Entropy-stable RE2O3-AO2-B2O5 oxide ceramic and preparation method thereof

A technology of RE2O3-AO2-B2O5 and oxide ceramics is applied in the field of entropy-stabilized RE2O3-AO2-B2O5 oxide ceramics and their preparation, and can solve the problems of insufficient oxygen transport capacity, insufficient thermal expansion coefficient, poor nuclear radiation resistance and the like, Achieve high density, excellent fracture toughness and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Aiming at the problems of poor high-temperature stability, poor anti-nuclear radiation performance, high high-temperature thermal conductivity, insufficient thermal expansion coefficient, and insufficient oxygen transmission capacity of current rare earth oxide ceramic materials with fluorite-type and pyrochlore-type structures, the present invention provides a entropy stable RE 2 o 3 -AO 2 -B 2 o 5 The preparation method of oxide ceramics obtains high-concentration lattice defects by adjusting the stoichiometric ratio of different metal elements, and at the same time cooperates with entropy stabilization and rapid sintering methods to obtain high-entropy fluorite-type or pyrochlore-type rare earth oxides with excellent thermo-mechanical properties Ceramics, making it meet the performance needs of various application fields. Concrete preparation method comprises the following steps:

[0032] (1) Weigh the raw material rare earth oxide RE according to the stoichiome...

Embodiment 1

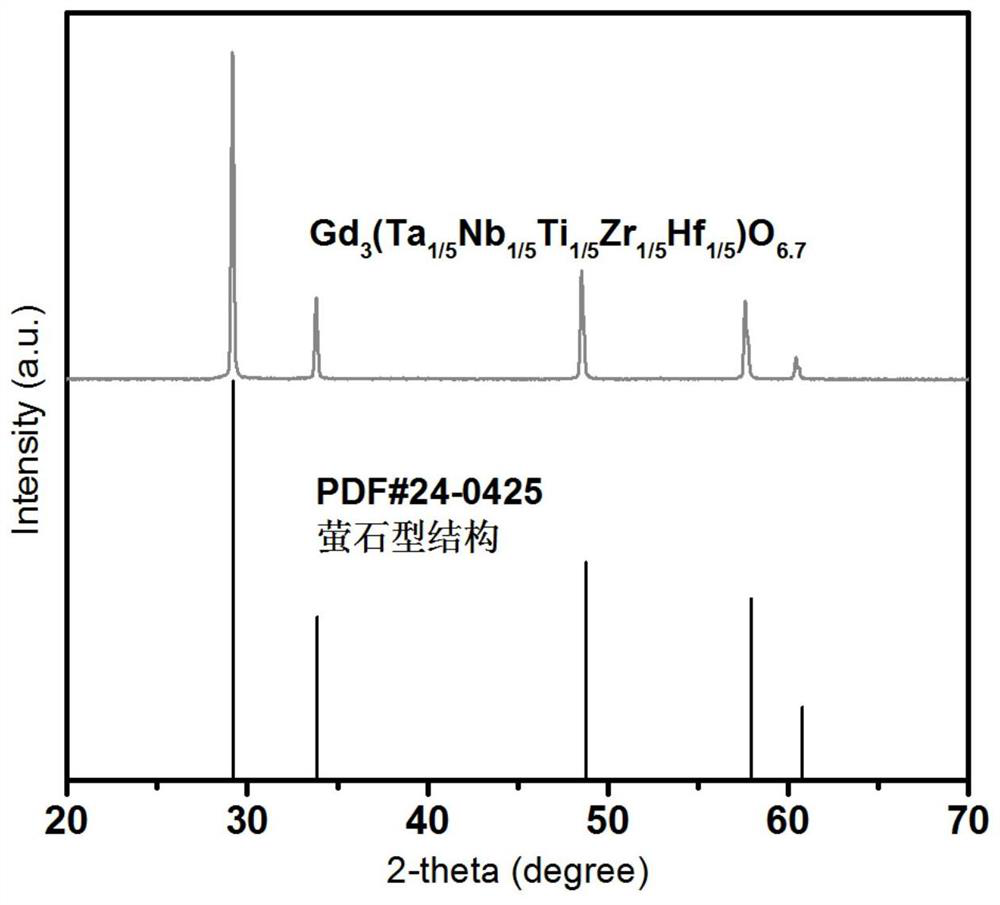

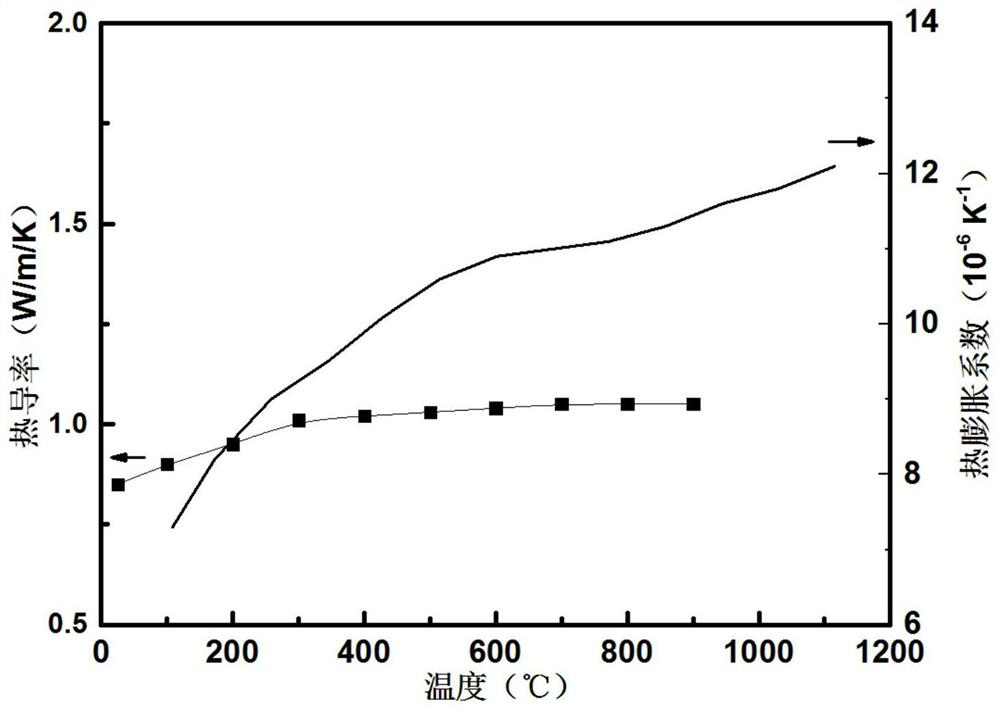

[0050] Preparation of Gd with fluorite structure 3 (Ta 1 / 5 Nb 1 / 5 Ti 1 / 5 Zr 1 / 5 f 1 / 5 )O 6.7 Ceramics, the specific process is as follows:

[0051] Will Gd 2 o 3 、 Ta 2 o 5 , Nb 2 o 5 、TiO 2 , ZrO 2 and HfO 2 Weigh according to the stoichiometric ratio, and then place it in a high-temperature furnace at 800°C for 5 hours to remove organic impurities contained in the powder and reduce the reactivity of the raw material powder; then cool the raw material powder to room temperature, and cool the The raw material powder, alcohol and zirconia balls are placed in a ball mill tank according to the mass ratio of 1:3:3 for ball mill mixing. Keep it warm at 100°C for 5 hours for drying treatment, and finally sieve with 600 mesh to obtain a fine powder. Weigh about 2.5g of the sieved powder and place it in a graphite grinding tool for development and molding, and then place it in a spark plasma sintering system for high temperature and high pressure sintering. The sinteri...

Embodiment 2

[0055] Preparation of pyrochlore-type Ho 2 (Ti 1 / 5 Zr 1 / 5 Hf 1 / 5 sn 1 / 5 Th 1 / 5 ) 2 o 7 Ceramics, the specific process is as follows:

[0056] Will Ho 2 o 3 、TiO 2 , SnO 2 , ThO 2 , ZrO 2 and HfO 2 Weigh according to the stoichiometric ratio, and then place it in a high-temperature furnace at 1200°C for 2 hours to remove organic impurities contained in the powder and reduce the reactivity of the raw material powder; then cool the raw material powder to room temperature, and cool the The raw material powder, alcohol and zirconia balls are placed in a ball mill tank according to the mass ratio of 1:2:2 for ball mill mixing. The speed of ball milling is 400 revolutions per minute, and the ball milling time is 36 hours. Insulate at 90°C for 8 hours for drying treatment, and finally sieve with 400 mesh to obtain fine powder. Weigh about 2.5g of the sieved powder and place it in a graphite grinding tool for development and molding, and then place it in a spark plasma s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com