Patents

Literature

33 results about "Nuclear waste storage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

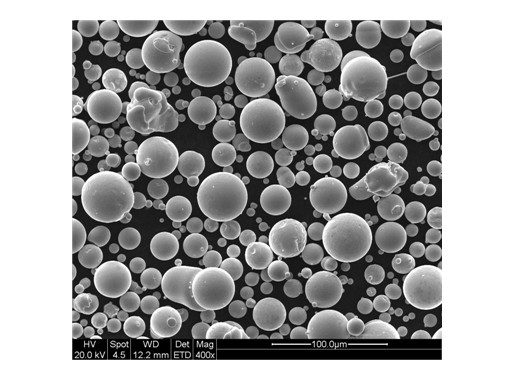

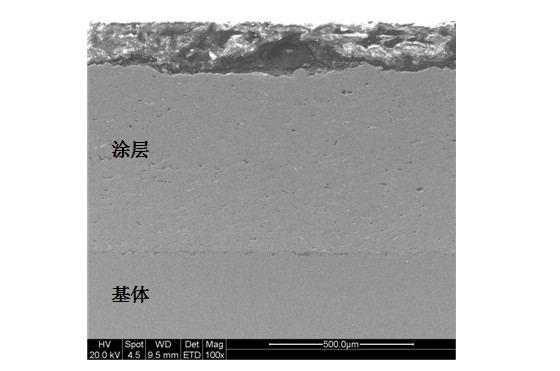

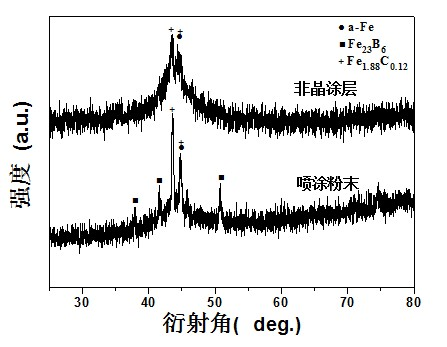

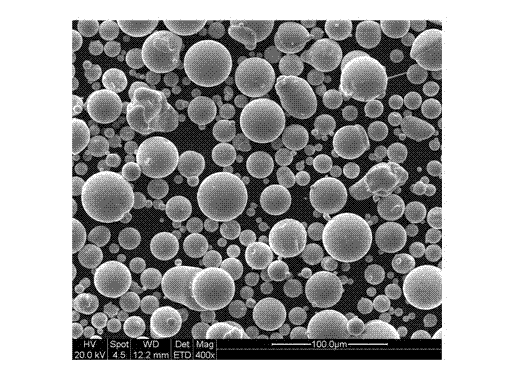

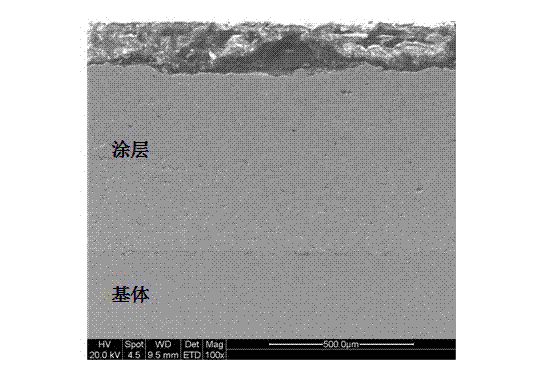

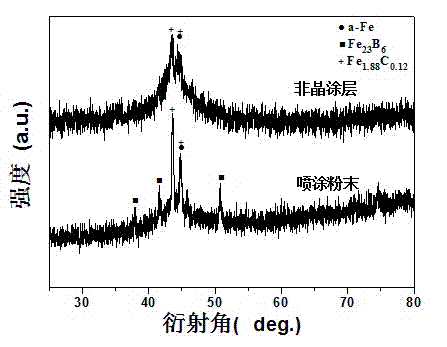

Preparation method of iron-based amorphous coating

InactiveCN102041468AImprove corrosion resistanceImprove liquidityMolten spray coatingPorosityAbsorption capacity

The invention provides a preparation method of an iron-based amorphous coating. Iron-based amorphous alloy powder is used as a raw material, and flame spraying is adopted to prepare the amorphous coating by activity combustion high speed fuel gas. The amorphous alloy powder contains the following elements and inevitable impurities: 16.0-19.0 of Cr; 1.0-3.0 of Mn; 4.0-9.0 of Mo; 1.0-3.0 of W; 13.0-17.0 of B; 2.5-4.5 of C; 1.0-3.5 of Si; and the balance of Fe. In the invention, preparation cost of the amorphous coating is reduced, the prepared iron-based amorphous coating and a substrate are bonded tightly, the structure is compact, the porosity and the oxygen content are very low, the iron-based amorphous coating has high hardness, excellent corrosion resistance and unique non-magnetism, thus the iron-based amorphous coating has a great application prospect in the field of ship, hydraulic, oil field development establishment, and nonmagnetic vessel hull; and because the content of B ishigher, the iron-based amorphous coating has favorable neutron absorption capacity, and can be used for a nuclear waste storage tank.

Owner:HUAZHONG UNIV OF SCI & TECH

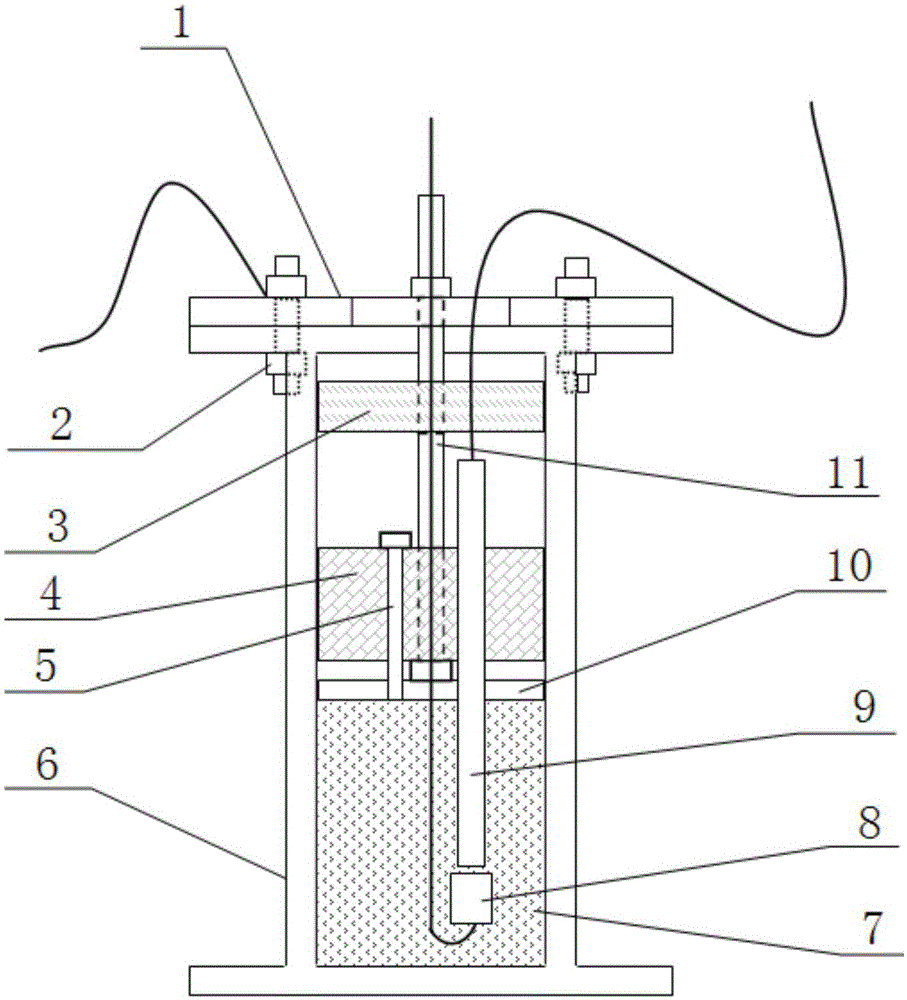

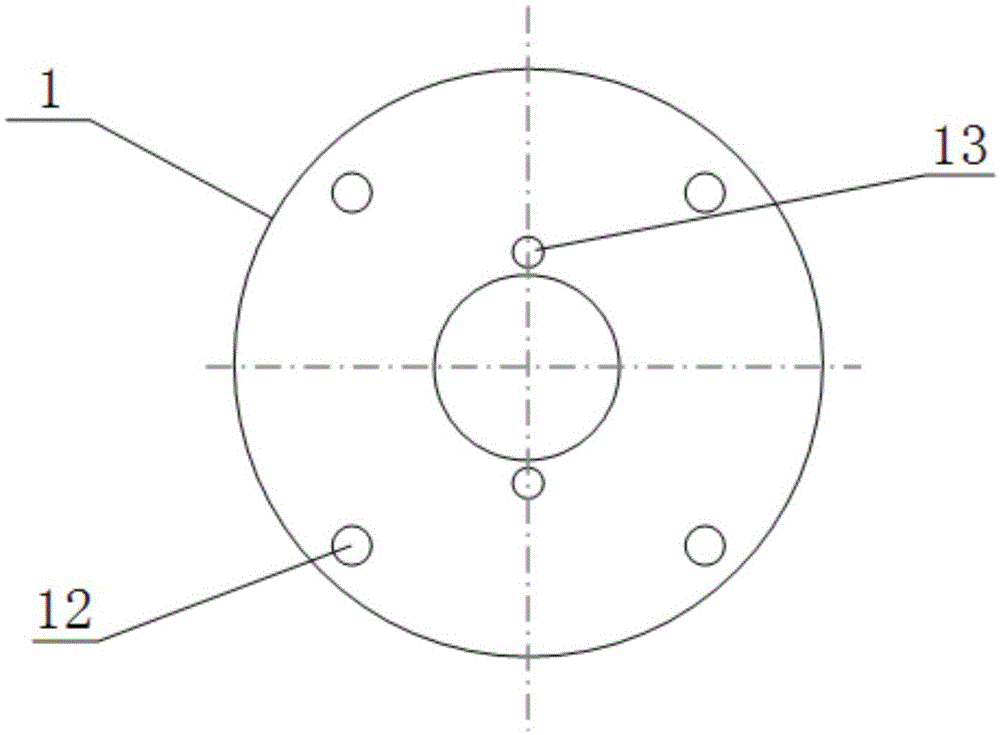

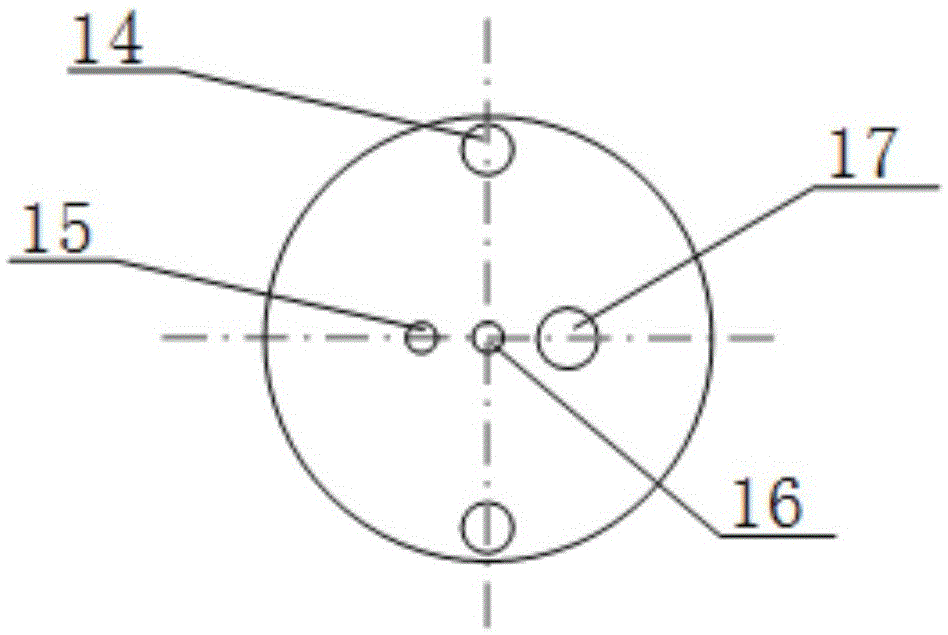

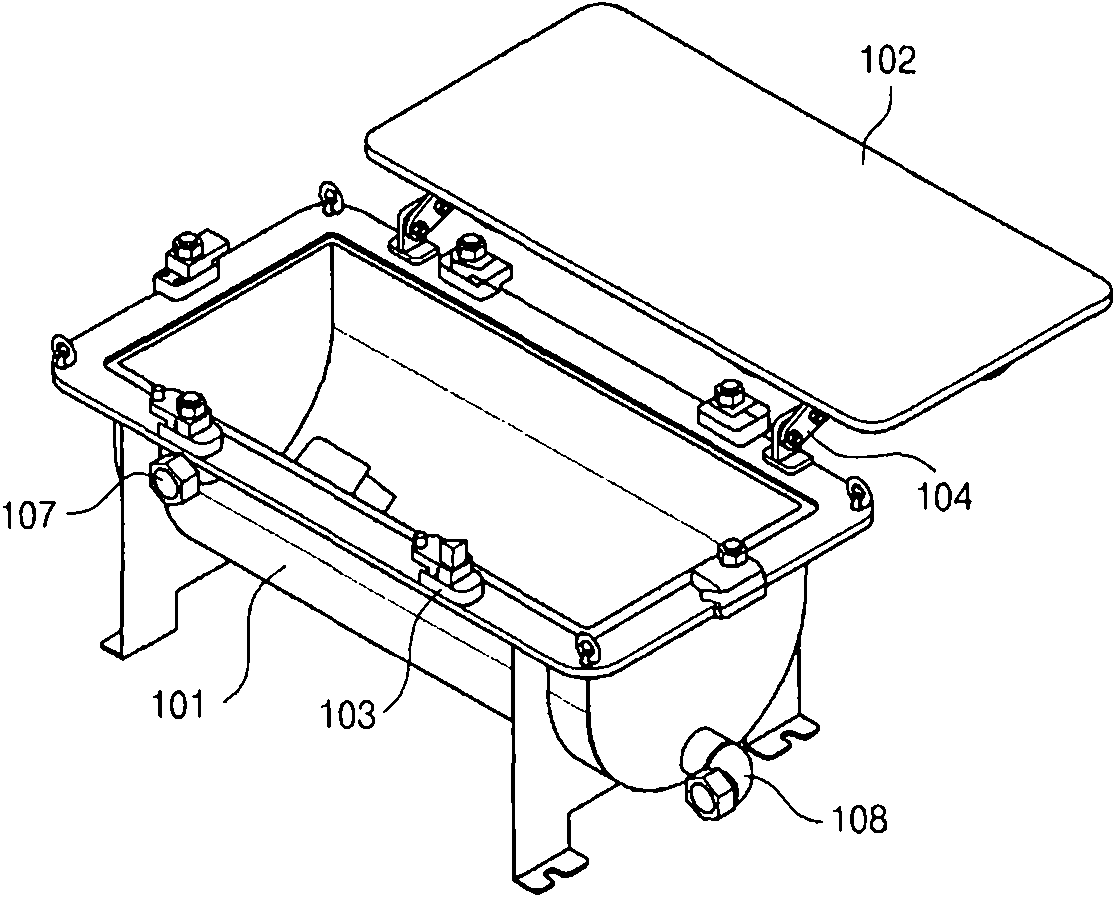

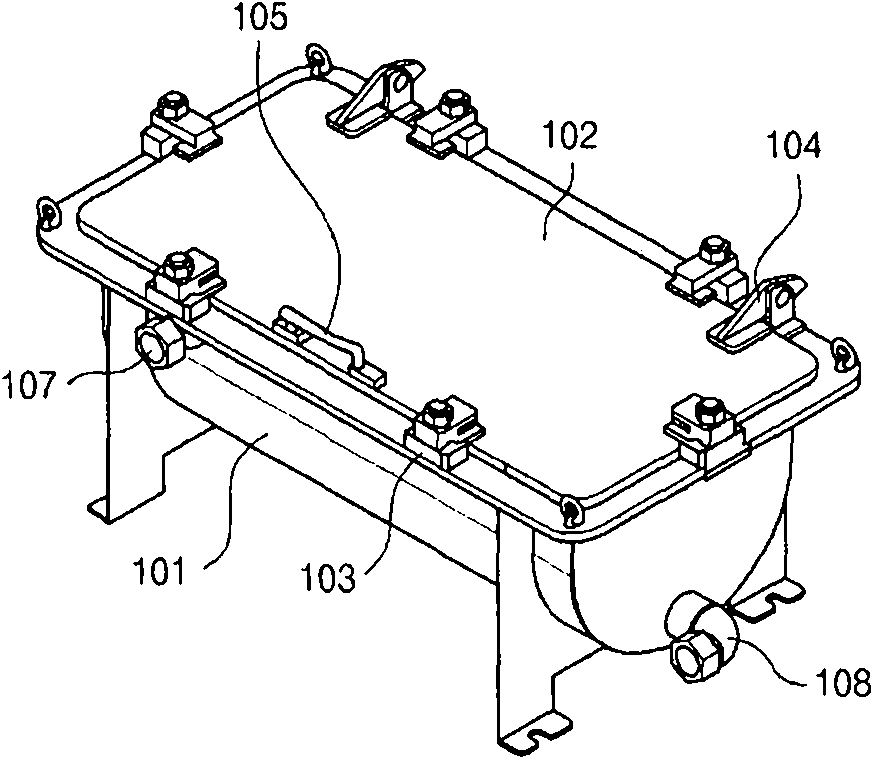

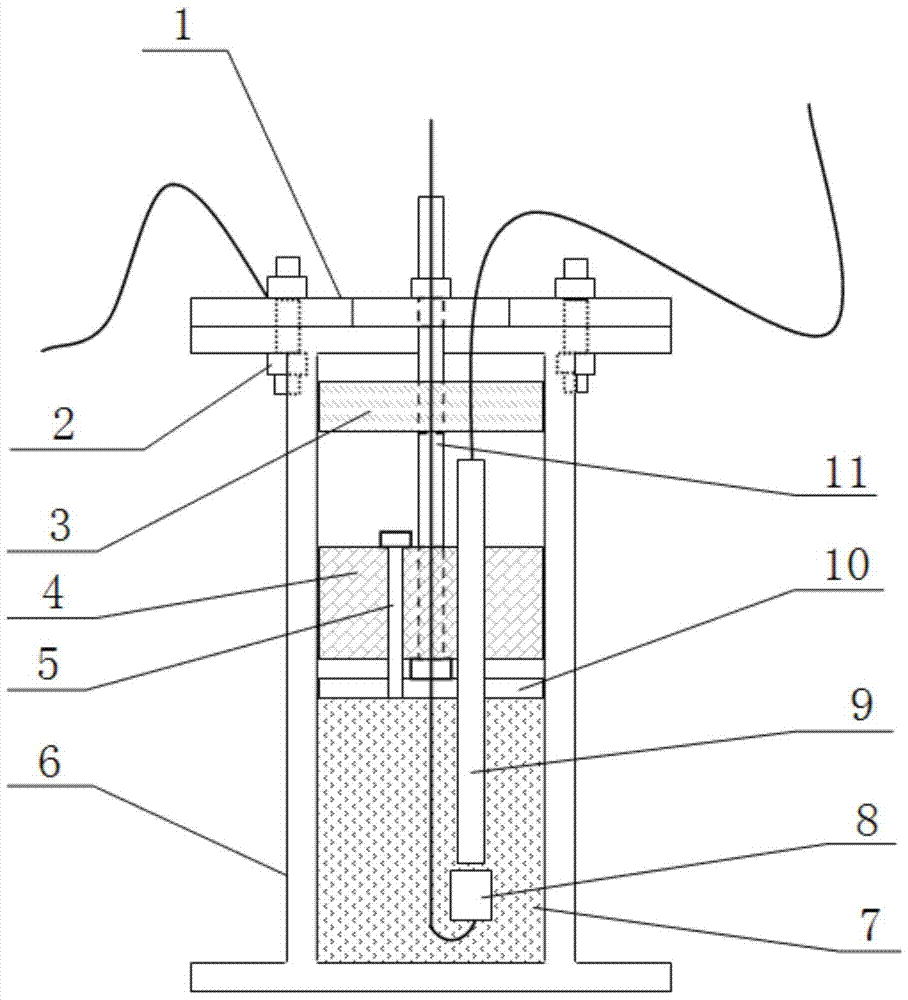

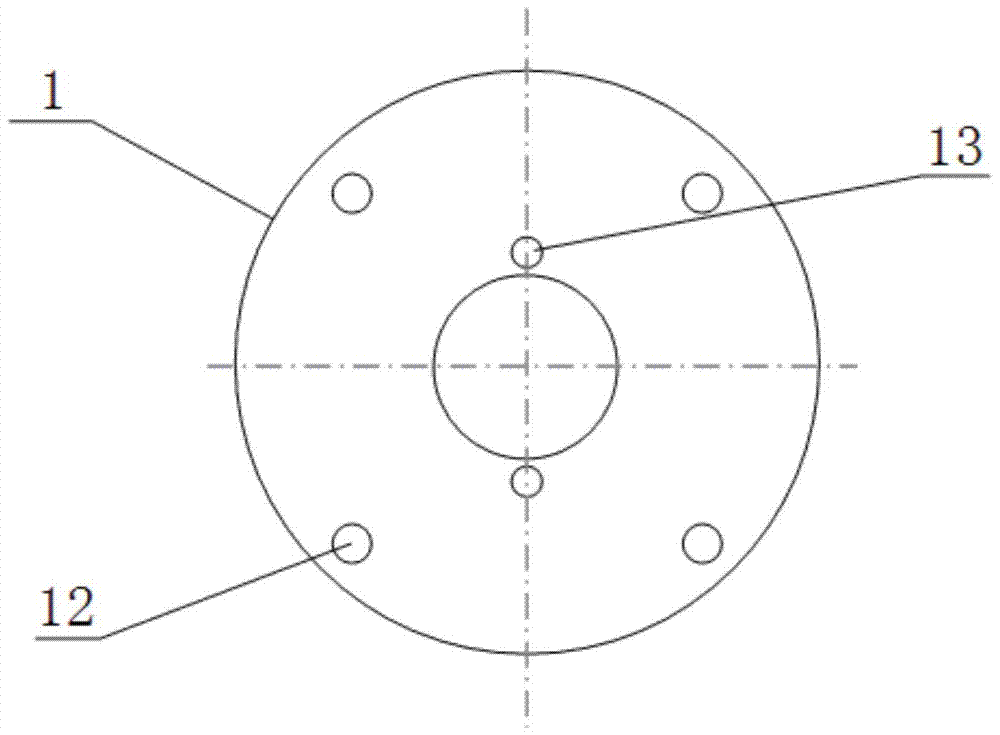

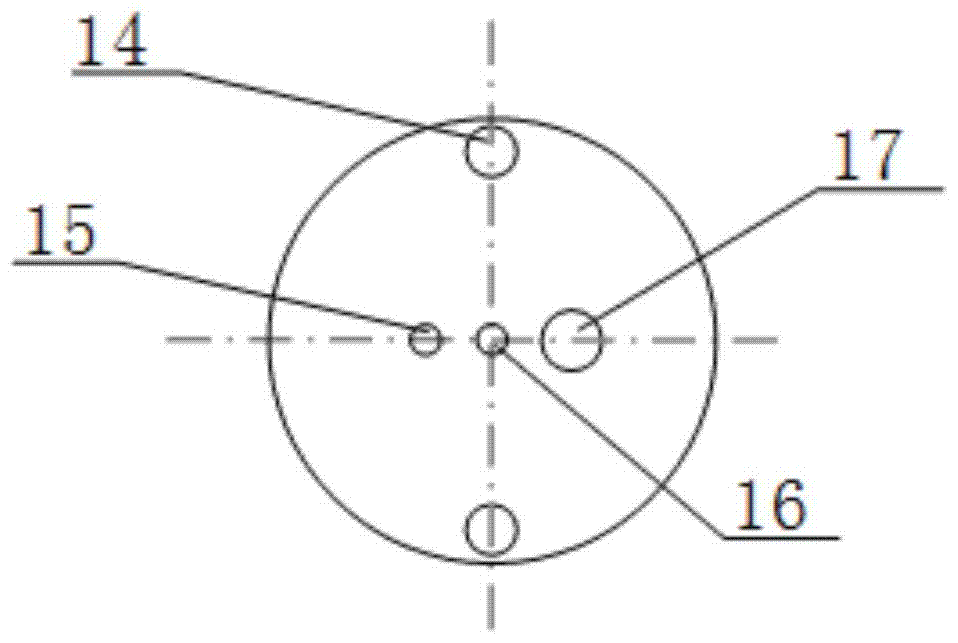

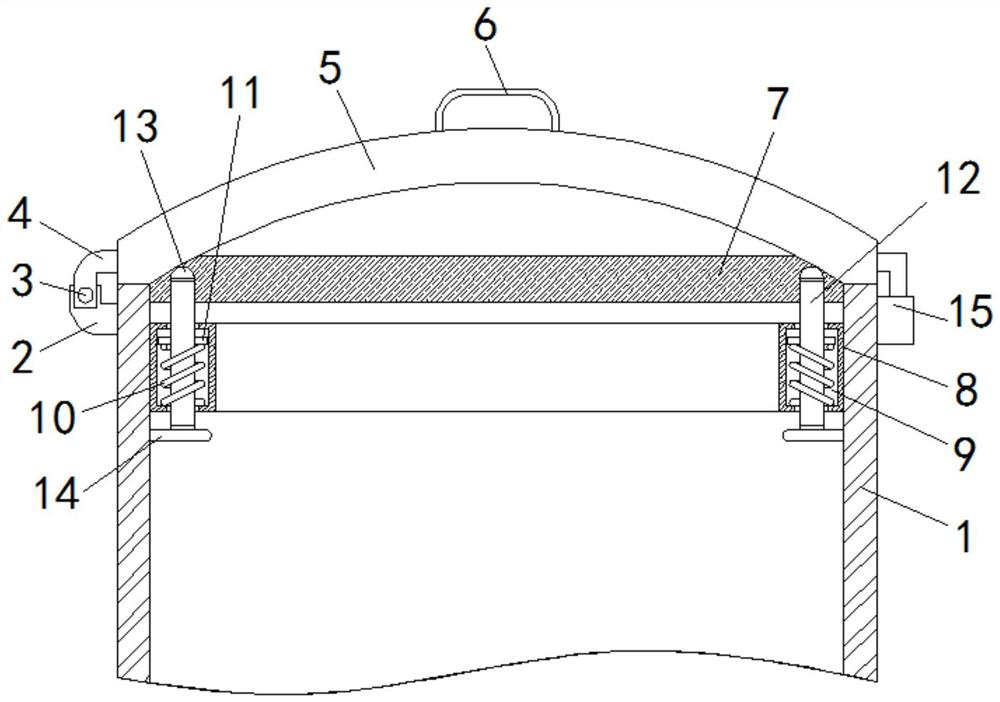

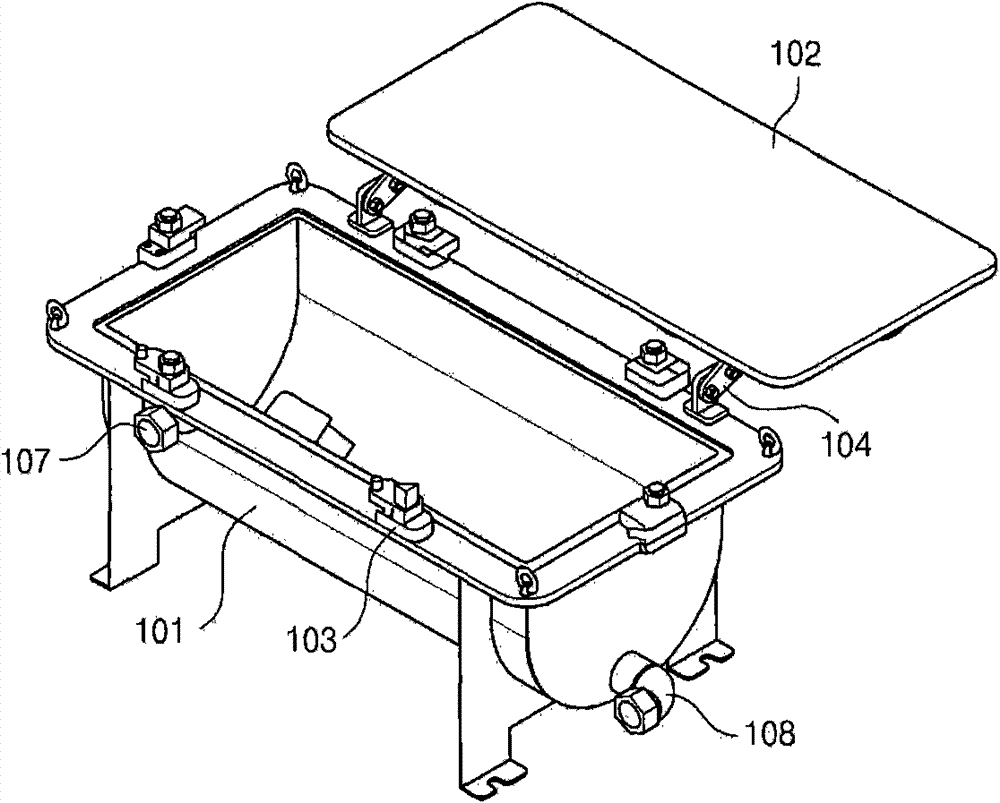

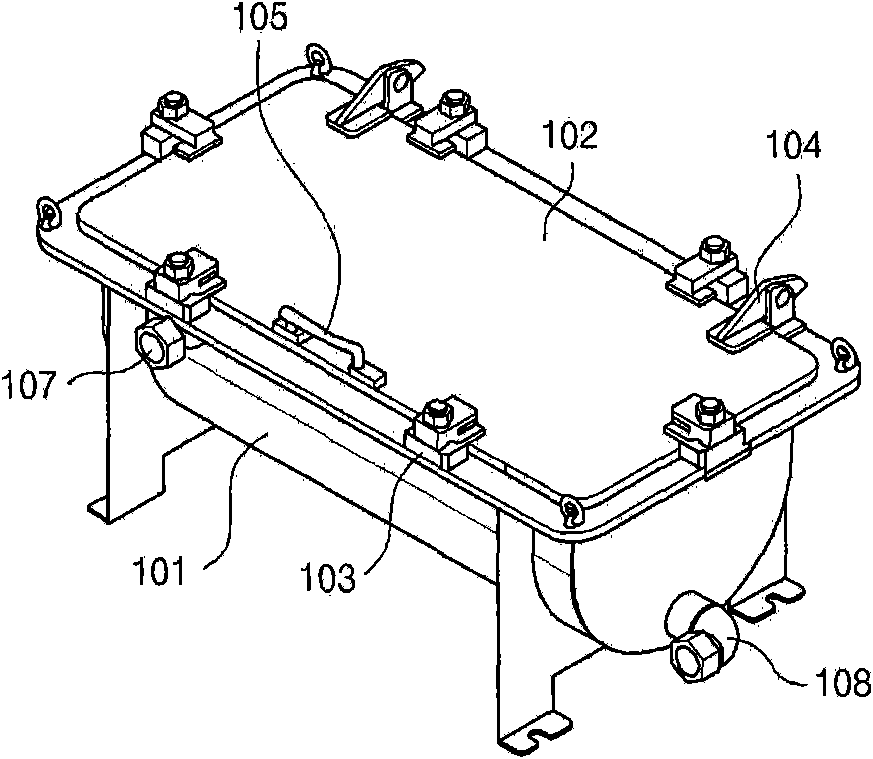

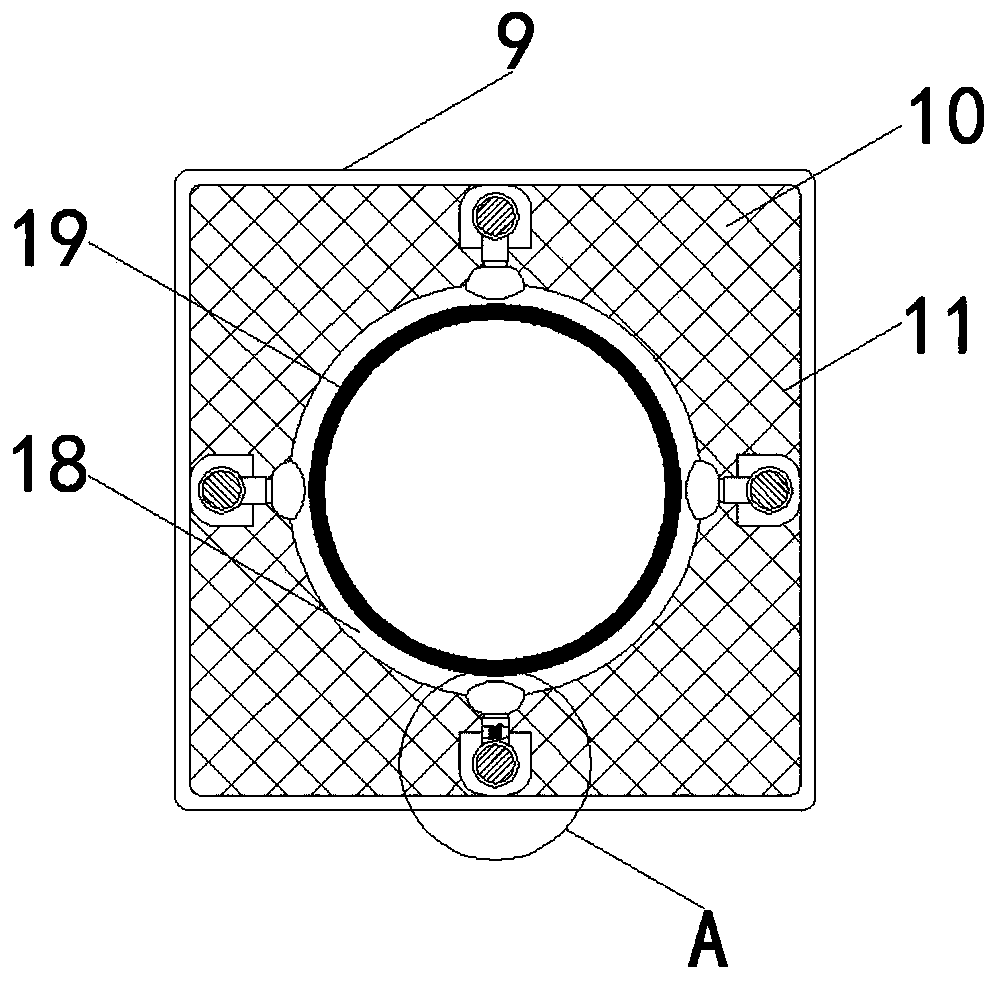

Metal material corrosion testing device and method under high-pressure densely-compacted bentonite environment

InactiveCN105115887ASolve preparation difficultiesAvoid concentration changesWeather/light/corrosion resistanceHigh pressureElectrochemistry

The invention belongs to the field of corrosion electrochemical testing, and particularly relates to a metal material corrosion testing device and method under a high-pressure densely-compacted bentonite environment. The metal material corrosion testing device comprises a high-pressure densely-compacted bentonite bearing cabin, as well as a bentonite compacting plate, a connection guide-out system, a three-electrode system and a seal plug which are arranged in the densely-compacted bentonite bearing cabin, wherein the bentonite compacting plate is connected with the high-pressure densely-compacted bentonite bearing cabin through the connection guide-out system, and is guided out of the densely-compacted bentonite bearing cabin through the connection guide-out system; the bentonite compacting plate is used for compacting bentonite loaded in the densely-compacted bentonite bearing cabin so as to prepare the densely-compacted bentonite; the seal plug is used for sealing the densely-compacted bentonite bearing cabin; and the three-electrode system is connected with an external electrochemical station through a lead for carrying out the testing on the metal material corrosion. The device and the method can truly simulate the deep geological environment in which a nuclear waste storage tank is buried, and the corrosion degree of the material of the storage tank in various burying stages can be obtained.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

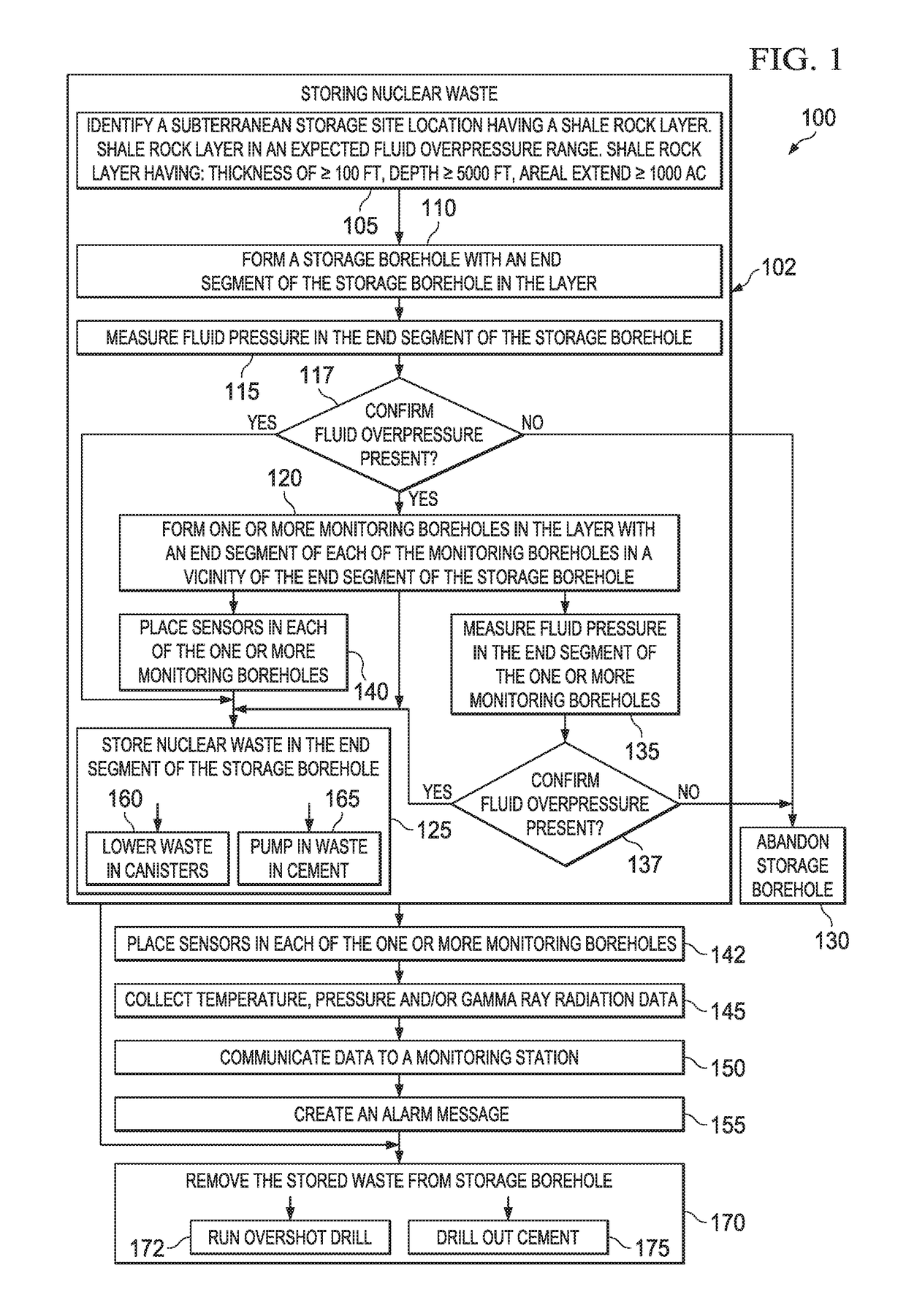

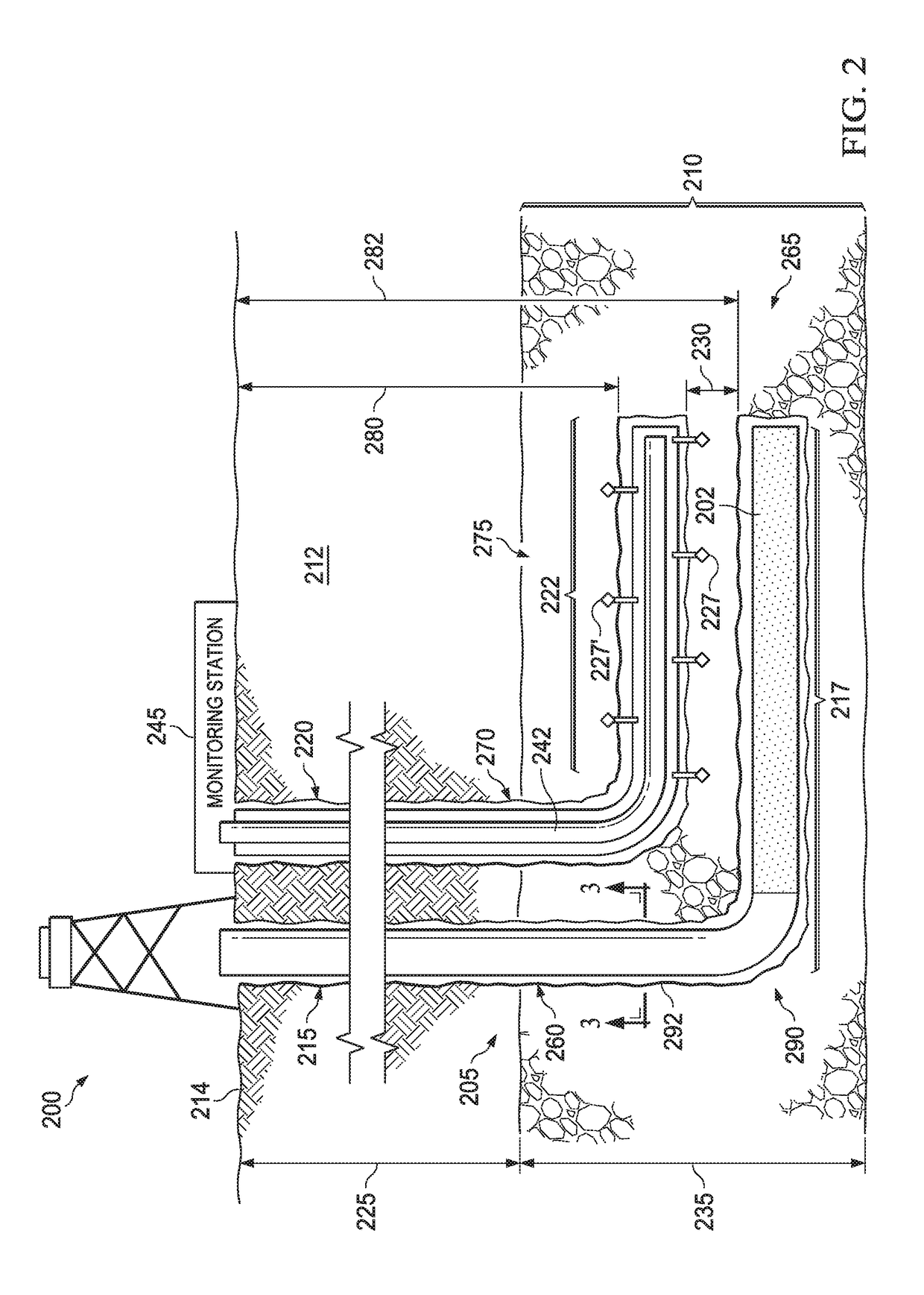

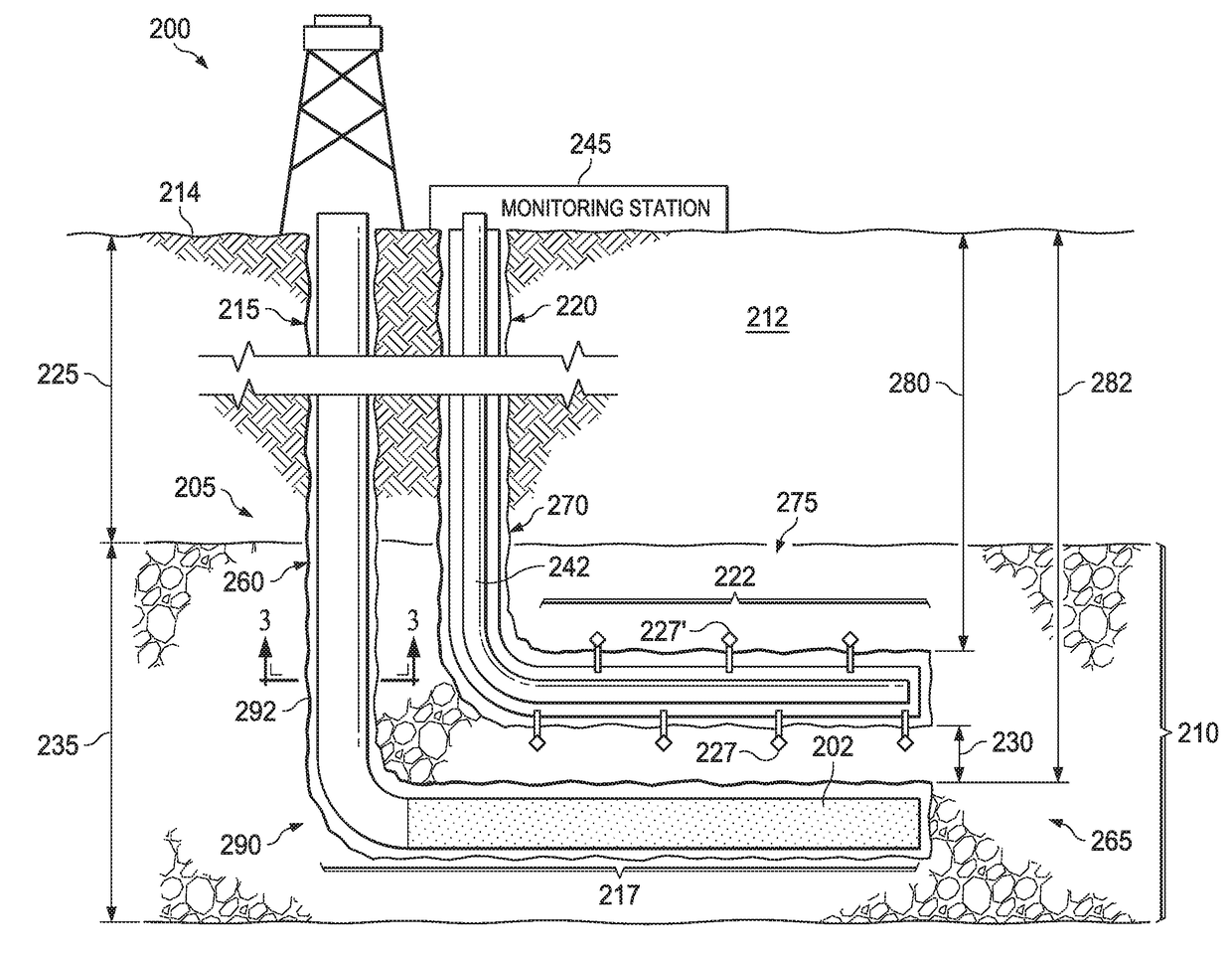

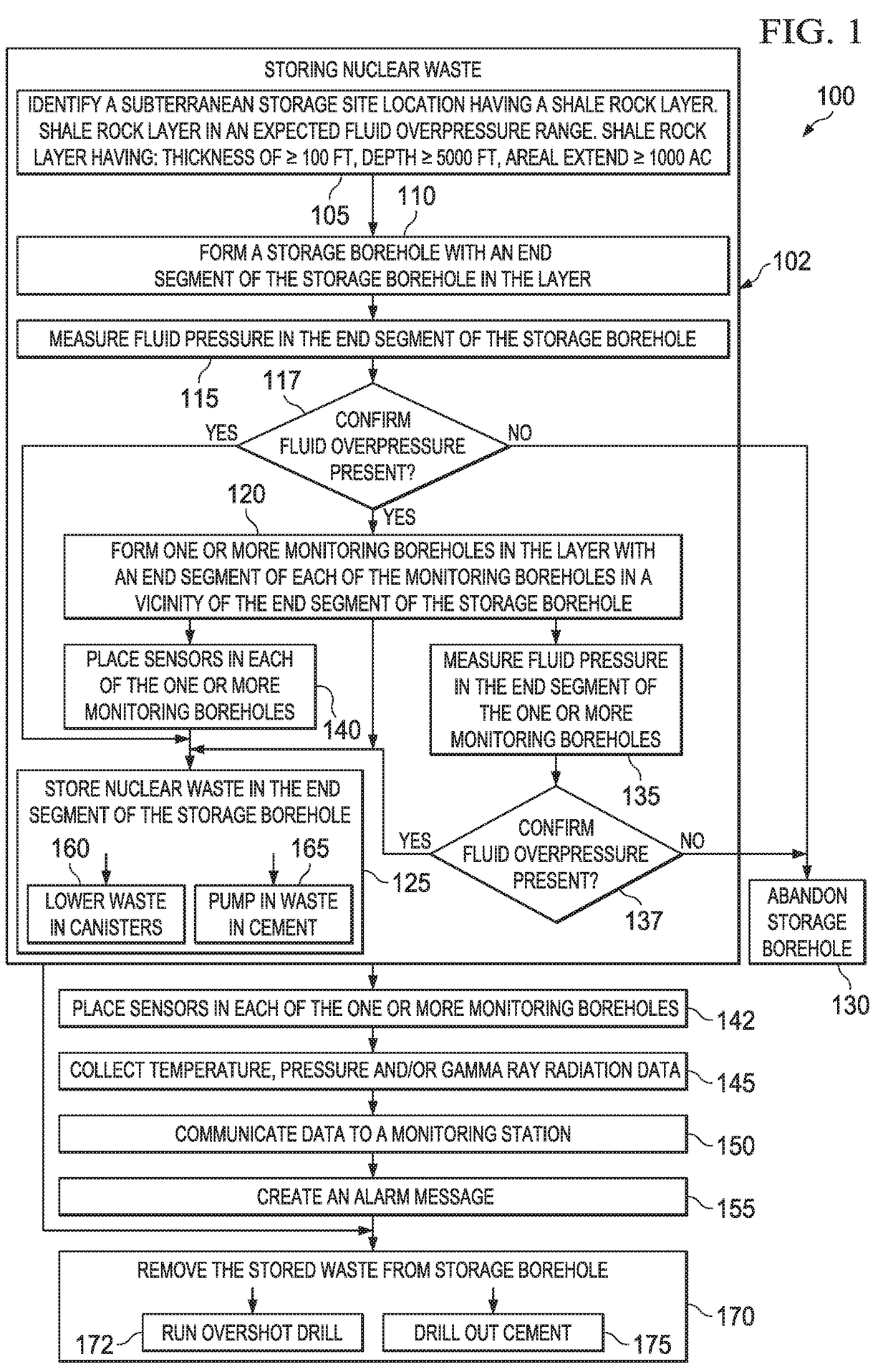

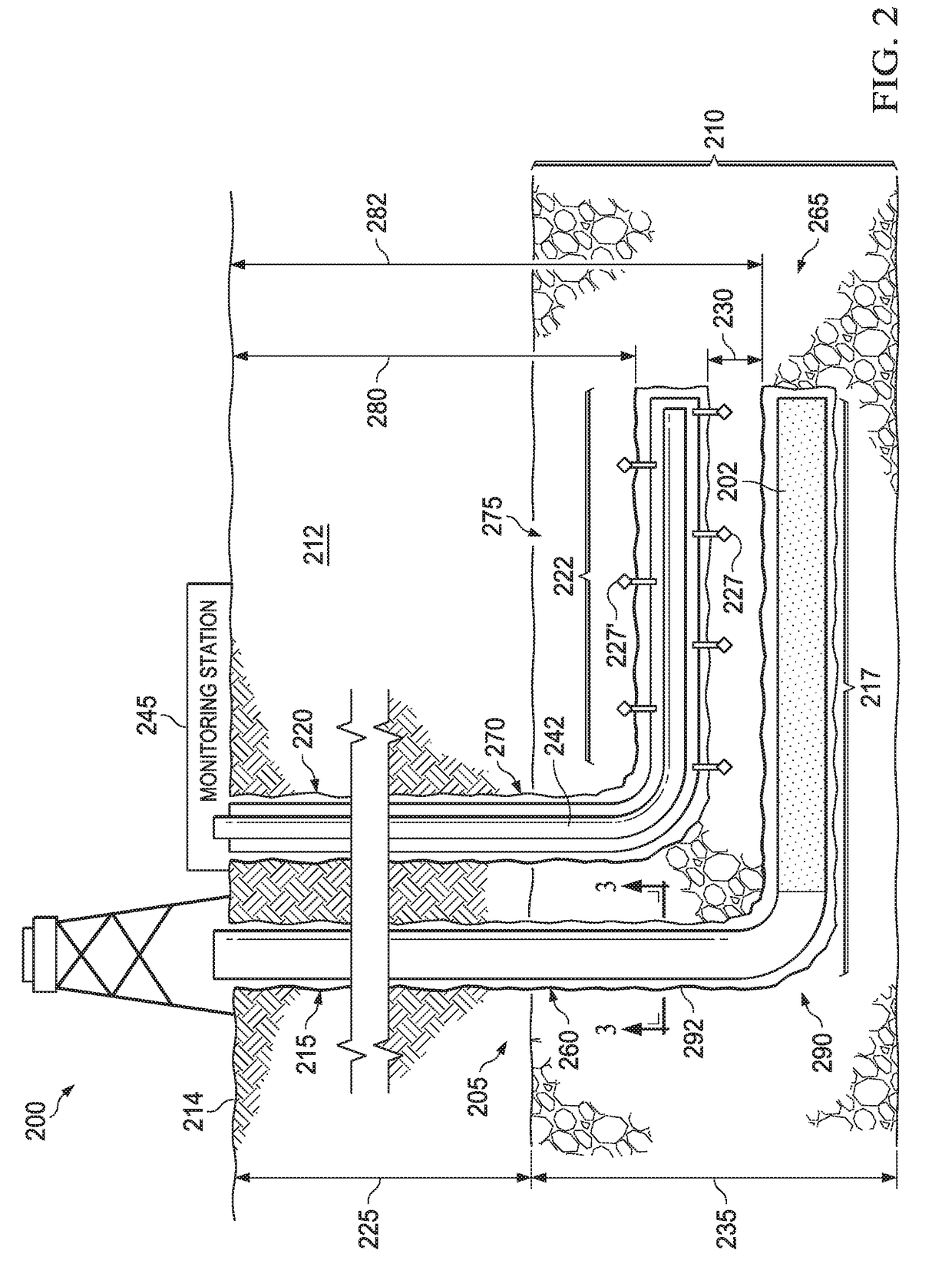

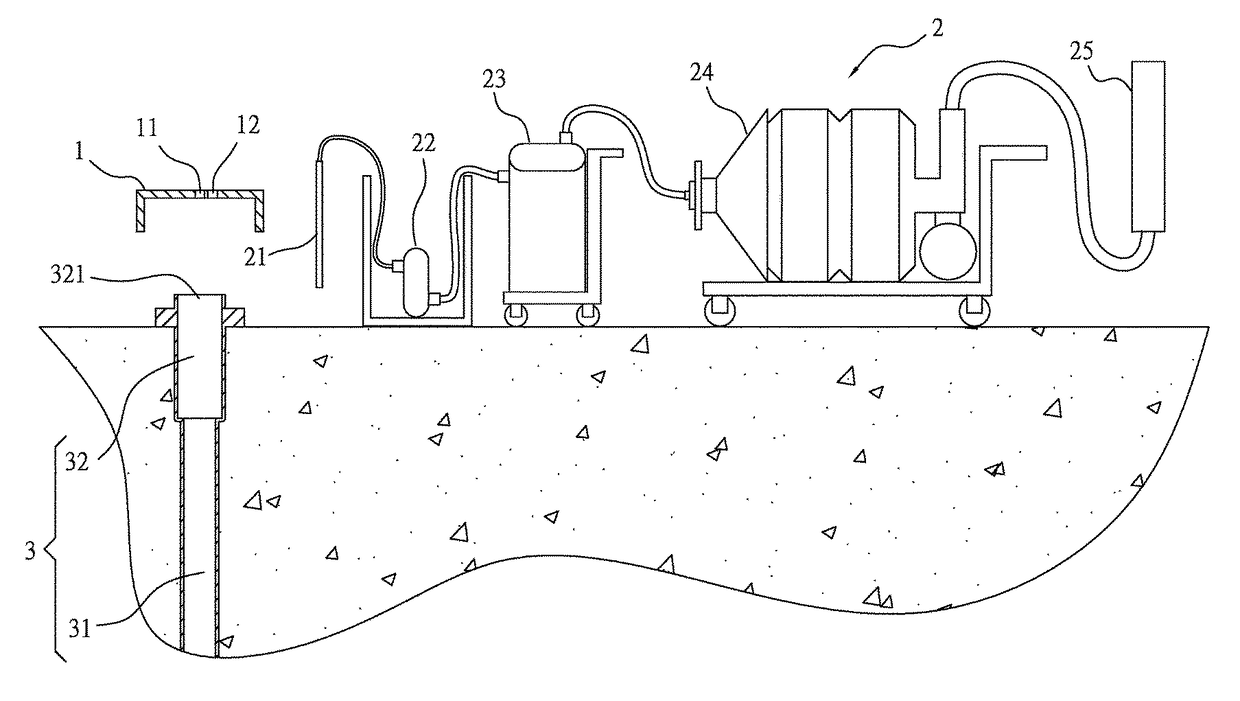

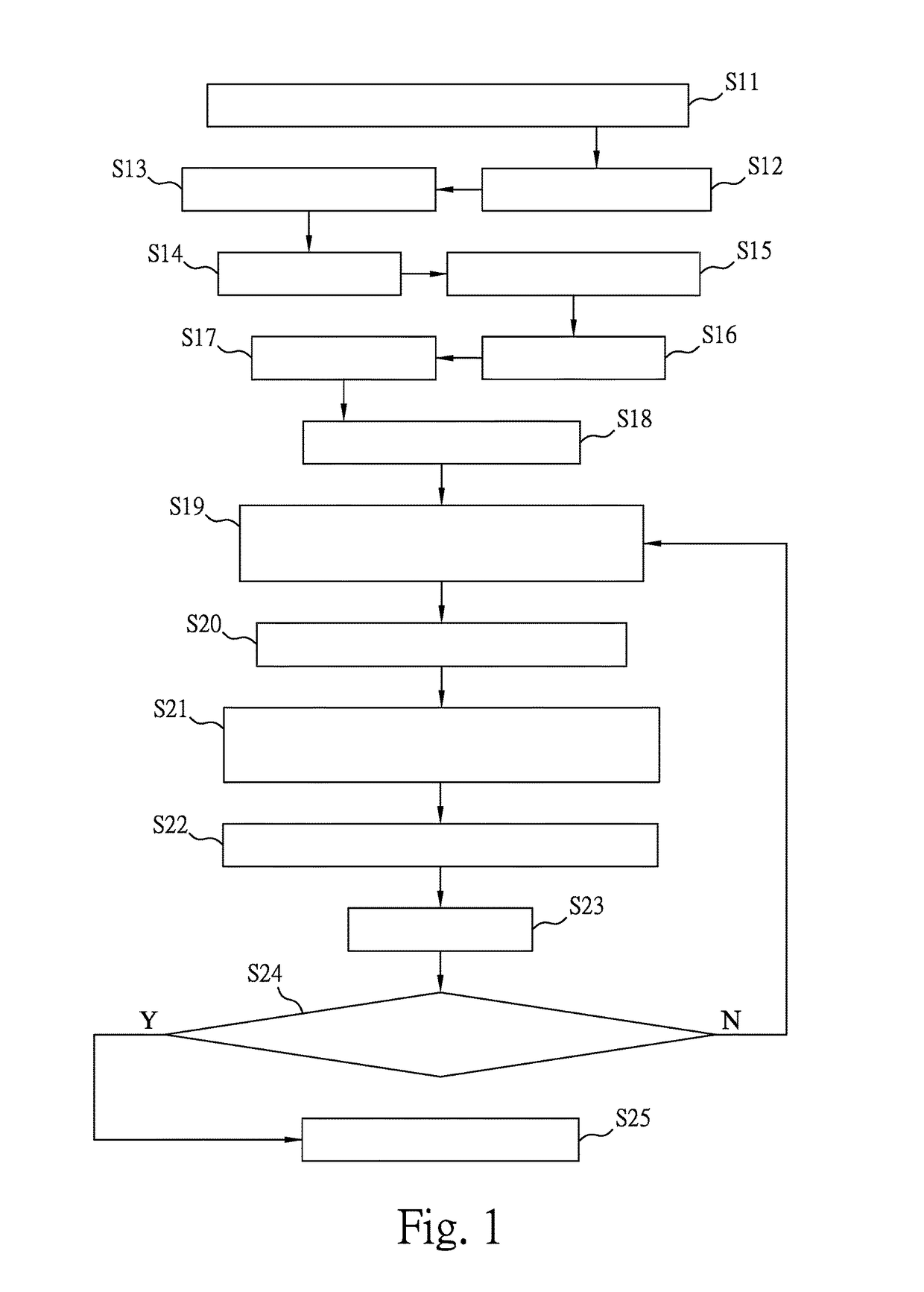

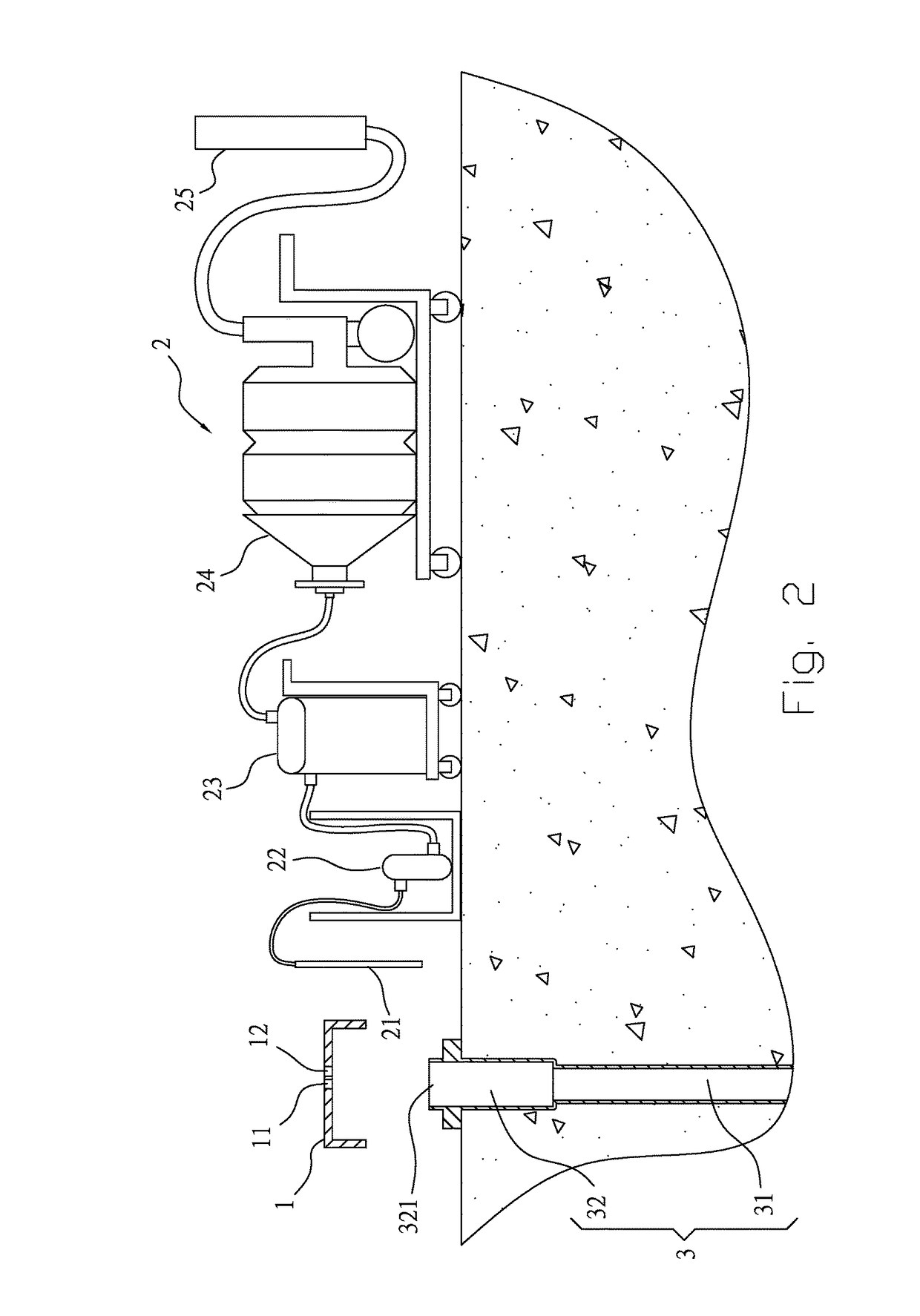

Method for nuclear waste storage and monitoring

A method comprising storing nuclear waste, including identifying a subterranean storage site location having a shale rock layer. The layer has an expected fluid overpressure in a range corresponding to greater than hydrostatic pressure to less than lithostatic pressure from overlying rock layers. Storing the waste can include forming a storage borehole, with an end segment of the storage borehole located within the layer and measuring the fluid pressure in the end segment of the storage borehole. If the measured fluid pressure in the end segment of the storage borehole is in the expected fluid overpressure range, forming a monitoring borehole in the layer with an end segment of each of the monitoring boreholes being in a vicinity of the end segment of the storage borehole and storing nuclear waste in the end segment of the storage borehole. A system for storing and monitoring nuclear waste is also described.

Owner:MWD IP HLDG LLC

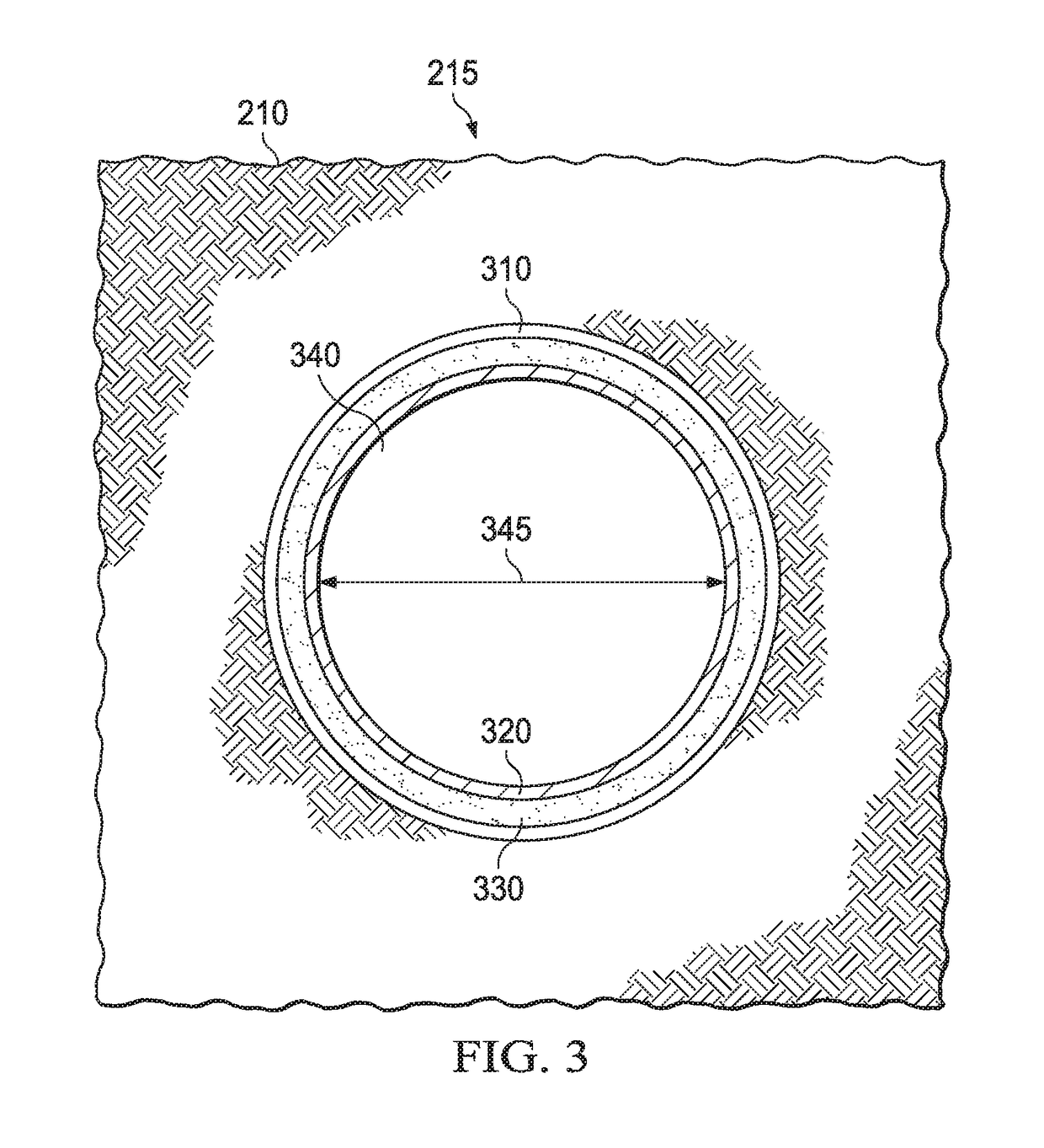

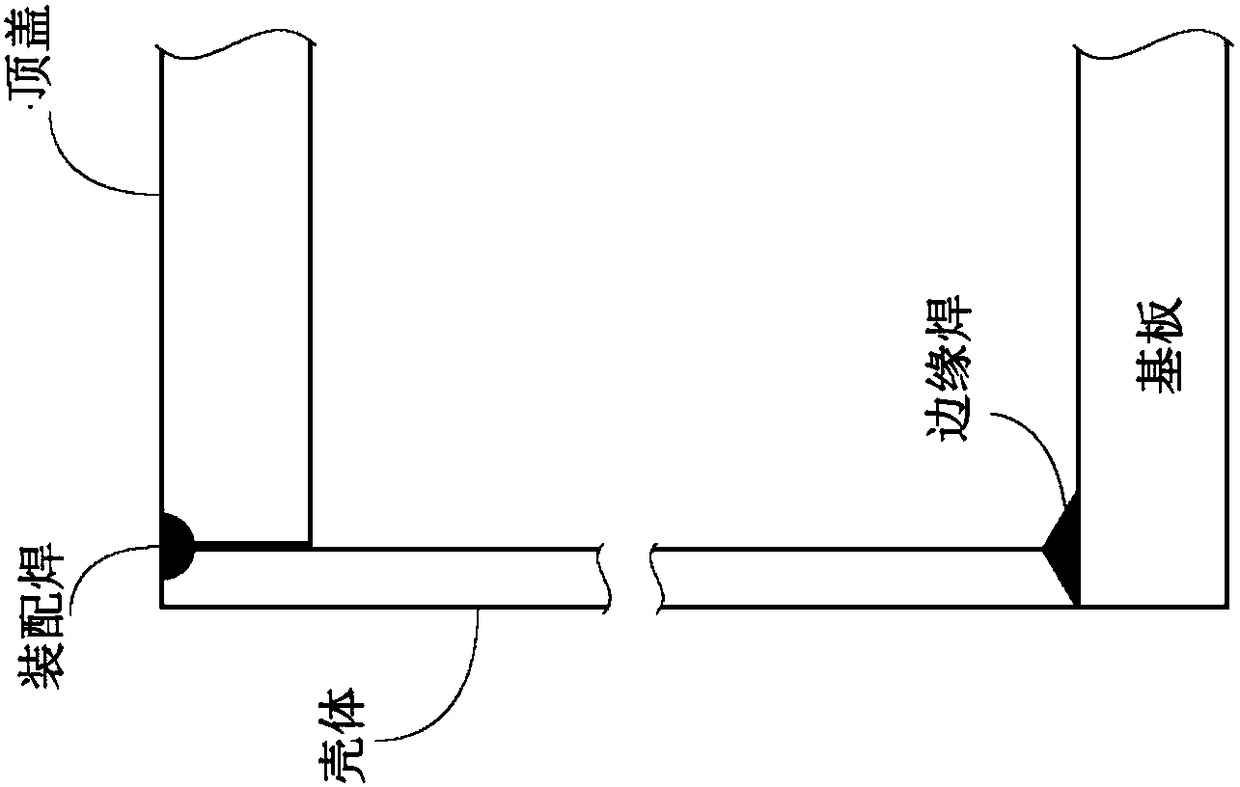

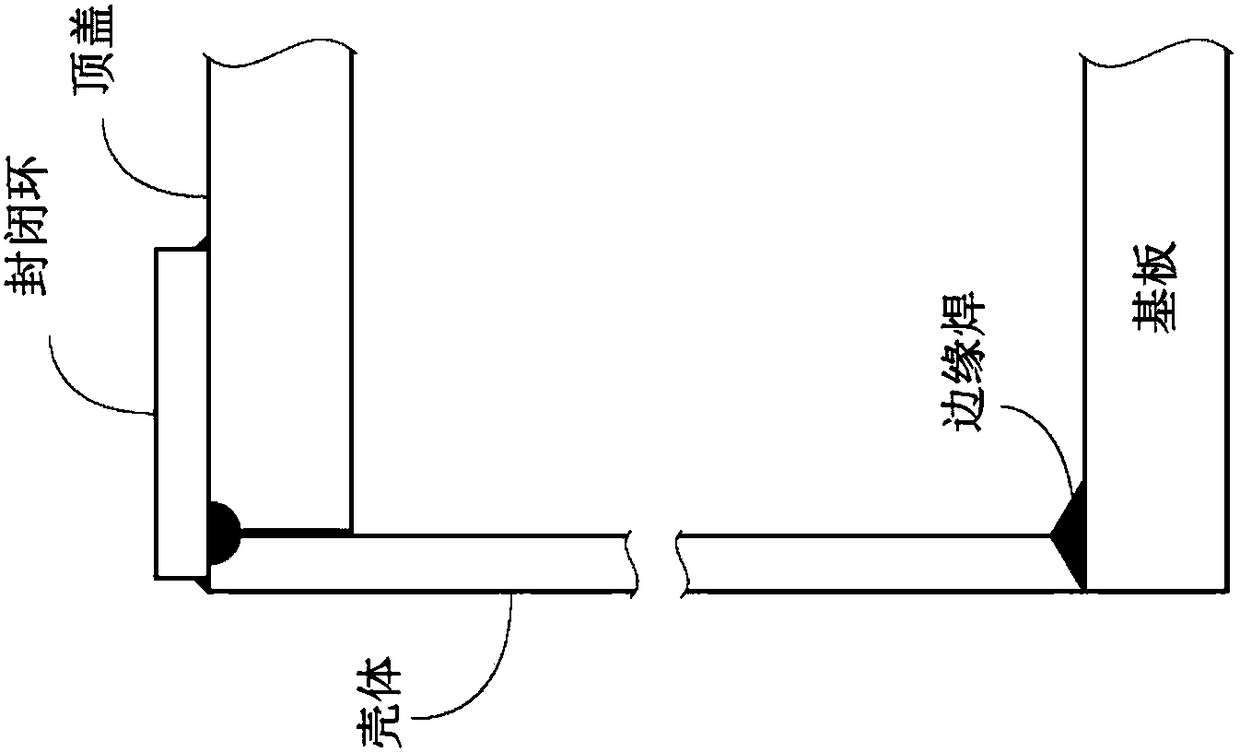

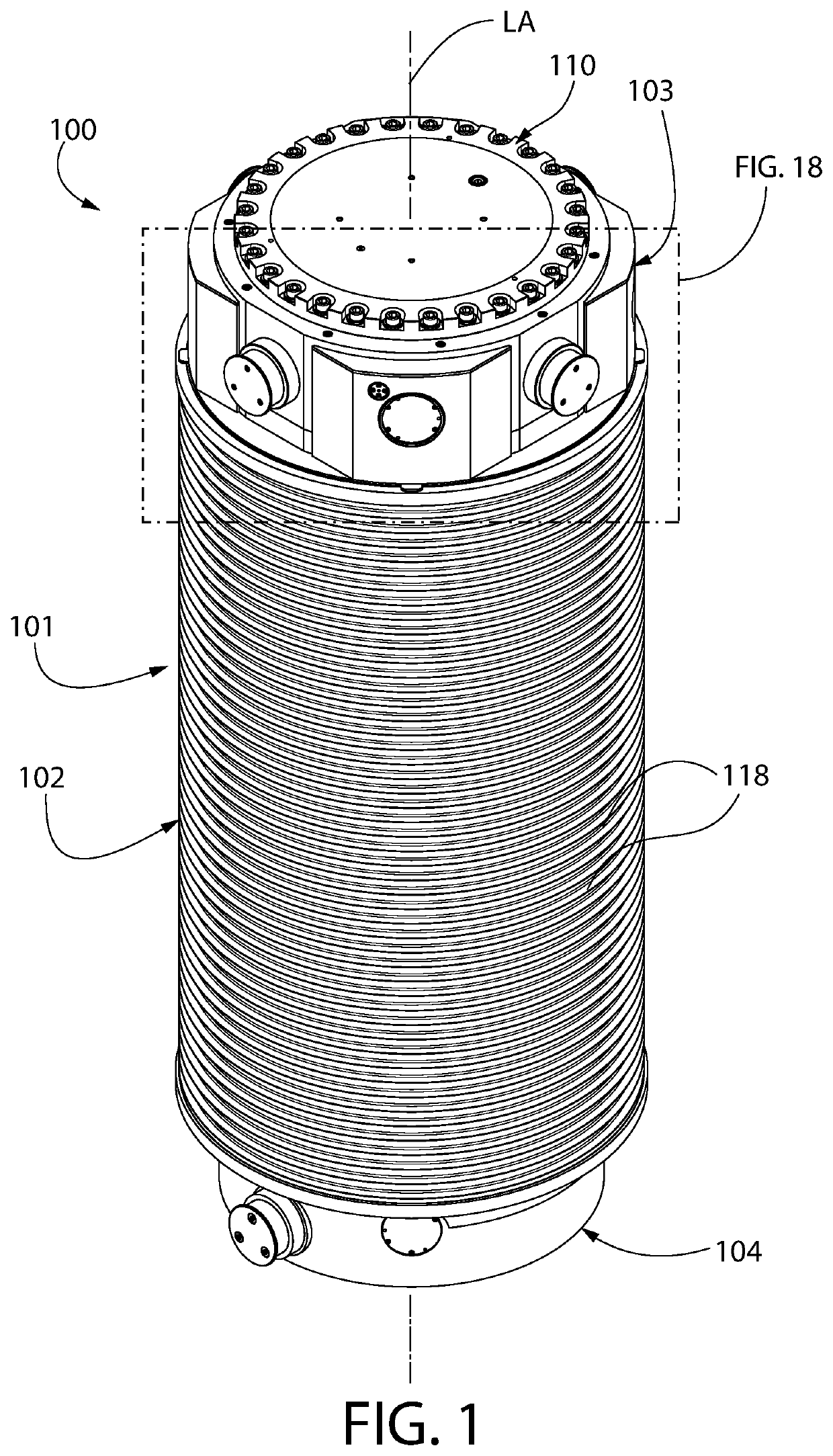

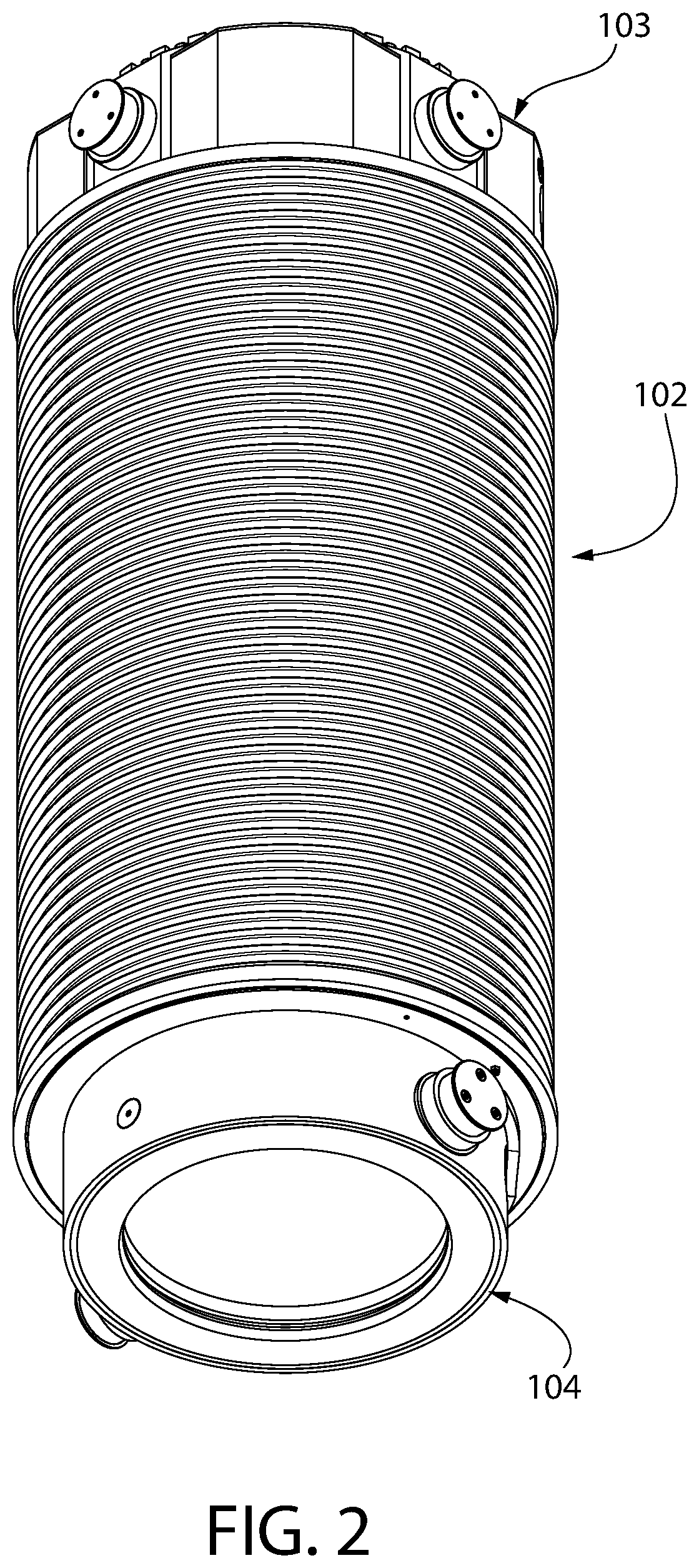

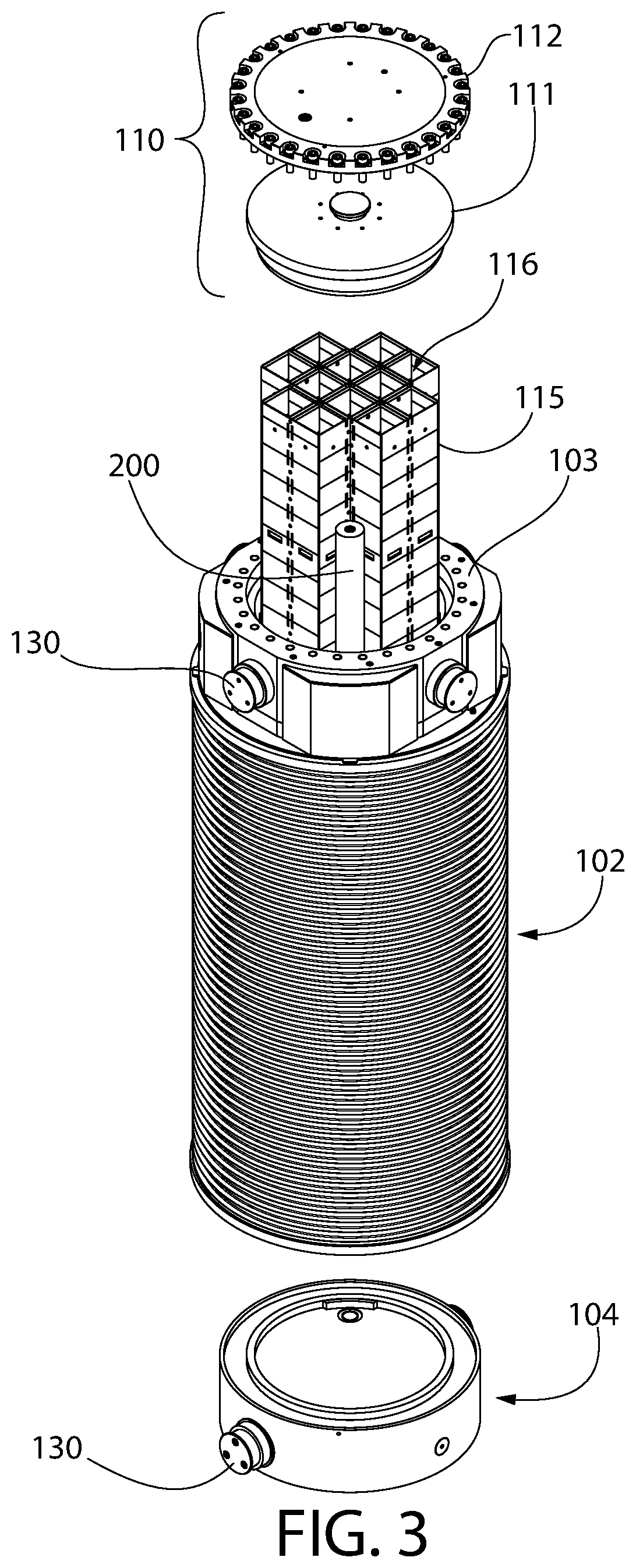

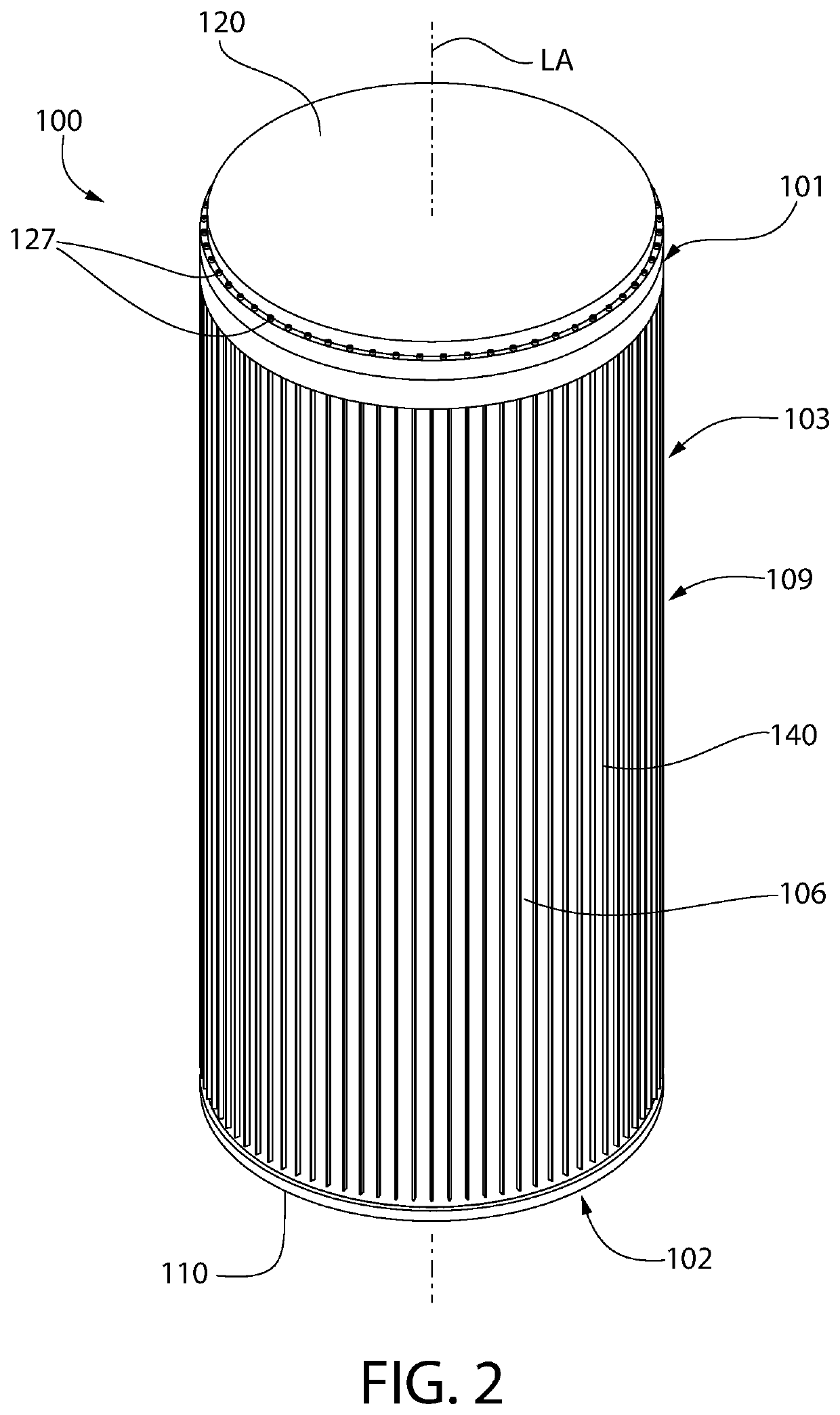

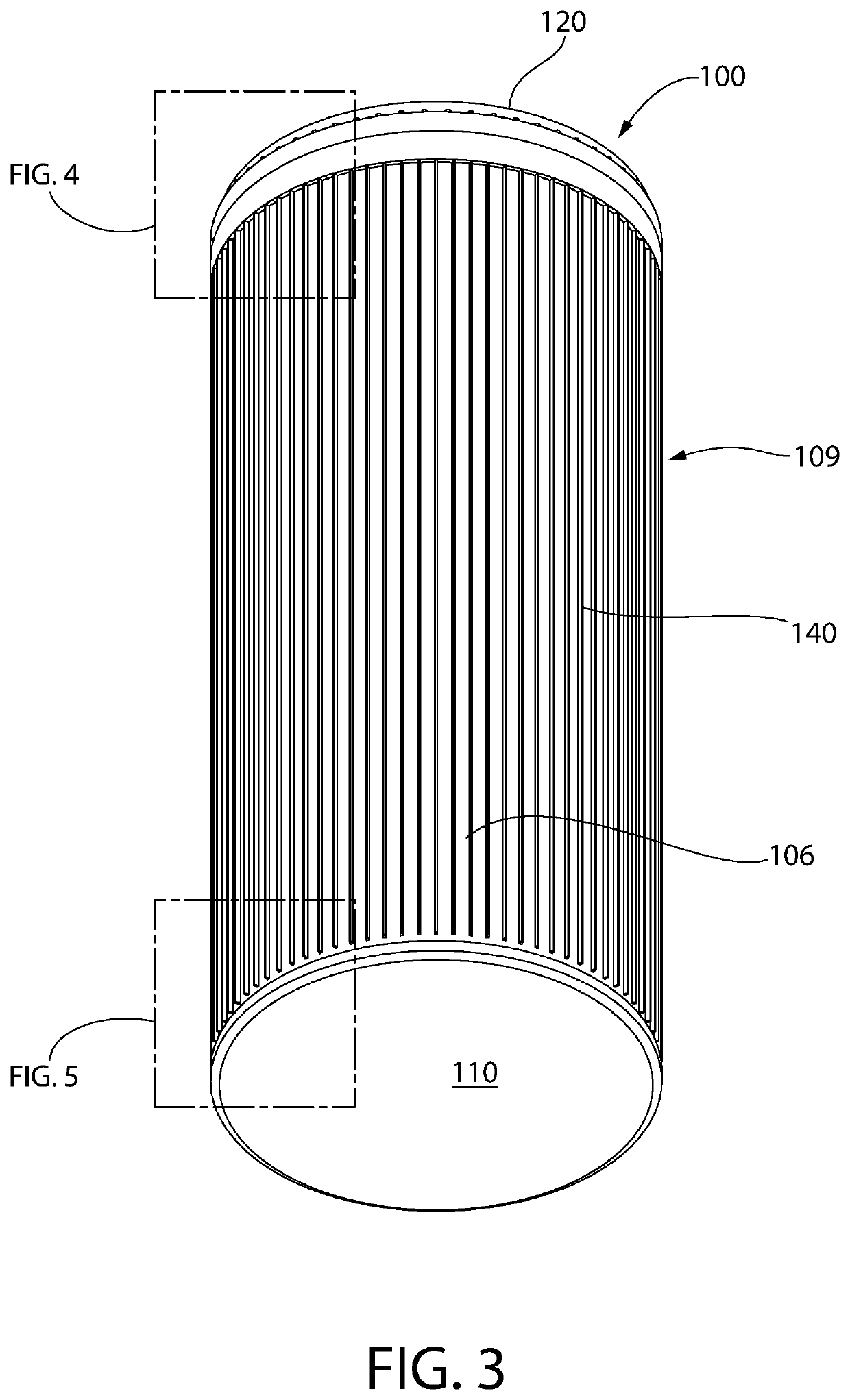

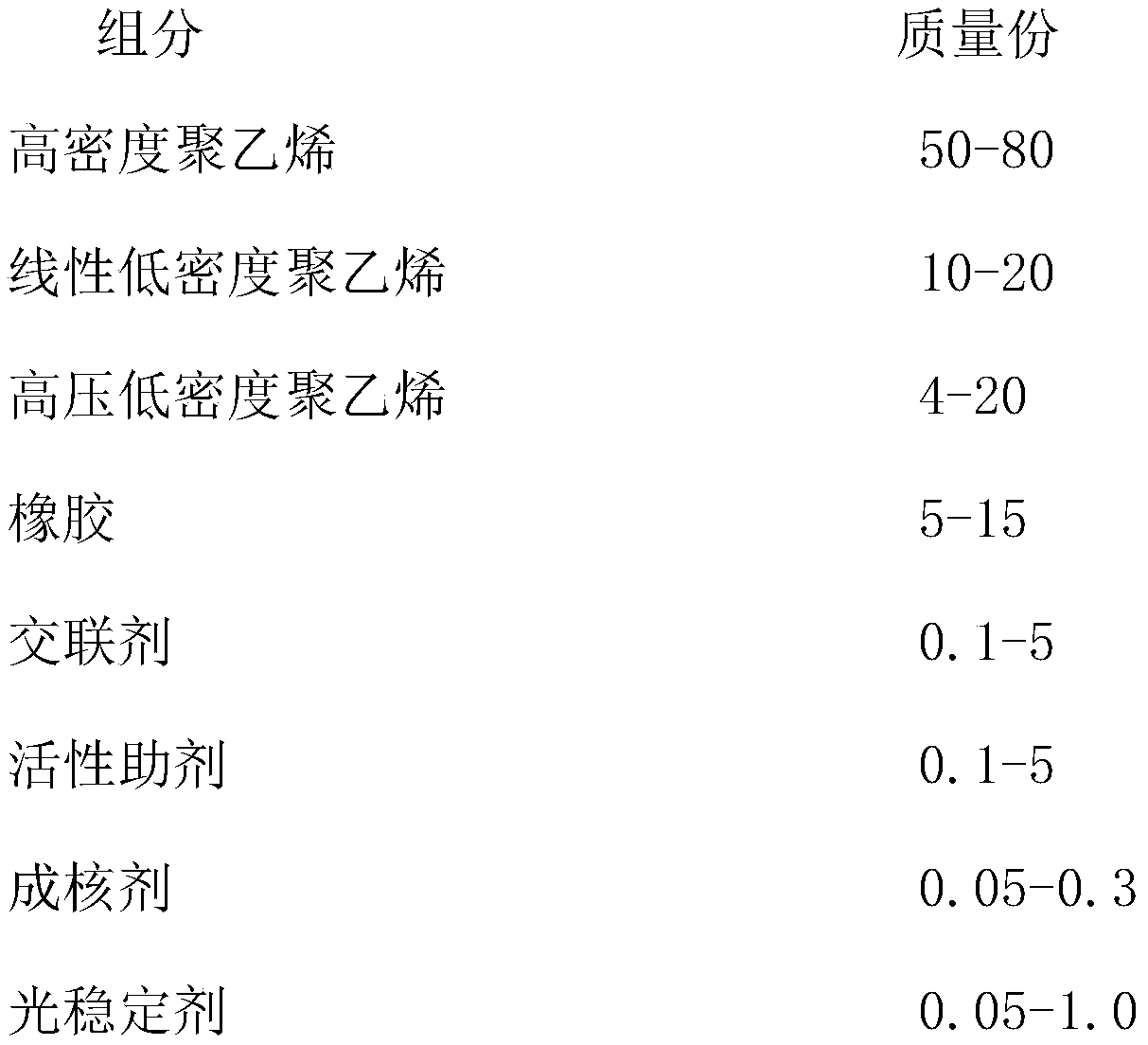

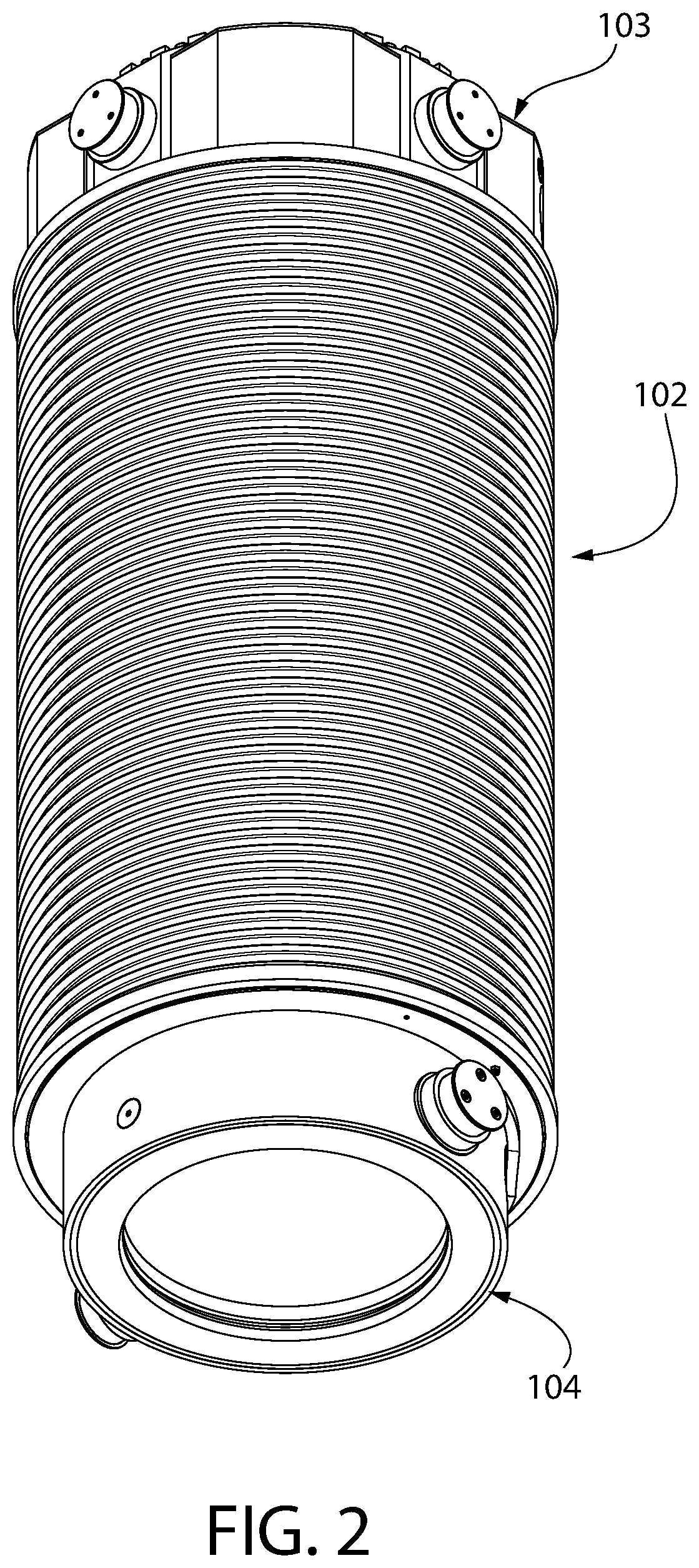

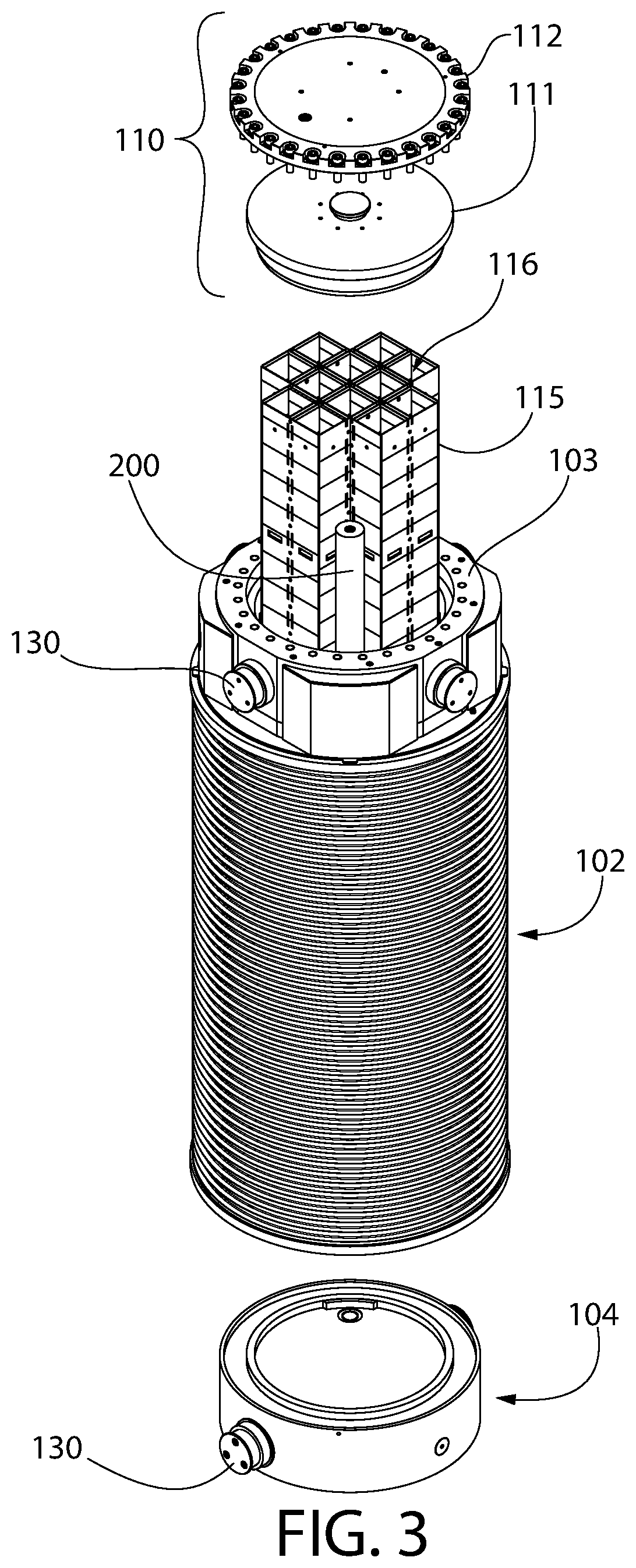

Nuclear waste storage canisters

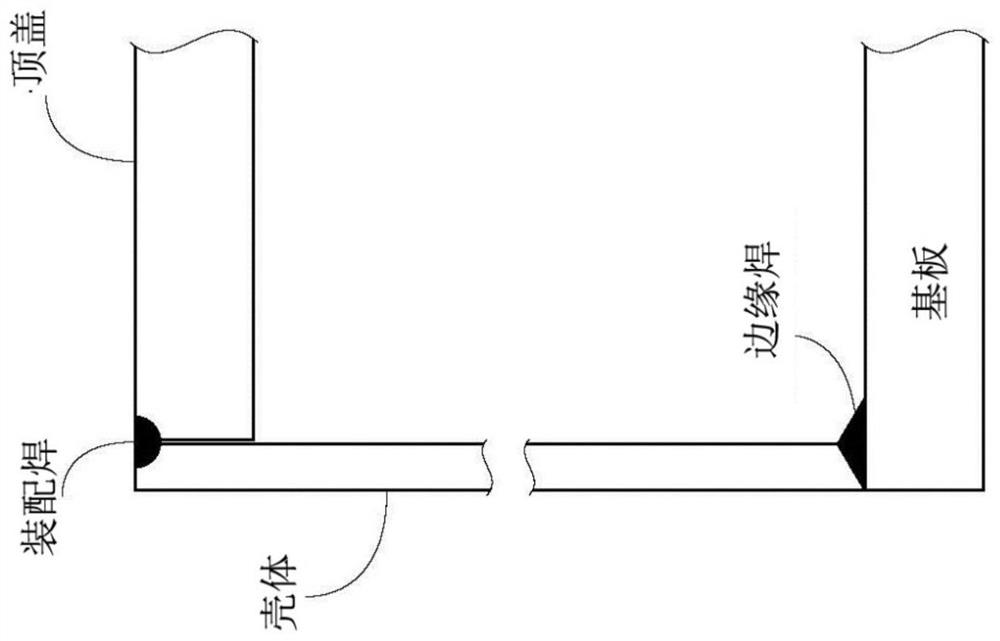

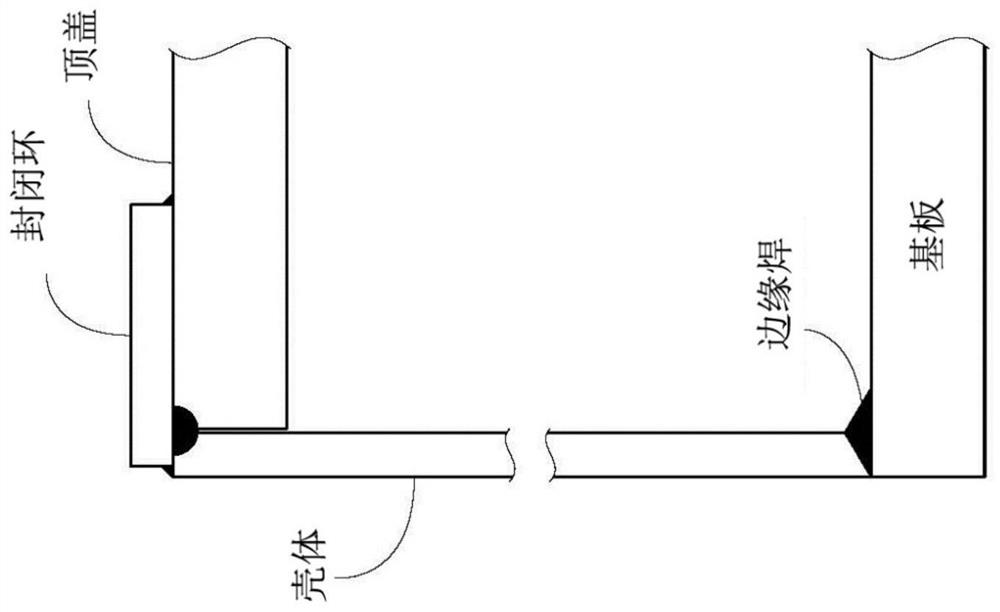

A dry storage systems for radioactive nuclear waste materials in one embodiment includes a canister having a tubular shell defining an internal cavity for storing nuclear waste material, a lid sealably welded to one end the shell, and an end closure attached to a second end of the shell. The end closure includes a base plate having an upturned peripheral annular closure flange. In one embodiment,a circumferentially-extending butt joint is formed between the closure flange and the shell second end which is hermetically seals by a full through-wall thickness butt weld. Various embodiments may further include secondary pressure retention barriers enclosing the canister or select portions thereof most susceptible to failure under certain conditions.

Owner:HOLTEC INT

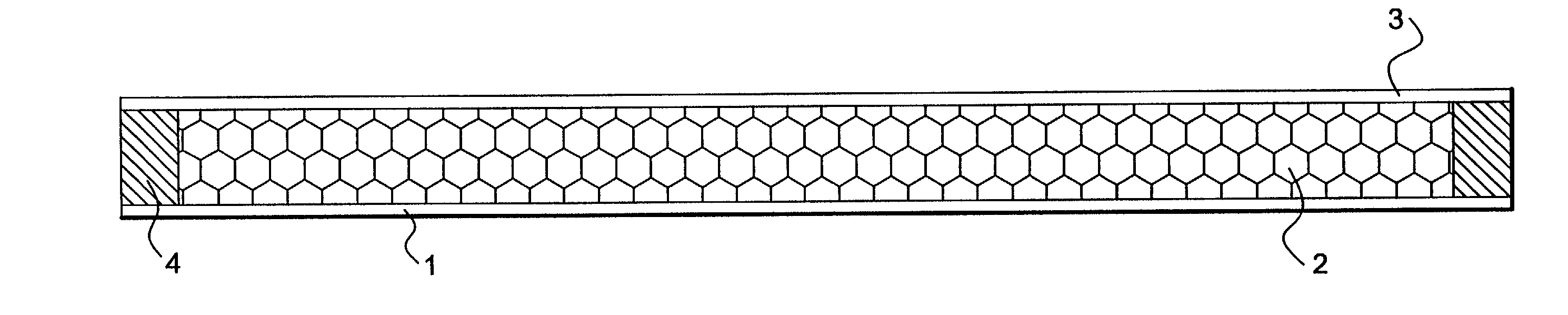

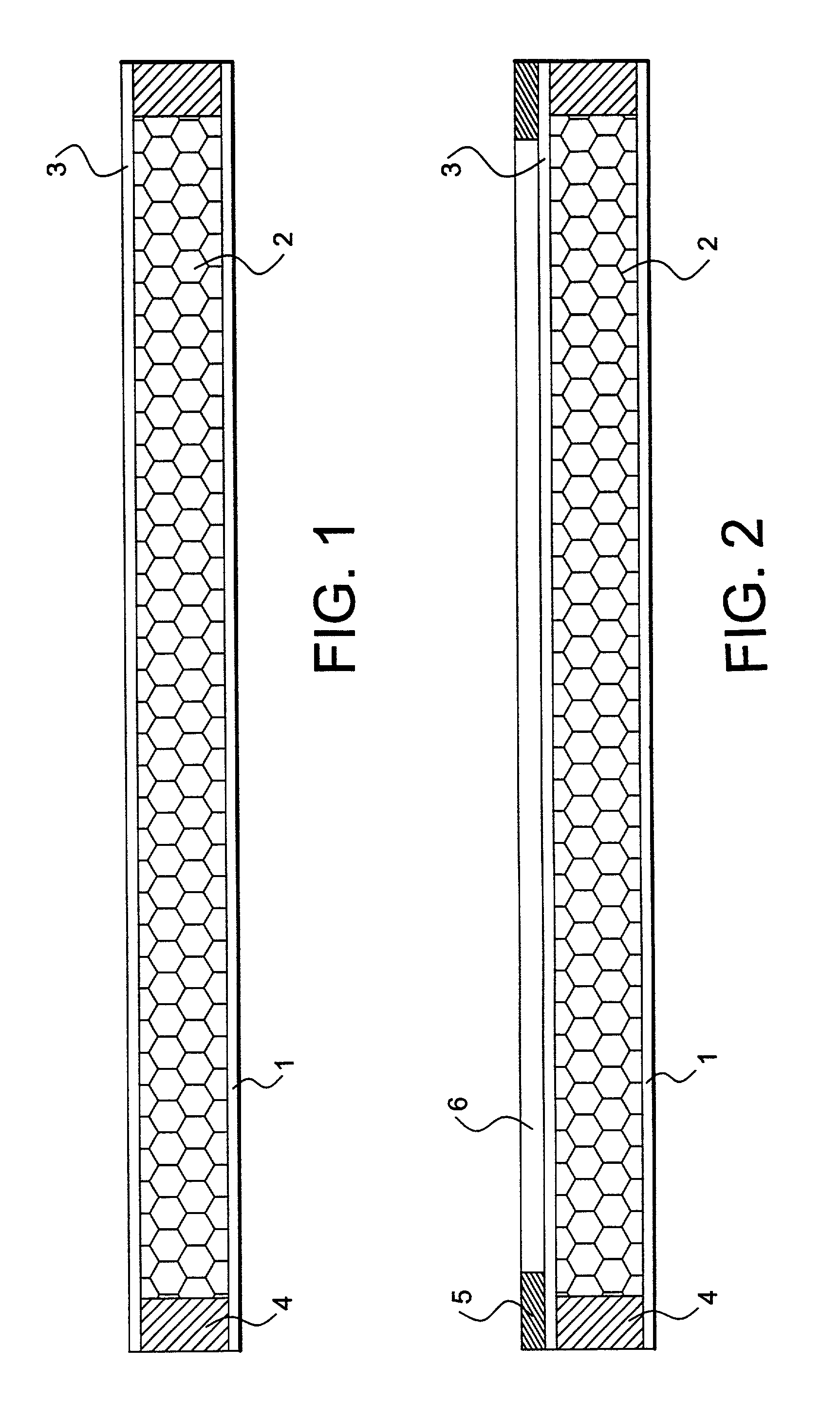

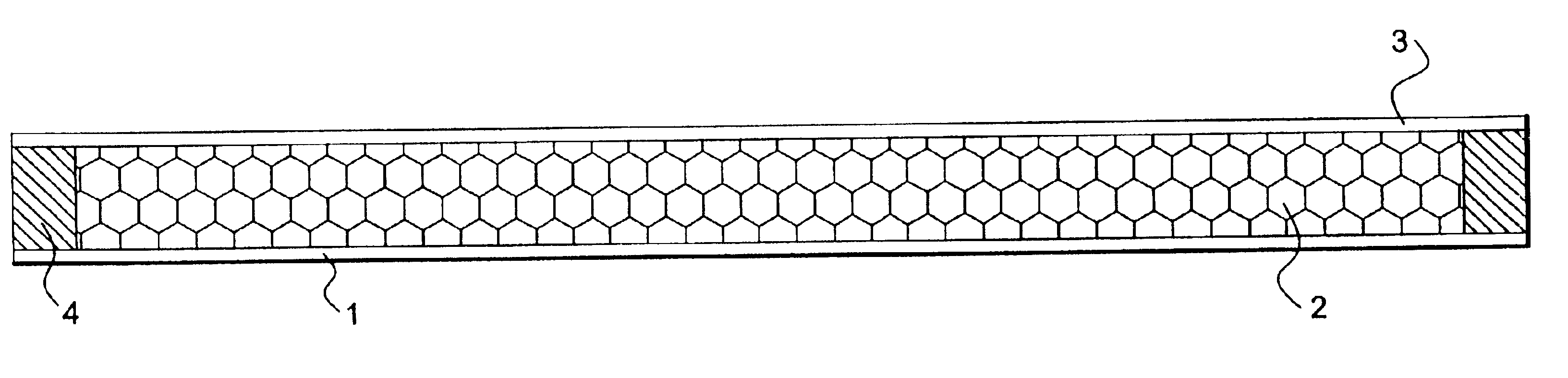

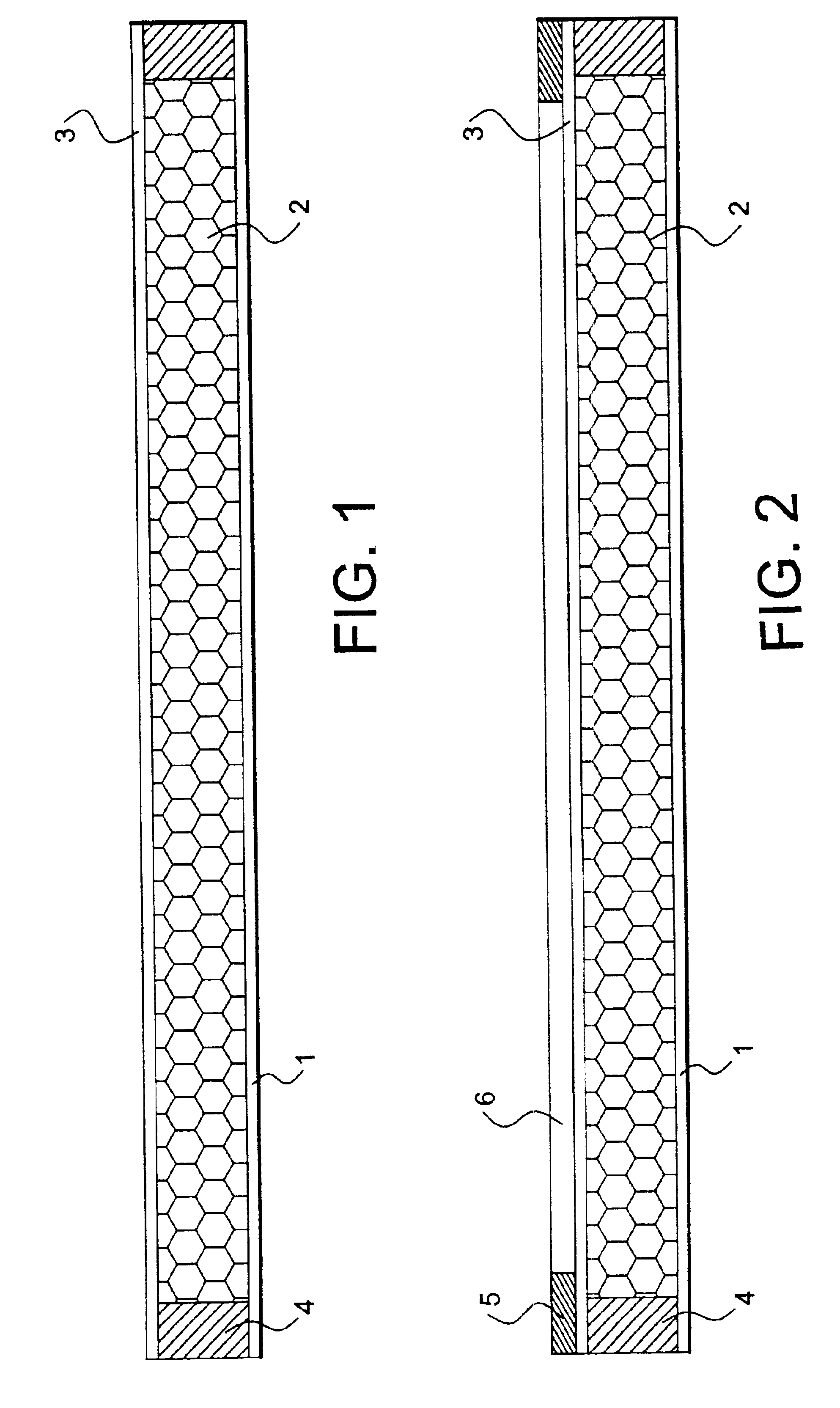

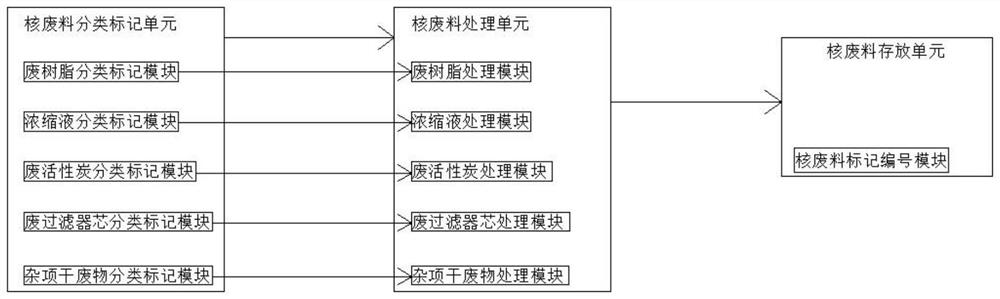

Screen for converting X-rays into light photons

InactiveUS20020130272A1Improve rigiditySmall attenuationX-ray/infra-red processesPhotometryNon destructiveX-ray

The present invention concerns a screen panel for converting X-rays into light photons. The panel comprises a rigid foam plate (2), a first layer (1) of composite material located on one face of the rigid foam plate (2) and a second layer (3) of composite material located on the other face of the rigid foam plate, parallel to the said first face. The invention applies, for example, to medical radiology and to non-destructive testing of nuclear waste storage packages.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

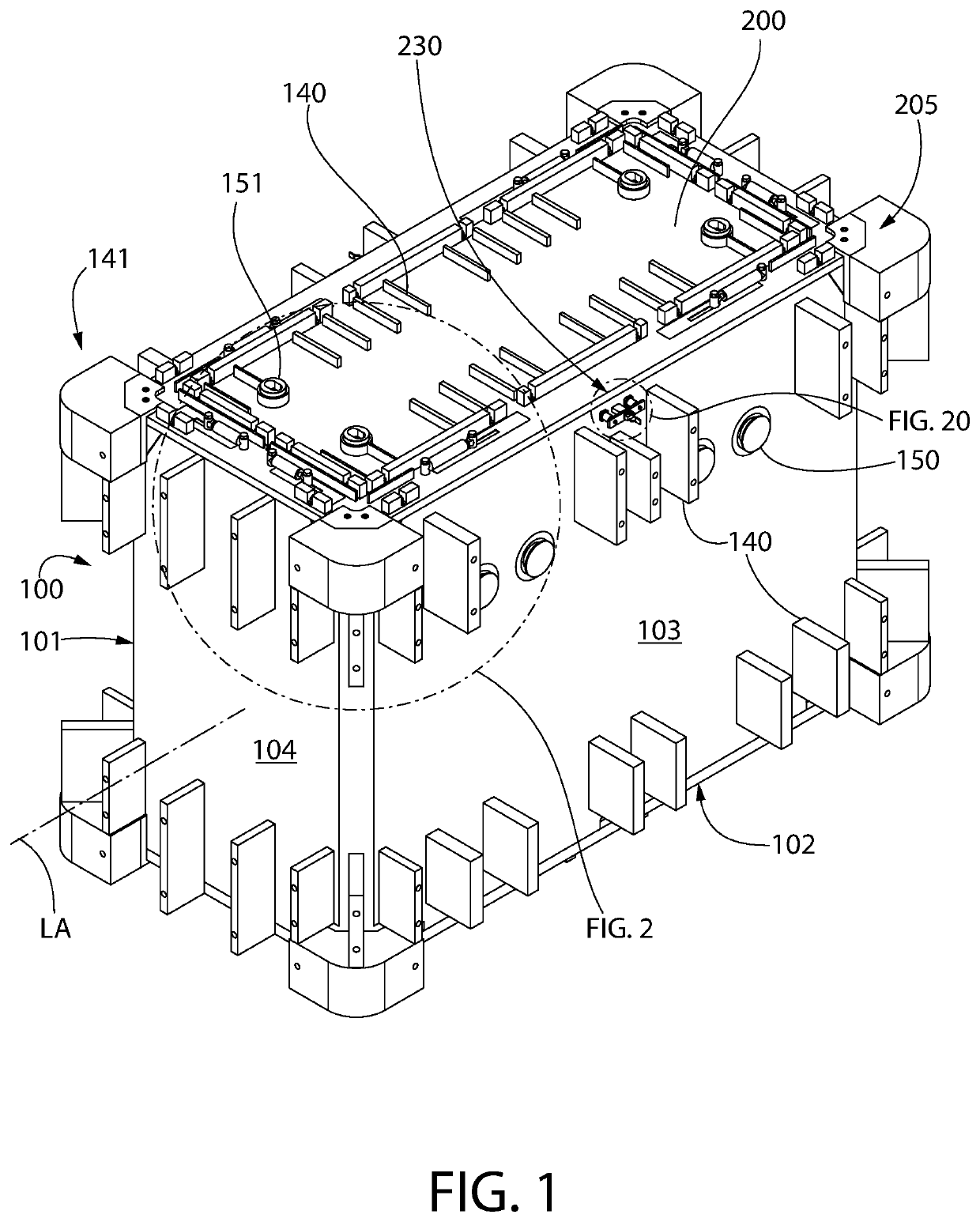

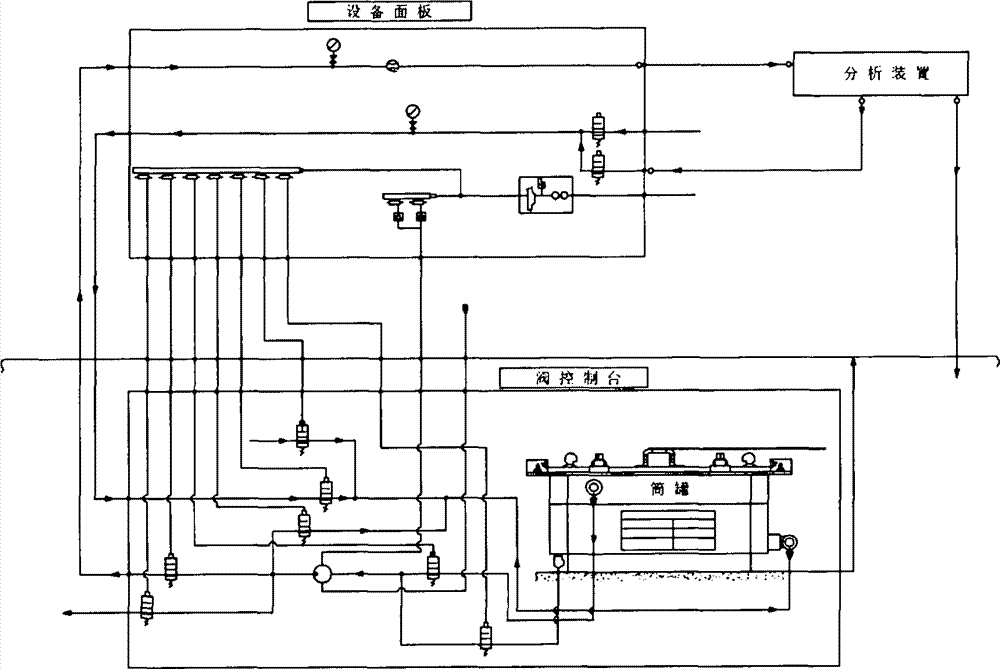

Spent fuel defect detecting system

ActiveCN101957357AMaterial analysis using wave/particle radiationNuclear energy generationPower stationNuclear fission

The invention relates to a system for detecting if nuclear waste defect exists in a heavy water furnace. In the case of existing defects of pin holes in the nuclear waste, the system can be used for detecting / judging if the defect of nuclear waste exists by testing and analyzing the collected nuclear schizoid nuclear matters (liquid and gas) leaked on the exterior of a fuel rod. The system can run as a spent fuel defect detecting system of a heavy water furnace nuclear waste detecting device by being mounted in a heavy water furnace type power station nuclear waste storage groove, while some devices (jars and peripheral systems and devices) which can release high radioactive rays are arranged in the water in order to detect the nuclear waste. The system of the invention is characterized in that devices can be dissembled, salt can be prepared and devices can be moved after ending the nuclear waste detection. In an atomic force power station, the nuclear fuel defect has high radioactive ray quantitative change due to the nuclear fission matters released from the nuclear fuel, so the fuel defect is required to be detected rapidly. A detecting device manufactured according to the invention can quickly and safely detect the nuclear fuel.

Owner:KEPCO NUCLEAR FUEL CO LTD

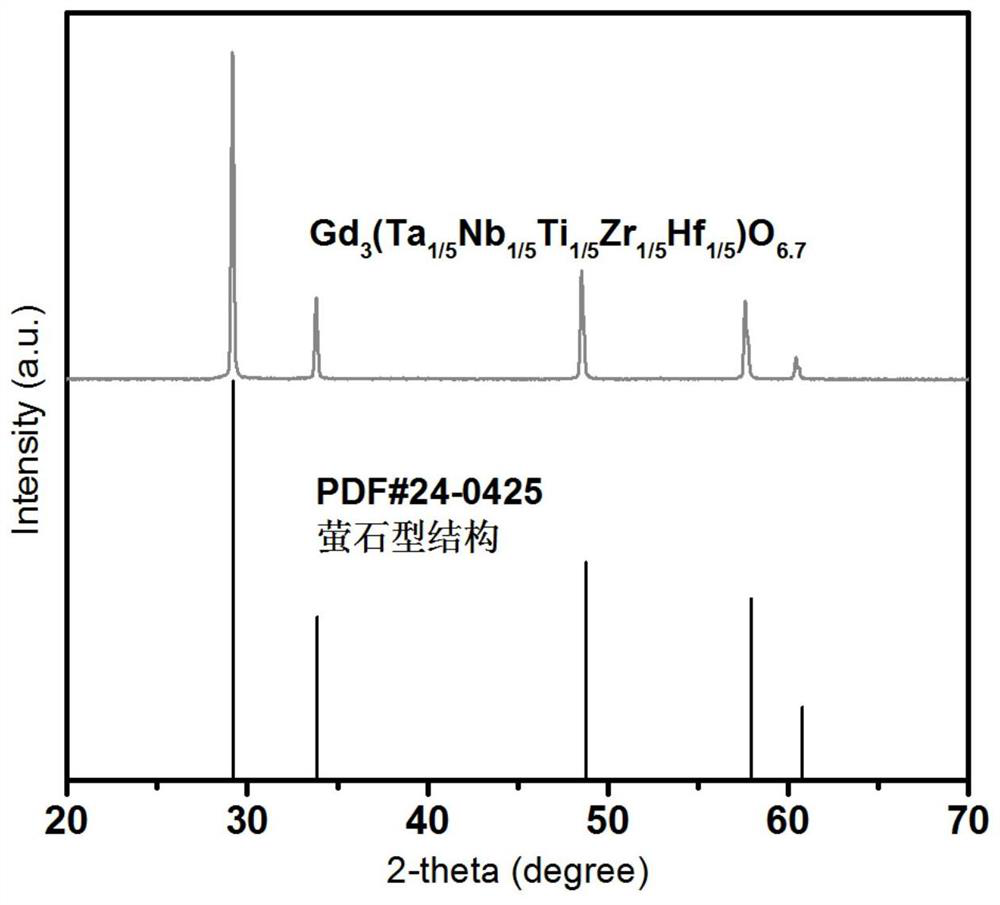

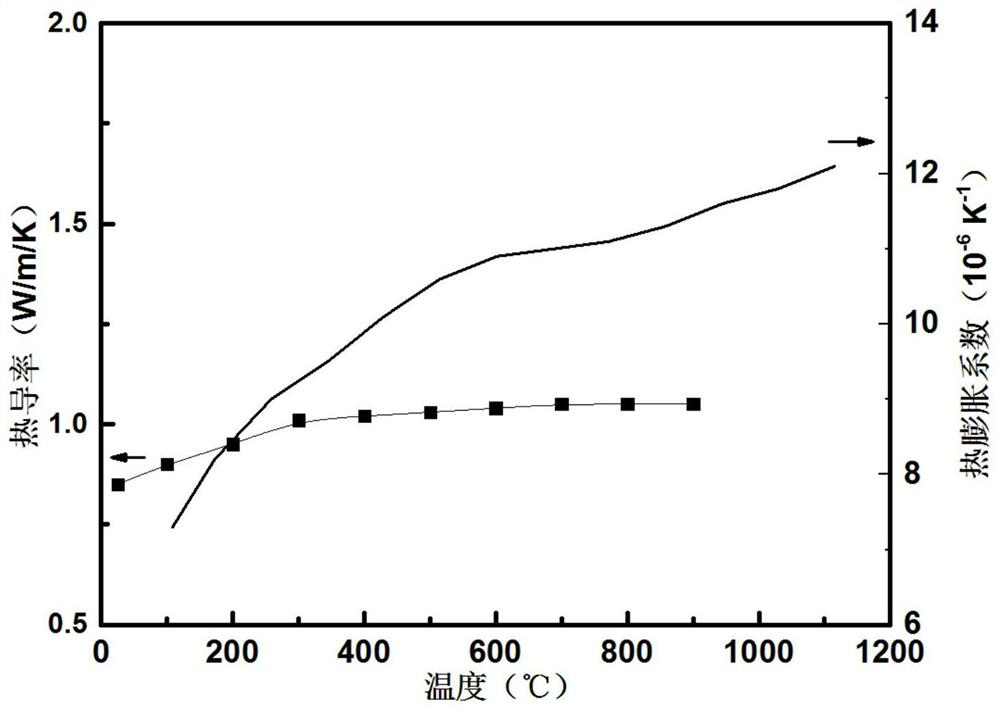

Entropy-stable RE2O3-AO2-B2O5 oxide ceramic and preparation method thereof

The invention discloses entropy-stabille RE2O3-AO2-B2O5 oxide ceramic and a preparation method thereof, and the preparation method comprises the following steps: taking raw material rare earth oxides RE2O3, AO2 (A = Ti, Zr, Hf, Sn, Th and Ce) and B2O5 (B = V, Nb, Ta and P), calcining, cooling, carrying out ball milling, drying, sieving to obtain powder, carrying out spark plasma sintering, and finally carrying out heat preservation, annealing and carbon removal to obtain the compact RE2O3-AO2-B2O5 rare earth oxide ceramic which takes RE2A2O7 and RE3BO7 as matrixes and is of a fluorite type or pyrochlore type structure is obtained. The fluorite type or pyrochlore type rare earth oxide ceramic material which is high in lattice defect concentration, low in heat conductivity, high in hardness, excellent in fracture toughness, high in phase purity and high in density is prepared by regulating and controlling the stoichiometric ratio of different metal elements and through the steps of high-temperature, high-pressure and short-time sintering; and the material can be applied to the fields of thermal barrier coatings, environmental barrier coatings, solid oxide fuel cells, nuclear waste storages and the like.

Owner:KUNMING UNIV OF SCI & TECH

Method for nuclear waste storage and monitoring

A method comprising storing nuclear waste, including identifying a subterranean storage site location having a shale rock layer. The layer has an expected fluid overpressure in a range corresponding to greater than hydrostatic pressure to less than lithostatic pressure from overlying rock layers. Storing the waste can include forming a storage borehole, with an end segment of the storage borehole located within the layer and measuring the fluid pressure in the end segment of the storage borehole. If the measured fluid pressure in the end segment of the storage borehole is in the expected fluid overpressure range, forming a monitoring borehole in the layer with an end segment of each of the monitoring boreholes being in a vicinity of the end segment of the storage borehole and storing nuclear waste in the end segment of the storage borehole. A system for storing and monitoring nuclear waste is also described.

Owner:MWD IP HLDG LLC

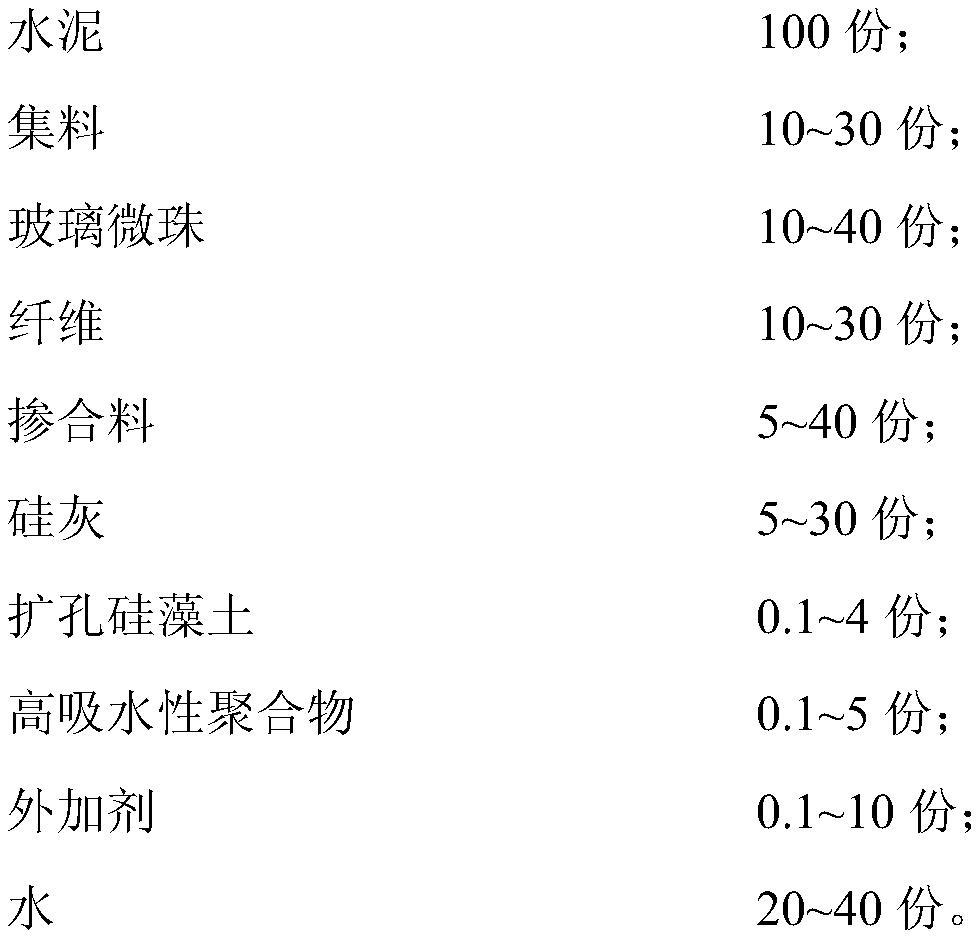

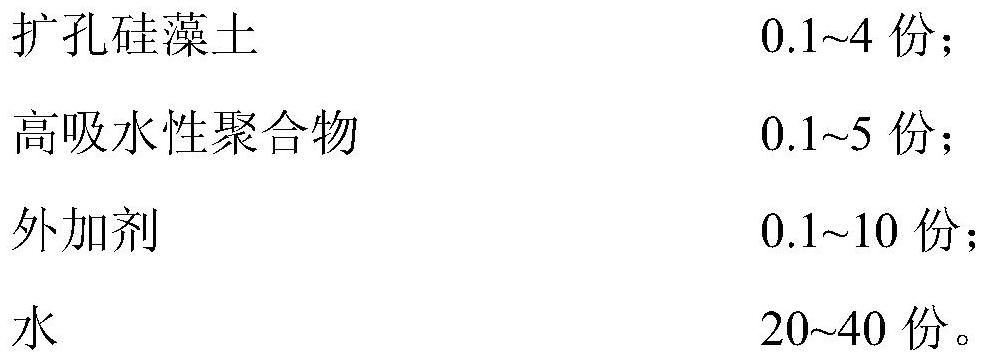

Radiation-proof concrete composition, preparation method and prefabricated container

The invention provides an anti-radiation concrete composition, a preparation method and a prefabricated container. The anti-radiation concrete composition comprises the following components in parts by weight: 100 parts of cement; 10-30 parts of aggregate; 10-40 parts of micro glass beads; 10-30 parts of fibers; 5-40 parts of an admixture; 5-30 parts of silica fume; 0.1-4 parts of chambering diatomite; 0.1-5 parts of a super absorbent polymer; 0.1-10 parts of an additive; and 20-40 parts of water. The anti-radiation concrete composition is good in mechanical property, good in durability, highin thermal stability and high in radiation resistance, so that the wall thickness and weight of a nuclear waste storage container are reduced, and the radiation resistance of the nuclear waste storagecontainer is improved.

Owner:CHINA TRIUMPH INT ENG

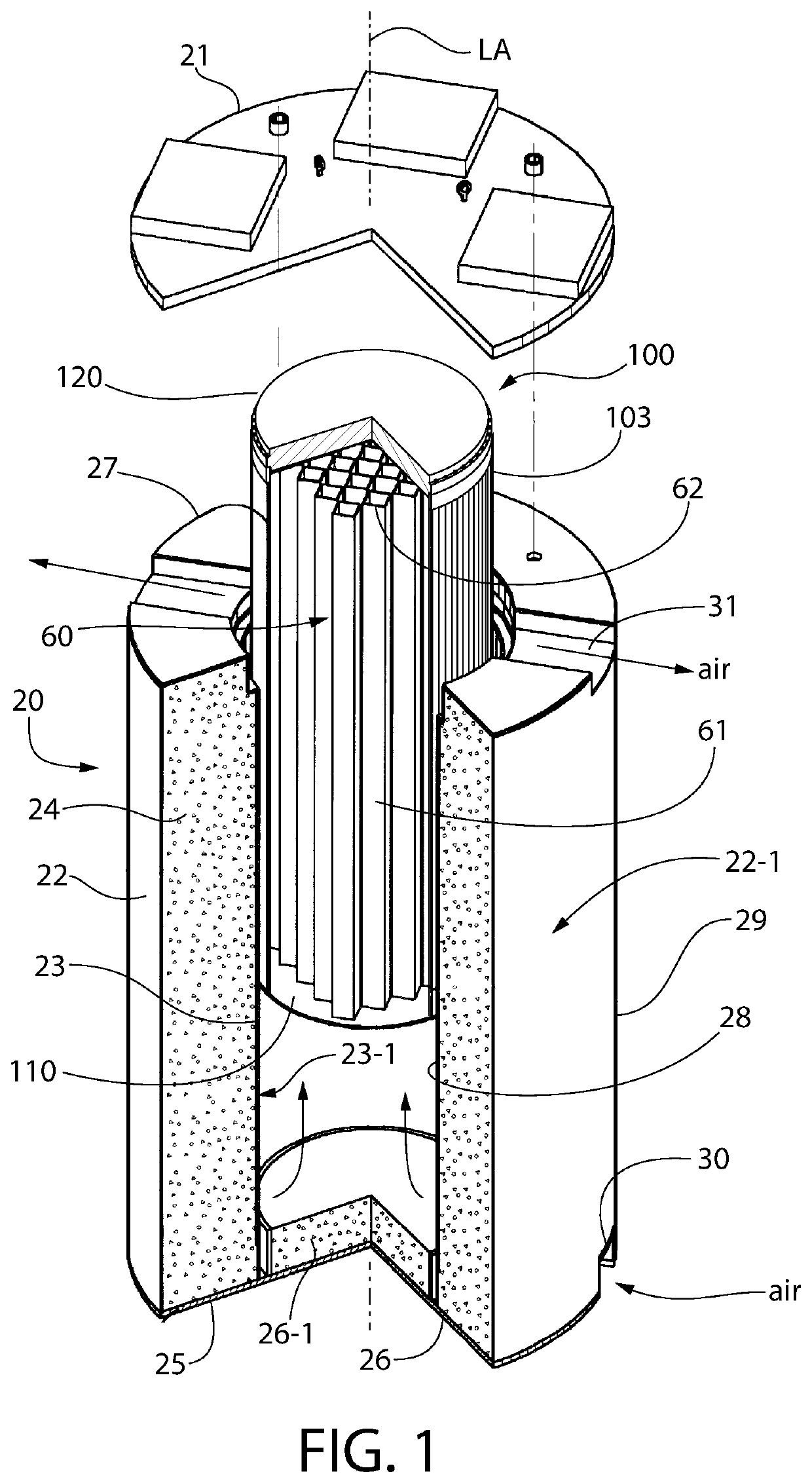

Cooling device for Stirling circulated dry storage container

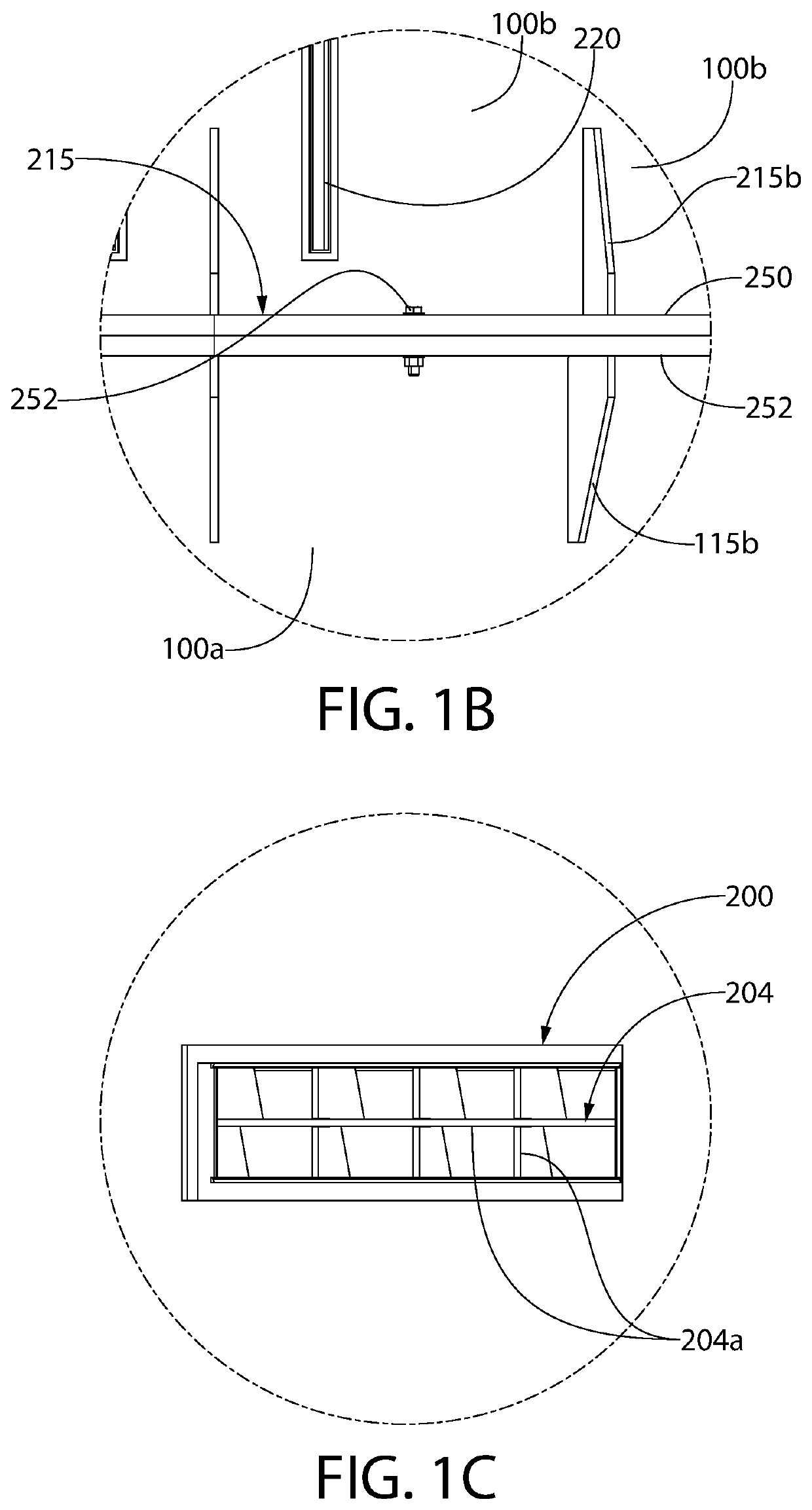

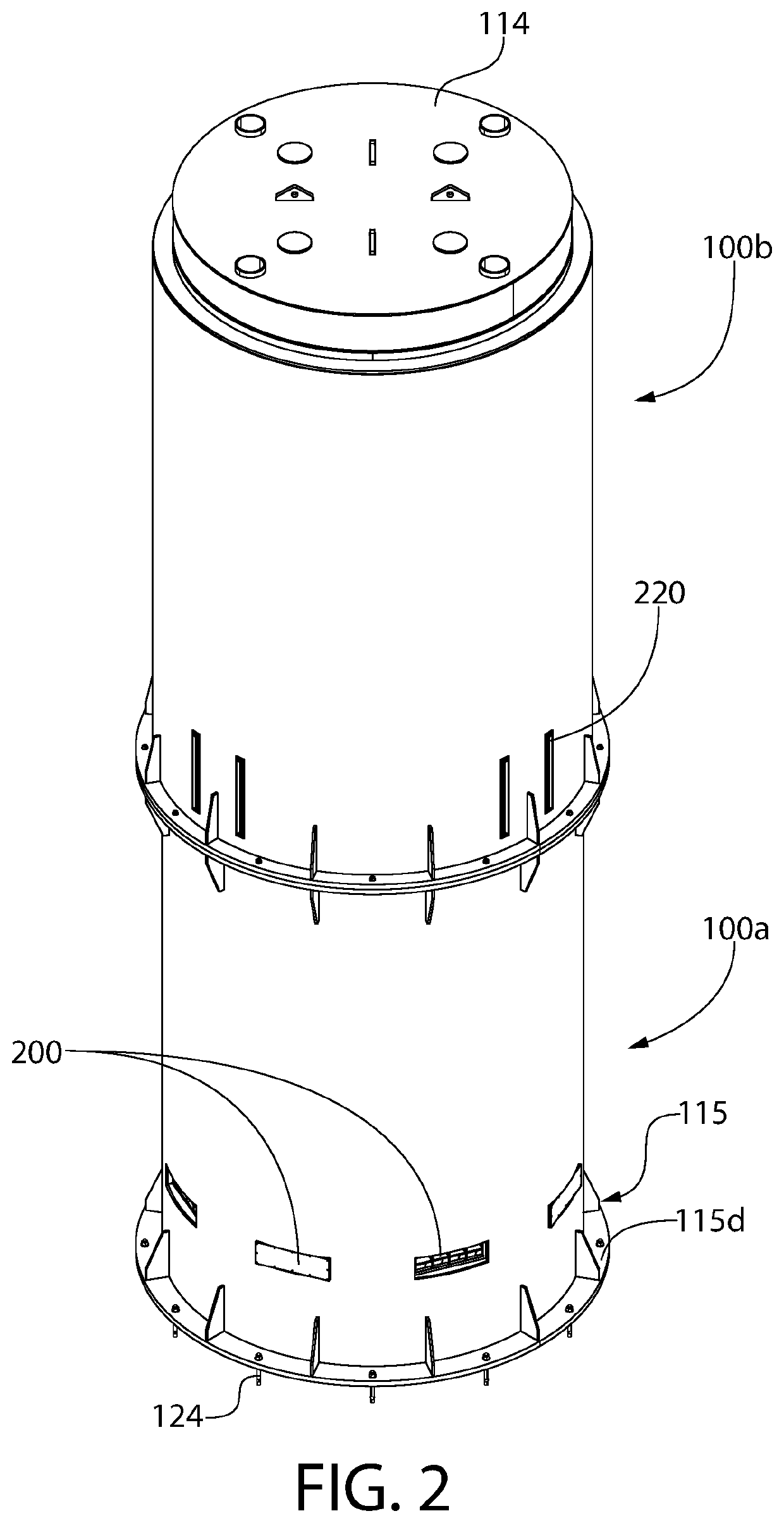

InactiveUS8555641B2Improve cooling efficiencyEconomic efficiency is excellentCompression machinesPortable shielded containersEngineeringNuclear waste storage

A cooling device for Stirling circulated dry storage container, which is mainly to make an accommodation space with opening within an external shield, and at the peripherals of the accommodation space, it is installed with a plurality of air flow inlets and air flow outlets that are connected to the external side. In addition, a shield cover is used to cover the opening of the accommodation space, and a nuclear waste storage container is installed within the accommodation space of the external shield, and the peripheral of the accommodation space and the nuclear waste storage container forms an air flow channel.

Owner:INST NUCLEAR ENERGY RES ROCAEC

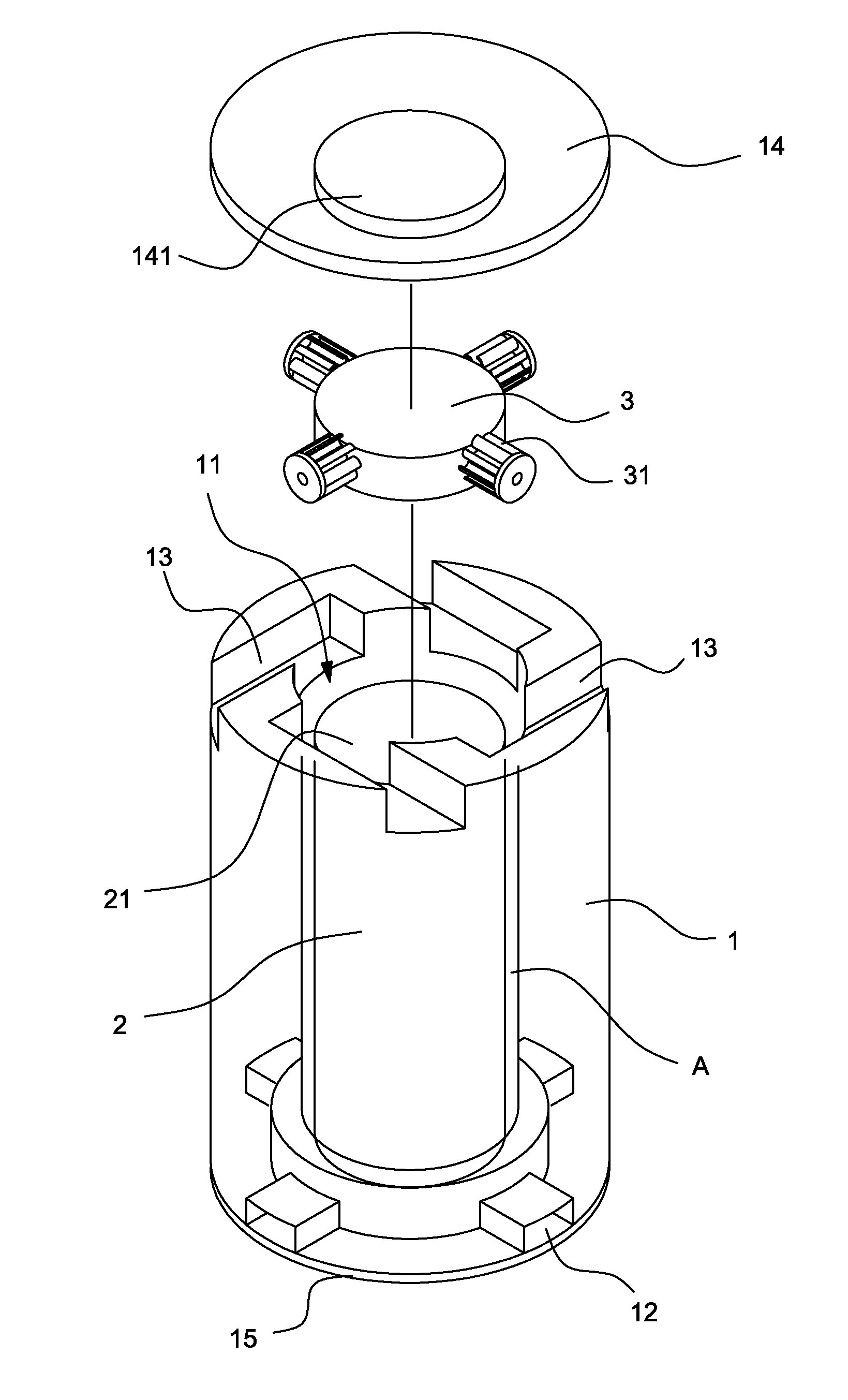

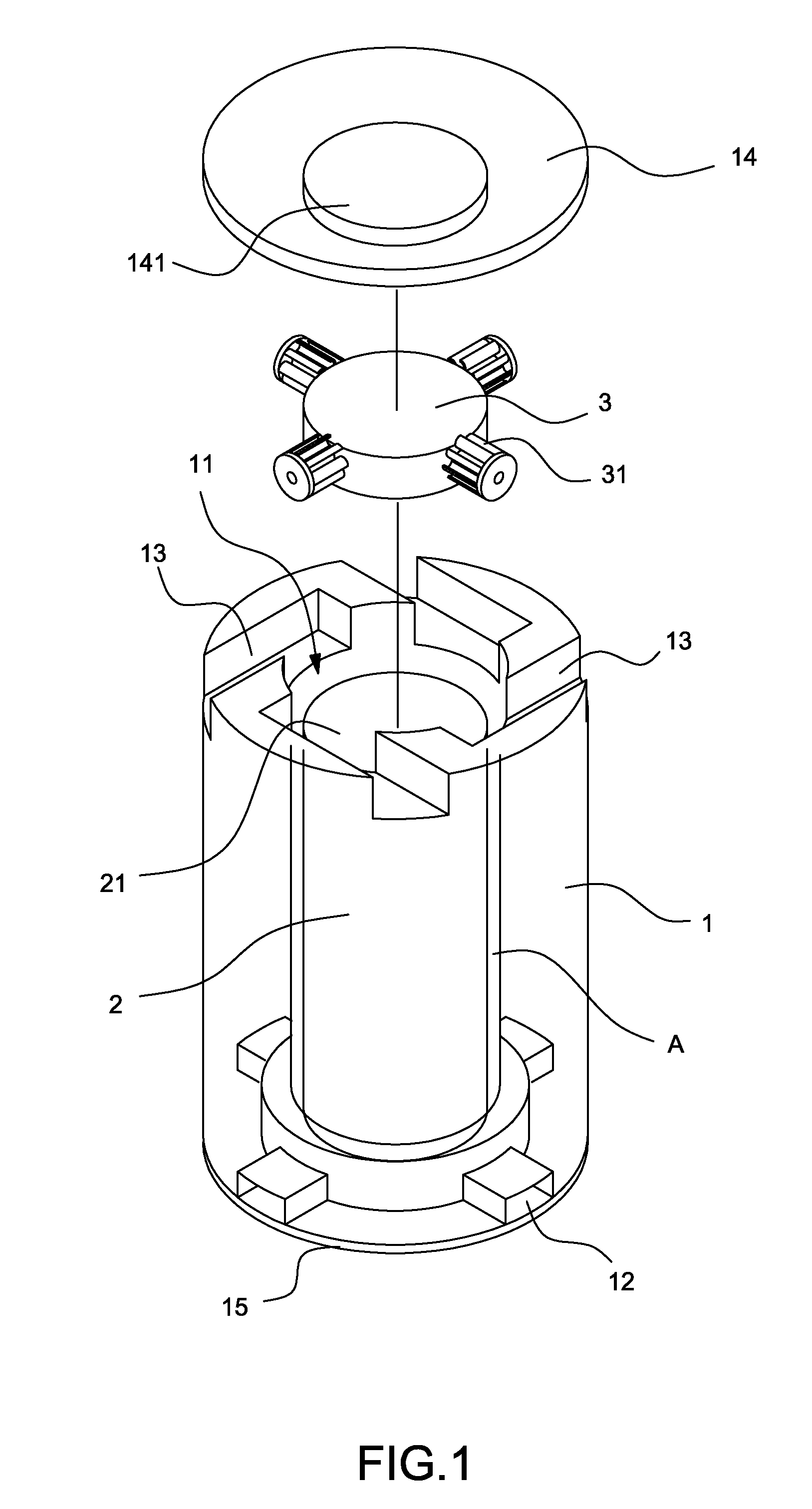

Storage and transport cask for nuclear waste

ActiveUS20210272714A1Reduce radiation doseOvercomes shortcomingNuclear energy generationPortable shielded containersChange positionsNuclear waste storage

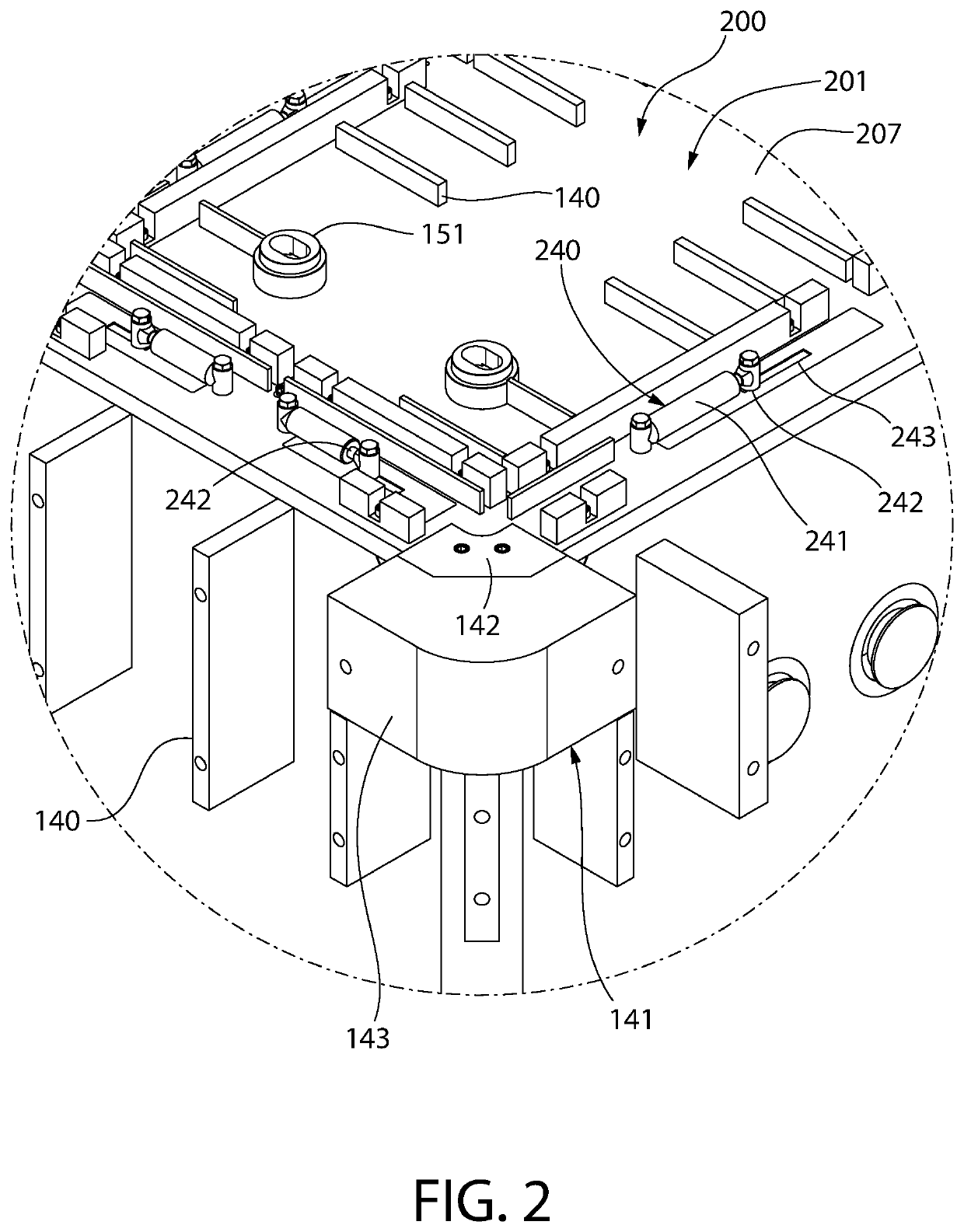

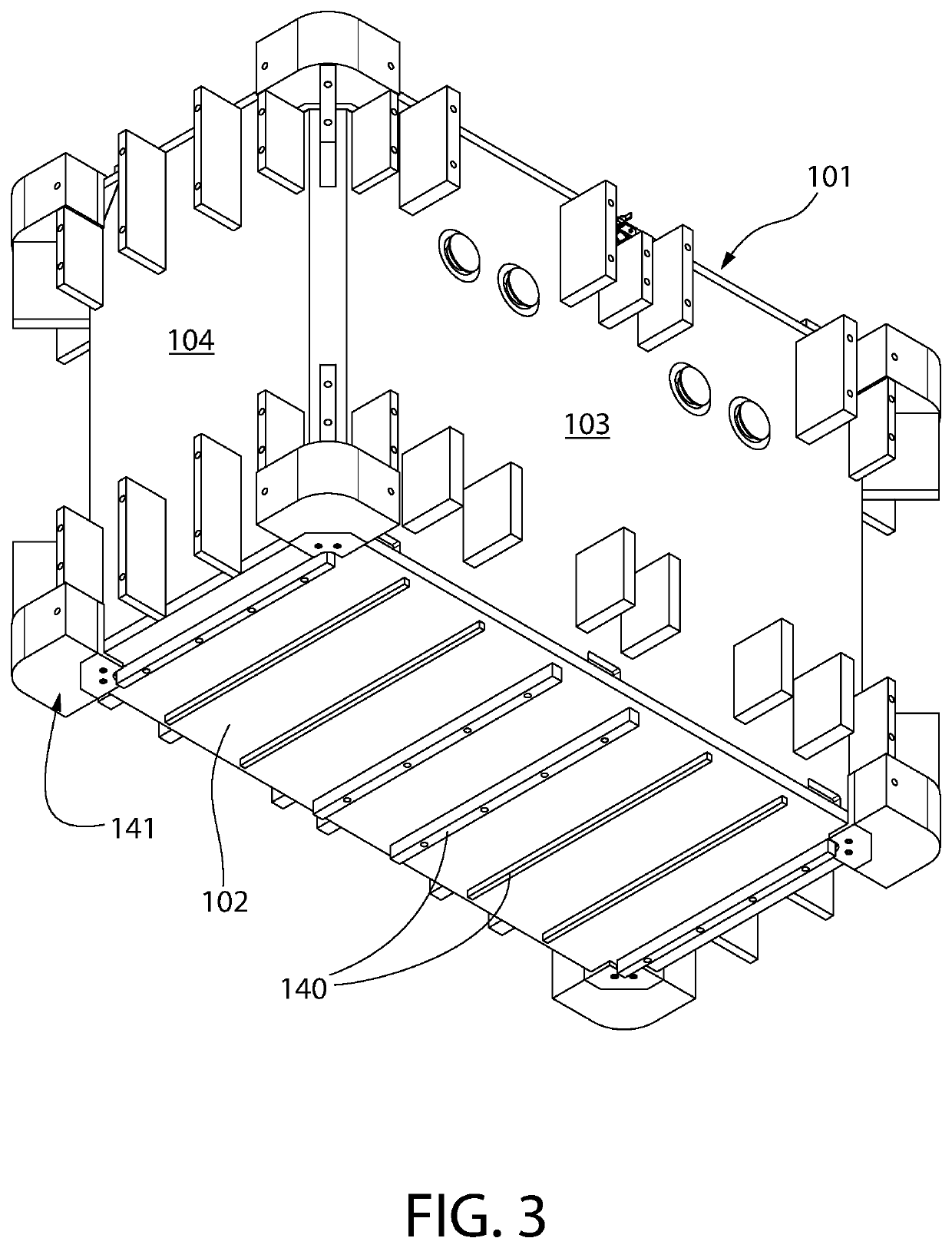

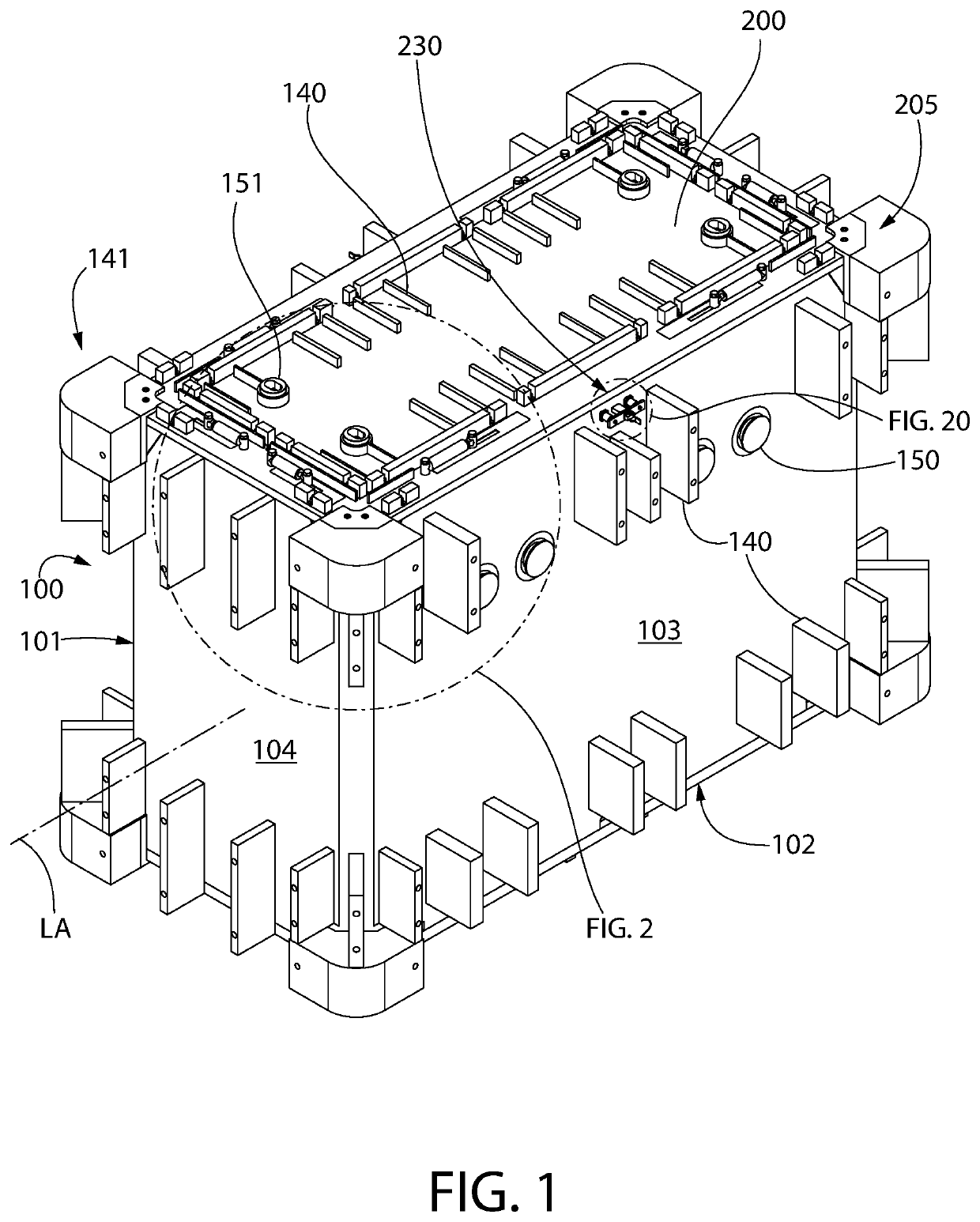

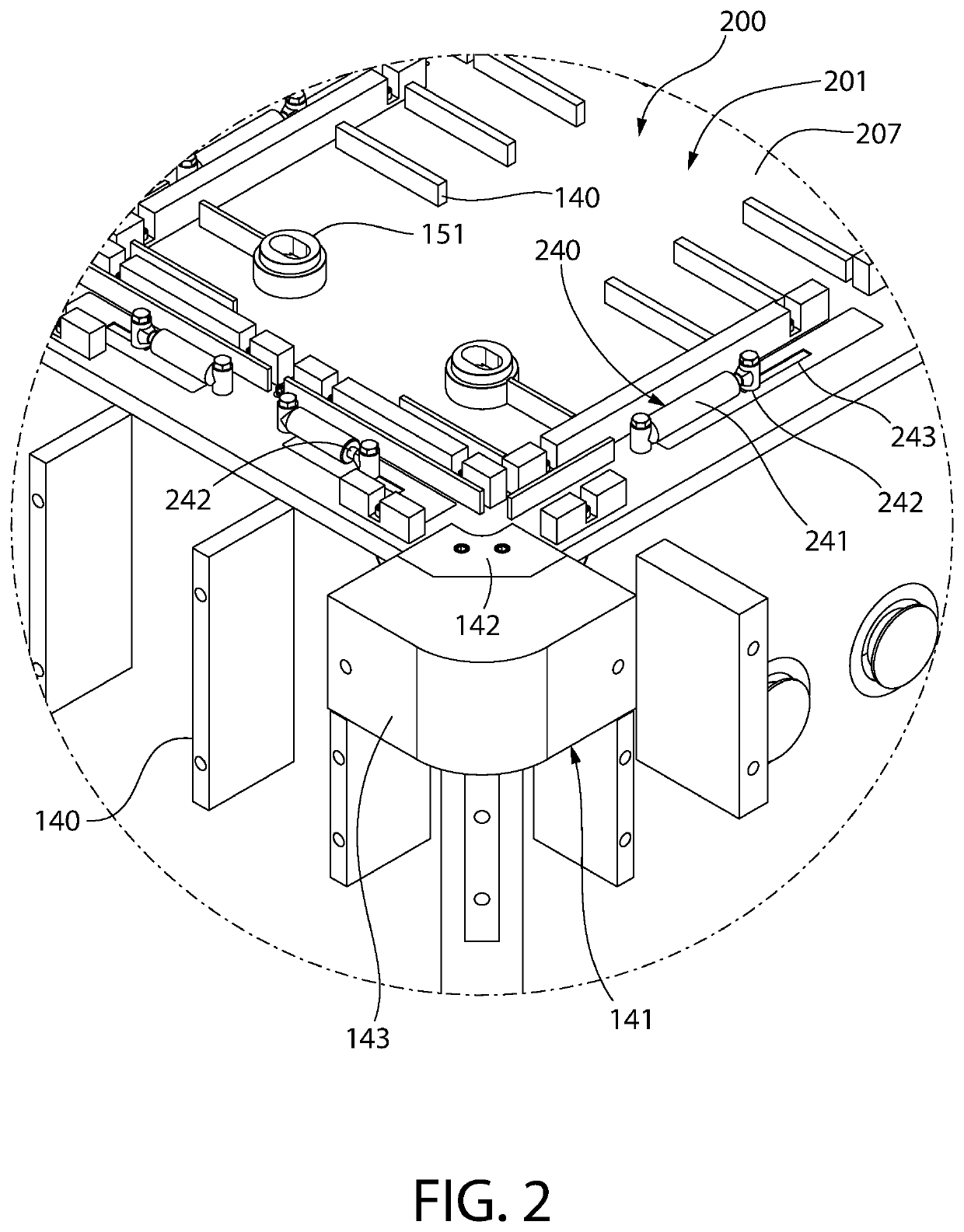

A nuclear waste cask in one embodiment includes an axially elongated cask body defining a longitudinally-extending opening forming an entrance to an internal storage cavity of the cask configured for holding radioactive nuclear waste materials. A closure lid detachably coupled to the cask body at the top opening seals the cavity. A cask locking mechanism includes a plurality of first locking protrusions spaced apart on the lid which are selectively interlockable with a plurality of second locking protrusions spaced apart on the cask body to lock the lid to the cask body. The first locking protrusions may be disposed on slideable locking bars moveable between locked and unlocked positions while the lid remains stationary on the cask body. Hydraulic or pneumatic actuators may be used to change position of the locking bars. The cask and lid may include other features such as impact absorbers and lifting elements.

Owner:HOLTEC INT

Storage and transport cask for nuclear waste

ActiveUS11373775B2Reduce radiation doseOvercomes shortcomingNuclear energy generationPortable shielded containersChange positionsNuclear waste storage

A nuclear waste cask in one embodiment includes an axially elongated cask body defining a longitudinally-extending opening forming an entrance to an internal storage cavity of the cask configured for holding radioactive nuclear waste materials. A closure lid detachably coupled to the cask body at the top opening seals the cavity. A cask locking mechanism includes a plurality of first locking protrusions spaced apart on the lid which are selectively interlockable with a plurality of second locking protrusions spaced apart on the cask body to lock the lid to the cask body. The first locking protrusions may be disposed on slideable locking bars moveable between locked and unlocked positions while the lid remains stationary on the cask body. Hydraulic or pneumatic actuators may be used to change position of the locking bars. The cask and lid may include other features such as impact absorbers and lifting elements.

Owner:HOLTEC INT

Storage system for radioactive nuclear waste with pressure surge protection

ActiveUS20210343438A1Improves Structural IntegritySuppress internal pressureNuclear energy generationPortable shielded containersHermetic sealVacuum chamber

A radioactive nuclear waste storage system includes a cask comprising a hermetically sealed internal cavity configured for holding the waste such as spent nuclear fuel submerged in an inventory of water. One or more pressure surge capacitors disposed inside the cask include a vacuum cavity evacuated to sub-atmospheric conditions prior to storage of fuel in the cask. At least one rupture disk seals a vacuum chamber inside each capacitor. Each rupture disk is designed and constructed to burst at a predetermined burst pressure level occurring inside the cask external to the capacitor. This allows excess cask pressure occurring during a high pressure excursion resulting from abnormal operating conditions to bleed into capacitor, thereby returning the pressure inside the cask to acceptable levels. In one embodiment, the capacitors are located in peripheral regions of the cask cavity adjacent to the circumferential wall of the cask body.

Owner:HOLTEC INT

Method of decontamination for a high activity nuclear waste polluted storage canister

ActiveUS9793022B1Reduce stressReduce the possibilityGas treatmentDispersed particle filtrationAir filtrationFilter system

A method of follow-up decontamination operation for the polluted storage canister of a high activity nuclear waste storage facility, using needle and steel brushes driven by pneumatic tools for abrading the bottom and the inner wall of the storage canister to remove contaminants, a multi-level filter system for air filtration and removing pollutants in the storage canister, and a cover to be used in association with the pneumatic tools and the multi-level filtration system suitable to cap the storage canister, thus effectively block the exposure of contaminant of the storage canister to the external environment, achieving effective decontamination of the radioactive waste and reducing spreading to the environment.

Owner:INST OF NUCLEAR ENERGY RES NUCLEAR ENERGY COUNCIL EXECUTIVE YUAN

Nuclear waste storage canisters and method of fabricating the same

ActiveUS20210210241A1Minimum human effortMinimum radiation exposureNuclear energy generationPortable shielded containersNuclear waste storageNuclear engineering

A dry storage systems for radioactive nuclear waste materials may include a double-walled canister system. The canister system may include a canister having a tubular inner shell defining an internal cavity for storing nuclear waste material, a first lid sealably welded to a first end of the inner shell, a primary base plate defining a peripheral edge portion and having an annular closure flange, and an annular full thickness butt weld formed at an abutment joint between the annular closure flange and a second end of the inner shell. The inner shell, first lid, and first end closure may collectively define a sealed primary pressure retention barrier. A tubular outer shell may adjoin the inner shell. The outer shell may be welded to the canister to form a hermetically sealed secondary pressure retention barrier.

Owner:HOLTEC INT

Preparation method of zinc-sprayed coating for long-acting corrosion prevention of nuclear waste storage barrel

InactiveCN102418063AEnhanced resistance to peelingImprove bindingMolten spray coatingEngineeringPre treatment

The invention discloses a process for preparing a zinc-sprayed coating for long-acting corrosion prevention of a nuclear waste storage barrel. The process comprises the step of substrate surface pretreatment, namely removing dirt and oil stain as well as roughening surface, and adjusting and controlling the arc spraying process parameters, such as voltage, current, air pressure, spraying distance, workpiece rotation rate and the like. The process disclosed by the invention has the following technical effects that: 1. the obtained coating has good binding force with a steel substrate and can carry out long-acting and durable protection on the substrate; 2. the coating has an excellent anti-stripping performance; and 3. the process is simple and convenient, has good repeatability and is convenient for large-scale industrial production.

Owner:SHANGHAI UNIV OF ENG SCI

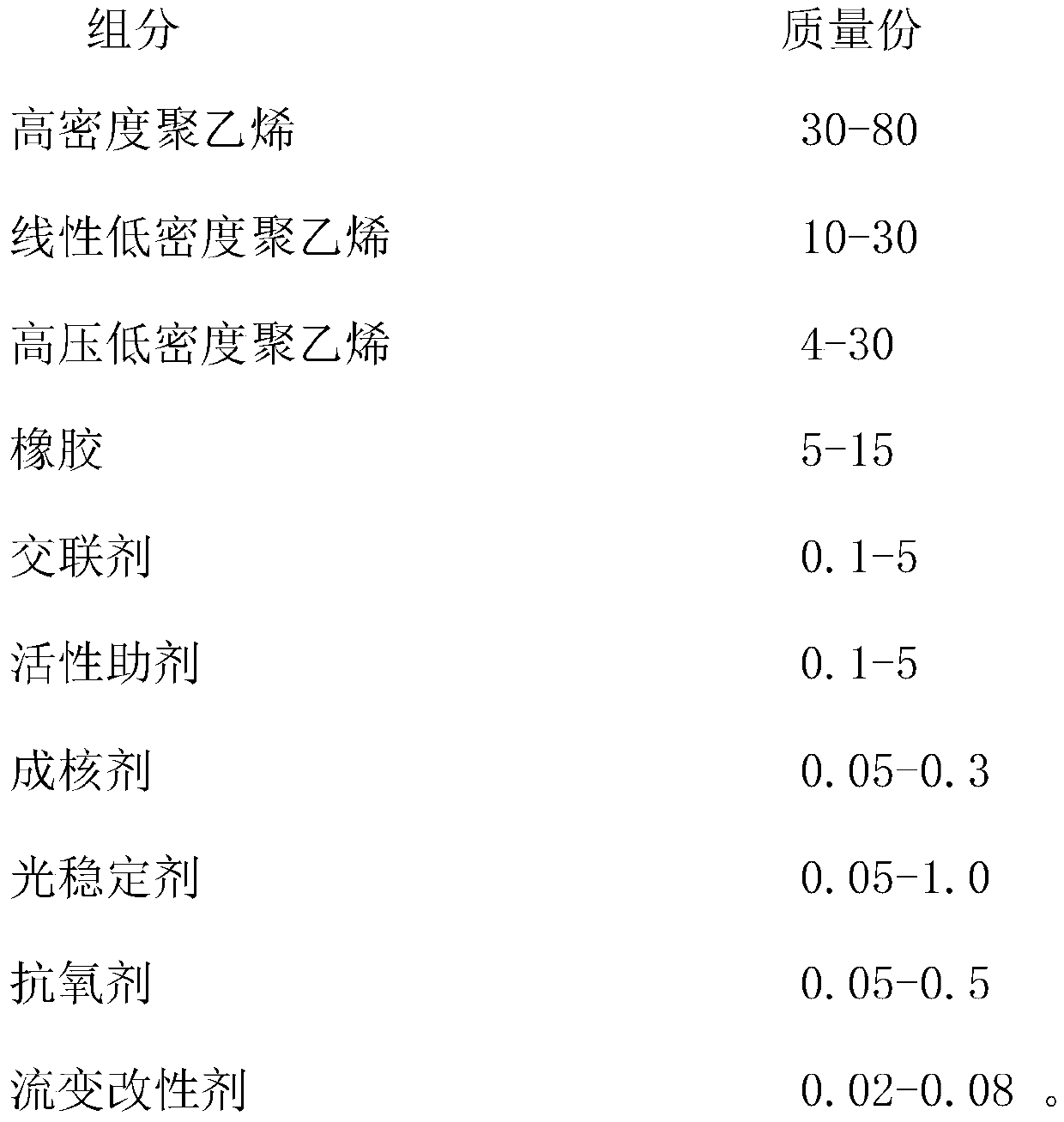

Polyethylene composition for hazardous waste storage containers

InactiveCN111518330AGood impact resistance at low temperatureLinear low-density polyethyleneLow-density polyethylene

The invention discloses a polyethylene composition for hazardous waste storage containers. The polyethylene composition comprises the following components in parts by mass: 30 to 80 parts of high-density polyethylene, 10 to 30 parts of linear low-density polyethylene, 4 to 30 parts of high-pressure low-density polyethylene, 5 to 15 parts of rubber, 0.1 to 5 parts of a cross-linking agent, 0.1 to 5parts of an active additive, 0.05 to 0.3 part of a nucleating agent, 0.05 to 1.0 part of a light stabilizer, 0.05 to 0.5 part of an antioxidant and 0.02 to 0.08 part of a rheology modifier. Accordingto the invention, high-density polyethylene is used as a main body, and linear low-density polyethylene and high-pressure low-density polyethylene are used as auxiliary materials; by adding the rubber components, the polyethylene composition has excellent low-temperature impact resistance, and is suitable for preparation of the hazardous waste storage containers, especially medium-and-low-level nuclear waste storage containers; and the hazardous waste storage containers are allowed to have excellent low-temperature impact resistance, and can store medium-and-low-level nuclear waste at a low temperature for 300 years or more.

Owner:康派新材料科技(扬州)有限公司

Storage system for radioactive nuclear waste with pressure surge protection

ActiveUS11443862B2Improves Structural IntegrityControl highNuclear energy generationPortable shielded containersHermetic sealVacuum chamber

A radioactive nuclear waste storage system includes a cask comprising a hermetically sealed internal cavity configured for holding the waste such as spent nuclear fuel submerged in an inventory of water. One or more pressure surge capacitors disposed inside the cask include a vacuum cavity evacuated to sub-atmospheric conditions prior to storage of fuel in the cask. At least one rupture disk seals a vacuum chamber inside each capacitor. Each rupture disk is designed and constructed to burst at a predetermined burst pressure level occurring inside the cask external to the capacitor. This allows excess cask pressure occurring during a high pressure excursion resulting from abnormal operating conditions to bleed into capacitor, thereby returning the pressure inside the cask to acceptable levels. In one embodiment, the capacitors are located in peripheral regions of the cask cavity adjacent to the circumferential wall of the cask body.

Owner:HOLTEC INT

Nuclear waste storage tank

ActiveCN108352203BNuclear energy generationPortable shielded containersHermetic sealEnvironmental engineering

In one embodiment, a dry storage system for radioactive nuclear waste includes a canister having a tubular shell defining an interior cavity for storing nuclear waste, a lid sealably welded to one end of the shell and attached to An end closure for the second end of the housing. The end closure includes a base plate having an upwardly turned peripheral annular closure flange. In one embodiment, a circumferentially extending butt joint is formed between the closing flange and the second end of the housing, the butt joint being hermetically sealed by a full wall thickness butt weld. Various embodiments may further include a secondary pressure maintaining barrier that encloses the tank or selected portions thereof that are most susceptible to failure under certain conditions.

Owner:HOLTEC INT

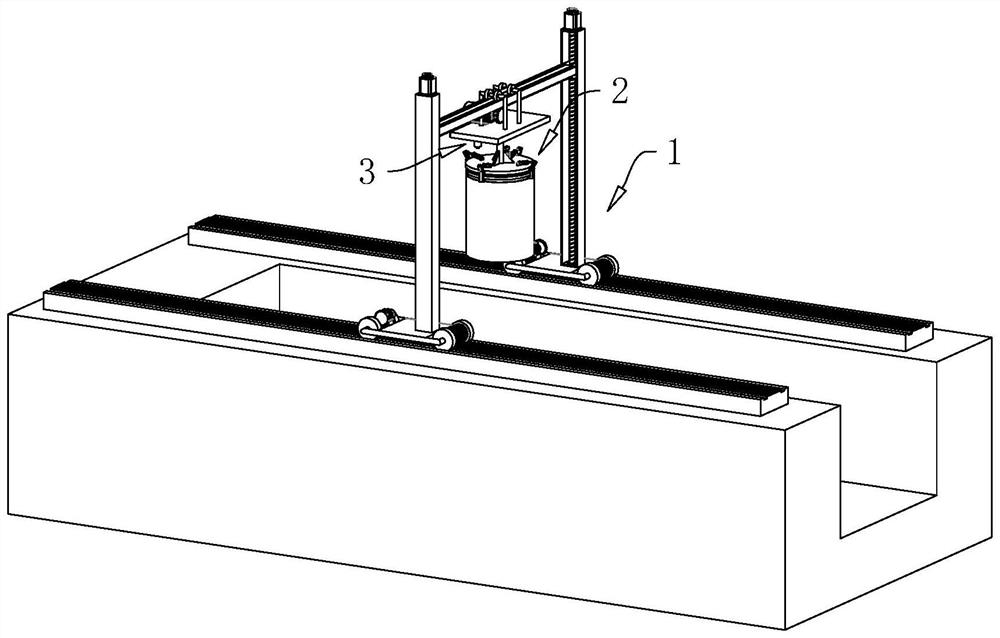

A metal material corrosion test device and method in a high-compacted bentonite environment

InactiveCN105115887BSolve preparation difficultiesAvoid concentration changesWeather/light/corrosion resistanceMetallic materialsChemical test

The invention belongs to the field of corrosion electrochemical testing, in particular to a metal material corrosion testing device and method in a high-pressure bentonite environment. The device includes a high-compacted bentonite bearing cabin and a compacted soil sheet located in the high-compacted bentonite loaded cabin, a connection and export system, a three-electrode system and a sealing plug, and the compacted soil sheet is connected to the high-compacted bentonite bearing cabin through the connection and export system , and lead out from the high-compacted bentonite bearing cabin through the connection export system, the compacted soil sheet is used to compact the bentonite carried in the high-compacted bentonite bearing cabin to prepare high-compacted bentonite, and the sealing plug is used for all The sealing of the high-compacted bentonite bearing compartment is described, and the three-electrode system is connected to an external electrochemical workstation through wires to conduct corrosion tests on metal materials. The invention can truly simulate the deep geological environment where the nuclear waste storage tank is buried, and obtain the corrosion degree of the storage tank material in each burial stage.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

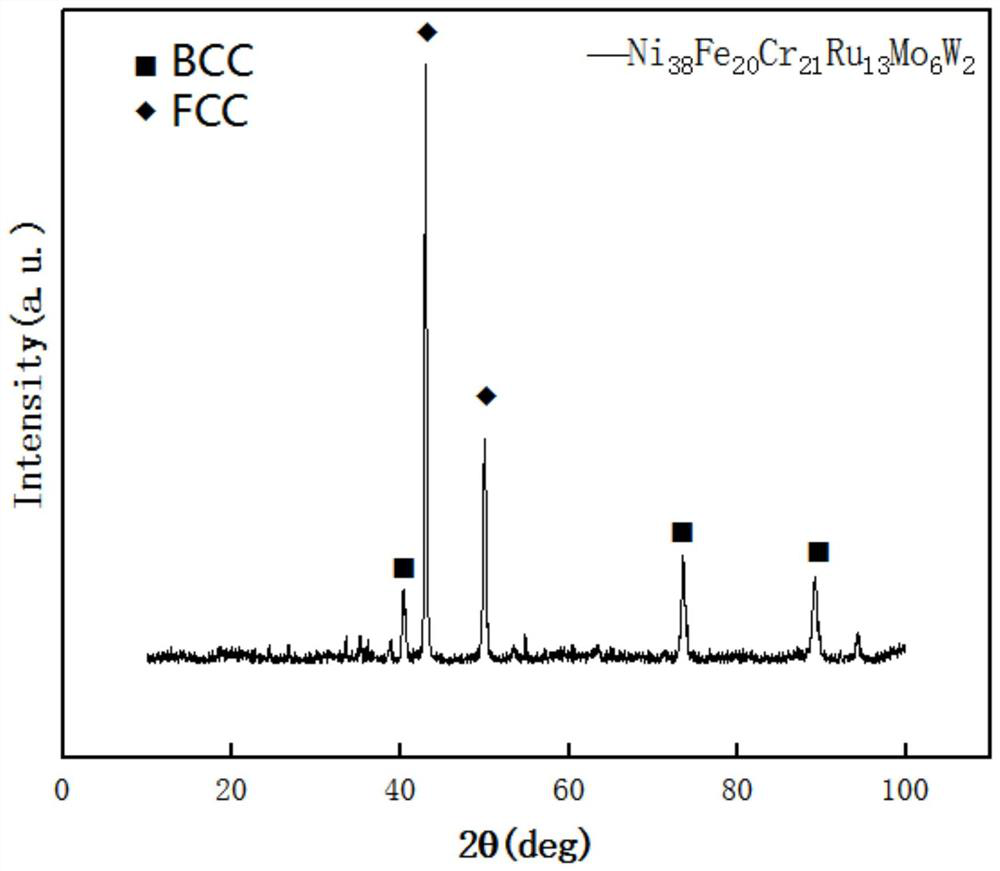

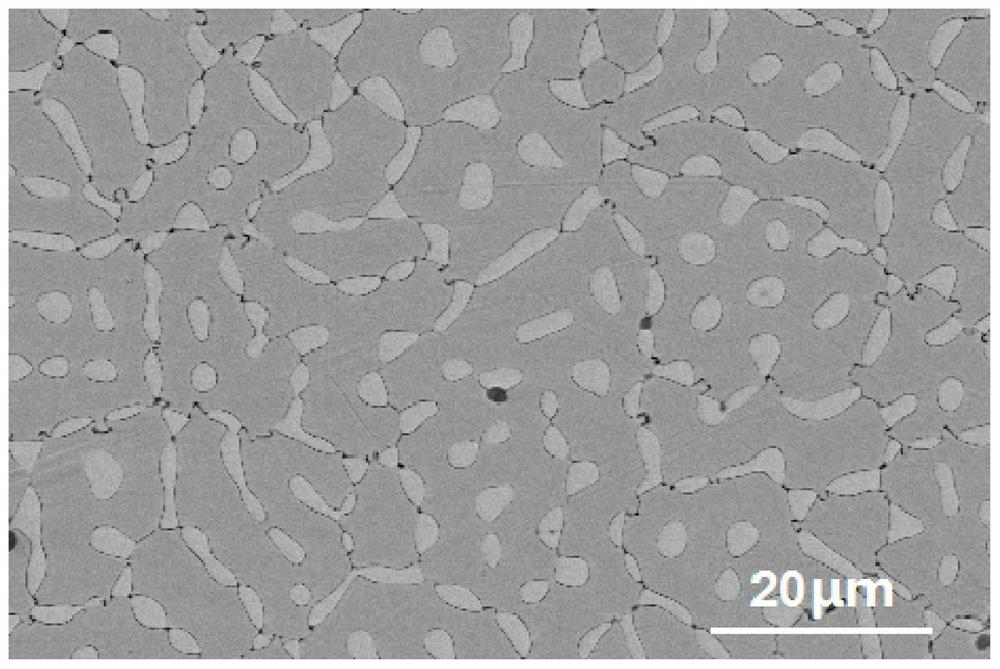

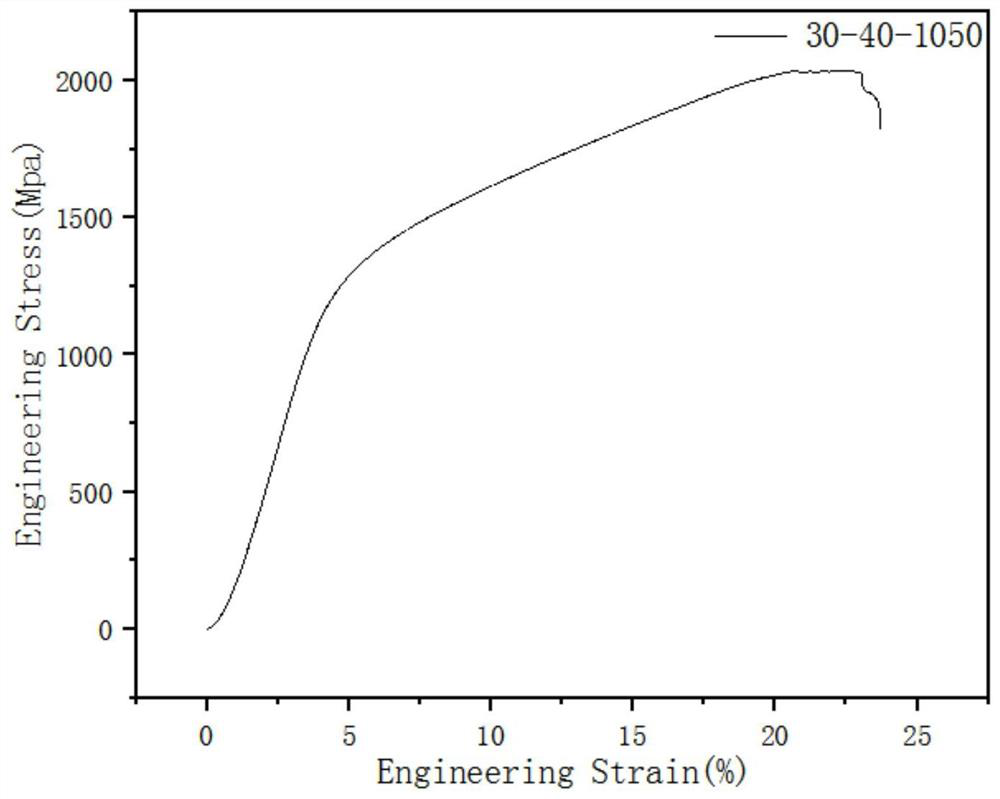

High-corrosion-resistance non-equimolar high-entropy alloy and preparation method thereof

The invention discloses a high-corrosion-resistance non-equimolar high-entropy alloy and a preparation method thereof. The NiFeCrRuMoW high-entropy alloy comprises the following components: Ni, Fe, Cr, Ru, Mo and W. Mechanical alloying is implemented through mechanical powder mixing and ball milling, then the NiFeCrRuMoW corrosion-resistant high-entropy alloy material with good comprehensive performance is prepared through spark plasma sintering, and the NiFeCrRuMoW corrosion-resistant high-entropy alloy material is uniform in structure and good in strength, hardness and other performance. In order to explore the optimal preparation conditions, an orthogonal experimental method is selected to carry out three-factor three-level variable design, and the factors are ball milling time, sintering pressure and sintering temperature. According to the finally prepared optimal alloy, the compressive strength is higher than 2, 000 Mpa, the yield strength is higher than 1, 100 Mpa, the hardness is larger than 550 HV, the corrosion rate is only 0.1107 mm / year, and the corrosion resistance is extremely excellent. In addition, the alloy is simple in preparation process and easy for industrial production, and can be used as a structural material of a nuclear waste storage container in the nuclear power industry.

Owner:XI AN JIAOTONG UNIV

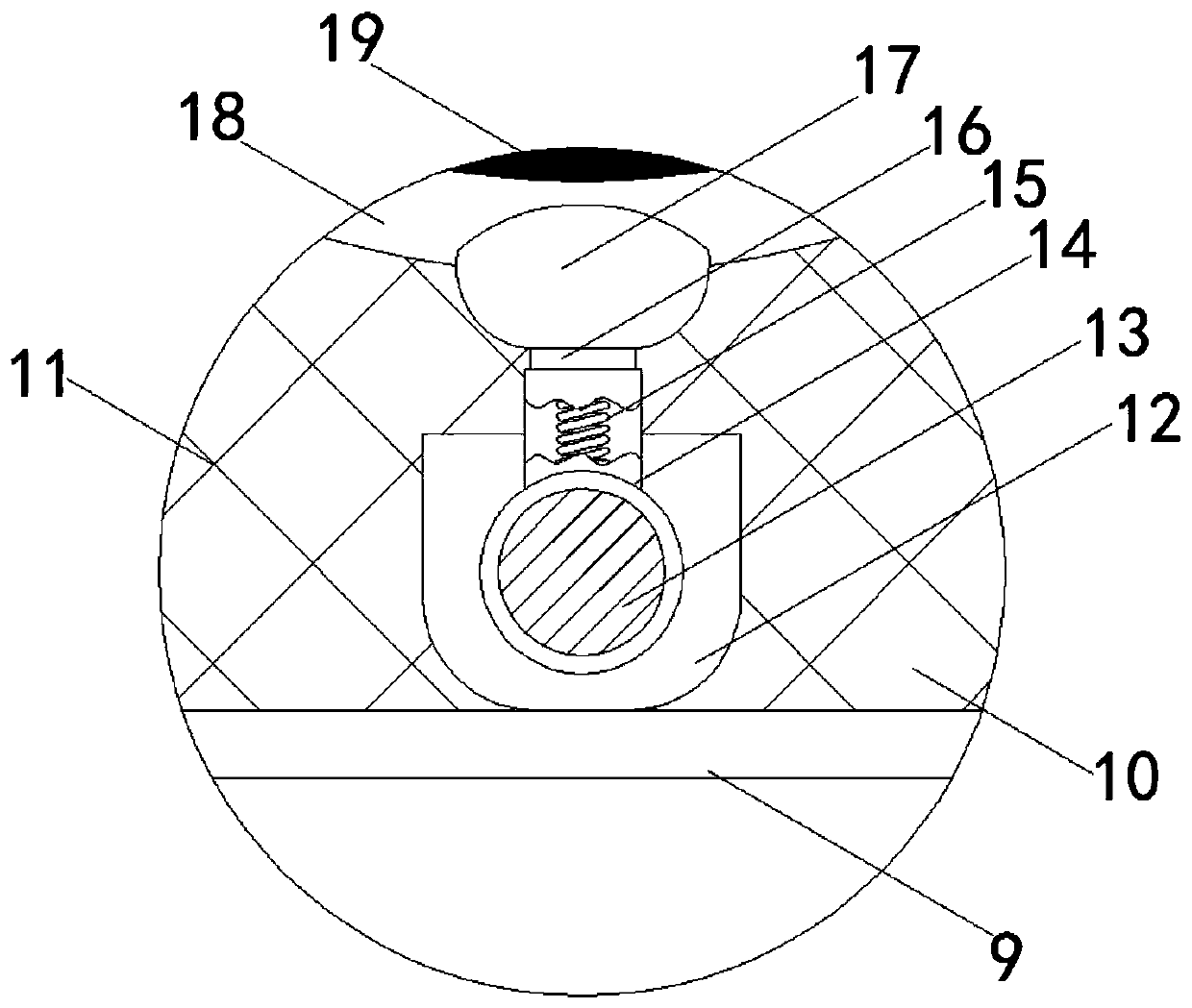

Nuclear waste storage container capable of monitoring sealing condition based on big data

InactiveCN111696696AImprove sealingStorage status can be monitoredPortable shielded containersRadioactive decontaminationWaste treatmentMechanical engineering

The invention relates to the technical field of nuclear waste treatment. The invention further discloses a nuclear waste storage container capable of monitoring the sealing condition based on the bigdata. The nuclear waste storage container includes a tank body, wherein the left side of the tank body is fixedly connected with a connecting rod; a rotating rod is movably connected to the interior of the connecting rod; the outer surface of the rotating rod is fixedly connected with a movable rod; the right side of the movable rod is fixedly connected with a sealing cover; the top of the sealingcover is fixedly connected with a handle; the inner surface of the sealing cover is fixedly connected with a sealing ring; and an annular block is fixedly connected to the inner surface of the tank body, fixing grooves are formed in the left side and the right side of the annular block correspondingly, springs are fixedly connected to the inner bottom walls of the two fixing grooves correspondingly, movable plates are fixedly connected to the tops of the two springs correspondingly, and supporting rods are fixedly connected to the interiors of the two movable plates correspondingly. The nuclear waste storage container capable of monitoring the sealing condition can monitor the sealing condition and is convenient to use.

Owner:YANGZHOU HONGXIN LINE EQUIP

Preparation method of iron-based amorphous coating

InactiveCN102041468BImprove corrosion resistanceImprove liquidityMolten spray coatingPorosityAbsorption capacity

The invention provides a preparation method of an iron-based amorphous coating. Iron-based amorphous alloy powder is used as a raw material, and flame spraying is adopted to prepare the amorphous coating by activity combustion high speed fuel gas. The amorphous alloy powder contains the following elements and inevitable impurities: 16.0-19.0 of Cr; 1.0-3.0 of Mn; 4.0-9.0 of Mo; 1.0-3.0 of W; 13.0-17.0 of B; 2.5-4.5 of C; 1.0-3.5 of Si; and the balance of Fe. In the invention, preparation cost of the amorphous coating is reduced, the prepared iron-based amorphous coating and a substrate are bonded tightly, the structure is compact, the porosity and the oxygen content are very low, the iron-based amorphous coating has high hardness, excellent corrosion resistance and unique non-magnetism, thus the iron-based amorphous coating has a great application prospect in the field of ship, hydraulic, oil field development establishment, and nonmagnetic vessel hull; and because the content of B ishigher, the iron-based amorphous coating has favorable neutron absorption capacity, and can be used for a nuclear waste storage tank.

Owner:HUAZHONG UNIV OF SCI & TECH

Screen for converting X-rays into light photons

A screen panel for converting X-rays into light photons includes a rigid foam plate (2), a first layer (1) of composite material located on one face of the rigid foam plate (2) and a second layer (3) of composite material located on the other face of the rigid foam plate, parallel to the first face. The screen panel applies, for example, to medical radiology and to non-destructive testing of nuclear waste storage packages.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

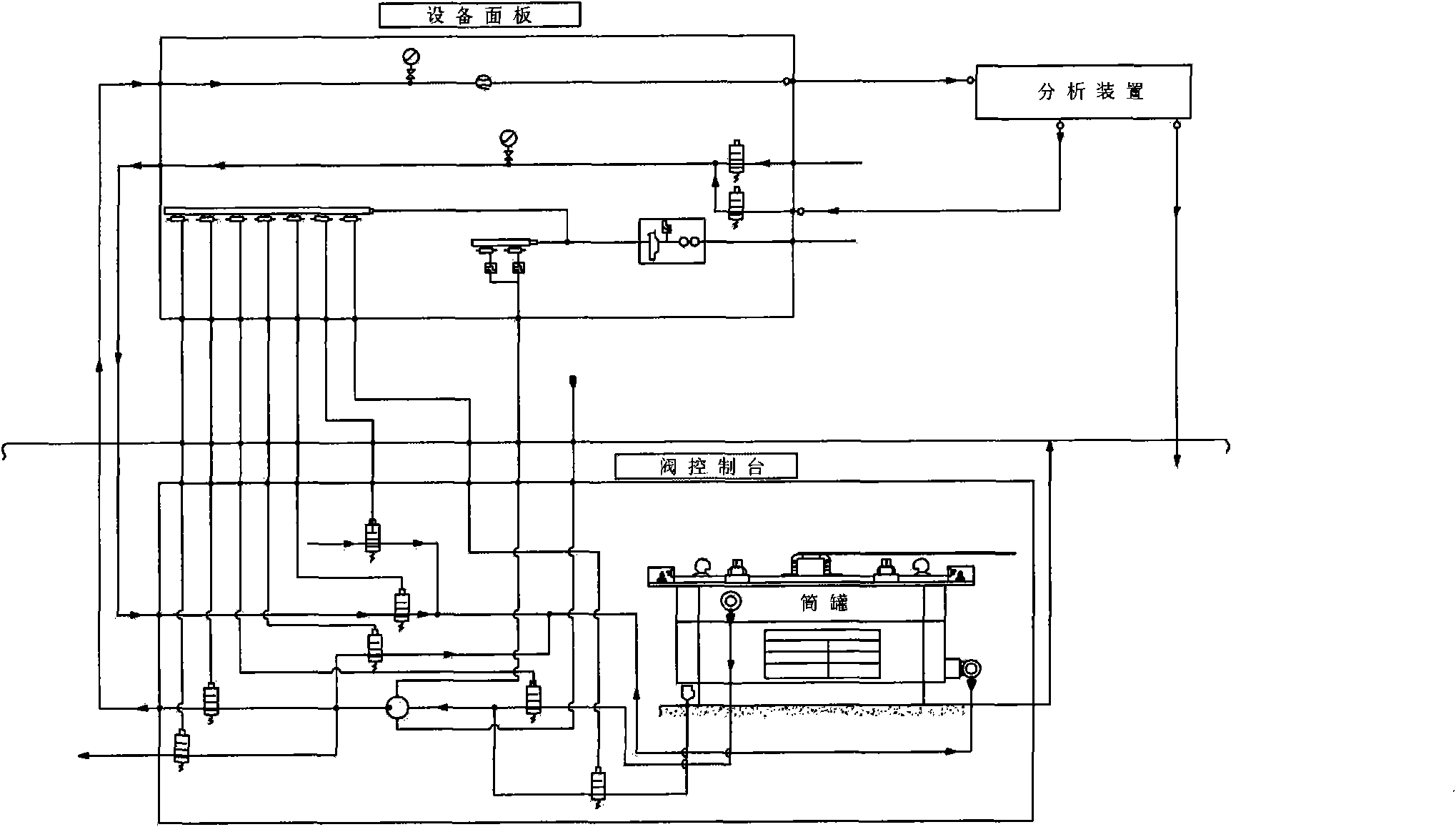

Spent fuel defect detecting system

ActiveCN101957357BMaterial analysis using wave/particle radiationNuclear energy generationNuclear waste storageHeavy water

PURPOSE: By safeing and rapidly advancing the test process of the nuclear fuel the use after-edge flaw detection system improves the safety of the Atomic Electrical Power Plant equipment. CONSTITUTION: In the inside which canister is shut tightly with cover, the fuel is stored after use after use in the coke weighing hopper floor. The valve cone brush has the MC type pickup bolt for pulling up canister, and the pump and the valve sending the nuclide sample to the reservoir outside. The equipment panel is installed outside reservoir(100).

Owner:KEPCO NUCLEAR FUEL CO LTD

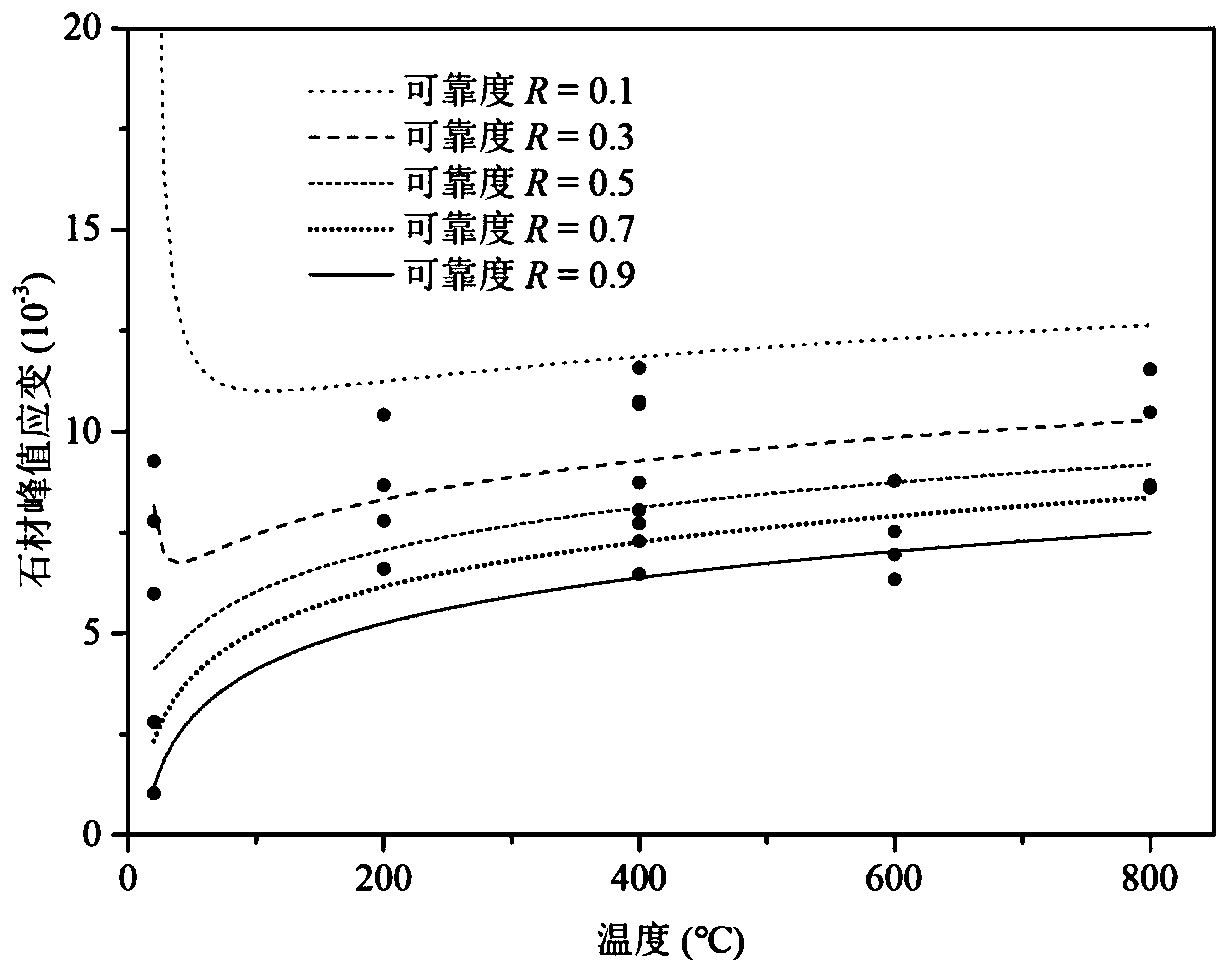

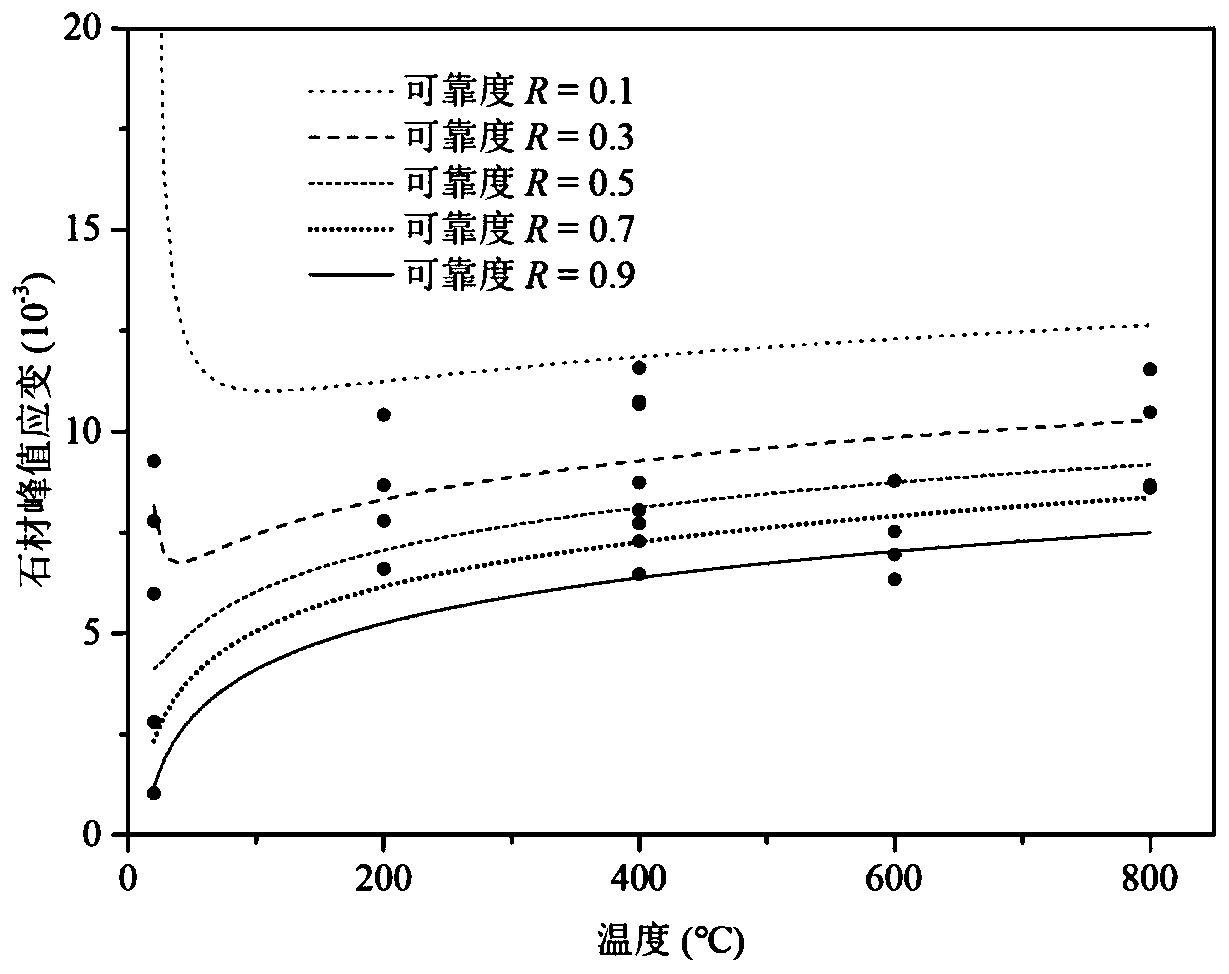

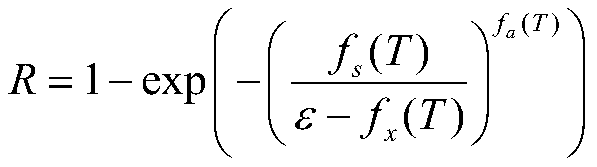

Reliability modeling method and prediction method for stone peak strain at high temperature

InactiveCN110008519AReduce constraintsIncrease flexibilityDesign optimisation/simulationSpecial data processing applicationsRock engineeringPredictive methods

The invention discloses a reliability modeling method and a prediction method for stone peak strain at high temperature. The stone is widely applied to the field of constructional engineering, and thehigh-temperature performance of the stone is very important for the safety of a building structure under fire. In addition, in the geological environment of projects such as deep resource mining, underground coal gasification, geothermal resource development and high-radioactivity nuclear waste storage, the rock engineering structure may experience a certain degree of high temperature. And the high temperature can cause the mechanical property of the stone to be degraded, so that the structural safety is reduced. According to the method, a Frechet distribution function is innovatively adoptedto describe the distribution law of the measured values of the stone peak strain. The reliability modeling method and the prediction method for the stone peak strain at the high temperature are invented, and technical support is provided for damage evaluation and prediction of the stone under the high temperature effect in building structures and rock engineering.

Owner:THE ARCHITECTURAL DESIGN & RES INST OF ZHEJIANG UNIV +1

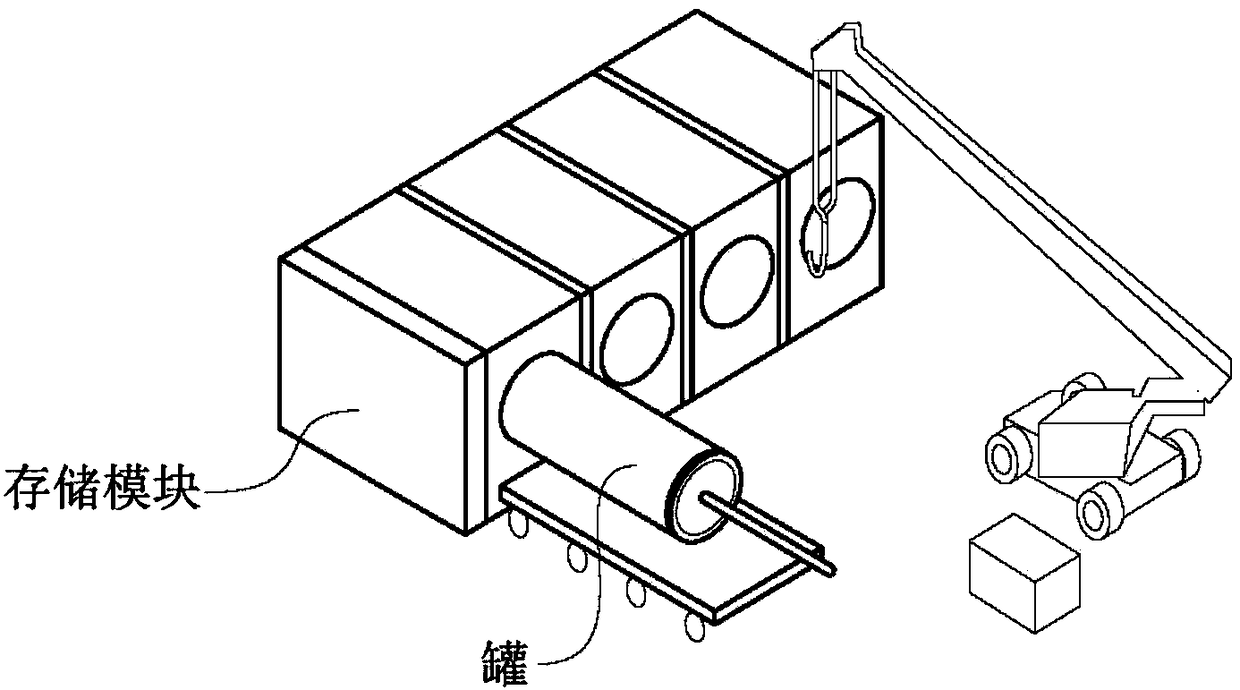

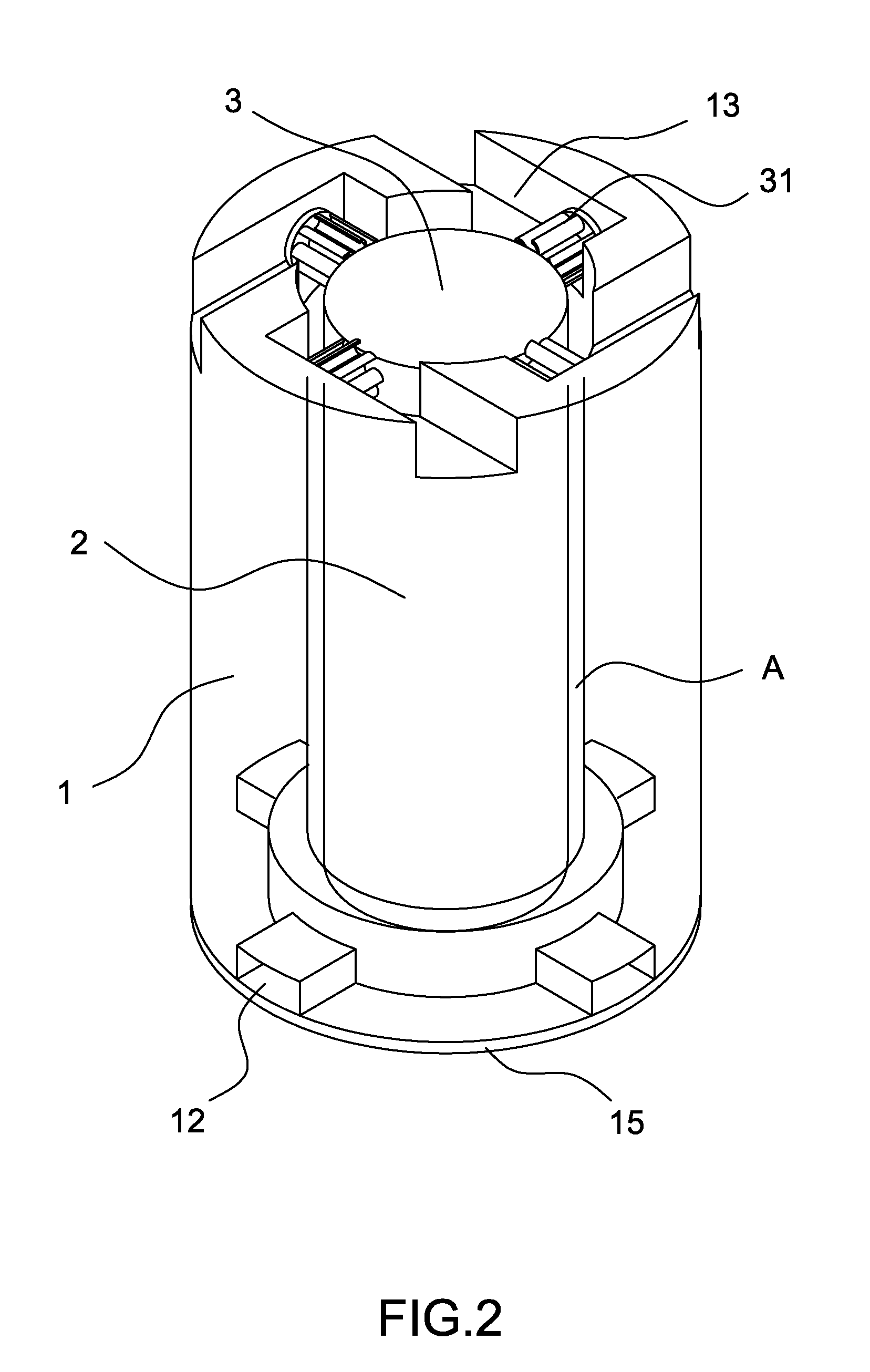

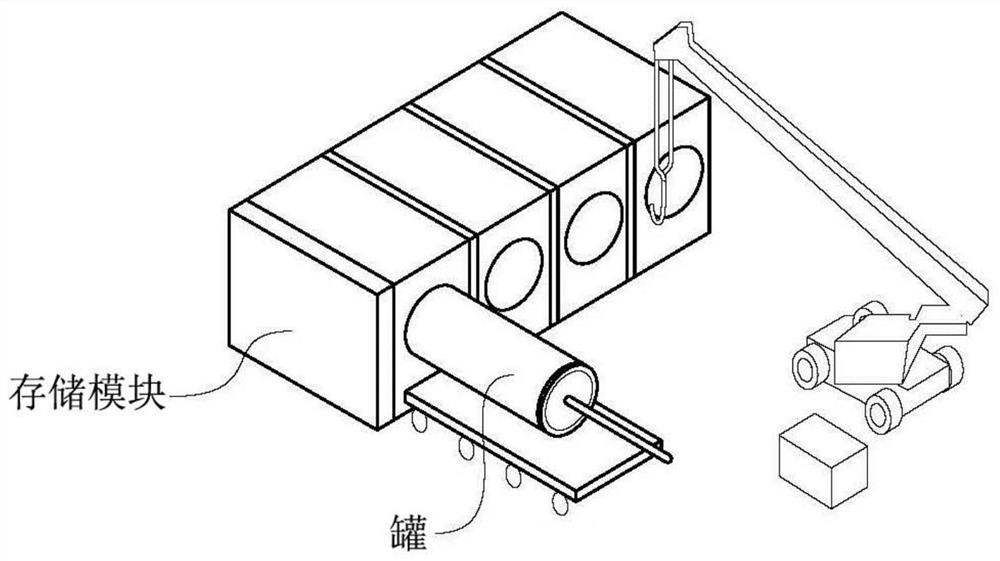

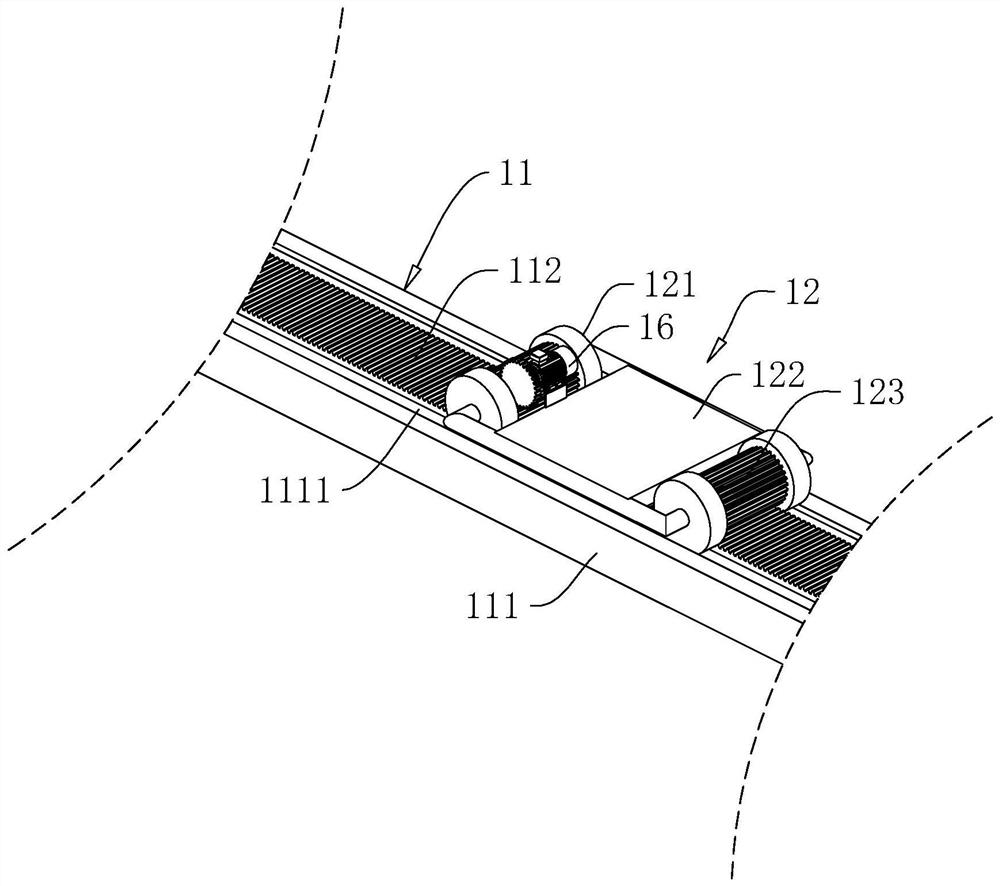

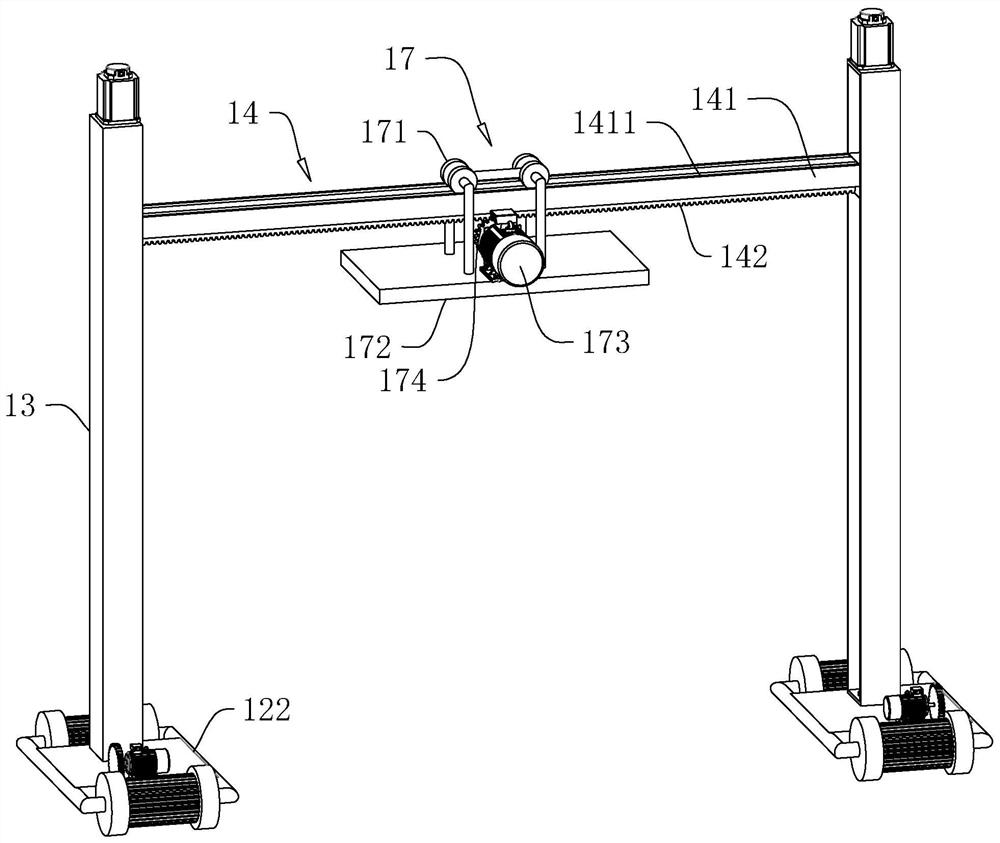

Warehousing and transporting device for nuclear waste

PendingCN114743708AEasy to shootEasy to handleNuclear energy generationPortable shielded containersNuclear waste storageEnvironmental geology

The invention relates to the field of storage and transportation, in particular to a nuclear waste storage and transportation device which comprises a first toothed rail, a first translation trolley is arranged on the first toothed rail, a lead screw is connected to the first translation trolley, and a second toothed rail is fixed to a sliding block of the lead screw. The second rack rail is connected with a translation assembly capable of moving along the second rack rail, the translation assembly is provided with a first camera for shooting downwards and a computer in communication connection with the first camera, and the translation assembly is further provided with a waste barrel grabbing structure used for grabbing nuclear waste barrels. The computer is further in communication connection with the first translation vehicle, the translation assembly and the waste barrel grabbing structure. The method has the effect that the unmanned level of the nuclear waste storage and transportation technology can be improved conveniently.

Owner:江苏西顿科技有限公司

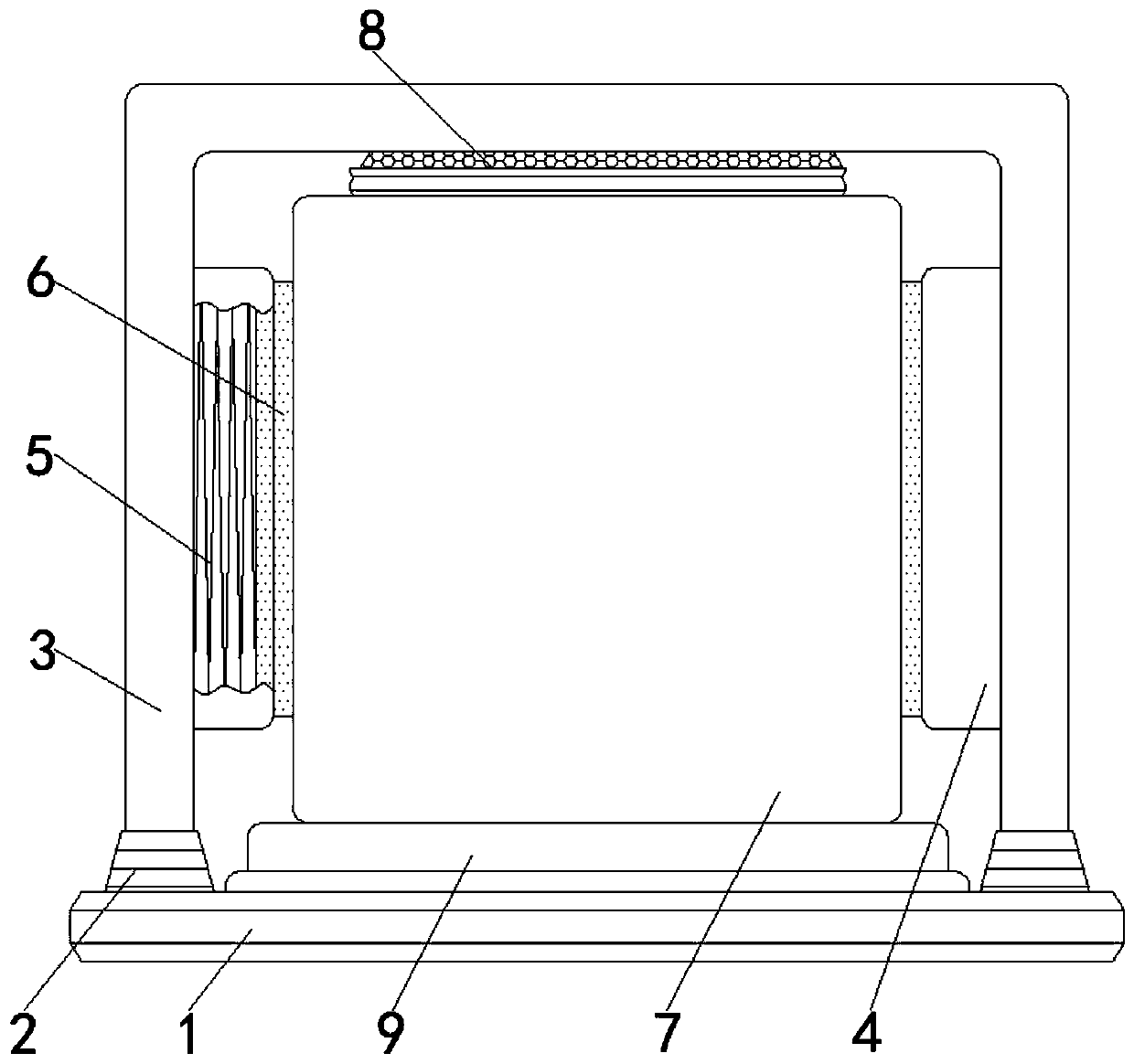

Nuclear waste storage container with good protectiveness

InactiveCN111508630AImprove protectionImprove stabilityPortable shielded containersMechanical engineeringNuclear waste storage

The invention relates to the technical field of nuclear waste, and discloses a nuclear waste storage container with good protectiveness. The nuclear waste storage container comprises a base, wherein the top of the base is fixedly provided with two supporting legs, and the tops of the two supporting legs are both connected with a supporting frame. According to the nuclear waste storage container with good protectiveness in the invention, a fixed rod, a second spring, a jacket, an anastomosis plate and a buffer sleeve are arranged, a storage barrel can be extruded and put into the anastomosis plate, and the buffer sleeve is extruded so as to allow the storage barrel to be placed stably; meanwhile, when the storage barrel is subjected to external acting force, the anastomosis plate can extrude the second spring through the jacket so as to disperse the acting force, and thus, the storage barrel is more stable and is not prone to toppling over; and a pressing plate, a first spring and a limiting box are arranged, the pressing plate extrudes the first spring to disperse the acting force when the storage barrel is subjected to external force, so the storage barrel is not prone to topplingover, the storage barrel used for nuclear waste is better in protectiveness, and a user can use the storage barrel more conveniently.

Owner:YANGZHOU HONGXIN LINE EQUIP

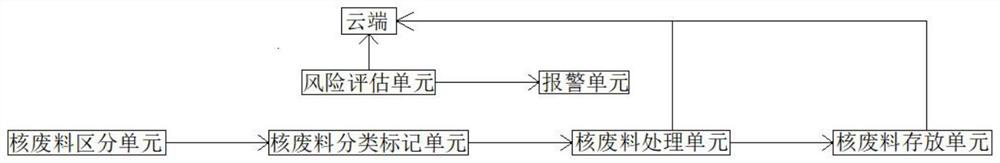

Nuclear power waste treatment system

PendingCN114203322AReduce pollutionConvenience for deep burial workRadioactive decontaminationNuclear powerProcess engineering

The invention relates to the technical field of nuclear power waste, and discloses a nuclear power waste treatment system which comprises a nuclear waste distinguishing unit, a nuclear waste treatment unit, a nuclear waste classification marking unit, a risk assessment unit, an alarm unit, a nuclear waste storage unit and a cloud end. And the output end of the nuclear waste distinguishing unit is in communication connection with the input end of the nuclear waste classifying and marking unit. According to the nuclear power waste treatment system, each piece of nuclear waste can be classified and marked through the arranged nuclear waste classifying and marking unit, risk judgment is conducted through the risk assessment unit according to the danger degree of the nuclear waste, workers can pay attention to treatment of high-risk nuclear waste conveniently, and through the arranged nuclear waste marking and numbering module, the work efficiency is improved. A unique number can be generated for each processed nuclear waste material, and the information is uploaded to the cloud for backup, so that a user can conveniently check the storage time of each nuclear waste material in time to judge whether the storage time meets the deep burying processing standard or not, and the deep burying work of the nuclear waste materials in the later period is facilitated.

Owner:神通特种机器人(江苏)有限公司

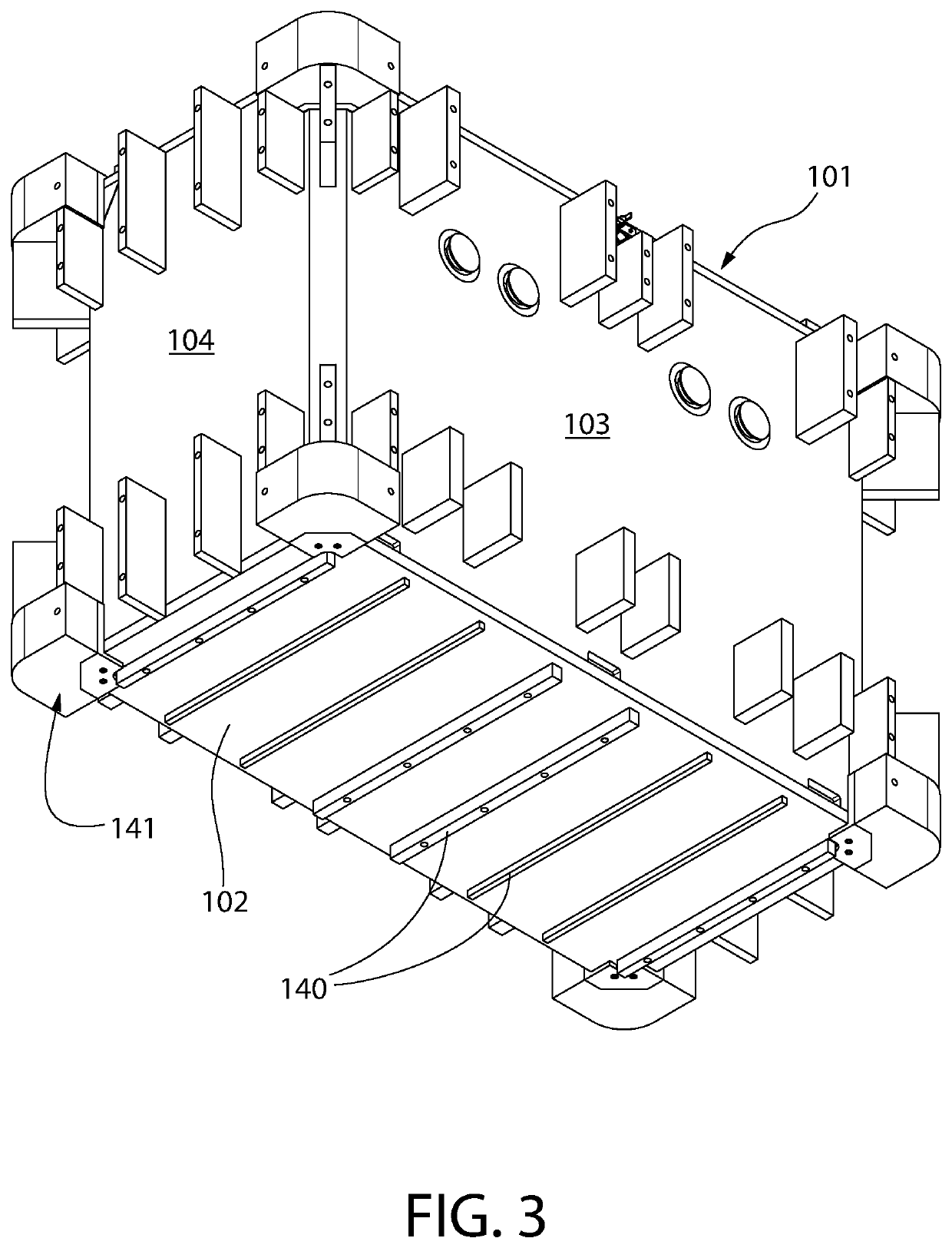

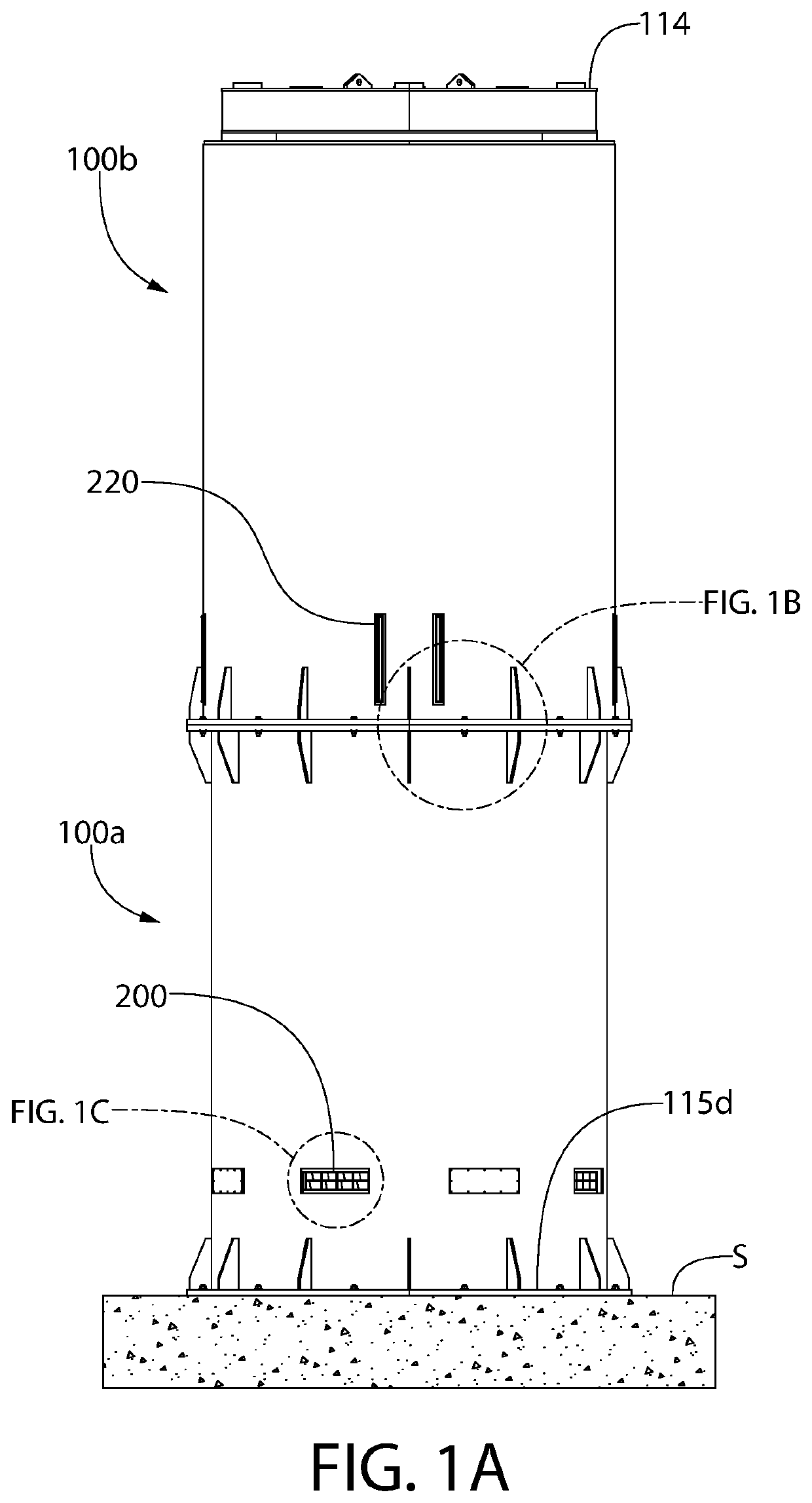

Stackable nuclear waste storage system

PendingUS20220367078A1Nuclear energy generationPortable shielded containersNuclear waste storageRadiation shield

A passively cooled stackable nuclear waste storage system may include a pair of vertically stacked radiation-shielded nuclear waste storage casks. Each cask has a cavity which holds a nuclear waste canister containing spent nuclear fuel or other high-level radioactive wastes. The lower cask may be founded on an above-grade concrete pad. The upper cask is vertically stacked on and detachably coupled to the lower cask. The upper cask comprises a perforated baseplate which establishes fluid communication between cavities of both casks and is configured to prevent radiation shine. One or both casks may include air inlet vents configured to draw ambient ventilation air into each respective cask cavity for cooling the nuclear waste. In operation, air is drawn inward into each cask cavity independently. Air heated in the lower cask rises into the upper cask where it mixes with air drawn into the upper cask and is returned to atmosphere.

Owner:HOLTEC INT

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com