Spent fuel defect detecting system

A technology for defect detection and waste fuel, which is applied in fuel oil testing, material inspection products, and analysis of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

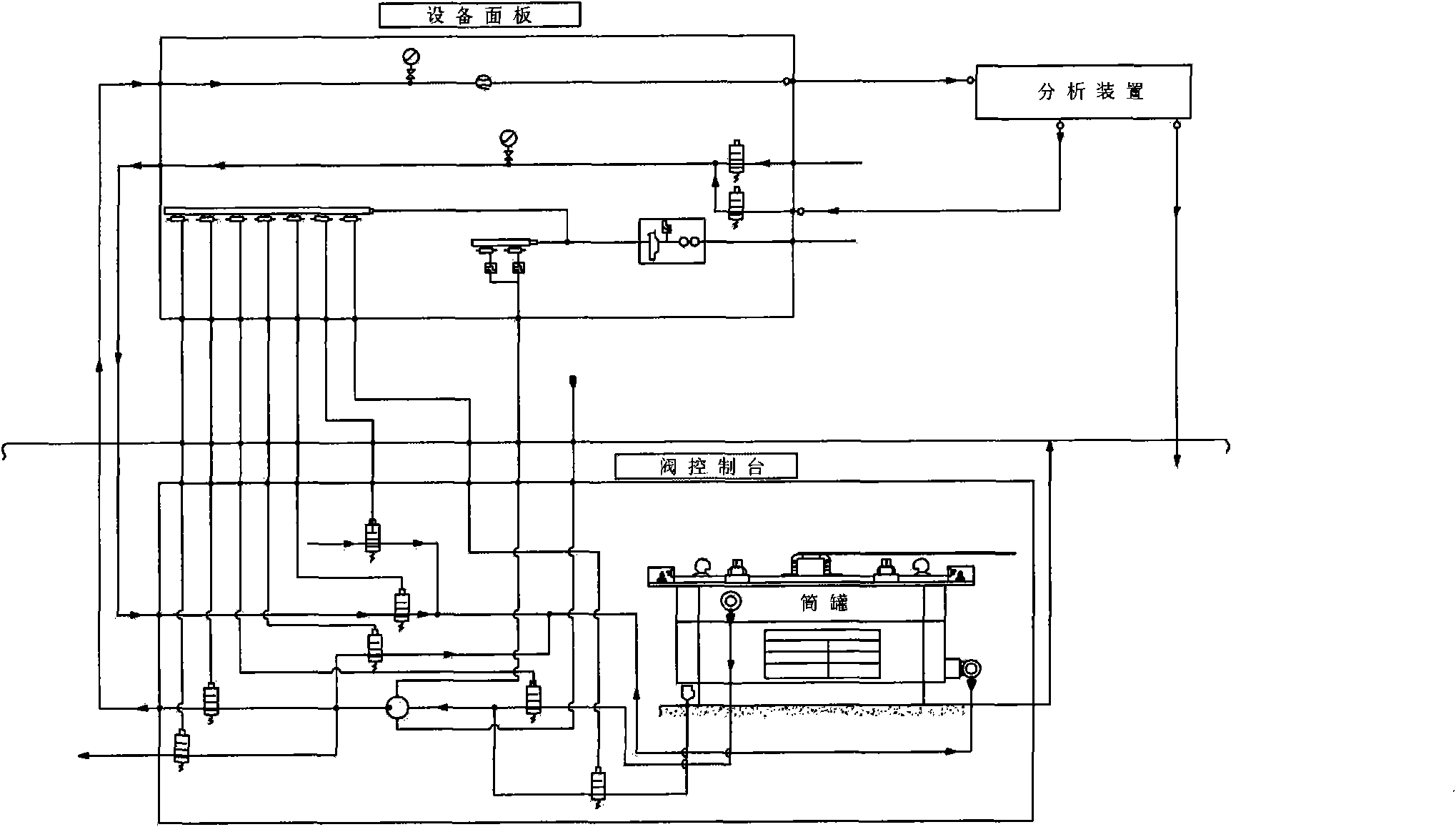

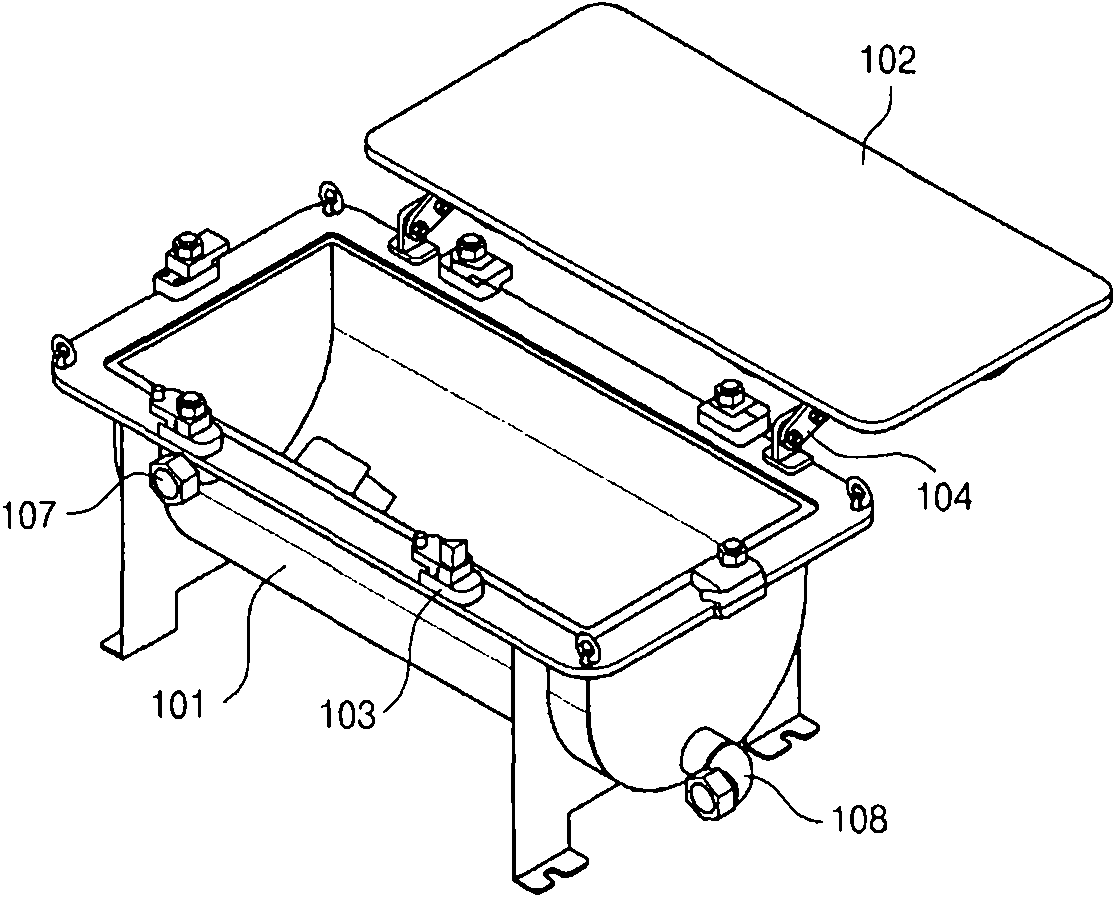

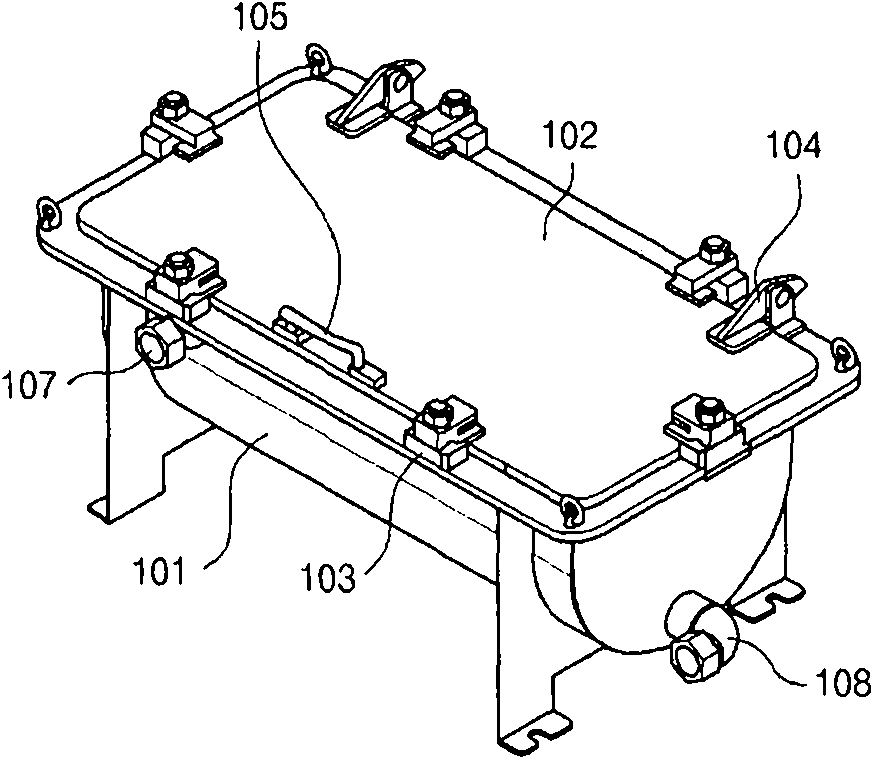

[0022] Hereinafter, a spent fuel defect detection system (hereinafter referred to as a detection system Sipping System) according to an embodiment of the present invention will be described with reference to the accompanying drawings.

[0023] figure 1 is a perspective view showing the overall structure of the system of the present invention, and FIG. 2 shows figure 1 The oblique view of the related canister, as shown in FIG. 3 figure 1 The oblique view of the valve console (ValveConsole) involved, Figure 4 shows figure 1 The oblique view of the involved equipment panel (Euipment Panel), as shown in FIG. 5 figure 1 An oblique view of the Operating Box involved.

[0024] figure 1 The overall structure of the detection system according to this embodiment is shown.

[0025] Accordingly, the detection system of the present embodiment is used in the detection of nuclear waste, and is installed in the nuclear waste storage tank of the nuclear power plant for heavy water furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com