, mixed and stirred evenly, configured into a slurry, and then transferred and coated on the diaphragm substrate on a coating machine to form a 10μm The coating is dried in a coater oven at 95°C and rolled up.

Embodiment 3

[0077] Will Al 2 o 3 Ceramic powder, Li 3 PMo 12 o 40 , propylene styrene rubber and water are weighed according to the mass ratio of 10:5:2:30, mixed and stirred evenly, configured into a slurry, and then transferred and coated on the diaphragm substrate on a coating machine to form a 5μm The coating is dried in a coater oven at 80°C and rolled up.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com