Radiation-proof concrete composition, preparation method and prefabricated container

A concrete composition and radiation protection technology, applied in shielding, nuclear engineering, reactors, etc., can solve the problems of high cost of storage containers, achieve good chemical stability, improve compactness and durability, and have good durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

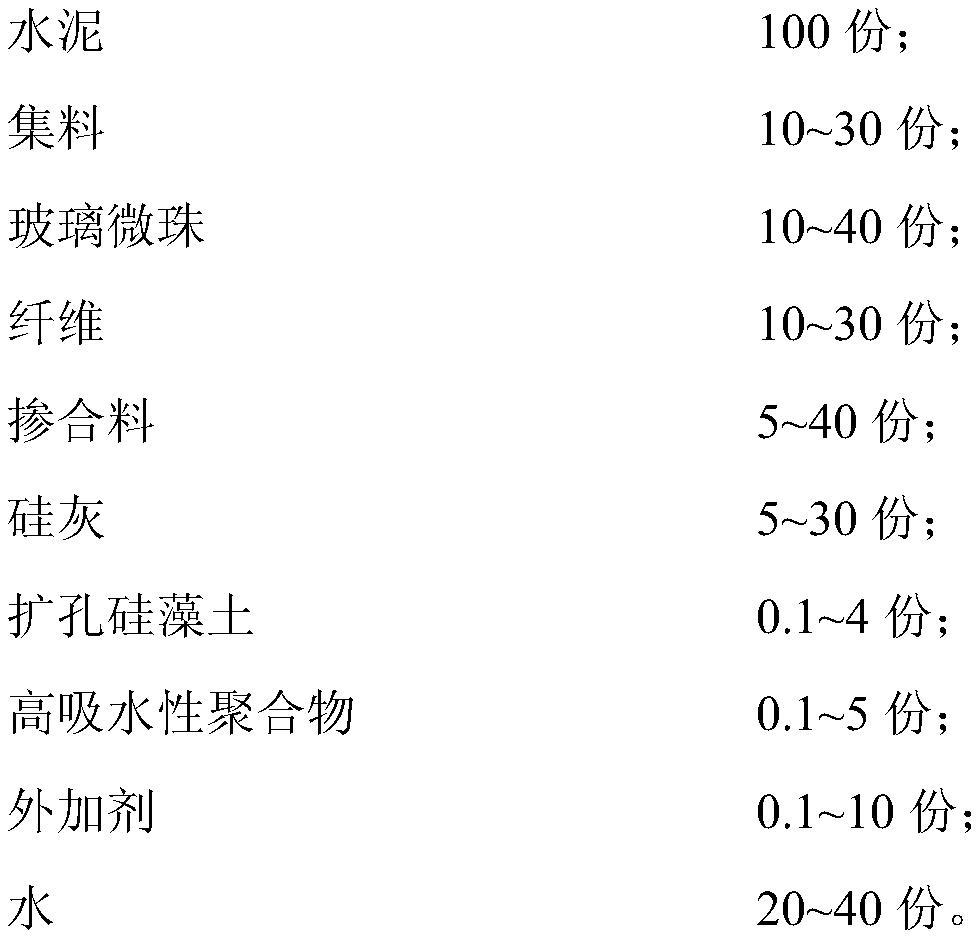

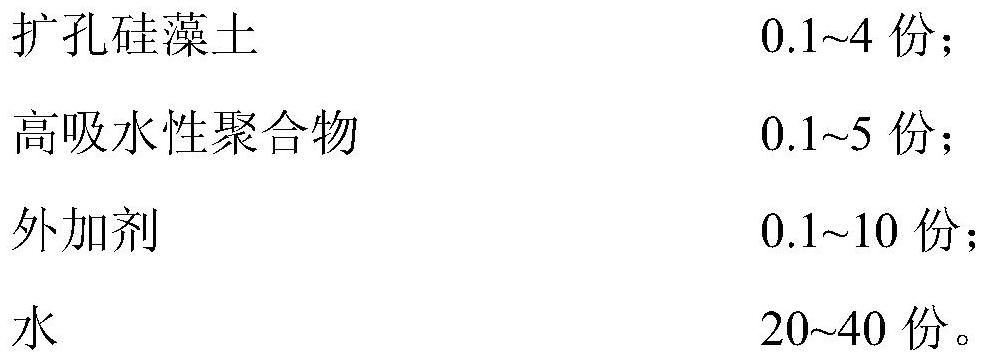

[0043] Embodiment 1: According to 100 parts of cement, 10 parts of aggregate, 10 parts of glass microspheres, 10 parts of fiber, 5 parts of admixture, 5 parts of silica fume, 0.1 part of diatomite for expanding pores, 0.1 part of superabsorbent polymer, and add It is prepared by weight ratio of 0.1 part of agent and 20 parts of water. The performance test results are shown in Table 1.

Embodiment 2

[0044] Embodiment 2: by 100 parts of cement, 15 parts of aggregate, 30 parts of glass microspheres, 15 parts of fiber, 10 parts of admixture, 15 parts of silica fume, 2 parts of diatomite for expanding pores, 0.5 part of superabsorbent polymer, plus It is prepared by the weight ratio of 0.9 parts of agent and 25 parts of water. The performance test results are shown in Table 1.

Embodiment 3

[0045] Embodiment 3: by 100 parts of cement, 30 parts of aggregate, 40 parts of glass microspheres, 30 parts of fiber, 40 parts of admixture, 30 parts of silica fume, 4 parts of expanded diatomite, 5 parts of superabsorbent polymer, plus It is prepared by weight ratio of 10 parts of agent and 40 parts of water. The performance test results are shown in Table 1.

[0046] Table 1 embodiment performance test result

[0047]

[0048] The present invention also provides a preparation method of the above-mentioned radiation-proof concrete composition, comprising the following steps:

[0049] S1, start the mixer, put cement, aggregates, glass beads, admixtures, silica fume, porous diatomite and superabsorbent polymer into the mixer in corresponding parts by weight, and the mixing time of the mixer is 2 to 4 minutes;

[0050] S2, putting the admixture and water corresponding to the parts by weight into the mixer until the mixture in the mixer is stirred into a fluidized state;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com