High-corrosion-resistance non-equimolar high-entropy alloy and preparation method thereof

A technology of high-entropy alloy and high corrosion resistance, which is applied in the field of molar high-entropy alloy and its preparation, can solve the problems of difficult control of volatile elements and poor alloy performance, and achieve uniform metallographic structure, excellent corrosion resistance, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

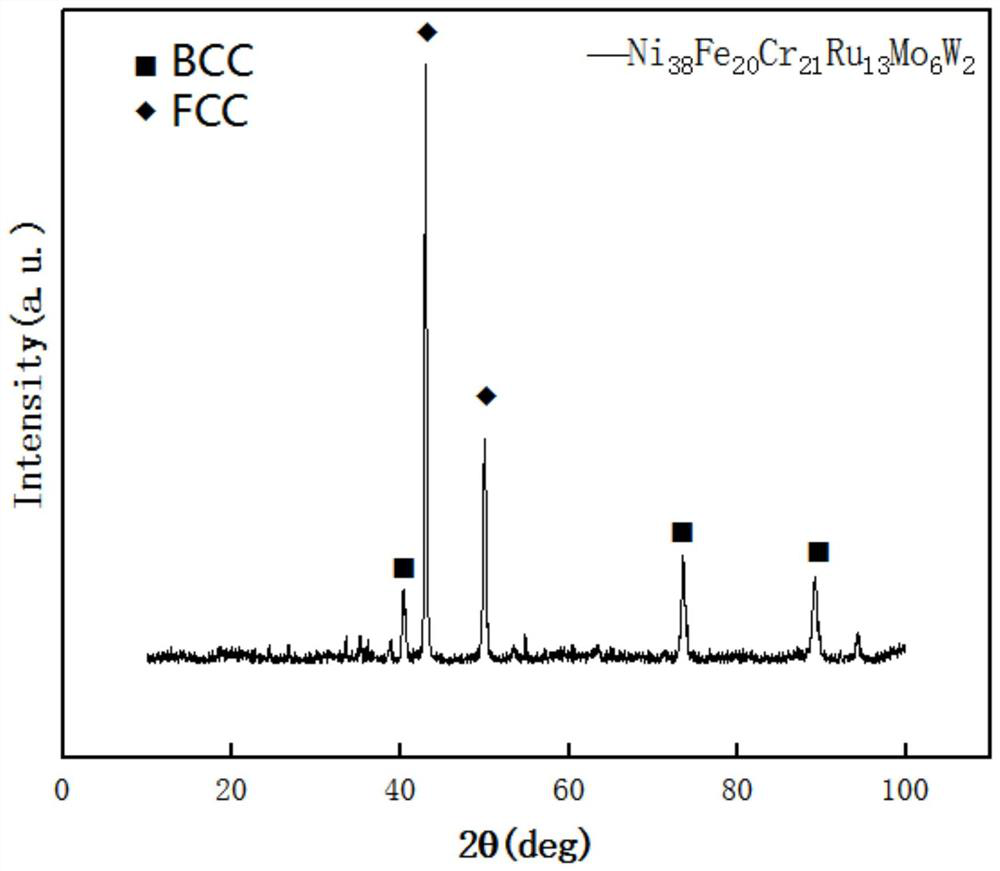

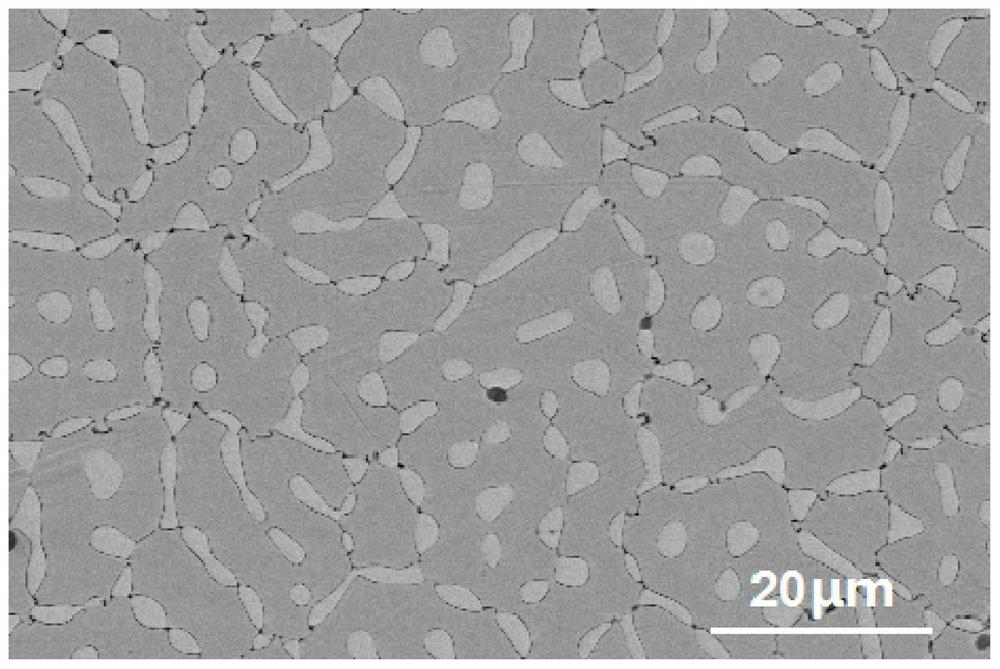

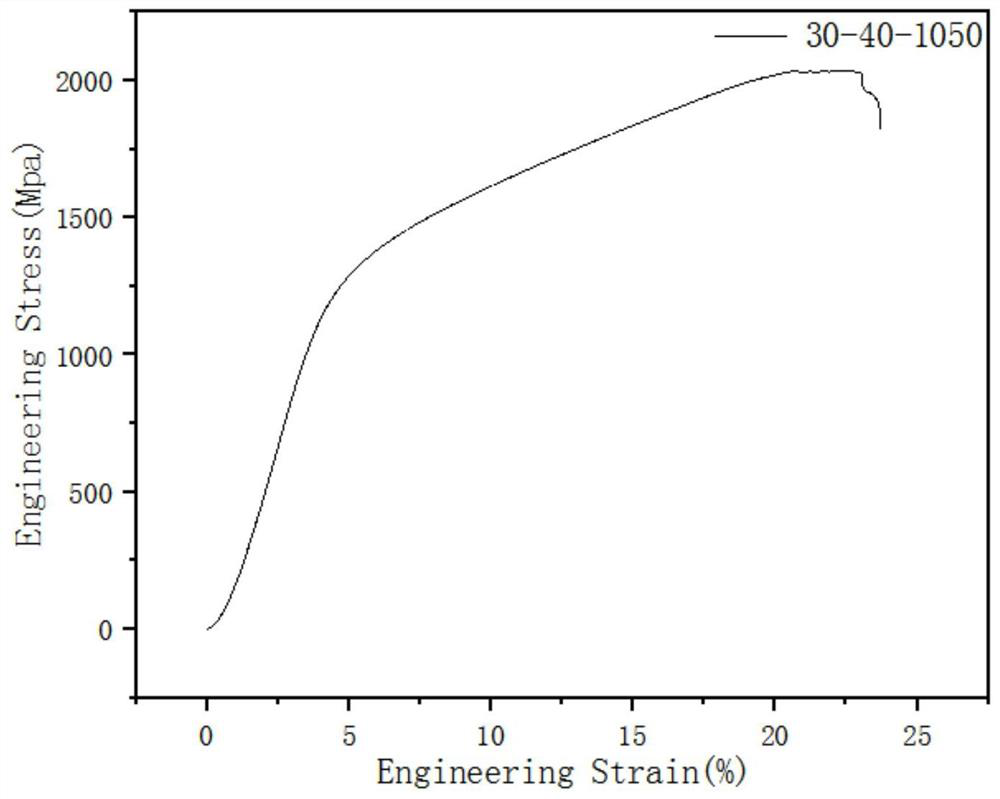

[0029] In this embodiment, the Ni-Fe-Cr-Ru-Mo-W corrosion-resistant high-entropy alloy is composed of Ni, Fe, Cr, Ru, Mo, W, and each component is constituted by mass percentage: Ni: 33.3 wt.%, Fe: 16.31wt.%, Cr: 16.68wt.%, Ru: 19.62wt.%, Mo: 8.6wt.%, W: 5.49wt.%.

[0030] The particle size of the original powder is: except the particle size of Ru powder is 100 microns, the particle size of other Ni, Fe, Cr, Mo, W powders are all 35-45 microns.

[0031] In the present embodiment, the preparation method of 30-40-1050 (the serial number represents ball milling for 30 hours, the sintering pressure is 40Mpa, and the sintering temperature is 1050°C) corrosion-resistant high-entropy alloy comprises the following steps:

[0032] Step 1: Ingredients

[0033] Weigh the six kinds of metal powders of Ni, Fe, Cr, Ru, Mo, and W according to the above mass ratio and transfer them to a ball milling tank lined with polytetrafluoroethylene with a capacity of 500mL;

[0034] Step 2: Ball Mill...

Embodiment 2

[0042]In this embodiment, the Ni-Fe-Cr-Ru-Mo-W corrosion-resistant high-entropy alloy is composed of Ni, Fe, Cr, Ru, Mo, W, and each component is constituted by mass percentage: Ni: 33.3 wt.%, Fe: 16.31wt.%, Cr: 16.68wt.%, Ru: 19.62wt.%, Mo: 8.6wt.%, W: 5.49wt.%.

[0043] The particle size of the original powder is: except the particle size of Ru powder is 100 microns, the particle size of other Ni, Fe, Cr, Mo, W powders are all 35-45 microns.

[0044] In this embodiment, the preparation method of 40-40-1050 (this number represents ball milling for 40 hours, the sintering pressure is 40Mpa, and the sintering temperature is 1050°C) corrosion-resistant high-entropy alloy comprises the following steps:

[0045] Step 1: Ingredients

[0046] Weigh the six kinds of metal powders of Ni, Fe, Cr, Ru, Mo, and W according to the above mass ratio and transfer them to a ball milling tank lined with polytetrafluoroethylene with a capacity of 500mL;

[0047] Step 2: Ball Milling

[0048] ...

Embodiment 3

[0053] In this embodiment, the Ni-Fe-Cr-Ru-Mo-W corrosion-resistant high-entropy alloy is composed of Ni, Fe, Cr, Ru, Mo, W, and each component is constituted by mass percentage: Ni: 33.3 wt.%, Fe: 16.31wt.%, Cr: 16.68wt.%, Ru: 19.62wt.%, Mo: 8.6wt.%, W: 5.49wt.%.

[0054] The particle size of the original powder is: except the particle size of Ru powder is 100 microns, the particle size of other Ni, Fe, Cr, Mo, W powders are all 35-45 microns.

[0055] In the present embodiment, the preparation method of 50-40-1050 (the serial number represents ball milling for 40 hours, the sintering pressure is 40Mpa, and the sintering temperature is 1050°C) corrosion-resistant high-entropy alloy comprises the following steps:

[0056] Step 1: Ingredients

[0057] Weigh the six kinds of metal powders of Ni, Fe, Cr, Ru, Mo, and W according to the above mass ratio and transfer them to a ball milling tank lined with polytetrafluoroethylene with a capacity of 500mL;

[0058] Step 2: Ball Mill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Compressive yield strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com