Patents

Literature

32results about How to "Avoid concentration changes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

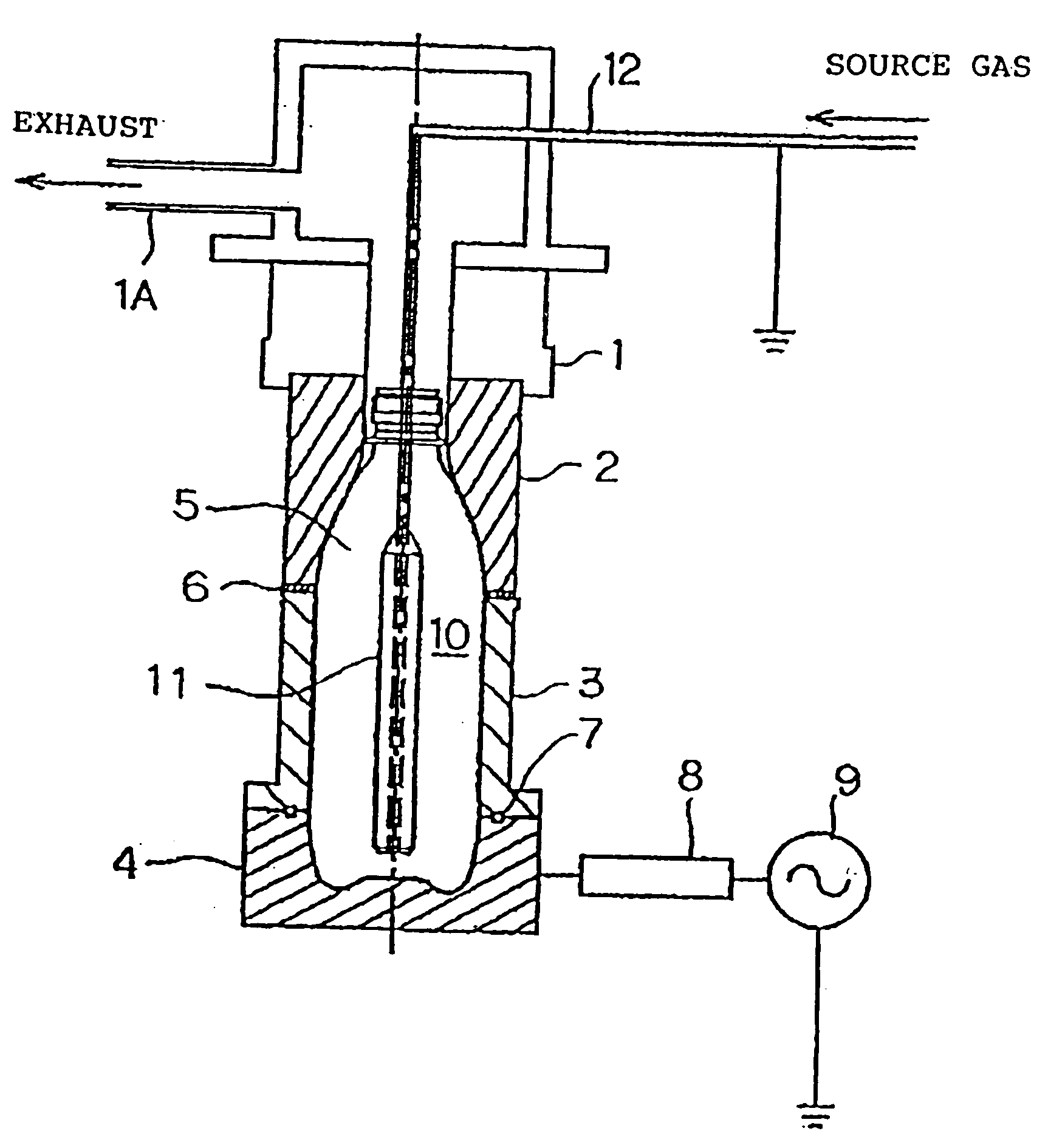

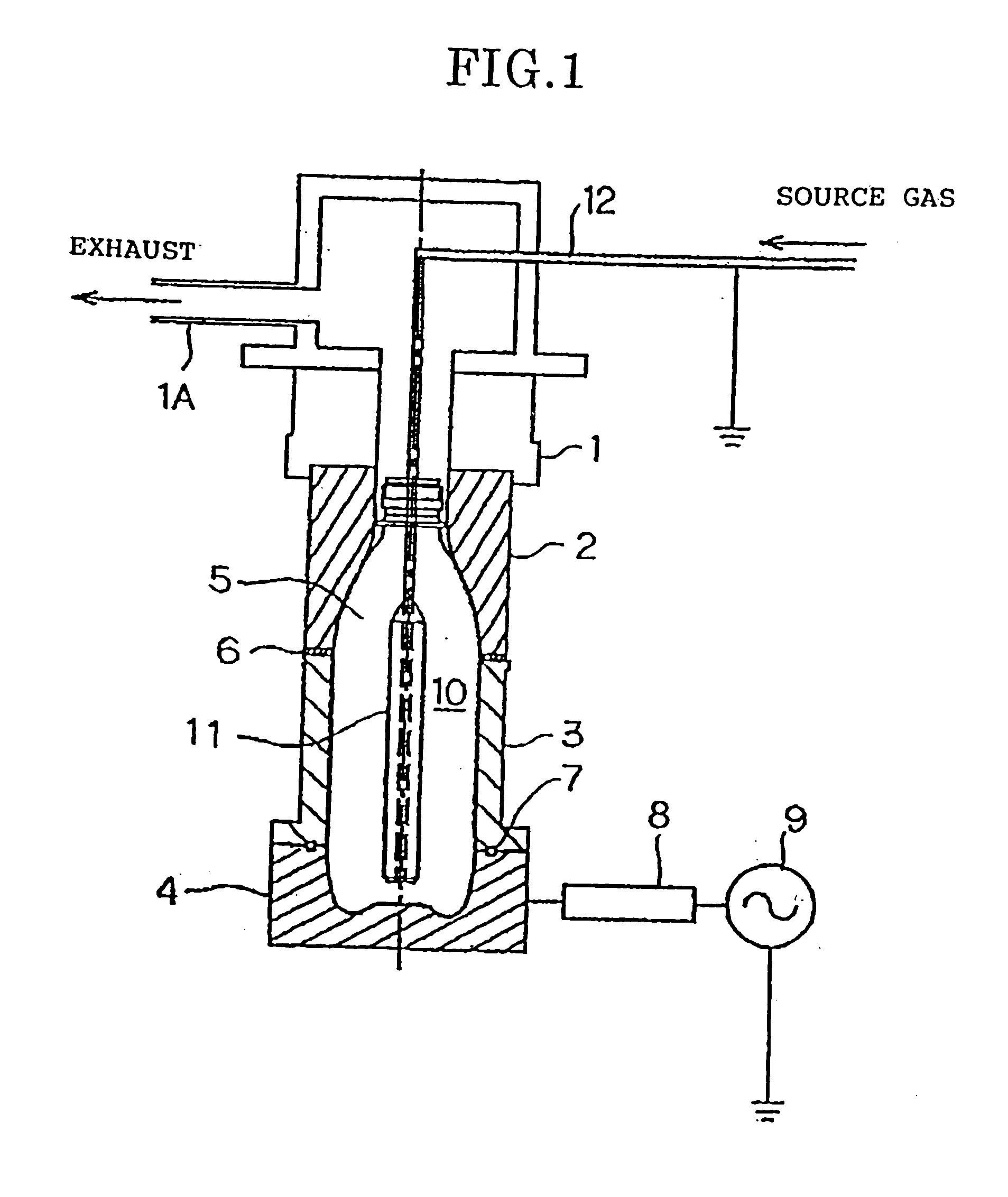

Plastic container for liquid medicine

InactiveUS20040050744A1Avoid concentration changesMaintain good propertiesBottlesSynthetic resin layered productsDiamond-like carbonWater vapor permeability

A plastic container for liquid medicine, which, concerning the effective components of liquid medicine, is capable of prevention of deterioration in quality due to mixing of oxygen and water vapor, prevention of variation in concentration due to water volatilization and moisture absorption, etc. A plastic container for liquid medicine, which is a plastic container internally coated with DLC (diamond-like carbon) film wherein water vapor permeability is 0-0.006 g / container / day and oxygen permeability is 0-0.011 ml / container / day, such properties being obtained by optimizing the three conditions, composition, density and film thickness of the DLC film.

Owner:MITSUBISHI SHOJI PLASTICS

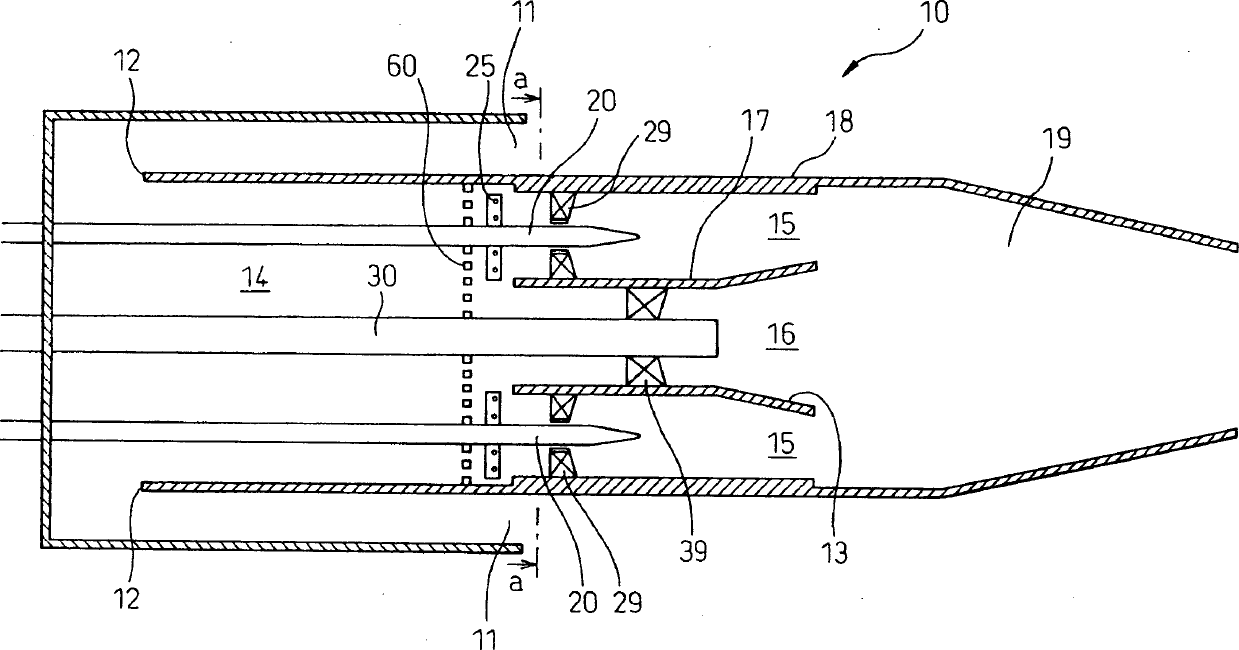

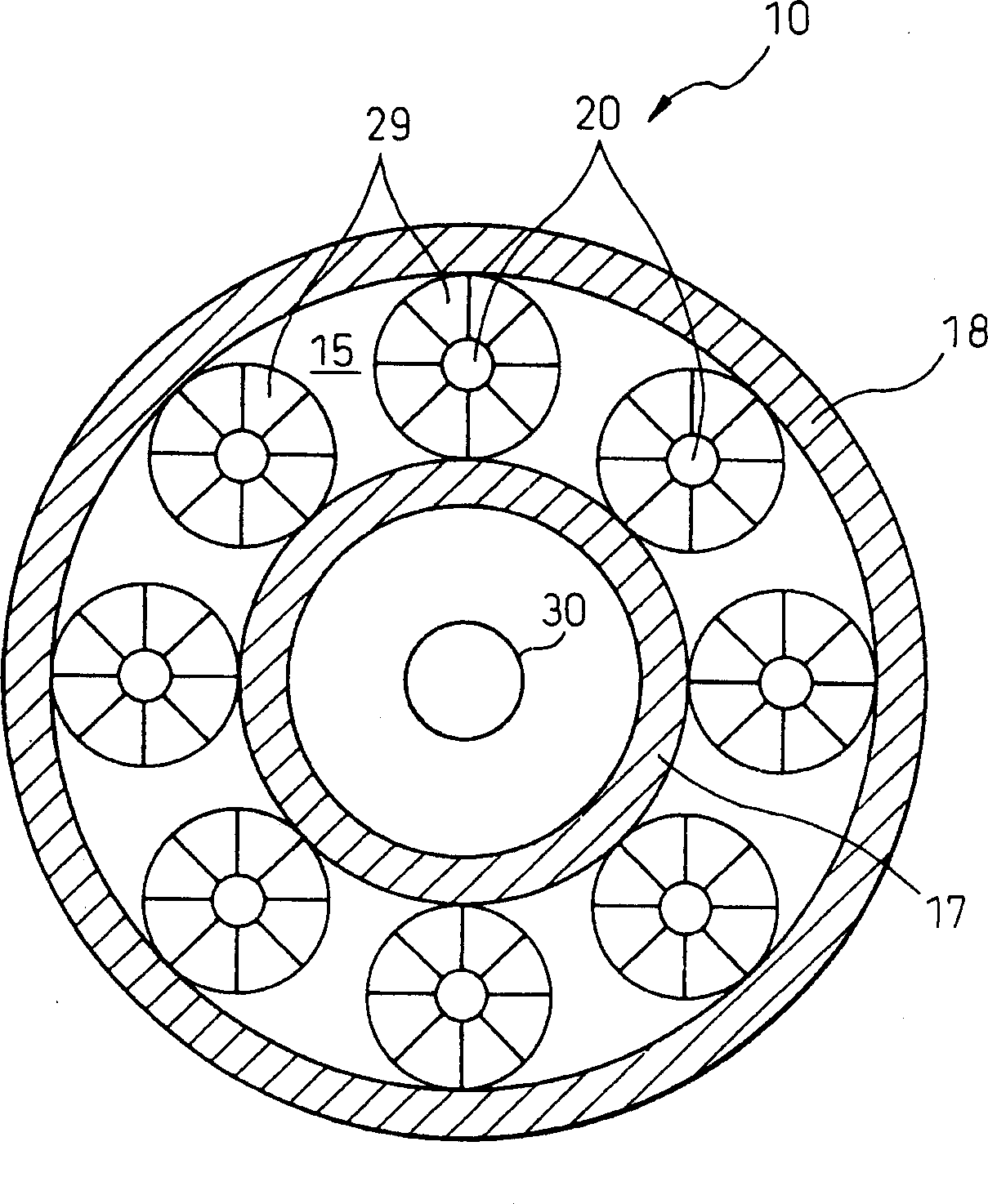

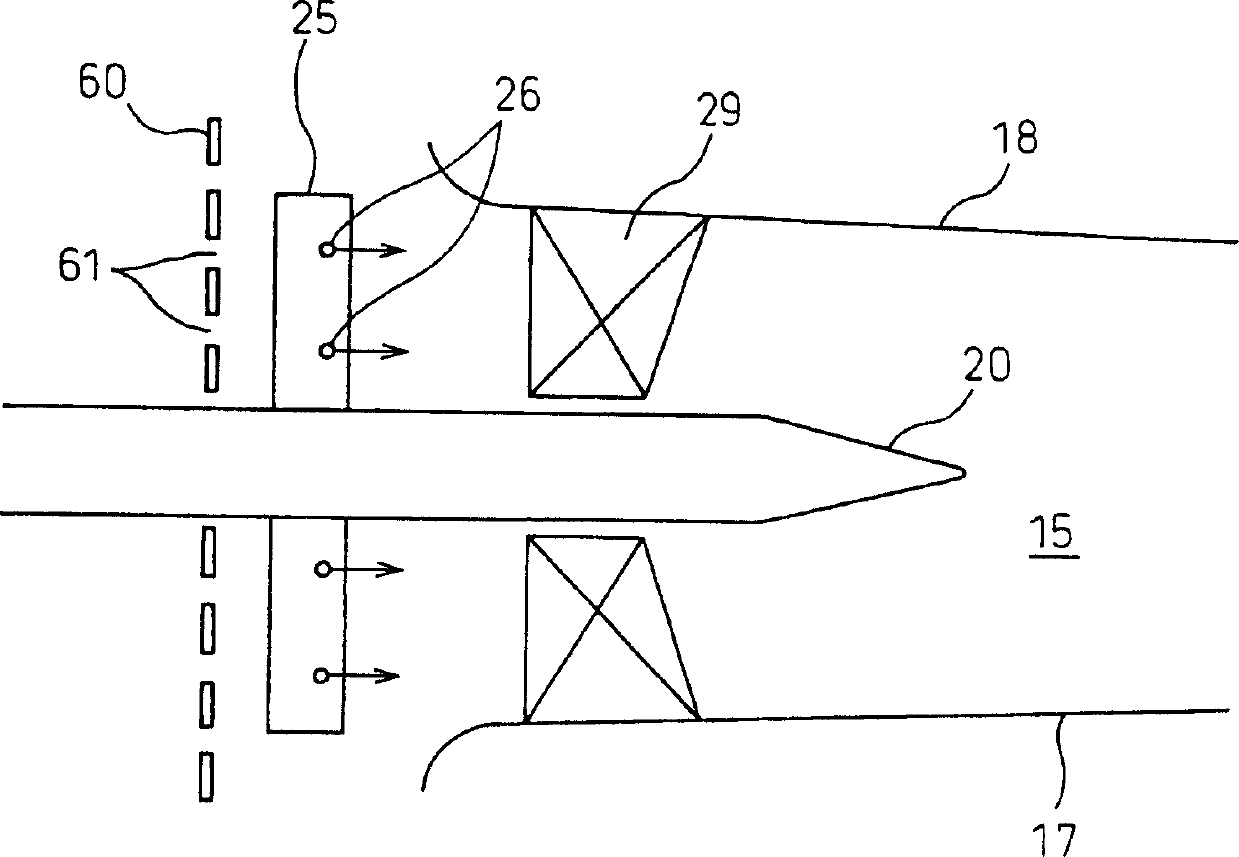

Combustor

InactiveCN1464959AAvoid concentration changesLittle change in concentrationContinuous combustion chamberGaseous fuel burnerCombustorEngineering

The invention relates to a combustor comprising an air flow channel for feeding air into the interior, and a fuel nozzle disposed in the air flow channel and having a spout port for spouting fuel, wherein a turbulence generating body adjacent the spout port of the fuel nozzle is installed in the air flow channel. It also relates to a combustor comprising an air flow channel for feeding air into the interior, and a fuel nozzle disposed in the air flow channel and having a spout port for spouting fuel, wherein a diffuser section is installed in the air flow channel, the diffuser section causing the cross sectional area of the portion of the air flow channel positioned in the vicinity of the spout port to be smaller than the cross sectional area of the downstream portion of the air flow channel positioned more downstream than the spout port with respect to the flow of air. Thereby, the generation of combustion vibration is suppressed while enhancing the fuel-air mixing action.

Owner:MITSUBISHI HEAVY IND LTD

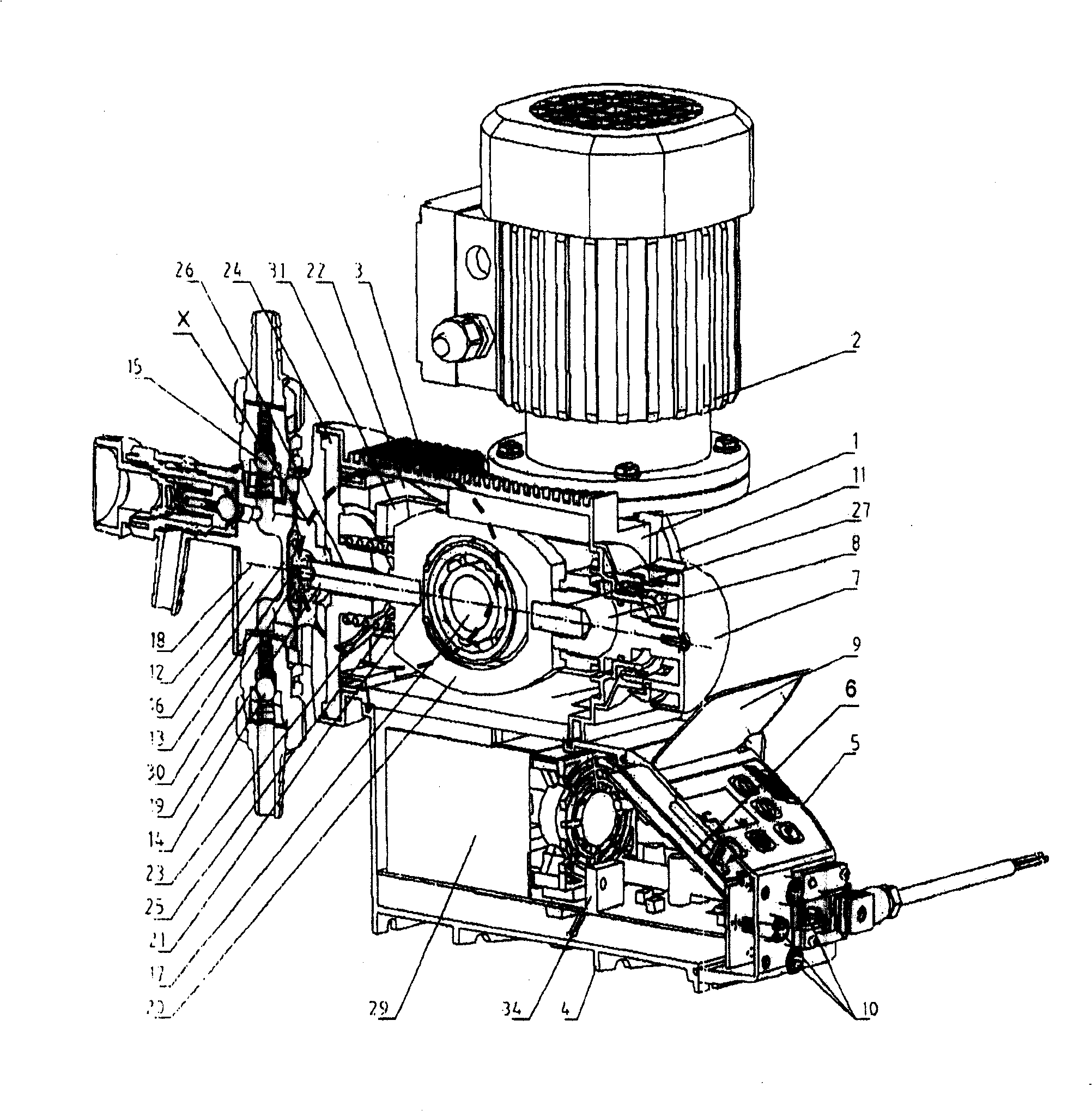

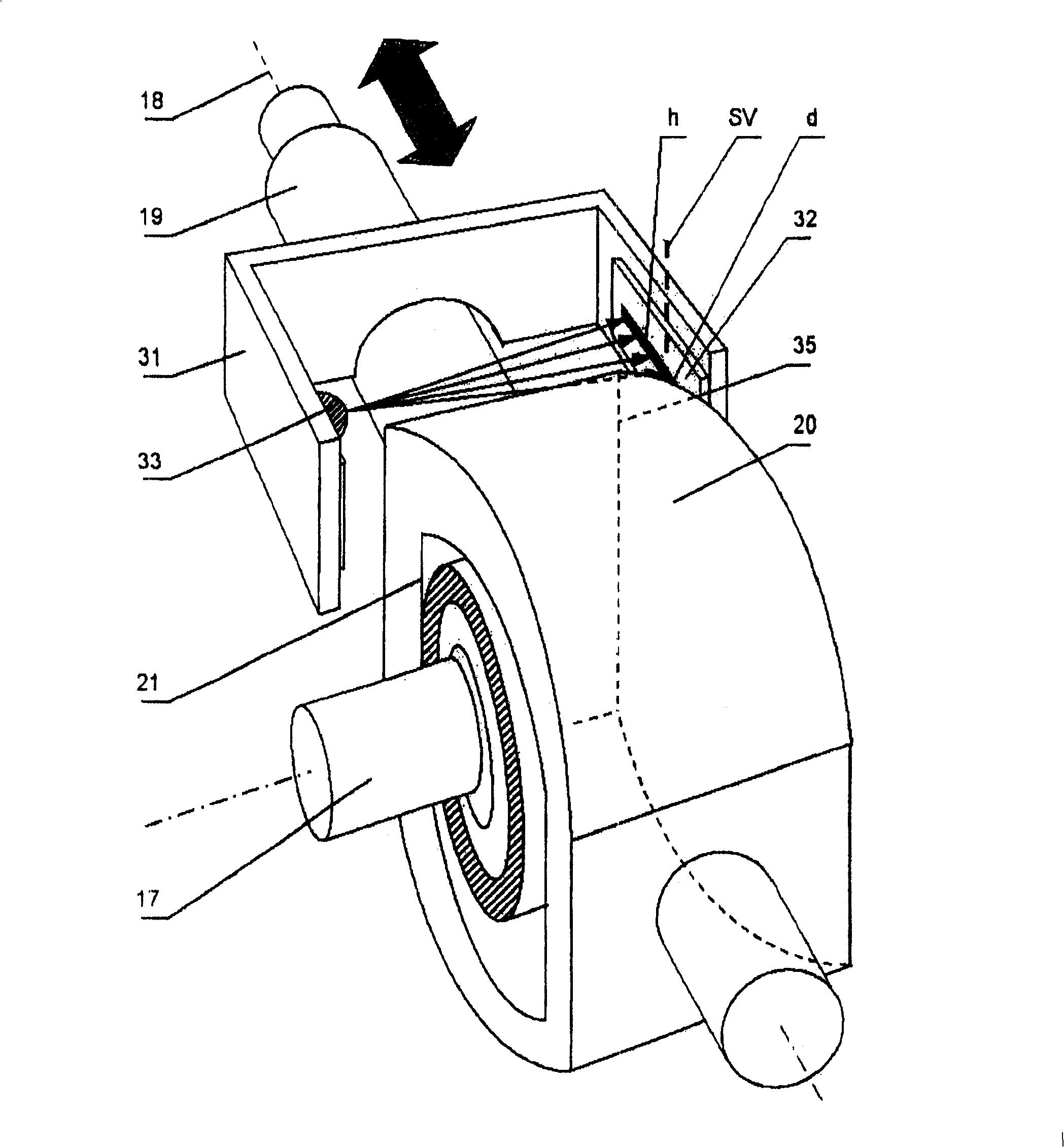

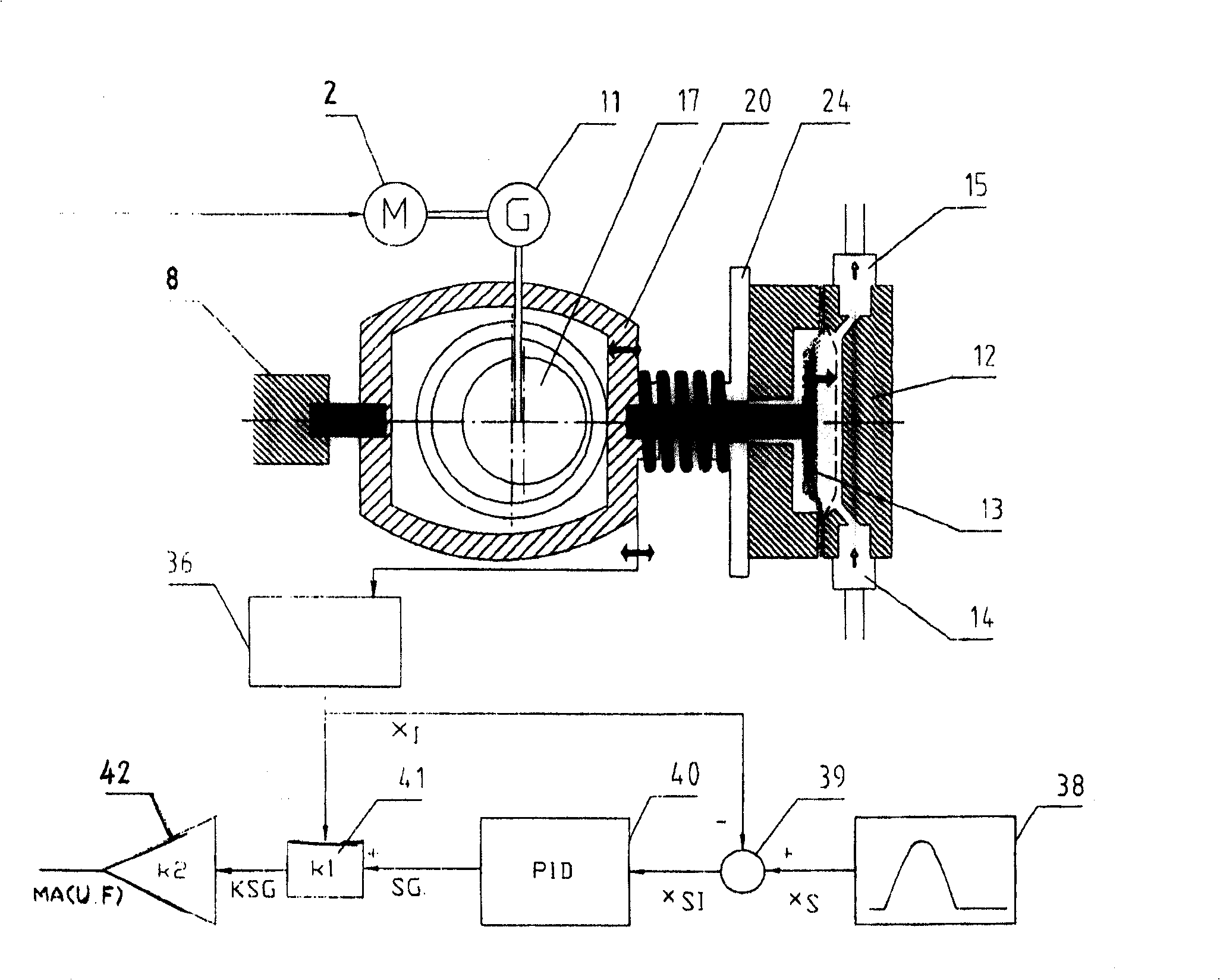

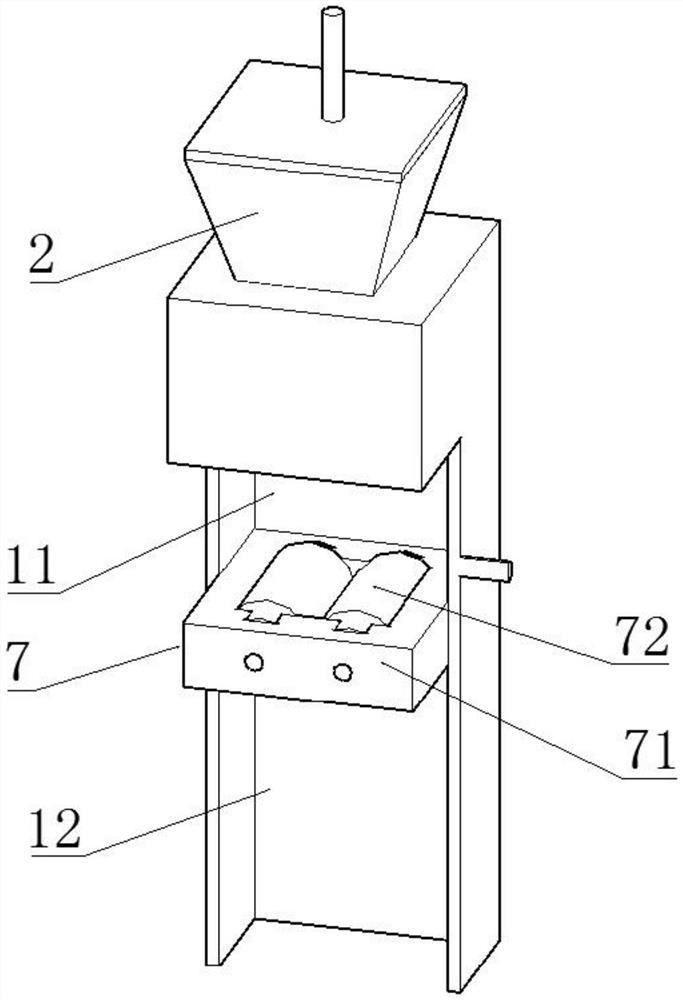

Electromotor driven metering pump

ActiveCN101245770AOperation without wearIncrease flexibilityFlexible member pumpsPump controlElectronic control systemControl system

The invention relates to a metering pump which is provided with a rotation driving motor and a swing piston; wherein, the rotation motion of the driving motor is converted into the swing of a connecting rod by a transmission device, thus leading the displacement device driven thereout to carry out a linear swing with the continuous rotation of the driving motor; therefore, the medium to be measured is transmitted in a metering head (12); the metering head is arranged along the longitudinal axis line of a connecting rod (19) and is alternatively matched with an outlet valve and an inlet valve so as to generate a pumping stroke (pressure stroke) and a filling stroke. In the metering pump, a reference element (35) is relevant to the connecting rod; the position of the connecting rod is detected by a position sensor; wherein, the position sensor provides a practical signal (x1) which forms a fixed relation with the position of the reference element, thus forming a fixed relation with the position of the displacement device; furthermore, the signal also provides an information which is corresponding to the motion of the displacement device, therefore, the electronic control system of the metering pump can respond to the metering circuit and the operation conditions of the pump.

Owner:PROMINENT DOSIERTECHN

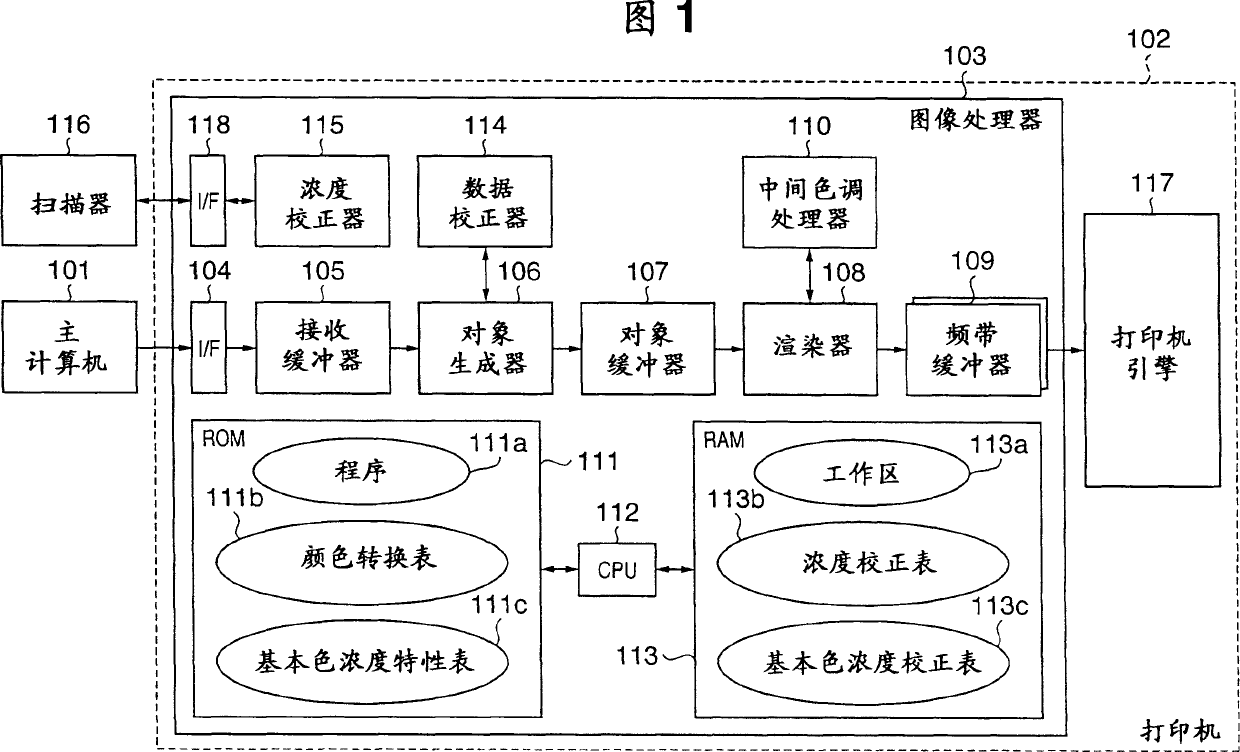

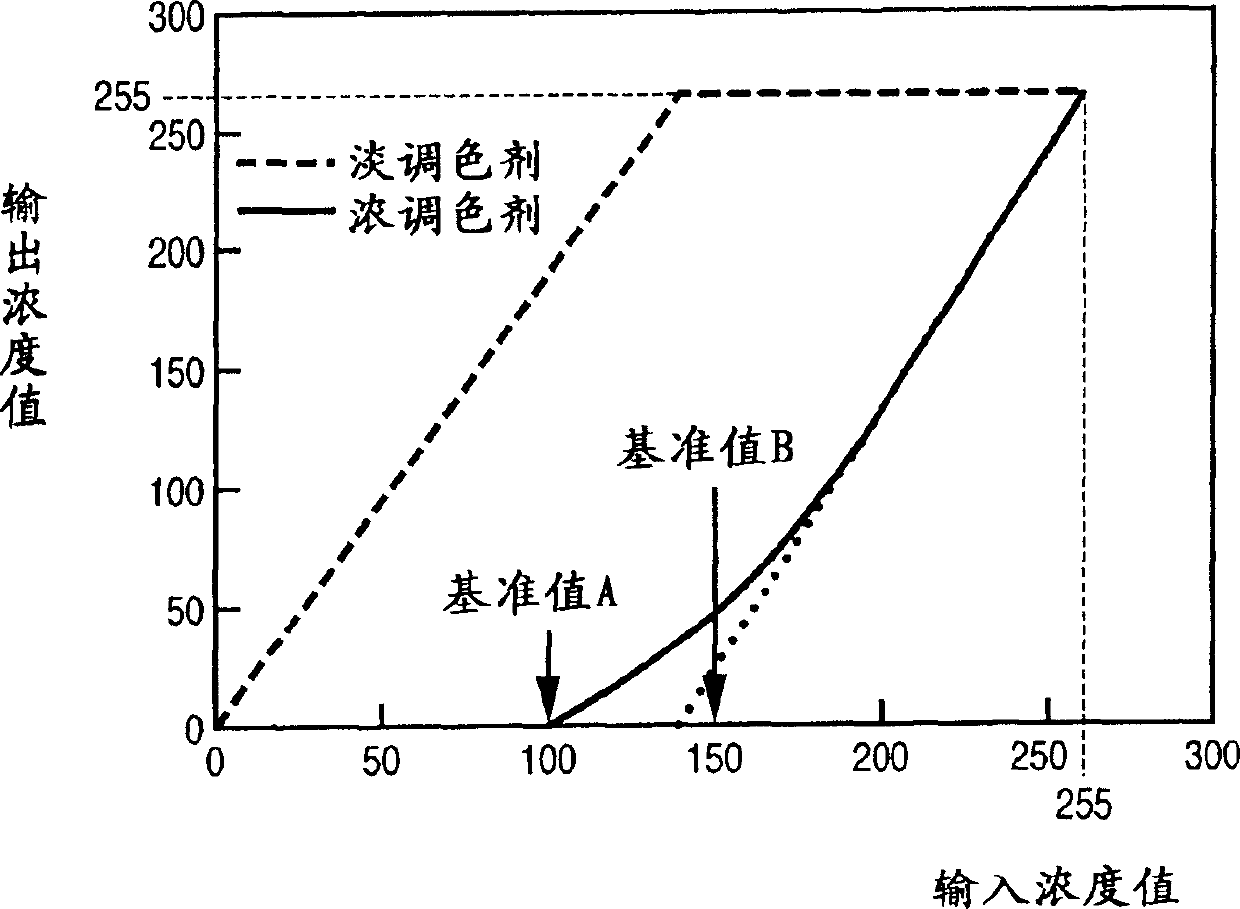

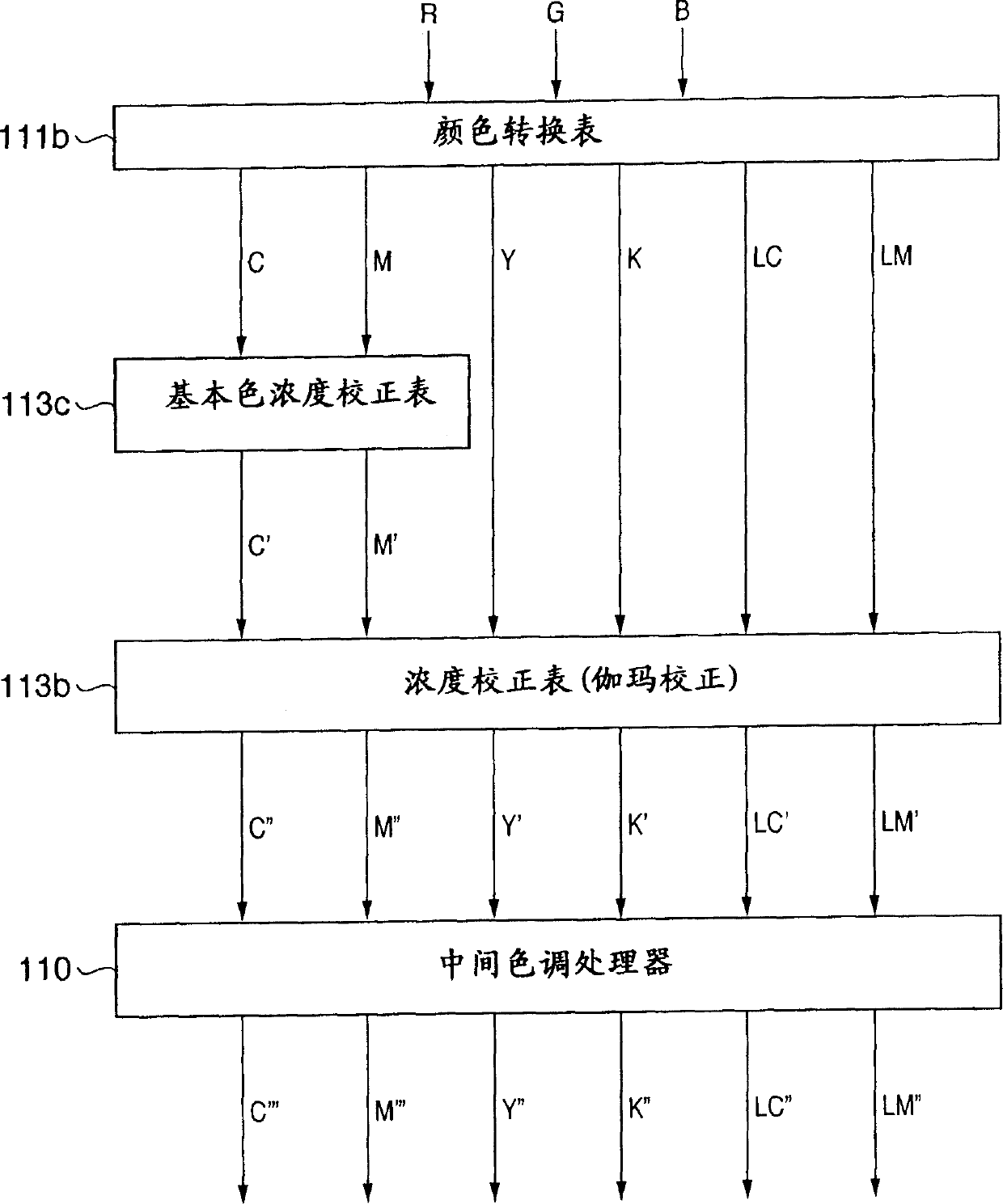

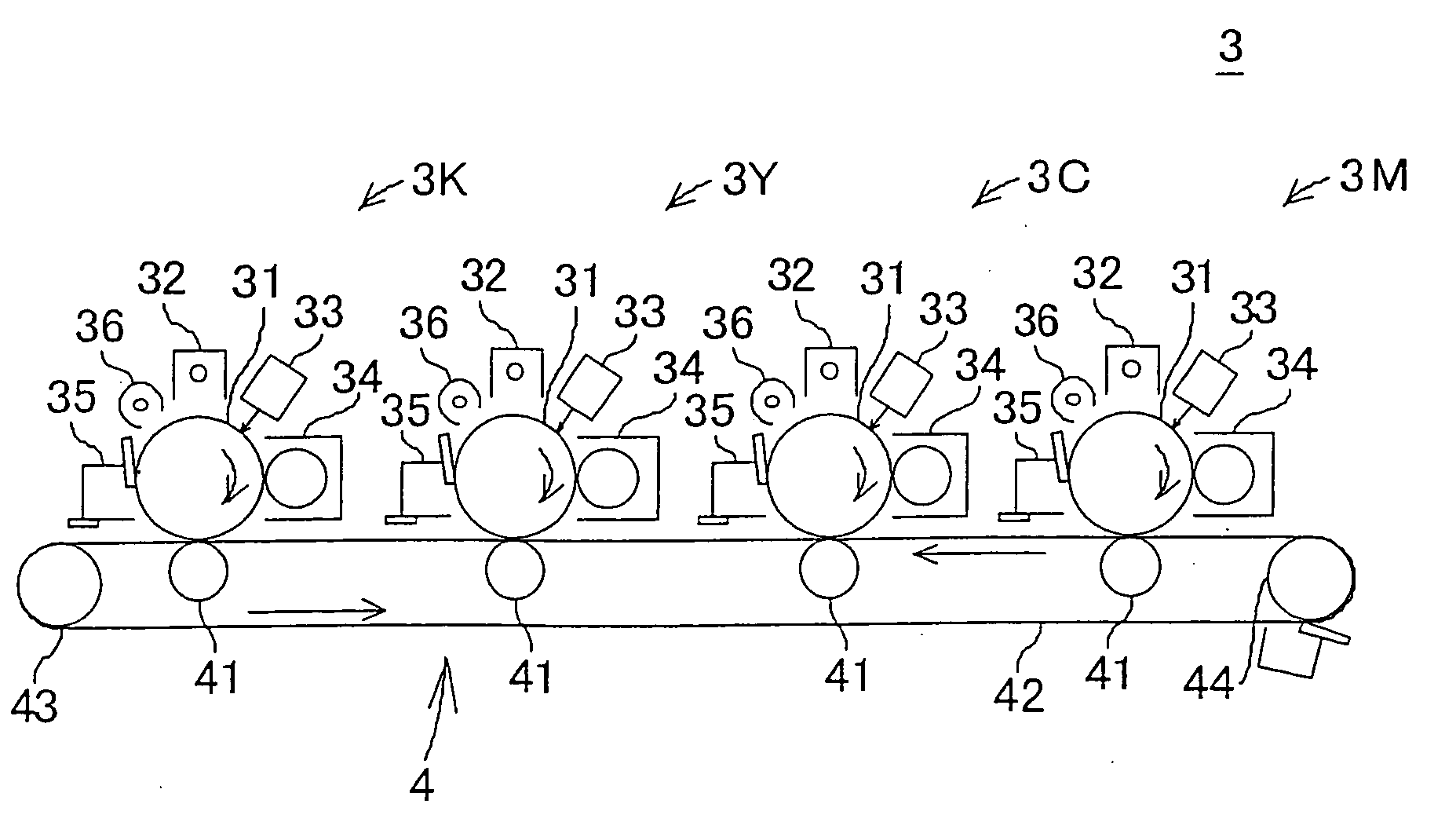

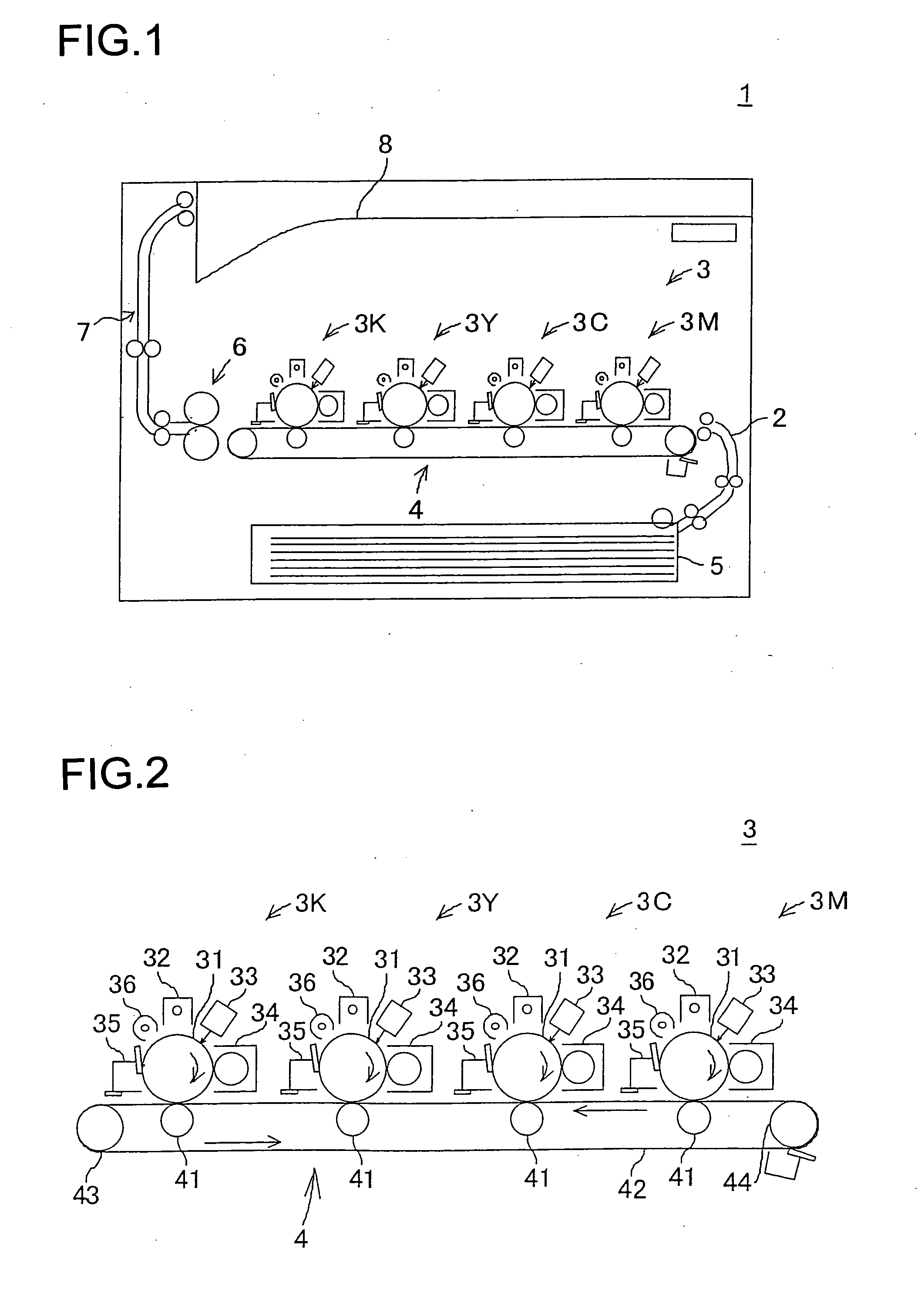

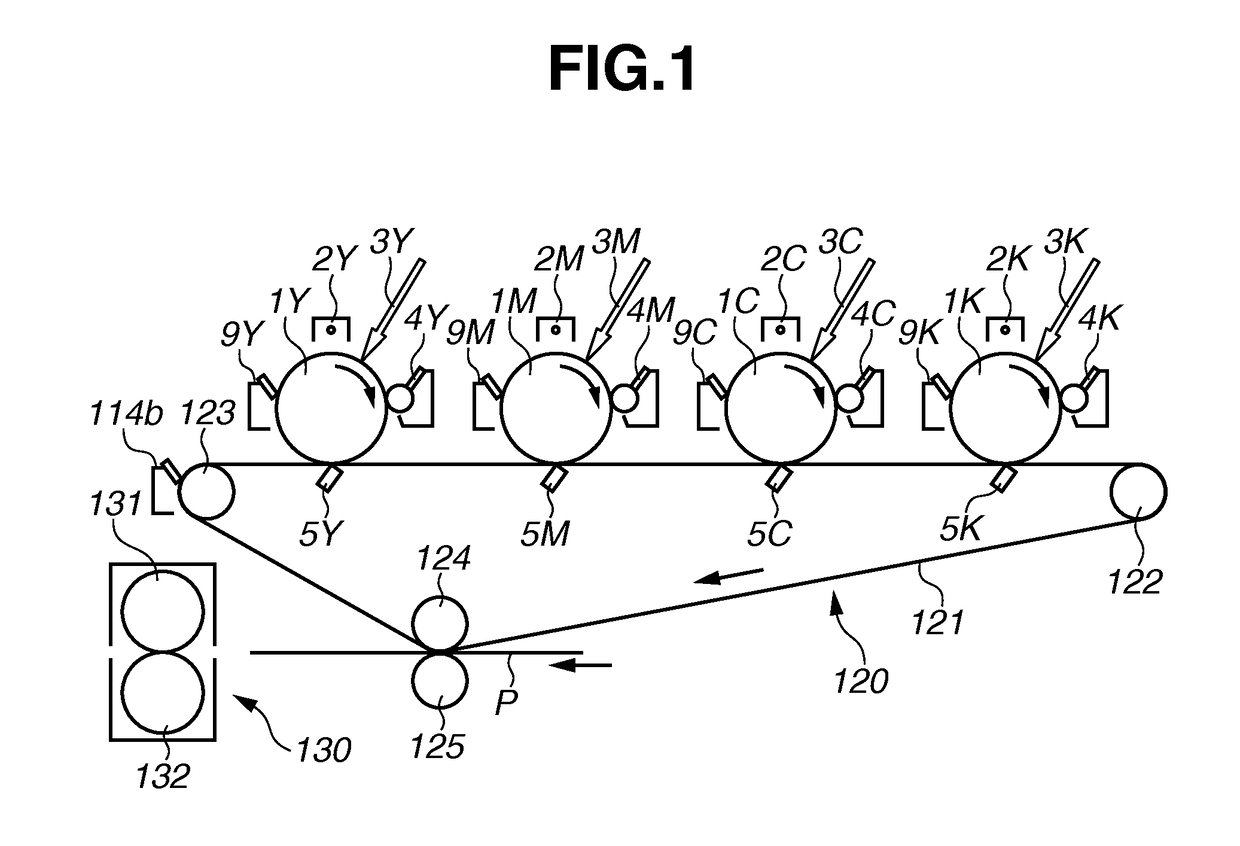

Image processing apparatus, its calibration method, and image processing method

InactiveCN1758152AAvoid concentration changesElectrographic process apparatusPictoral communicationImaging processingImaging quality

A stable, unicolor intermediate density region in a four-color system is defined by mixing dark and light color recording materials in a six-color system. For this reason, a calibration for the four-color system cannot correct density variations, and a pseudo-contour due to discontinuity of tones is produced in a transition region from the light color recording materials to dark color recording materials included in the intermediate density region, thus considerably deteriorating image quality. The tone characteristics of respective colors are obtained from a patch pattern of respective color recording materials, and a tone correction table used to correct the tones of the respective colors is created on the basis of the tone characteristics of the respective colors. The tone characteristics of primary colors calculated from the tone characteristics of the respective colors with reference to a basic color density characteristic table indicating the density characteristics when the dark and light color recording materials are mixed. A basic color density correction table used to correct the tone characteristics of the primary colors is created with reference to the basic color density characteristic table and the density correction table.

Owner:CANON KK

In-situ detection method for ammonia and nitrogen

The method for on-line monitoring ammonia nitrogen includes following steps: Ammonia nitrogen escaped from the sample is blown in the absorption liquid. With ammonia nitrogen being leaded in the absorption liquid, testing the conductance value of the absorption liquid and comparing the said conductance value with the calibrated conductance value of the absorption liquid calculates out the contentof ammonia nitrogen in the sample. In the invention, ammonia is separated from the sample so as to prevent the irrespective elements (such as suspended matter) in the sample from disturbing the measurement. The traditional distillation method spends more time and gets low measuring accuracy and sensitivity since the absorption liquid is diluted by the vapor. Comparing with prior art, the invention provides the features of high accuracy (0.01 ml / L), and high efficiency.

Owner:HENGDA ENVIRONMENT PROTECTION SCI & TECH DEV SHANDONG

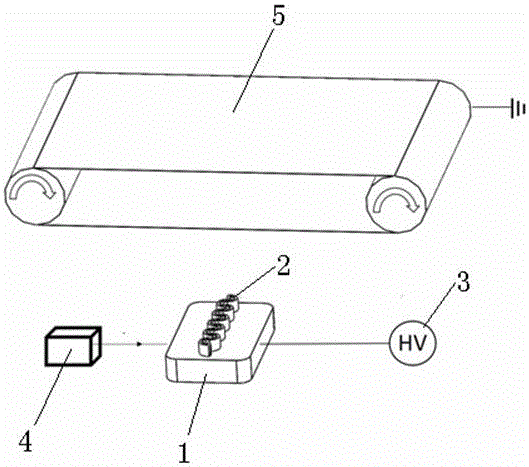

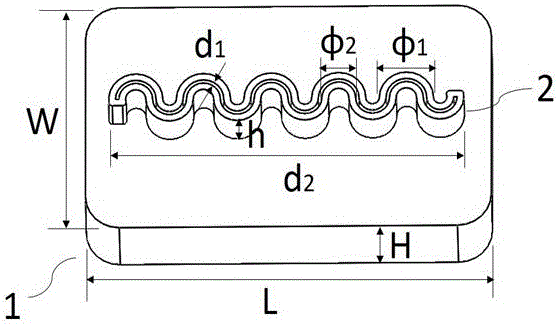

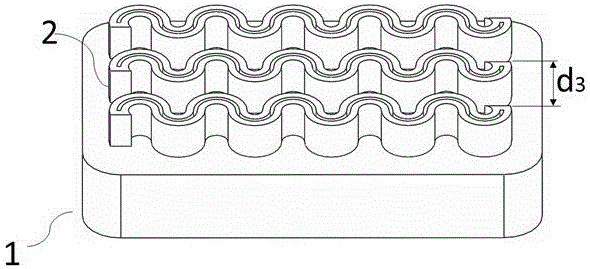

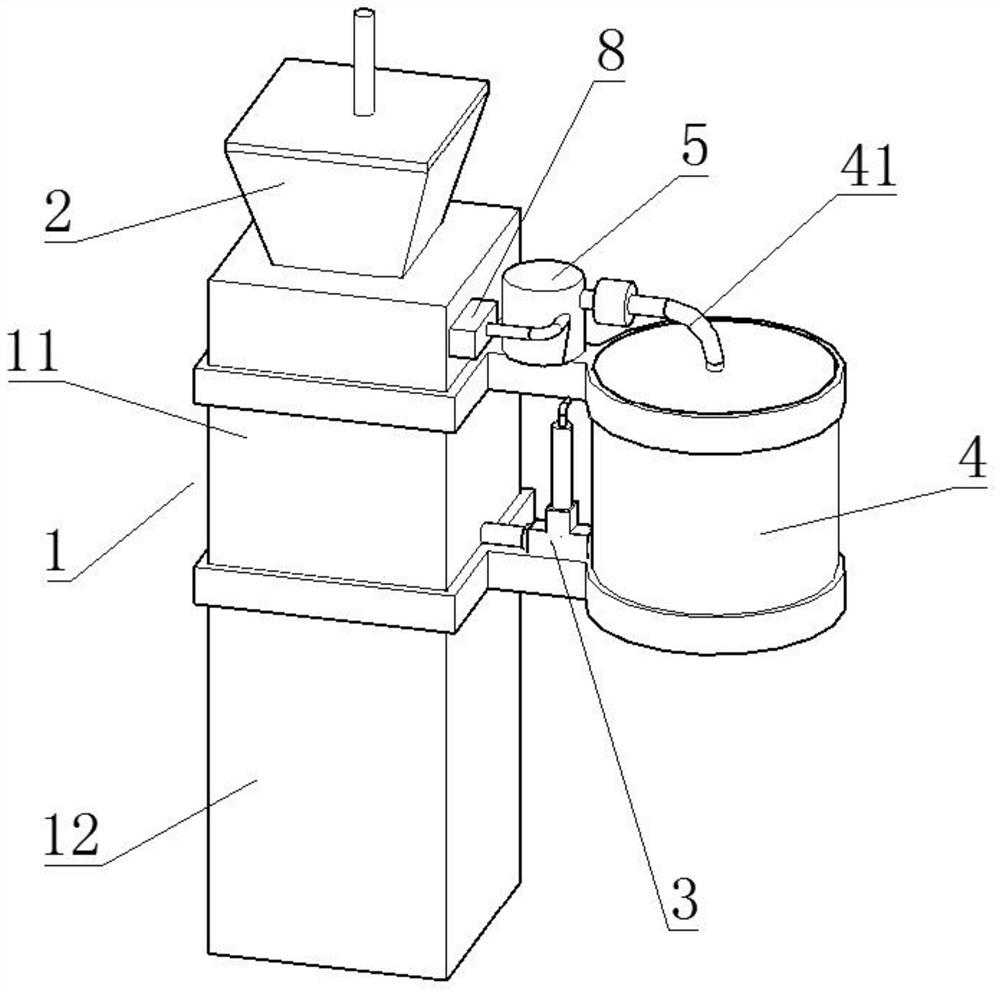

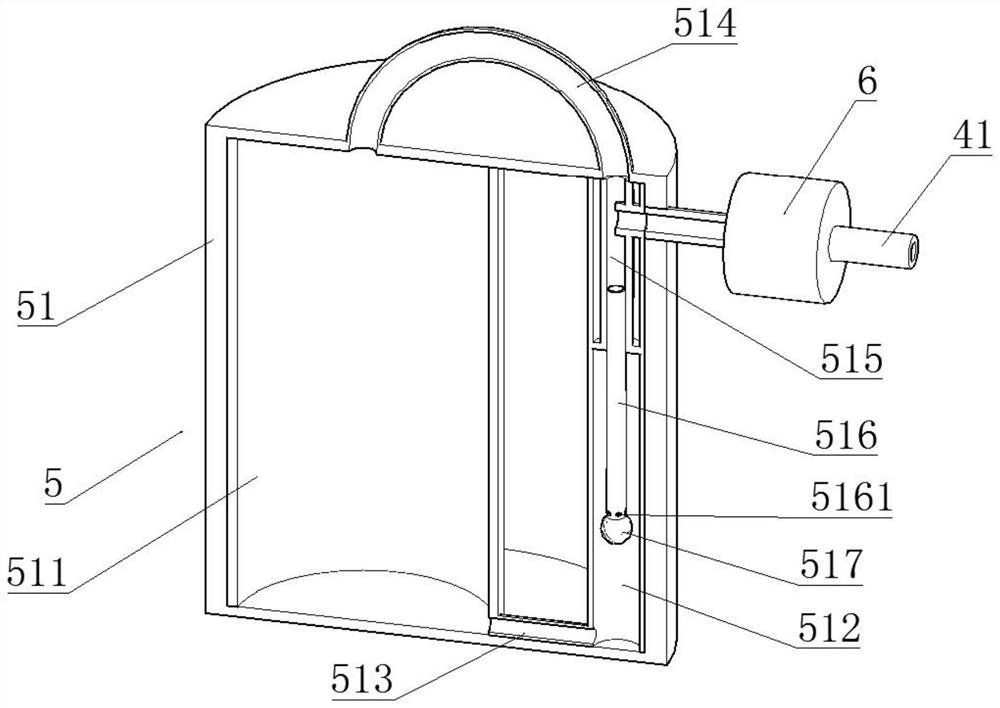

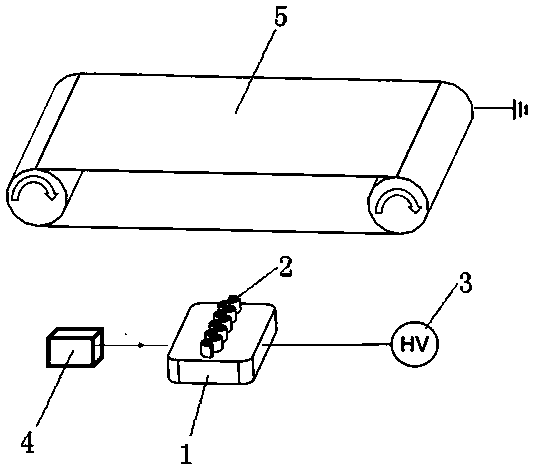

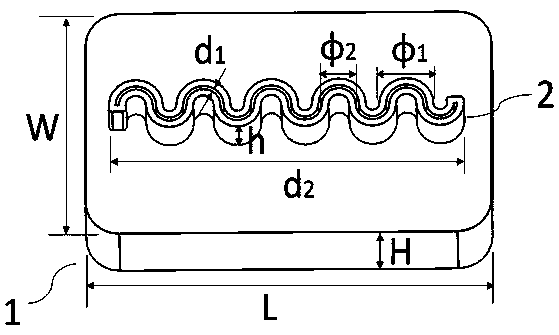

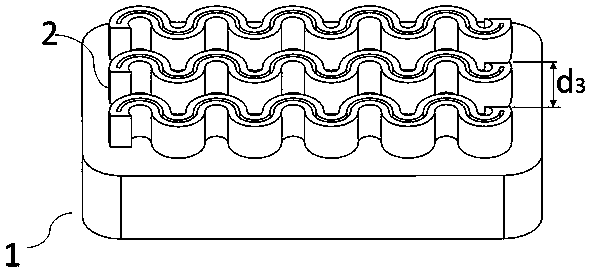

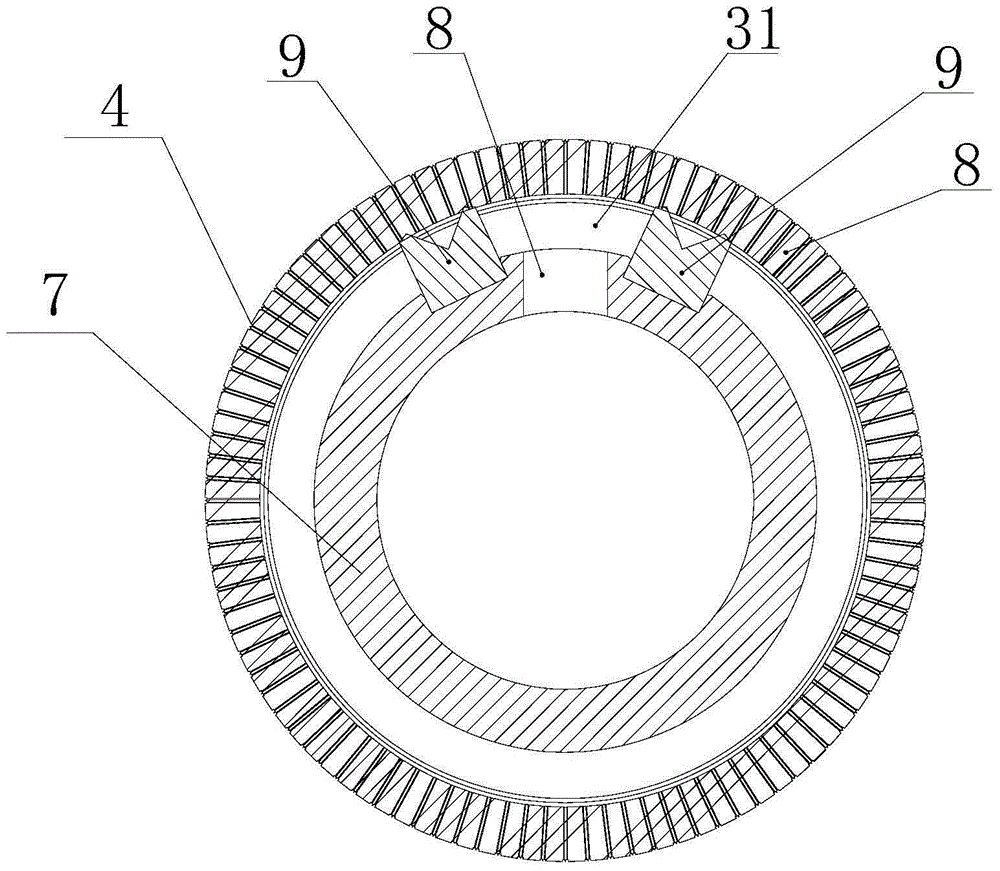

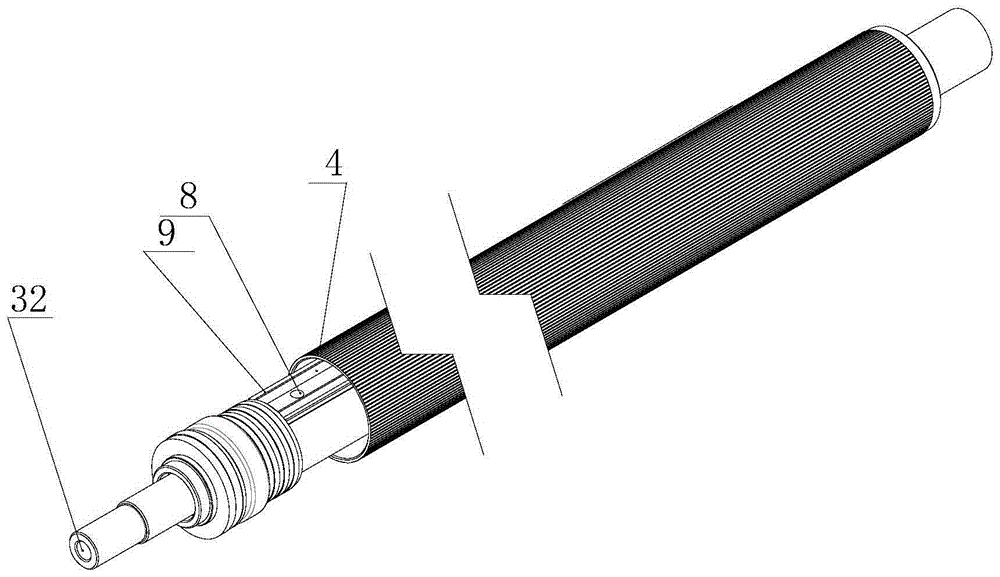

Electrostatic spinning nanofiber generating device

ActiveCN106757418AImprove stabilitySuitable for continuous large-scale productionFilament/thread formingViscous liquidFiber

The invention discloses an electrostatic spinning nanofiber generating device. The electrostatic spinning nanofiber generating device comprises a fiber generator, a fiber collecting device and a high-voltage generator, wherein the fiber generator comprises a spinning cavity, silk spray thread slots and a liquid storage tank; a slit is formed in each silk spray thread slot, and is communicated with the inner part of the spinning cavity; the liquid storage tank is communicated with the spinning cavity; each silk spray thread slot adopts a structure with twists and turns; the fiber collecting device is placed right above the silk spray thread slots; the high-voltage generator is provided with a high-voltage terminal and a ground terminal. According to the electrostatic spinning nanofiber generating device disclosed by the invention, nanofibers are produced by using viscous liquid as raw materials and utilizing an electrostatic spinning principle. Compared with the prior art, the core of the electrostatic spinning nanofiber generating device disclosed by the invention is the fiber generator with the bent slits; through the adoption of the fiber generator, the change of the concentration of spinning liquid, which is caused by solvent evaporation, is effectively inhibited, so that the producing stability of the nanofibers is greatly improved; besides, the uniformity and the production efficiency of produced fiber films are improved, so that the electrostatic spinning nanofiber generating device is suitable for the continuous scale production of nanofibers.

Owner:上海云同新材料科技有限公司

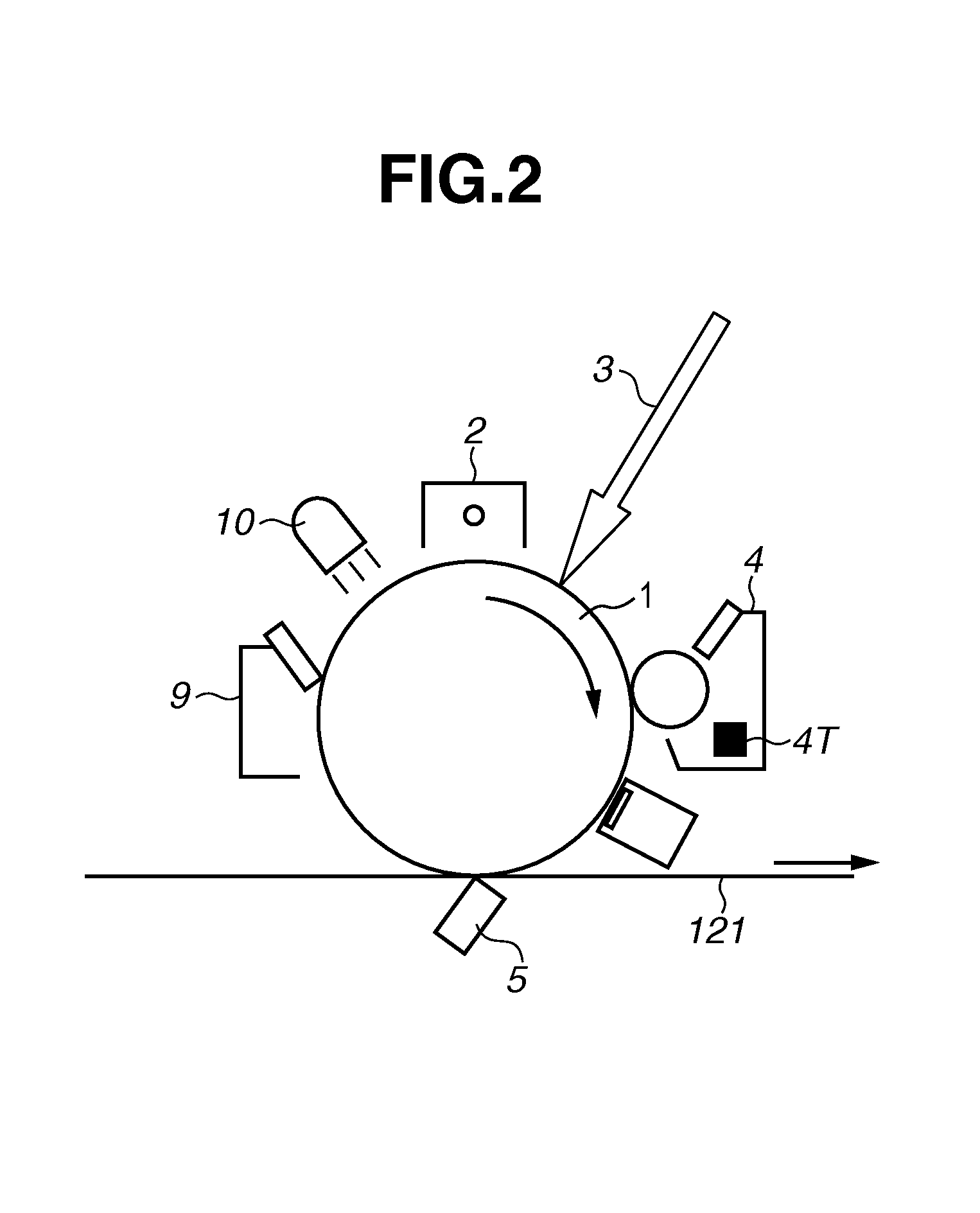

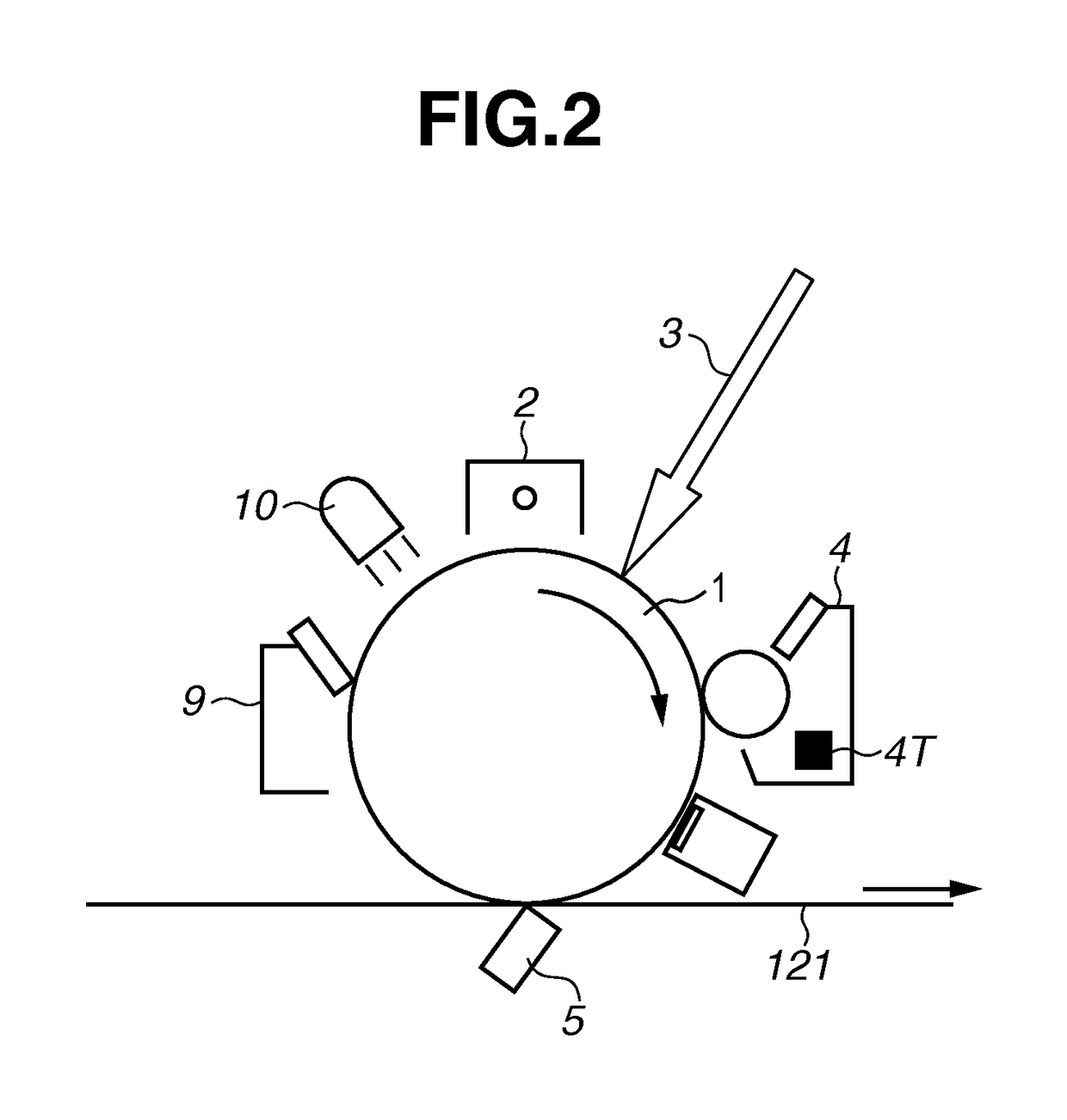

Image forming apparatus

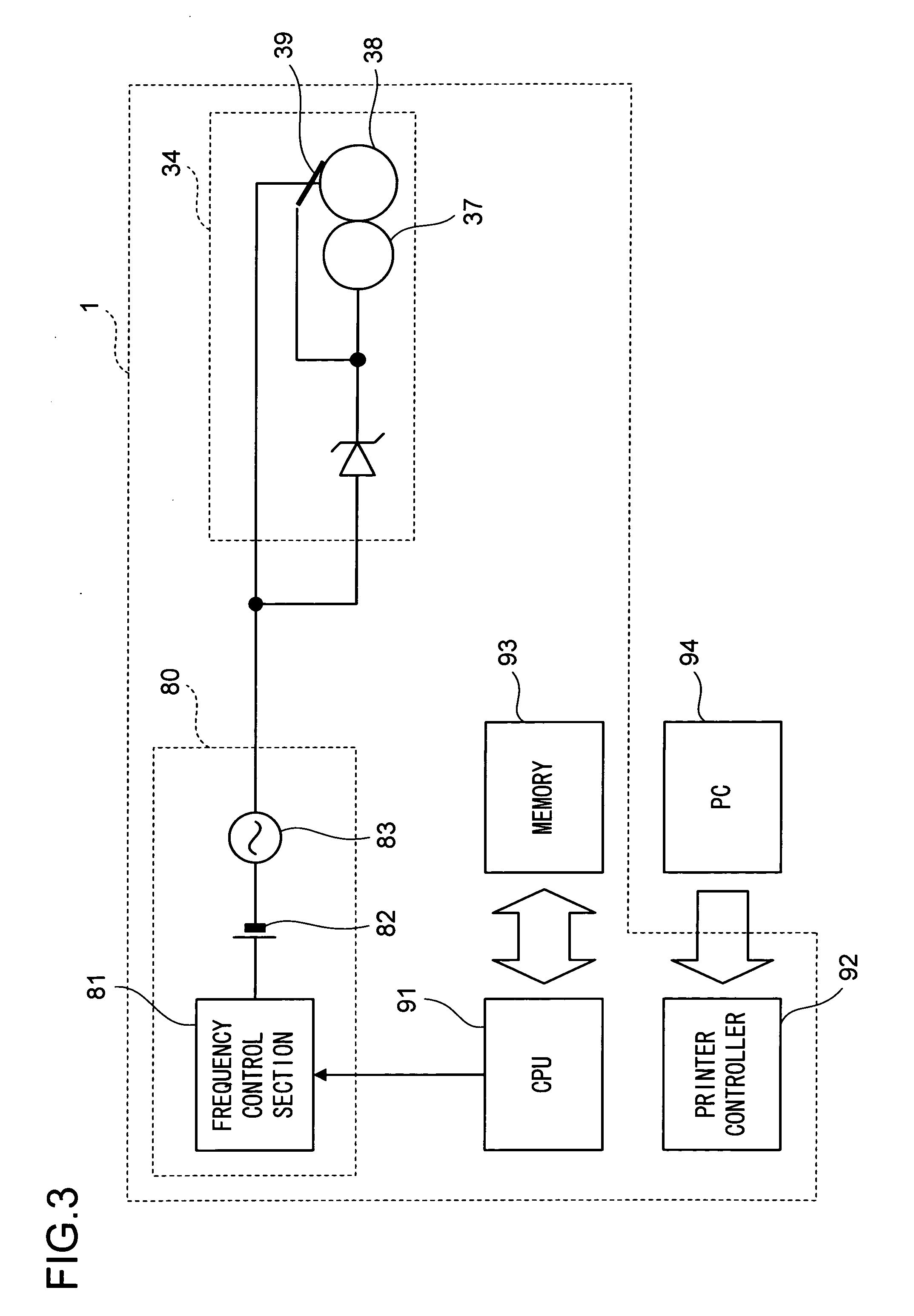

InactiveUS20080232863A1Avoid concentration changesLow heat generationElectrographic process apparatusLatent imageImage formation

In an image forming apparatus 1 including a photoconductive drum 31 on which an electrostatic latent image is formed and a developer carrier that is allowed to carry a developer thereon by a developing bias voltage applied thereto composed of a DC component and an AC component and that is arranged in the vicinity of the photoconductive drum 31, the image forming apparatus 1 visualizing the electrostatic latent image using the developer carried on the developer carrier, a high-frequency region A with respect to which image forming is performed with the frequency of the AC component of the developing bias voltage increased and a low-frequency region B with respect to which image forming is performed with the frequency of the AC component of the developing bias voltage decreased are formed in an image to be formed on recording paper.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

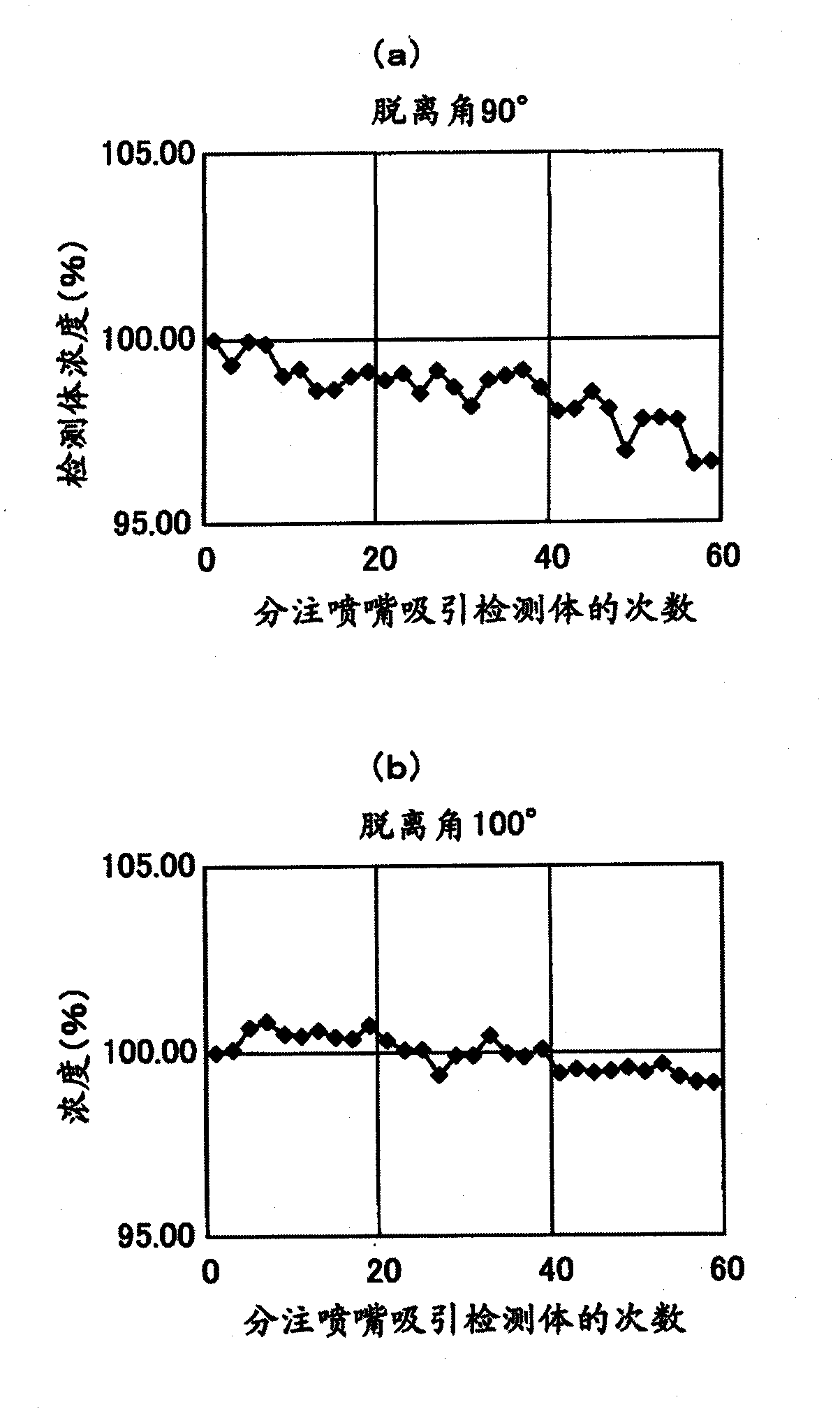

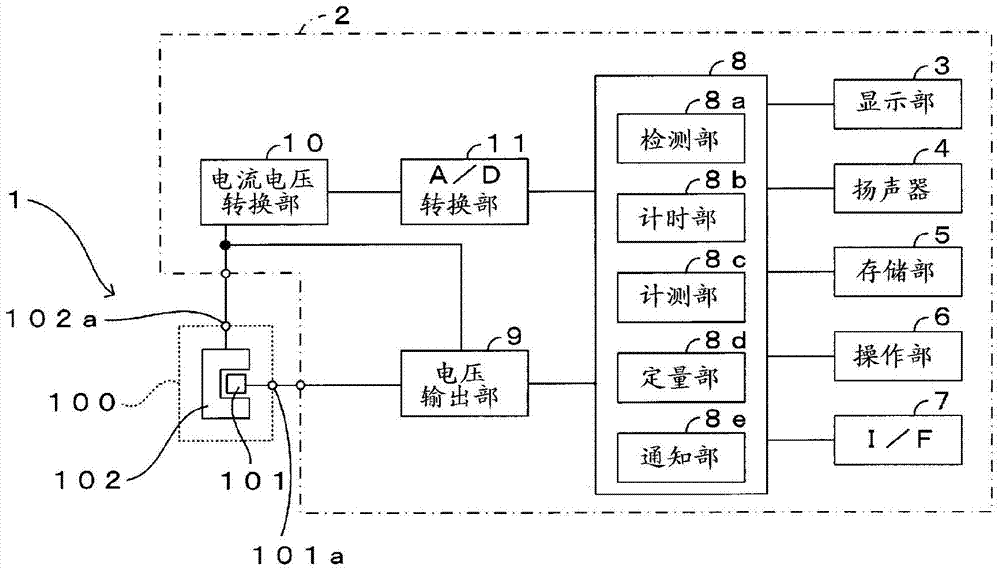

Automatic analyzing device

InactiveCN102112882AAvoid concentration changesReduce the amount of adhesionMaterial analysisEngineeringSpecimen containers

When dispensing operation is conducted plural times from an identical specimen, a rinsing liquid having stuck to the outer wall of a dispensing nozzle rinsed may be brought into a specimen container when the specimen is sucked, thereby to thin the specimen and lower an analyzing precision. The invention provides a rinsing mechanism for an automatic analyzing device, the rinsing range of the outer wall of the dispensing nozzle is changed according to the range, within which the nozzle is blotted. The quantity of the rinsing liquid to stick to the outer wall of the dispensing nozzle is reduced by an ejector effect to act between the dispensing nozzle and a rinsing liquid flow, thereby to prevent the specimen from becoming thinner. The rinsing mechanism decides a discharged state of the rinsing liquid flow by using the liquid level detecting function of the nozzle and the pressure fluctuation detecting function of the inside of a nozzle pipe, so that a highly reliable analysis is realized in an automatically adjustable manner for the proper rinsing range.

Owner:HITACHI HIGH-TECH CORP

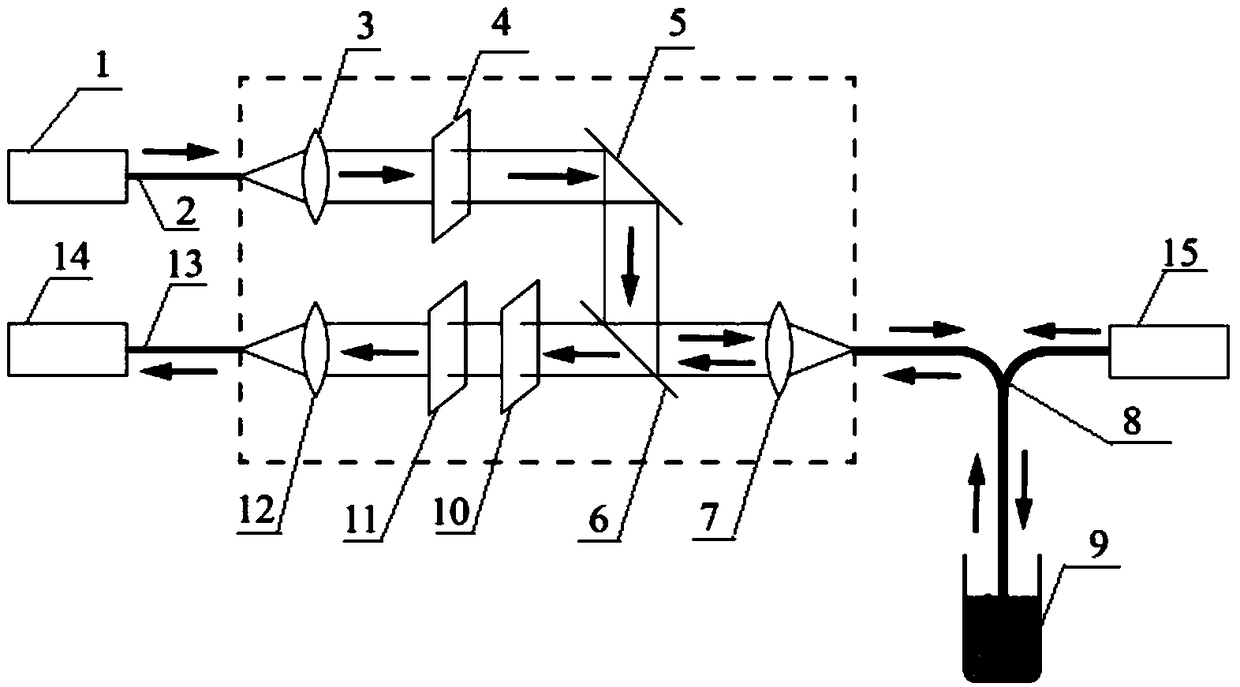

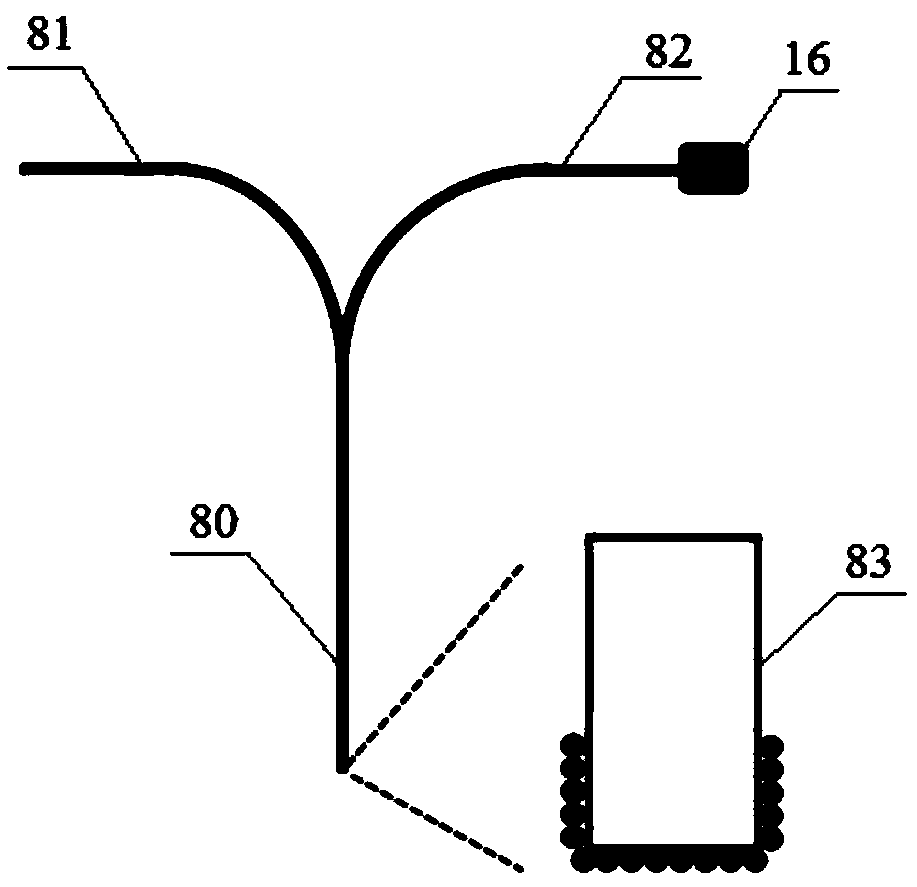

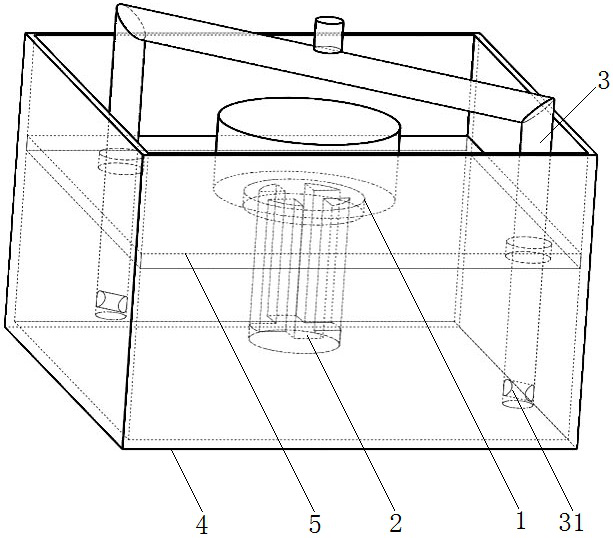

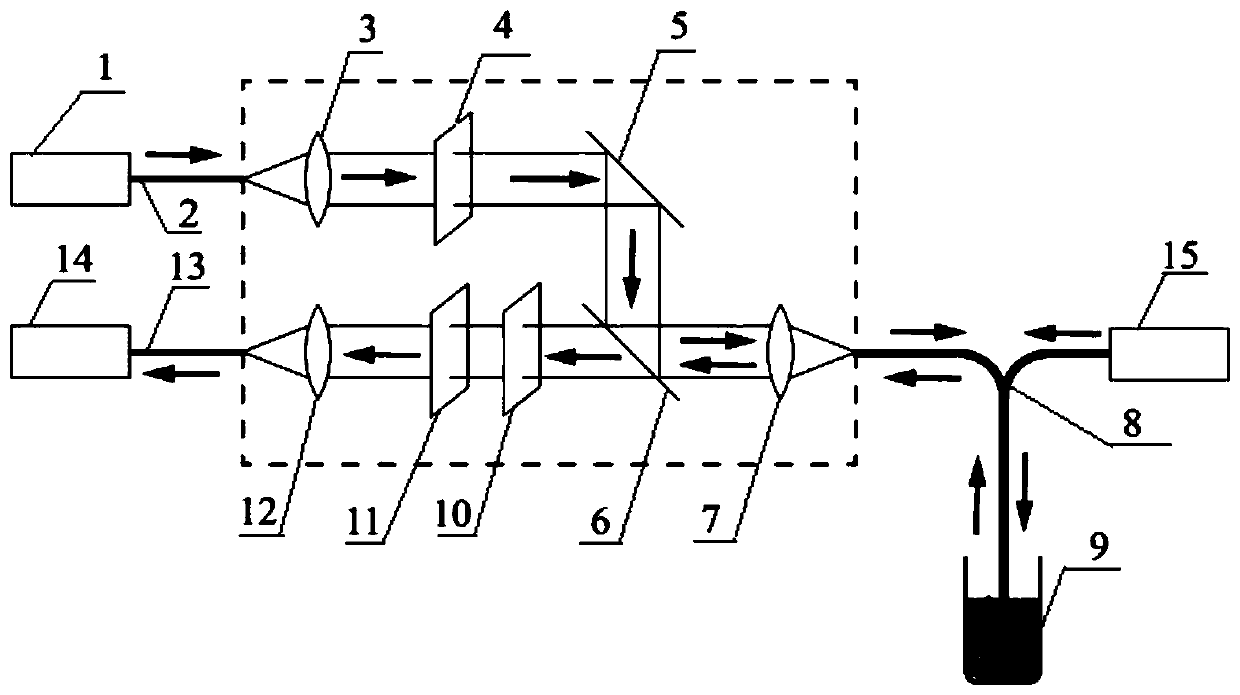

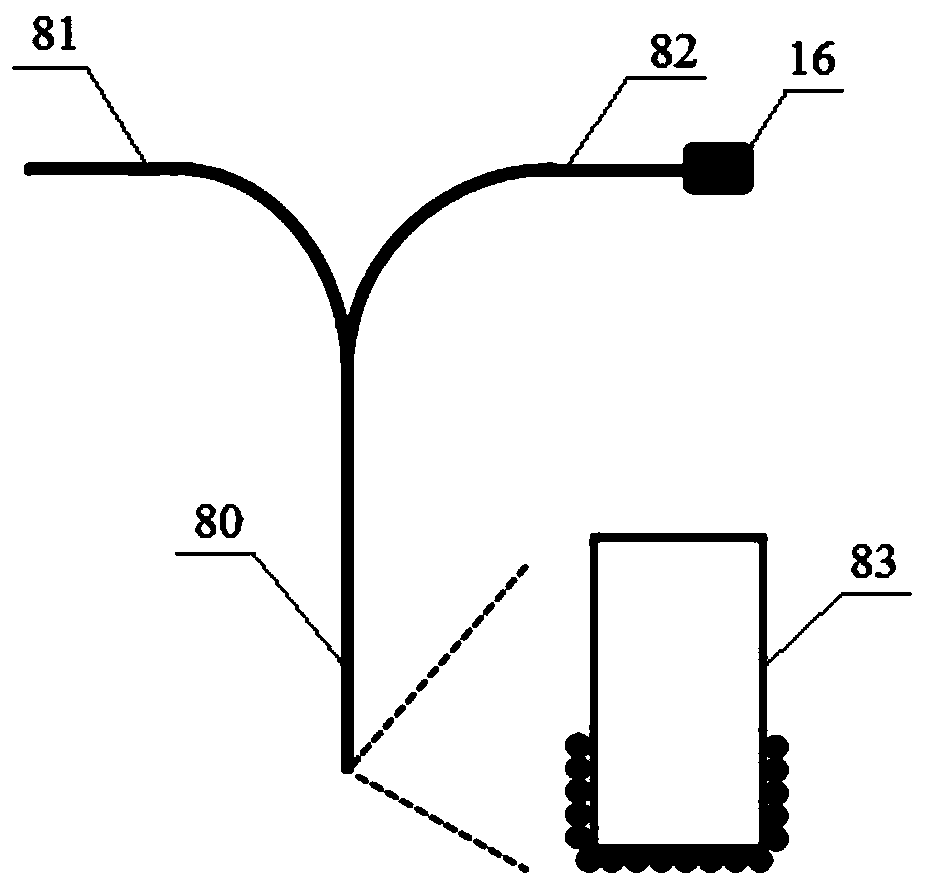

Surface-enhanced Raman spectroscopy-based photocatalytic in-situ monitoring system

ActiveCN109444106AImprove accuracyRealize in-situ real-time monitoringPhysical/chemical process catalystsWater treatment compoundsSurface-enhanced Raman spectroscopyCoupling

The invention discloses a surface-enhanced Raman spectroscopy-based photocatalytic in-situ monitoring system. The monitoring system comprises a Raman excitation light source, a laser coupling lens, anarrow band filter, a total reflection mirror, a dichroic mirror, a focus coupling lens, a surface enhanced Raman scattering fiber probe, a liquid phase photocatalytic reactor, a photocatalytic lightsource, a Raman collection lens and a spectrometer, wherein one end of a common detecting portion of the surface-enhanced Raman scattering fiber probe extends to from a first branching portion and a second branching portion; the extending end of the first branching portion is coupled to the focus coupling lens, and the extending end of the second branchingportion is coupled with the photocatalyticlight source; the other end of the common detecting portion is disposed in the liquid phase photocatalytic reactor; and a Raman excitation light and a photocatalytic light are in co-transmission, which greatly reduces the experimental difficulty and can effectively avoid a monitoring error caused by incomplete coincidence of focus points, thereby effectively improving the accuracy of Raman dynamic monitoring. The monitoring system is compact in structure and high in portability.

Owner:DONGGUAN UNIV OF TECH

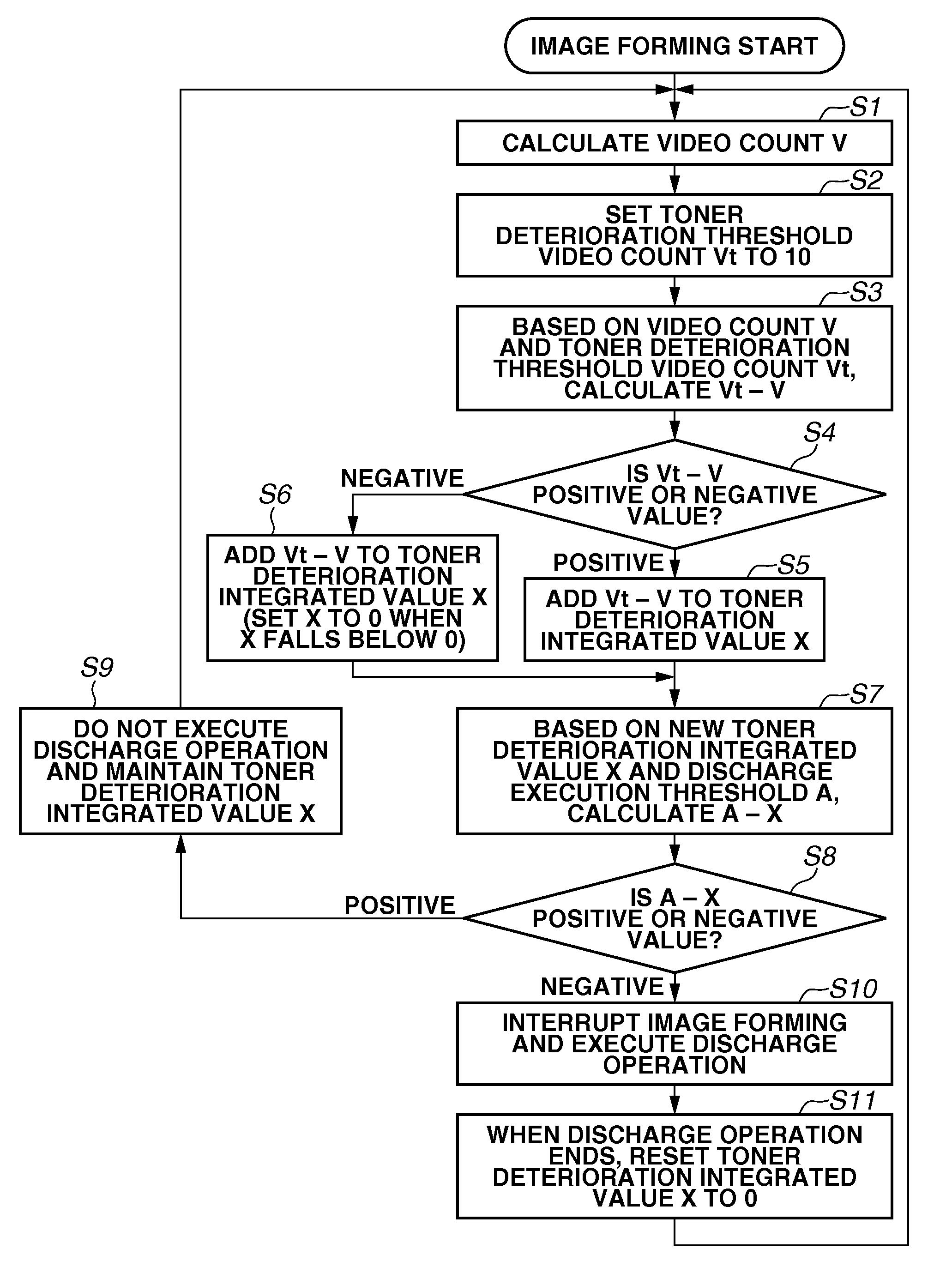

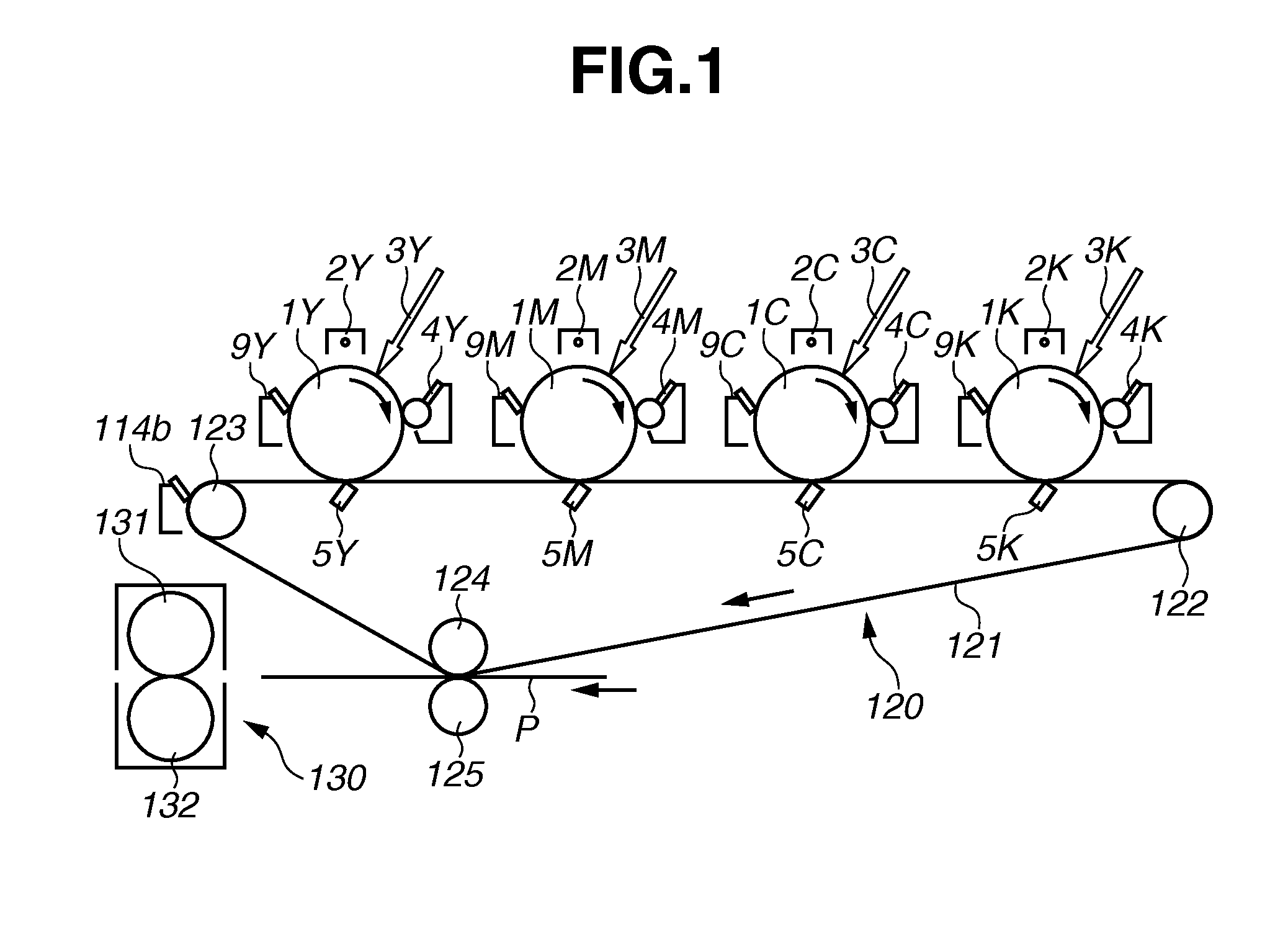

Image forming apparatus

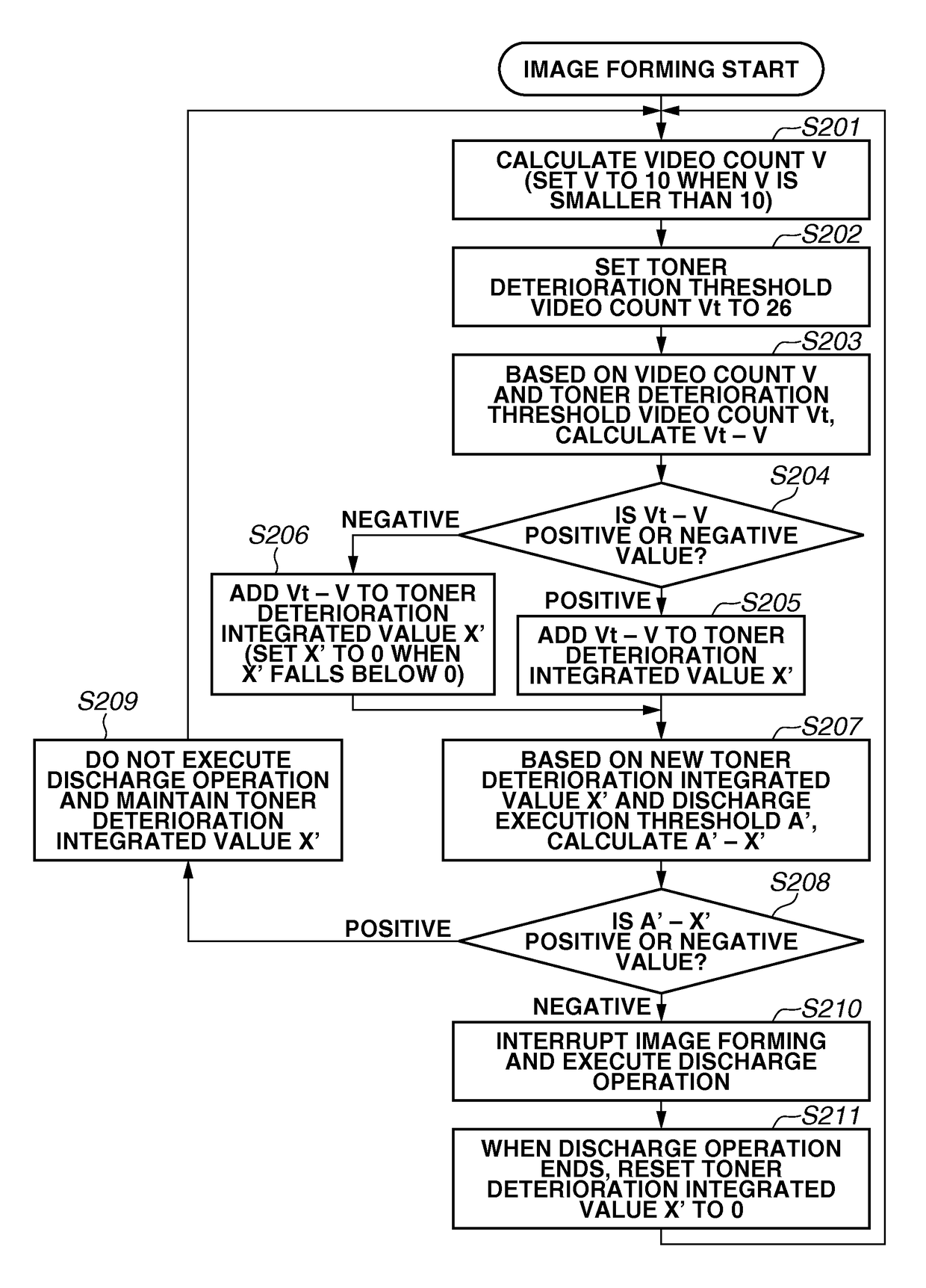

InactiveUS20160085197A1Preventing Image Quality DeteriorationPreventing deterioration of tonerElectrographic process apparatusLatent imageImage formation

An image forming apparatus includes an image bearing member, a developing device, a supplying device, and a control unit. The image bearing member bears a latent image. The developing device develops the latent image with a toner. The supplying device supplies toner to the developing device. The control unit executes a discharge operation to consume toner transferred onto the image bearing member from the developing device without transferring the toner onto a recording medium. The control unit executes the discharge operation where first deterioration integrated information exceeds a first executing threshold, and where second deterioration integrated information exceeds a second executing threshold that is larger than the first executing threshold. The control unit acquires the first deterioration information based at least a first deterioration threshold, and acquires the second deterioration information based on at least a second deterioration threshold that is larger than the first deterioration threshold.

Owner:CANON KK

Soilless covering agent and garbage treatment method thereof

InactiveCN107804951AAvoid handling inconvenienceSolve the inconvenience of handlingLandfill technologiesSolid waste disposalSludgeDecomposition

The invention discloses a soilless covering agent in the field of landfill treatment. The soilless covering agent comprises the following raw materials in parts by weight: 700-750 parts of sludge, 950-1000 parts of garbage concentrate, 100-120 parts of straws, 60-70 parts of newspaper and 720-750 parts of clay. The soilless covering agent disclosed by the invention is a comprehensive utilization of the garbage concentrate and the domestic sludge; thallus in the sludge is adhered to the straw and the newspaper, and colloids and the clay in the sludge can be quickly cured, and further, a curingfilm is formed, therefore, a suitable growth environment is provided for microorganisms, the sludge is reasonably treated, and the problem that the garbage leachate concentration is higher and higherwhile the decomposition treatment of garbage is facilitated.

Owner:GUIZHOU OURUIXIN ENVIRONMENTAL PROTECTION TECH

Paint stirring device

InactiveCN104474947ASuitable for a wide range of environmentsAvoid changes in concentrationRotary stirring mixersEngineering

The invention discloses a paint stirring device. The paint stirring device comprises a paint stirring device body and a bracket used for supporting the paint stirring device body, wherein the paint stirring device body is fixedly connected with the upper end face of the bracket; a top cover is fixed on the upper end face of the paint stirring device body; a hole used for mounting a rotary shaft is formed in the top cover; a sealing piece is fixedly arranged between the rotary shaft and the top cover; the upper end of the rotary shaft is fixedly connected with a power connecting piece; the lower end of the rotary shaft is fixedly connected with a stirring paddle; the upper end of the stirring paddle is fixedly connected with a scraper plate used for collecting materials splashed onto the inner surface of the paint stirring device body; a discharging opening is further formed in the lower end face of the paint stirring device body and is fixedly connected with a discharging opening cover. The paint stirring device has the positive effects that by internally arranging the scraper plate, the phenomenon of change of the overall concentration of the materials such as mortar caused by adhesion of the mortar to the inner wall of the paint stirring device during stirring can be effectively prevented.

Owner:天津市亿腾顺泰建筑材料有限公司

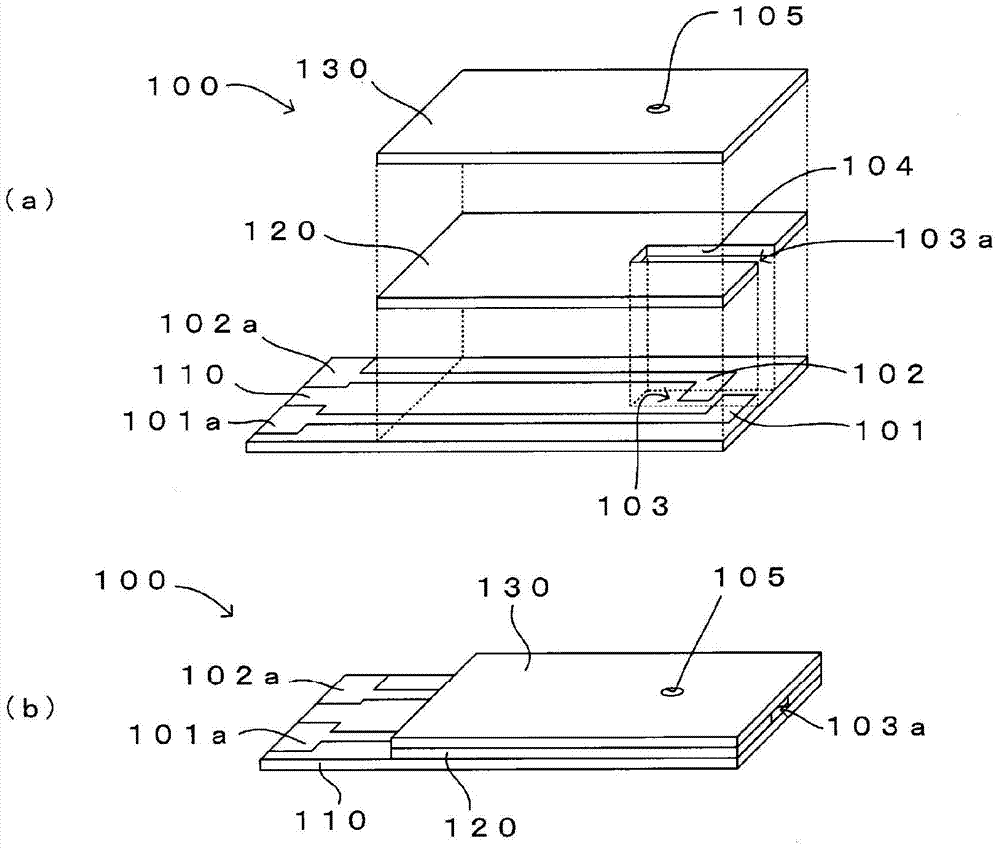

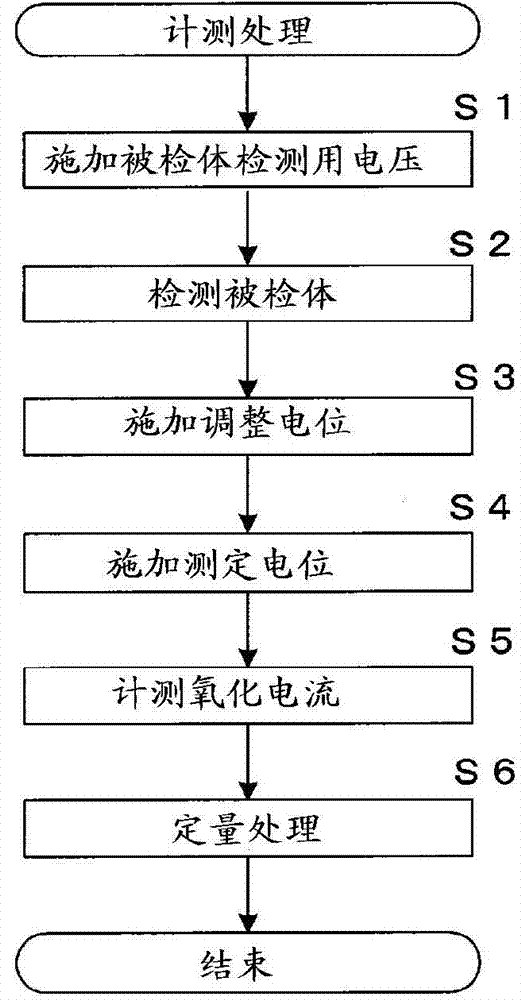

Method for measuring substances

InactiveCN103946701AHigh measurement accuracyAvoid concentration changesMicrobiological testing/measurementMaterial analysis by electric/magnetic meansReducing substancesMeasurement precision

Provided is a technique that enables measurement precision to be improved when quantifying a substance to be measured, which is contained in a sample, by decreasing the impact of current components different from the oxidation current resulting from the oxidization of a reducing substance produced by a reaction between enzymes and the substance to be measured in the sample, among the current components in a response current obtained by applying a counter electrode-based measurement potential to a working electrode. Because an adjustment potential with higher potential than a measurement potential is applied in the form of a pulse to the working electrode, among the current components contained in the response current obtained by applying the counter electrode-based measurement potential to the working electrode, the impact of the current components different from the oxidation current resulting from oxidization of the reducing substance produced by the reaction between the substance to be measured and enzymes in the sample can be reduced. Thus, the response current can be stably measured, and measurement precision can be improved when quantifying the substance to be measured, which is contained in the sample.

Owner:MURATA MFG CO LTD

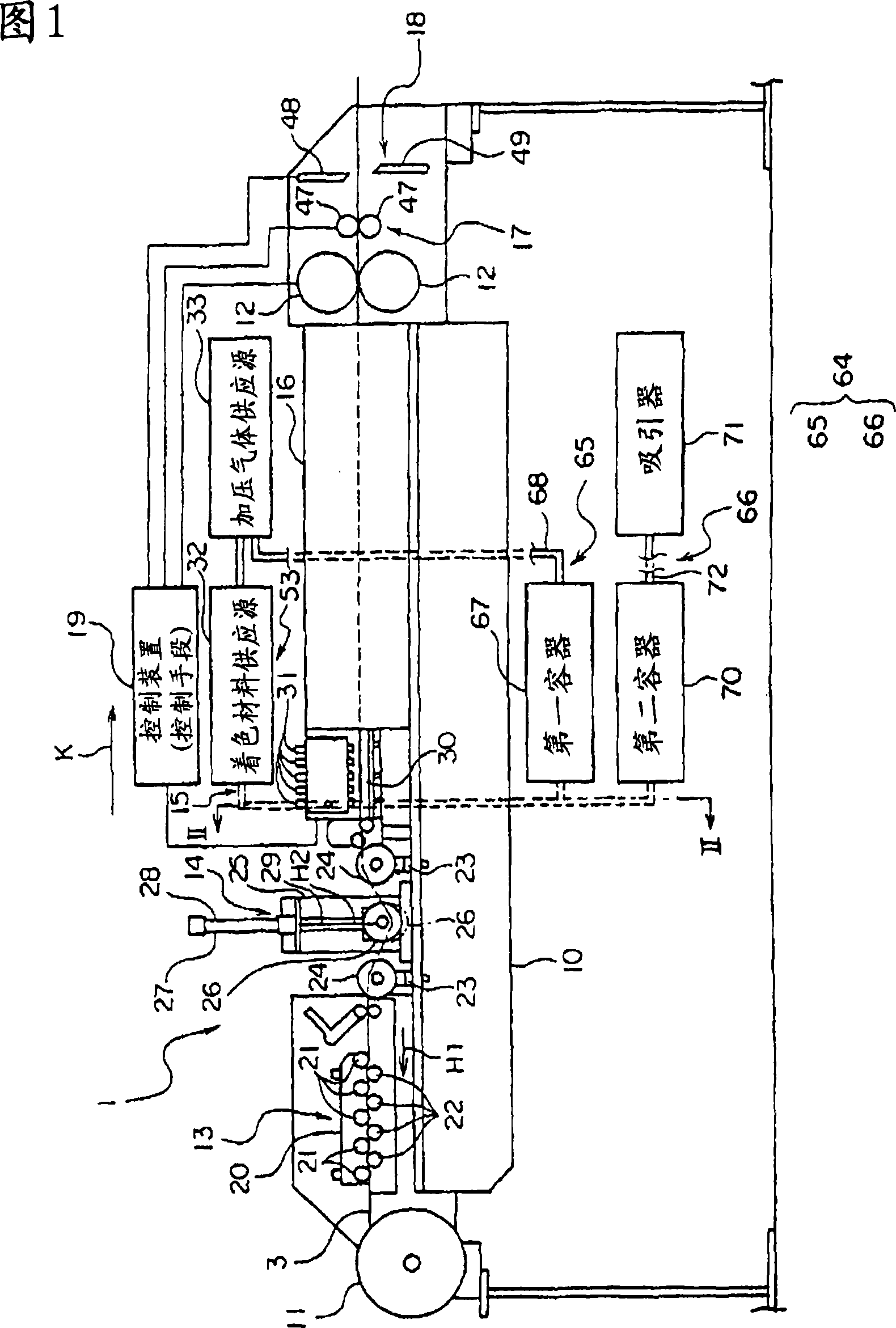

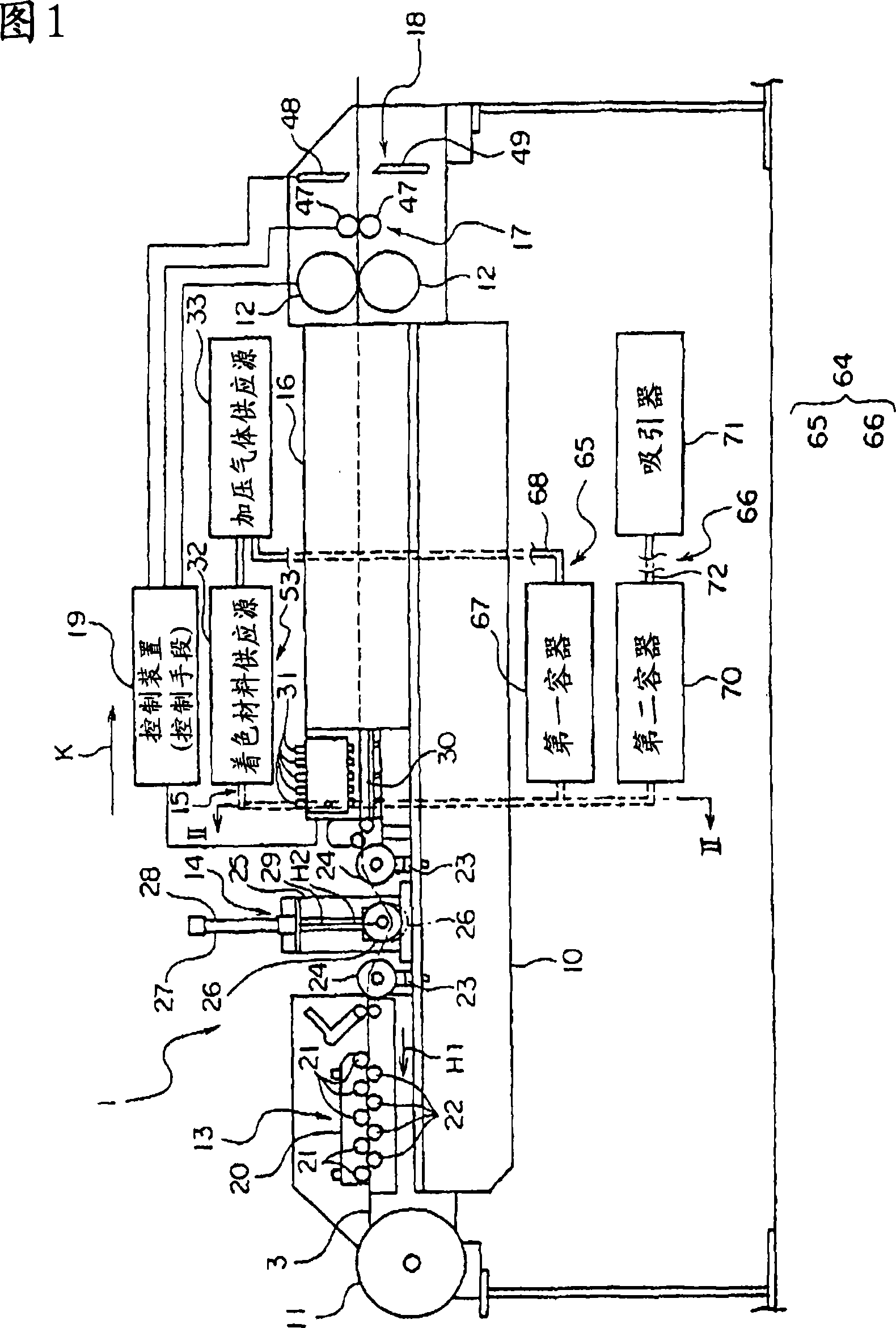

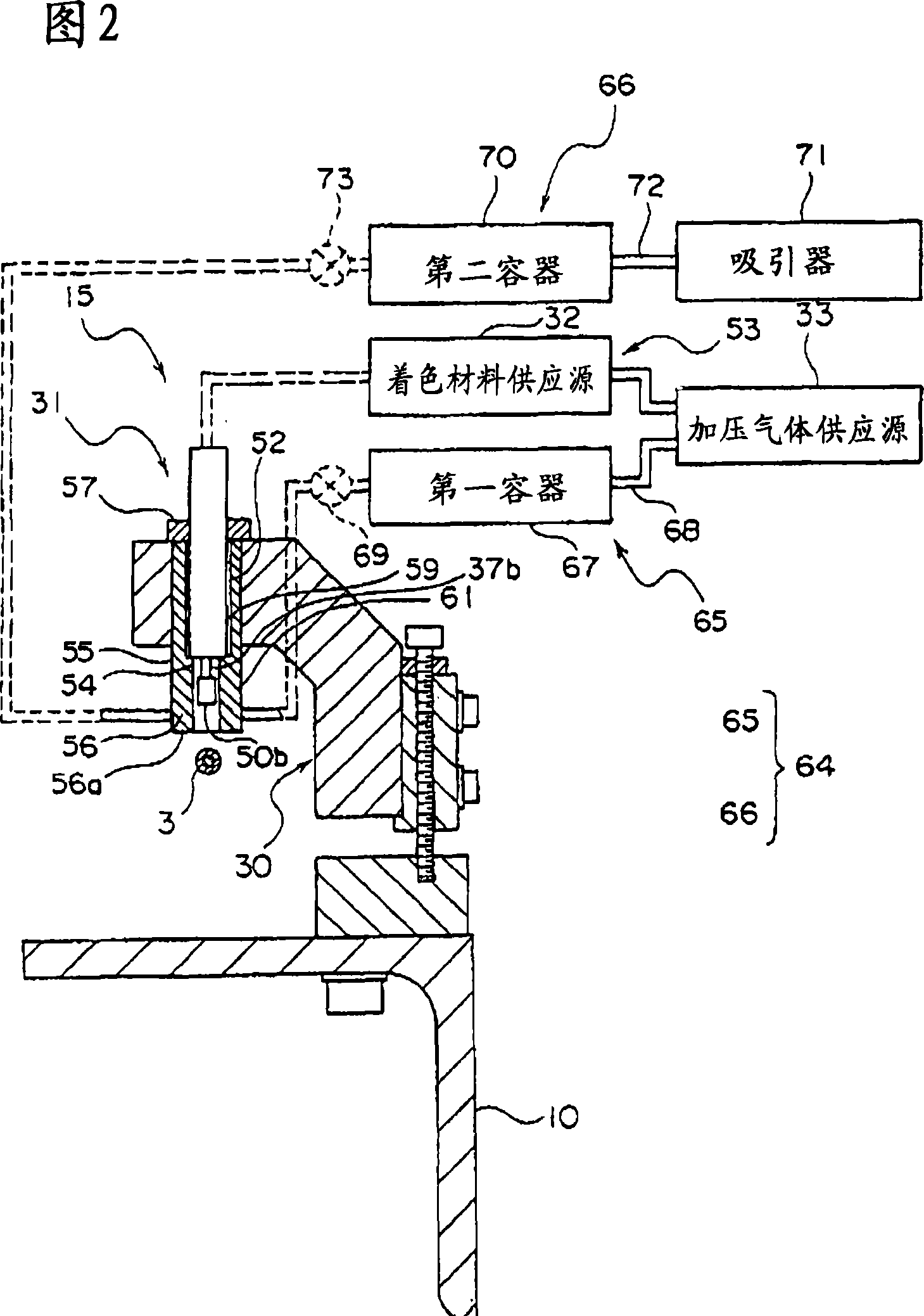

Coloring nozzle

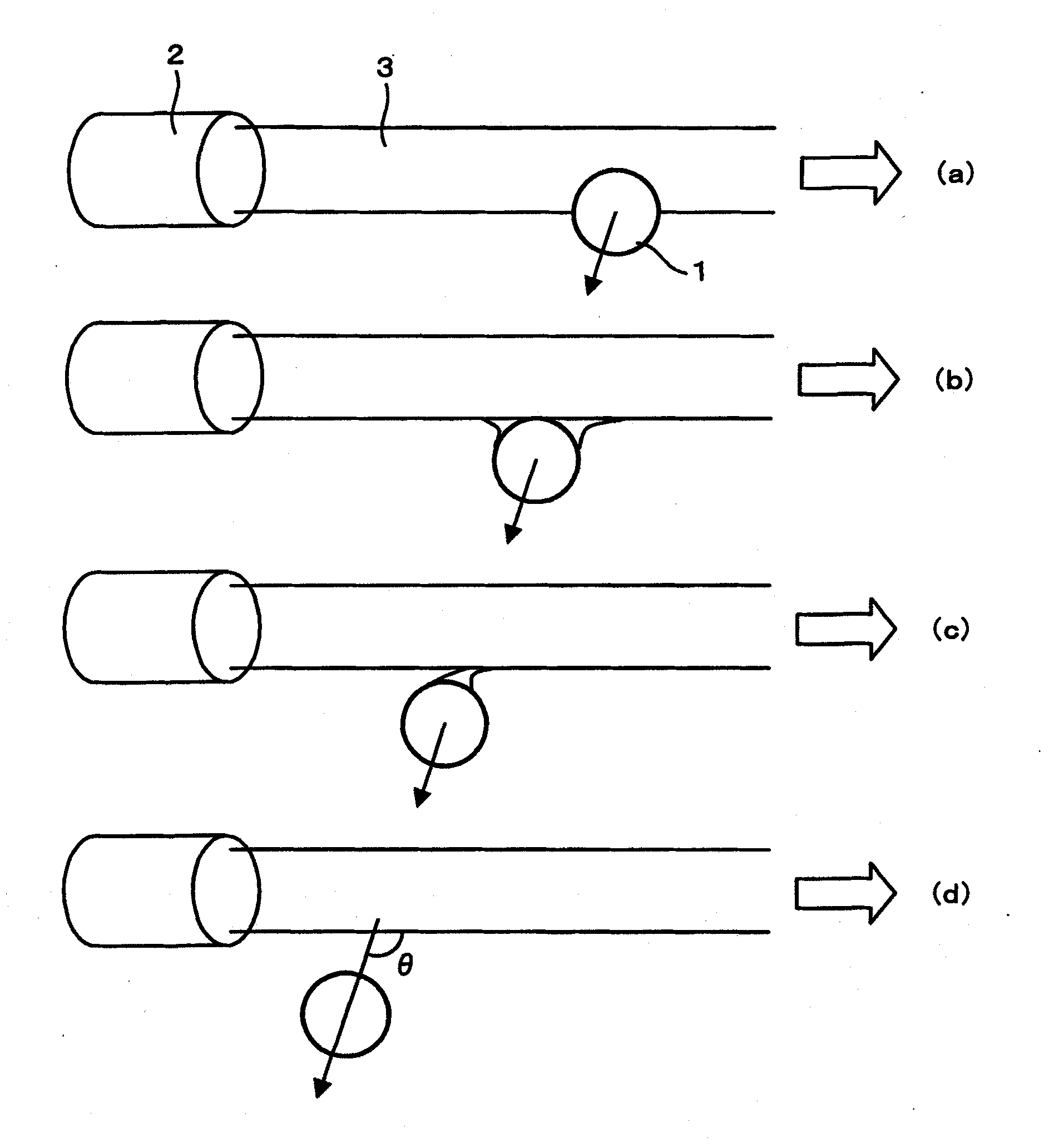

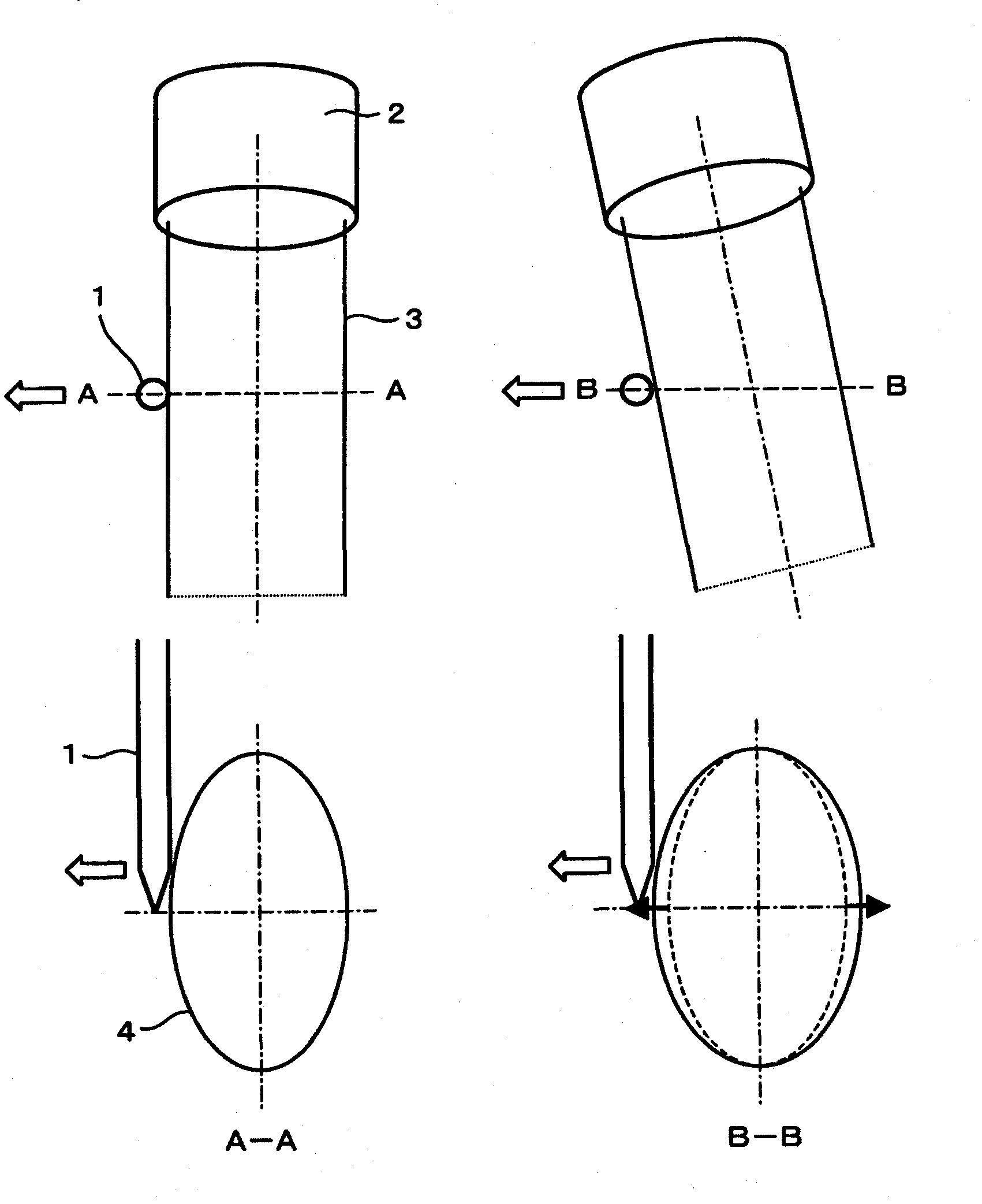

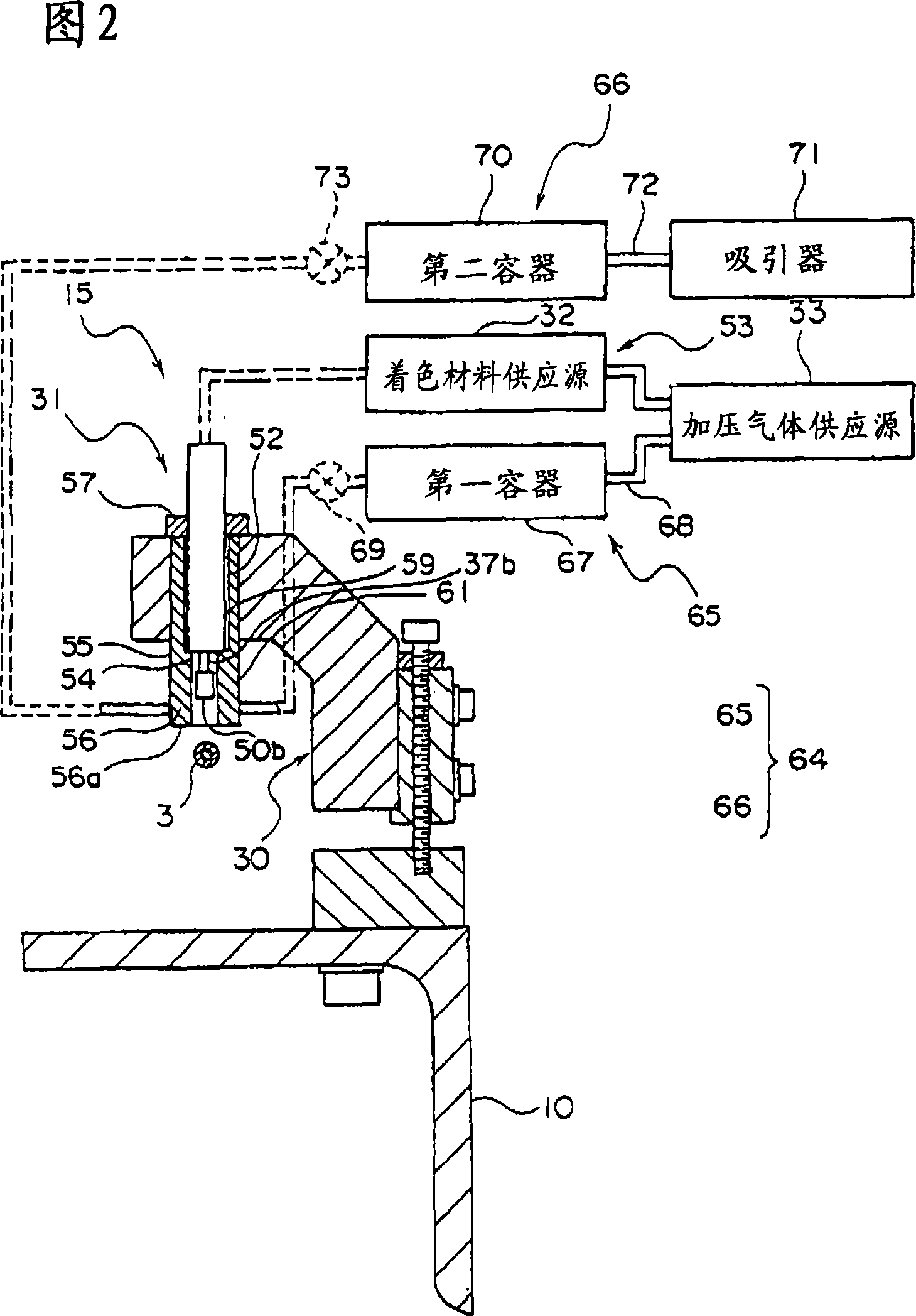

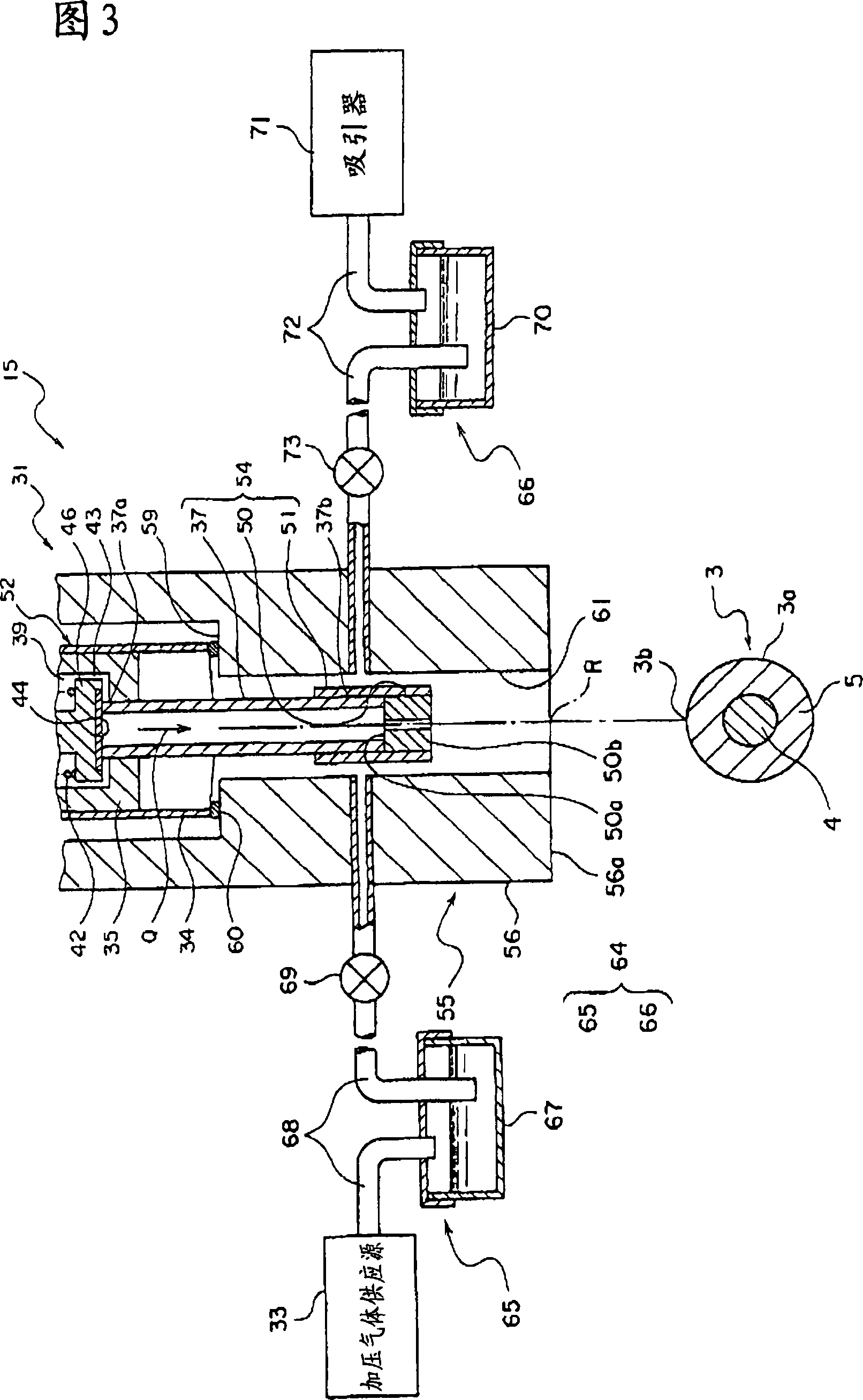

InactiveCN101027731APrevent leakageInfluence of direction of injectionLiquid surface applicatorsSpraying apparatusElectric wireNozzle

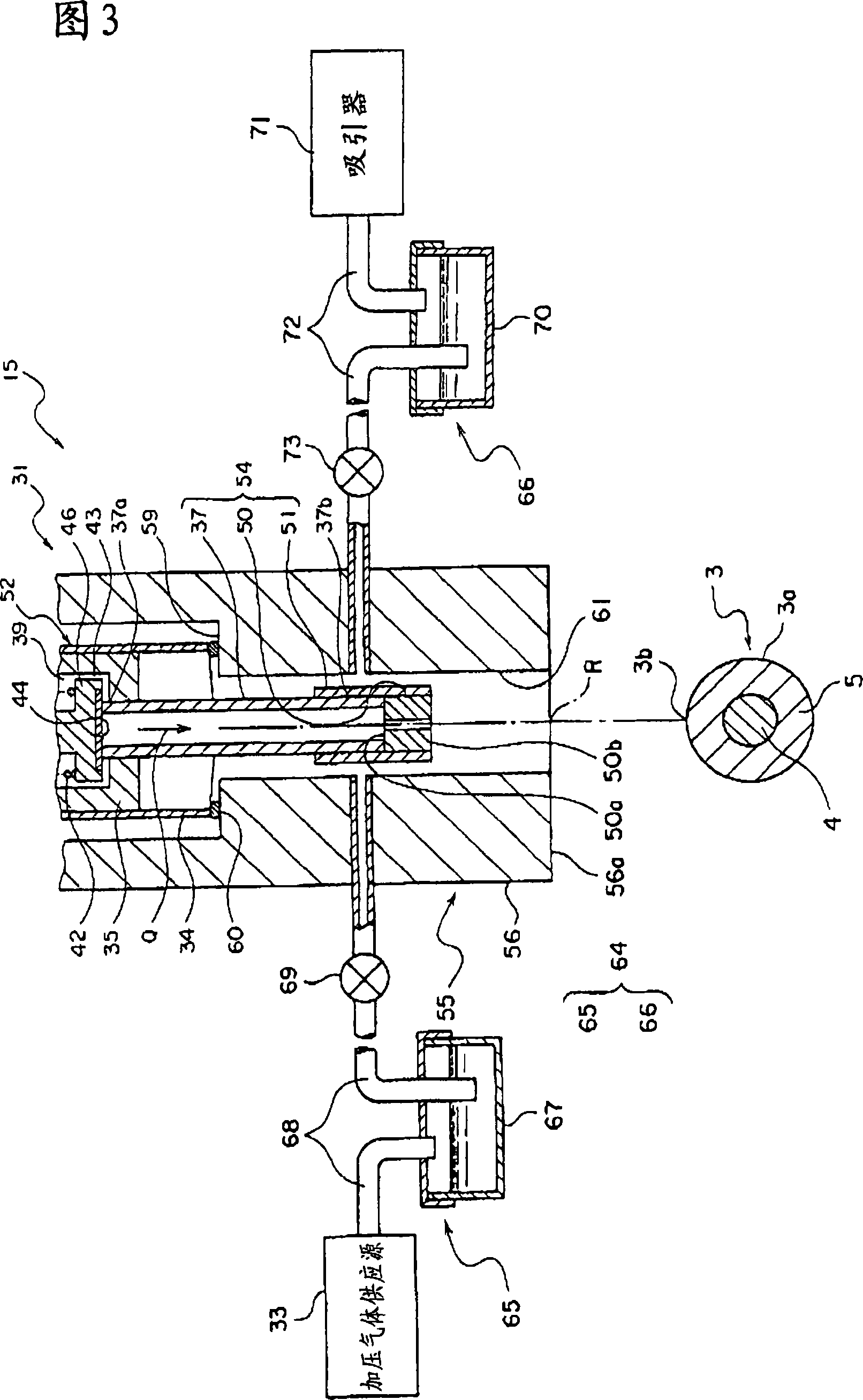

Disclosed is a coloring nozzle which is capable of surely spraying a certain amount of a coloring material toward a desired position on the outer surface of an article. Specifically disclosed is a coloring nozzle (31) which colors an electrical wire (3) as an article by spraying a certain amount of a liquid coloring material toward the outer surface (3a) of the electrical wire (3). The coloring nozzle (31) comprises a nozzle (54) for spraying the coloring material, a nozzle cover (55) and a cleaning unit (64). The nozzle cover (55) covers at least the front end portion (37b) of the nozzle (54). The cleaning unit (64) comprises a cleaning liquid supplying section (65) and a cleaning liquid discharging section (66). The cleaning liquid supplying section (65) supplies a cleaning liquid to the inside of the nozzle cover (55), while the cleaning liquid discharging section (66) discharges the cleaning liquid in the nozzle cover (55).

Owner:YAZAKI CORP

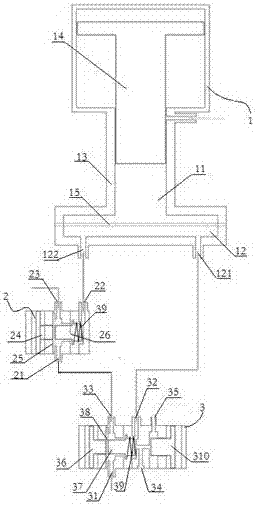

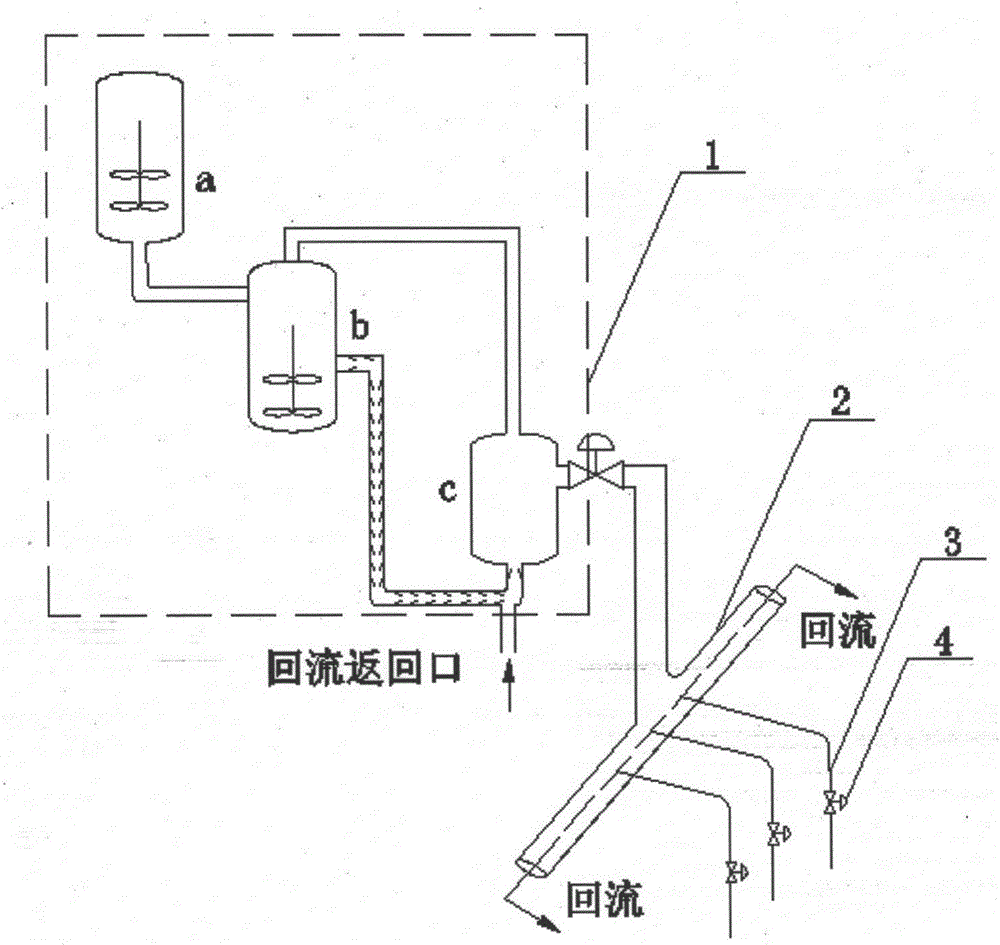

Filling device special for injectable suspension

ActiveCN107539507AGuaranteed circulating flowAvoid concentration changesLiquid materialMedicineInjectable Suspension

The invention discloses a filling device special for an injectable suspension. The filling device comprises a dosing device, a dosing control valve and a filling head. The dosing device comprises a piston booster device and a dosing cavity. A dosing cavity inlet and a dosing cavity outlet are formed in the lower part of the dosing cavity. The dosing cavity is connected with the filling head. The dosing control valve is a three-way valve and comprises two inlets and a liquid outlet. One of the inlets is connected with the filling head. The other inlet is connected with the dosing cavity outlet.The filling head is internally provided with a control valve set. A liquid inlet, a dosing cavity connecting opening, a dosing control valve connecting opening, a filling opening and a liquid discharging opening are formed in the filling head. The dosing cavity connecting opening in the filling head is connected with the dosing cavity inlet. The dosing control valve connecting opening is connected with one inlet of the dosing control valve. The liquid discharging opening is controlled to communicate with the filling opening through a piston. A filling container is arranged at the lower part of the filling opening. Liquid can be made to be always at a circulation state in the filling process, the consistency of concentration of the injectable suspension is ensured, the filling quality is ensured, and a non-mixed suspension liquid can be filled.

Owner:苏州康乐辉医药科技有限公司

Spinning solvent circulating equipment and circulating method for producing polypropylene threads by dry method

ActiveCN113718360ARelieve pressurePrevent spillageArtificial thread manufacturing machinesTextile/flexible product manufactureSpinningProcess engineering

The invention discloses spinning solvent circulating equipment for producing polypropylene threads by a dry method, and relates to the field of polypropylene thread production. The spinning solvent circulating equipment comprises a spinning channel, the spinning channel comprises a curing channel and a discharging channel which are separated by a sealed thread outlet mechanism, the curing channel communicates with a solvent supply cylinder, the solvent supply cylinder communicates with a hot air supply pipe, the other end of the hot air supply pipe communicates with an air storage cylinder, the air storage cylinder communicates with the curing channel through an exhaust mechanism, a communicating vessel is arranged in the solvent supply cylinder, the end, with the smaller diameter, of the communicating vessel communicates with the hot air supply pipe, so that internal circulation can be realized, volatile solvents are prevented from overflowing, the exhaust mechanism is adopted to exhaust part of gas in the curing channel, so that the pressure in the curing channel is reduced, the solvent is easier to volatilize, and the polypropylene fiber is easier to cure in a lower-temperature environment.

Owner:界首市三宝宏达制线有限公司

Coloring nozzle

InactiveCN101027731BPrevent leakageInfluence of direction of injectionLiquid surface applicatorsSpraying apparatusEngineeringElectric wire

Disclosed is a coloring nozzle which is capable of surely spraying a certain amount of a coloring material toward a desired position on the outer surface of an article. Specifically disclosed is a coloring nozzle (31) which colors an electrical wire (3) as an article by spraying a certain amount of a liquid coloring material toward the outer surface (3a) of the electrical wire (3). The coloring nozzle (31) comprises a nozzle (54) for spraying the coloring material, a nozzle cover (55) and a cleaning unit (64). The nozzle cover (55) covers at least the front end portion (37b) of the nozzle (54). The cleaning unit (64) comprises a cleaning liquid supplying section (65) and a cleaning liquid discharging section (66). The cleaning liquid supplying section (65) supplies a cleaning liquid to the inside of the nozzle cover (55), while the cleaning liquid discharging section (66) discharges the cleaning liquid in the nozzle cover (55).

Owner:YAZAKI CORP

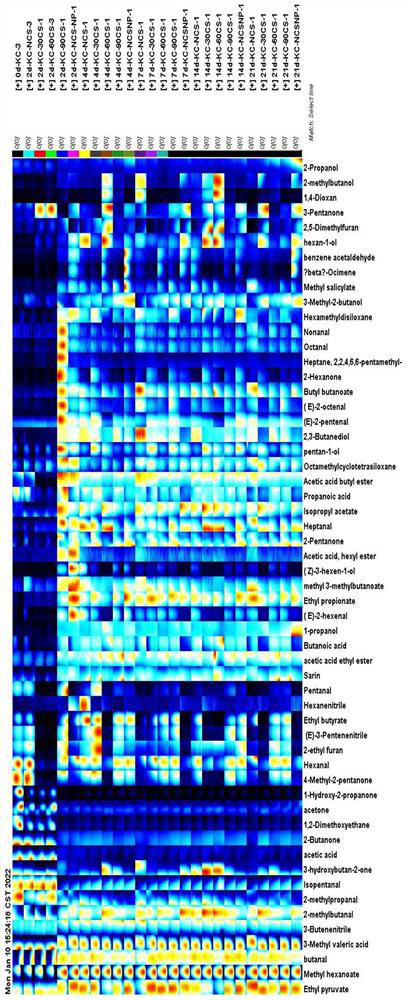

Preservation method for picked fruits and vegetables

ActiveCN114711287AGuaranteed hardnessReduce yellowingFood processingClimate change adaptationNutritionPropanedial

The invention belongs to the technical field of fresh-keeping, and particularly relates to a fresh-keeping method for picked fruits and vegetables. According to the method, the picked fruits and vegetables are sequentially subjected to cold shock treatment and packaging treatment, and the gas environment in the package can be changed, so that the consumption of nutrient substances caused by respiration is reduced, the loss of water is reduced, the hardness of the picked fruits and vegetables is maintained, the increase of the weight loss rate is slowed down, and the oxygenolysis of chlorophyll is delayed, and the original color of the picked fruits and vegetables is maintained to a great extent; the fruit and vegetable fresh-keeping agent is capable of delaying yellowing of fruits and vegetables, inhibiting physiological metabolic activities of the picked fruits and vegetables, delaying consumption of soluble solids of the fruits and vegetables, inhibiting membrane lipid peroxidation, reducing accumulation of malonaldehyde and inhibiting concentration change of volatile organic compounds, has a synergistic effect on physicochemical, nutrition and flavor quality of the picked fruits and vegetables, and improves the fresh-keeping effect of the picked fruits and vegetables.

Owner:HEBEI AGRICULTURAL UNIV.

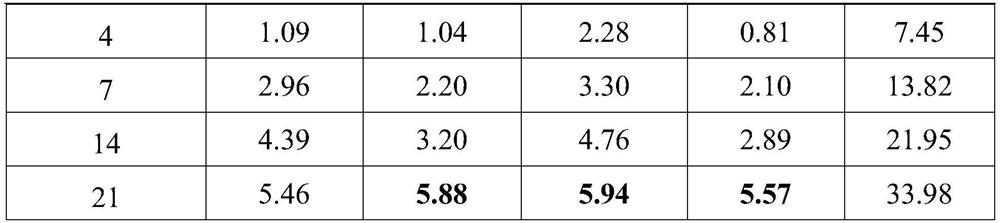

Image forming apparatus with toner discharge operation

InactiveUS10108106B2Preventing Image Quality DeteriorationPreventing deterioration of tonerElectrographic process apparatusLatent imageEngineering

An image forming apparatus includes an image bearing member, a developing device, a supplying device, and a control unit. The image bearing member bears a latent image. The developing device develops the latent image with a toner. The supplying device supplies toner to the developing device. The control unit executes a discharge operation to consume toner transferred onto the image bearing member from the developing device without transferring the toner onto a recording medium. The control unit executes the discharge operation where first deterioration integrated information exceeds a first executing threshold, and where second deterioration integrated information exceeds a second executing threshold that is larger than the first executing threshold. The control unit acquires the first deterioration information based at least a first deterioration threshold, and acquires the second deterioration information based on at least a second deterioration threshold that is larger than the first deterioration threshold.

Owner:CANON KK

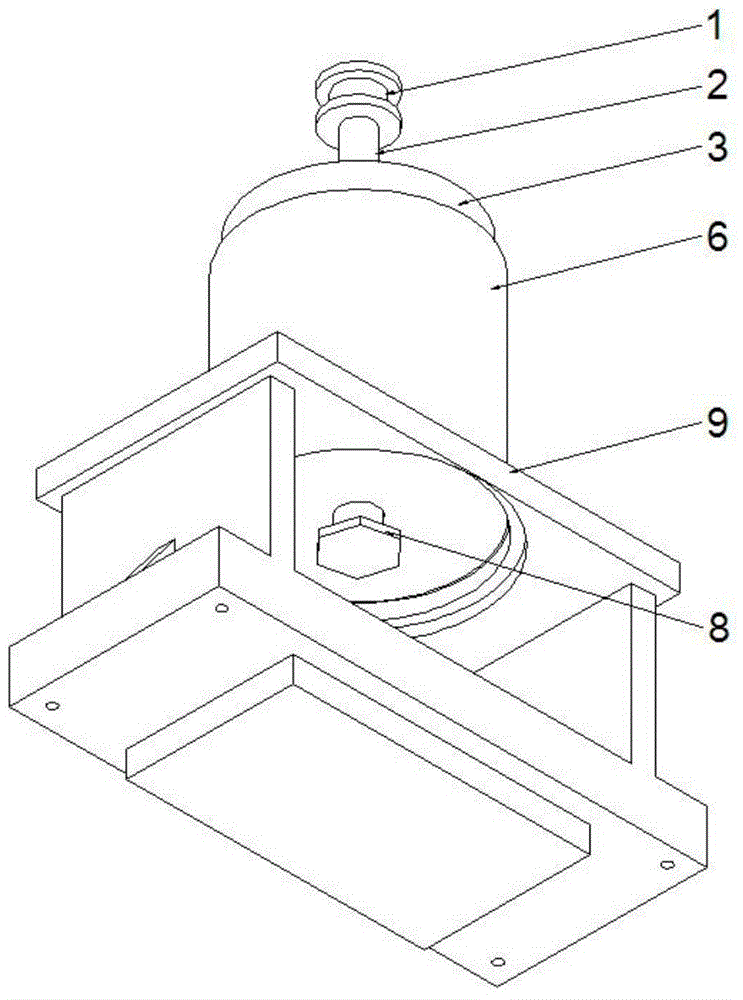

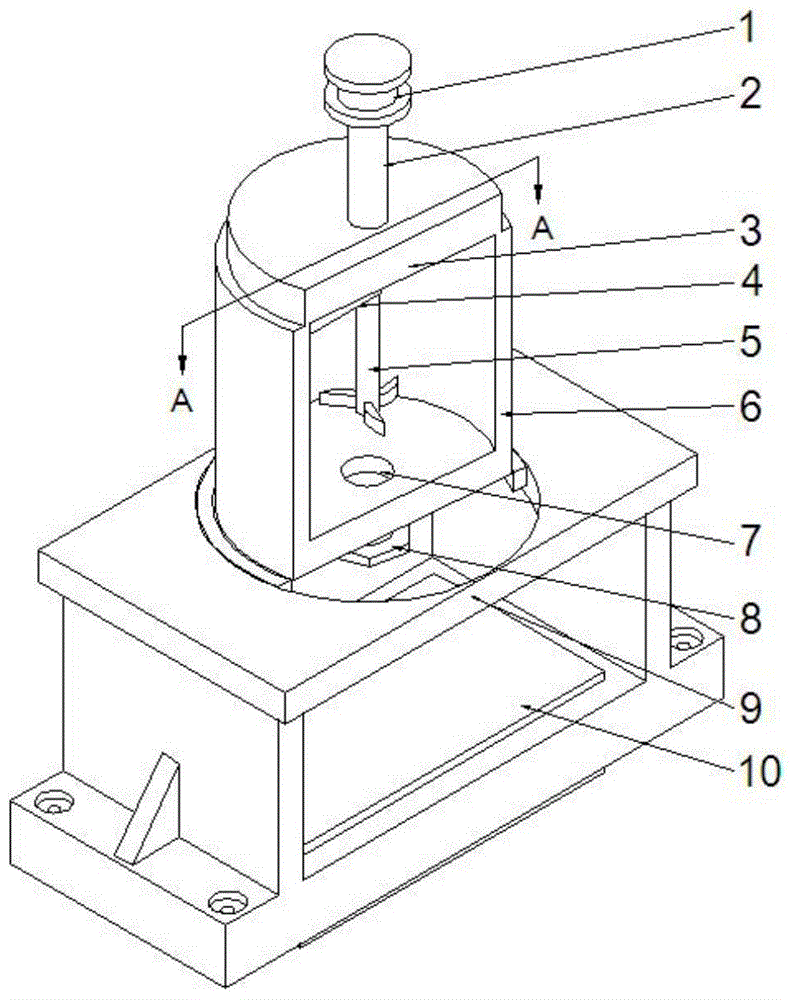

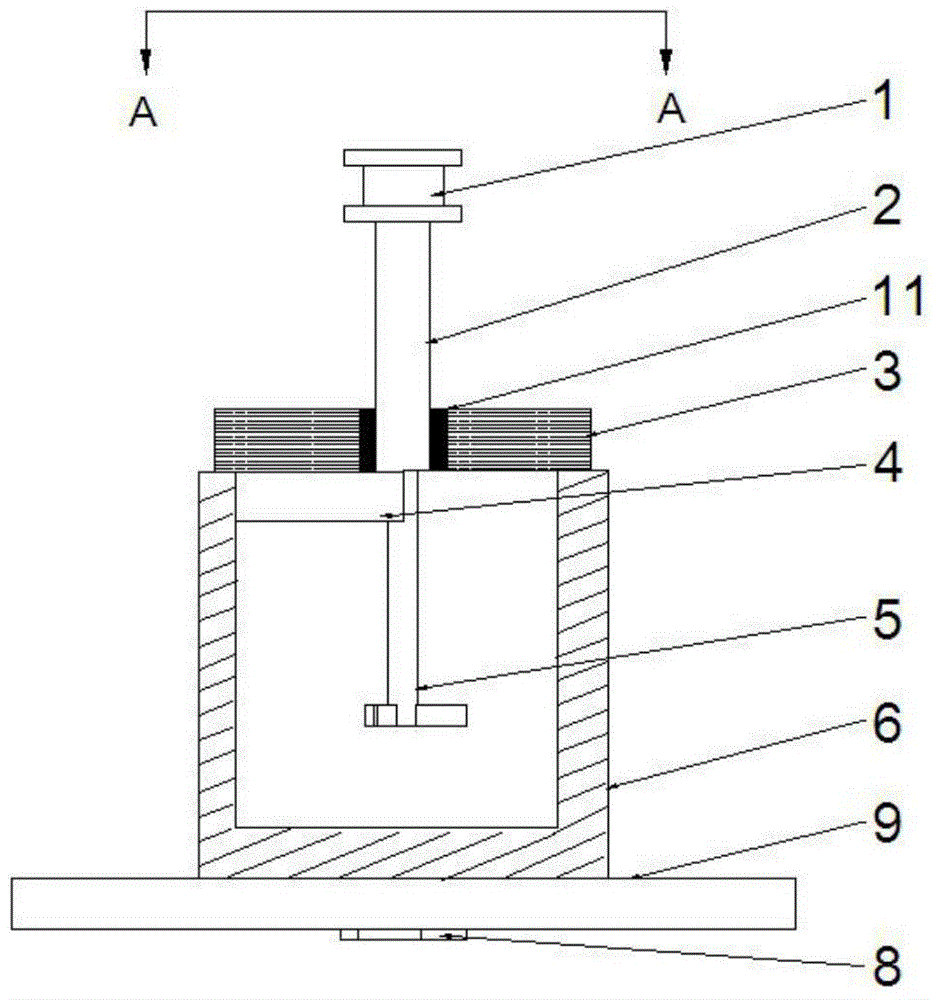

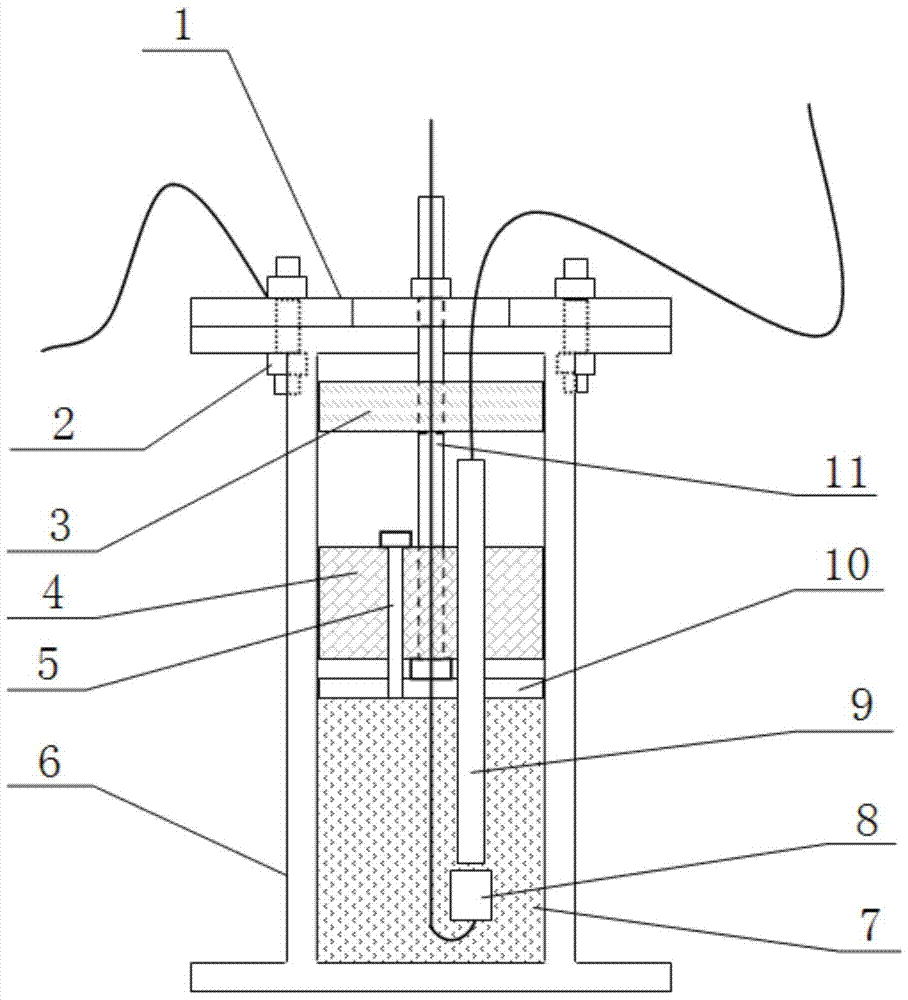

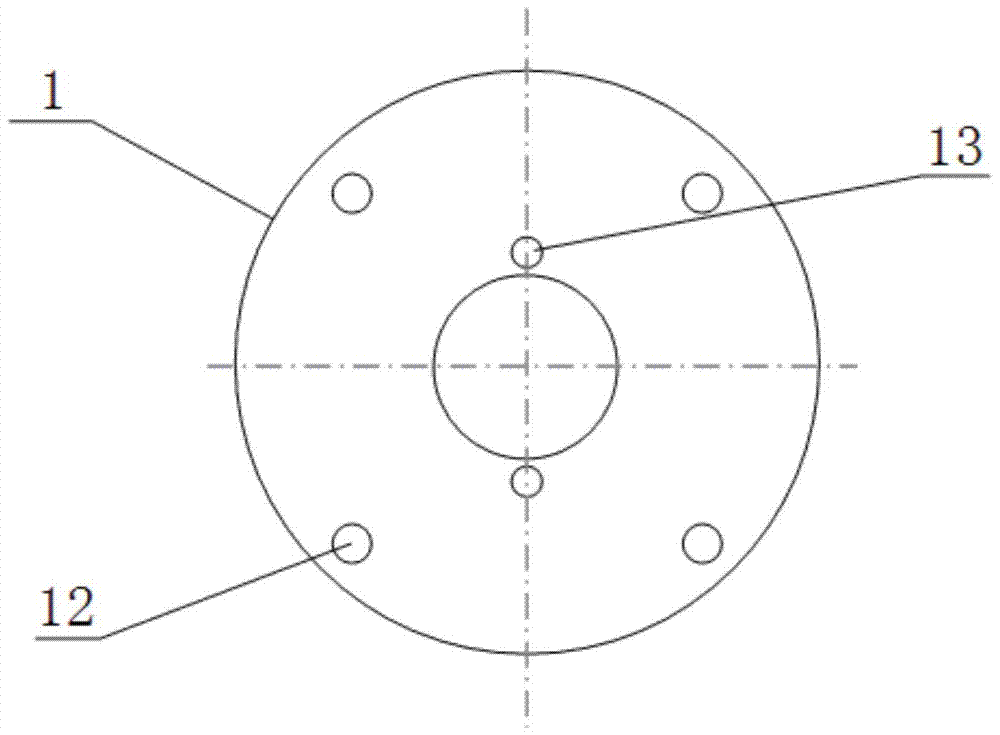

A metal material corrosion test device and method in a high-compacted bentonite environment

InactiveCN105115887BSolve preparation difficultiesAvoid concentration changesWeather/light/corrosion resistanceMetallic materialsChemical test

The invention belongs to the field of corrosion electrochemical testing, in particular to a metal material corrosion testing device and method in a high-pressure bentonite environment. The device includes a high-compacted bentonite bearing cabin and a compacted soil sheet located in the high-compacted bentonite loaded cabin, a connection and export system, a three-electrode system and a sealing plug, and the compacted soil sheet is connected to the high-compacted bentonite bearing cabin through the connection and export system , and lead out from the high-compacted bentonite bearing cabin through the connection export system, the compacted soil sheet is used to compact the bentonite carried in the high-compacted bentonite bearing cabin to prepare high-compacted bentonite, and the sealing plug is used for all The sealing of the high-compacted bentonite bearing compartment is described, and the three-electrode system is connected to an external electrochemical workstation through wires to conduct corrosion tests on metal materials. The invention can truly simulate the deep geological environment where the nuclear waste storage tank is buried, and obtain the corrosion degree of the storage tank material in each burial stage.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

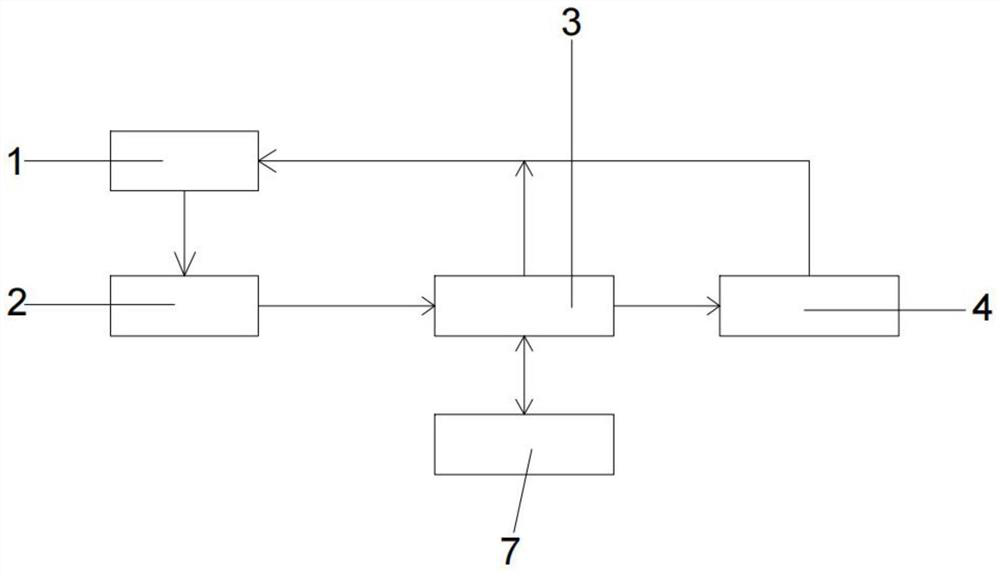

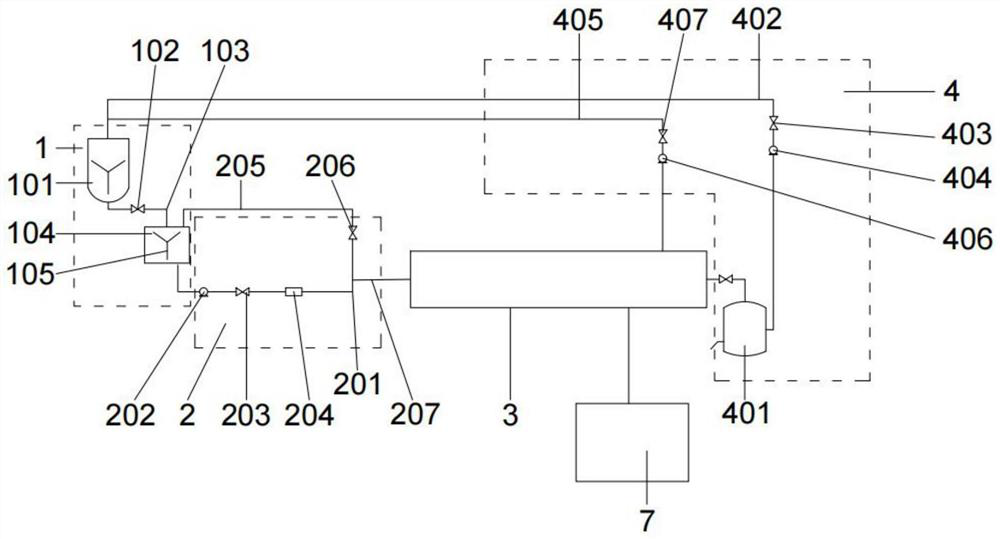

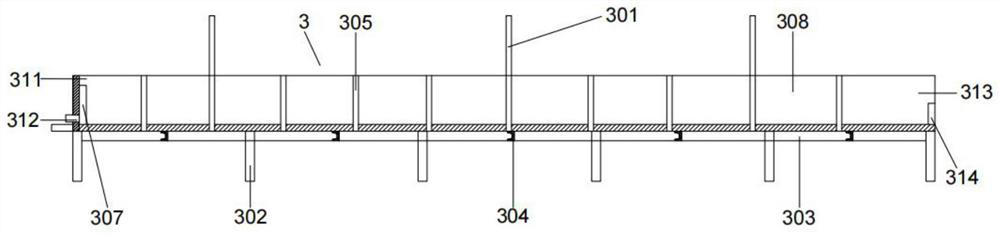

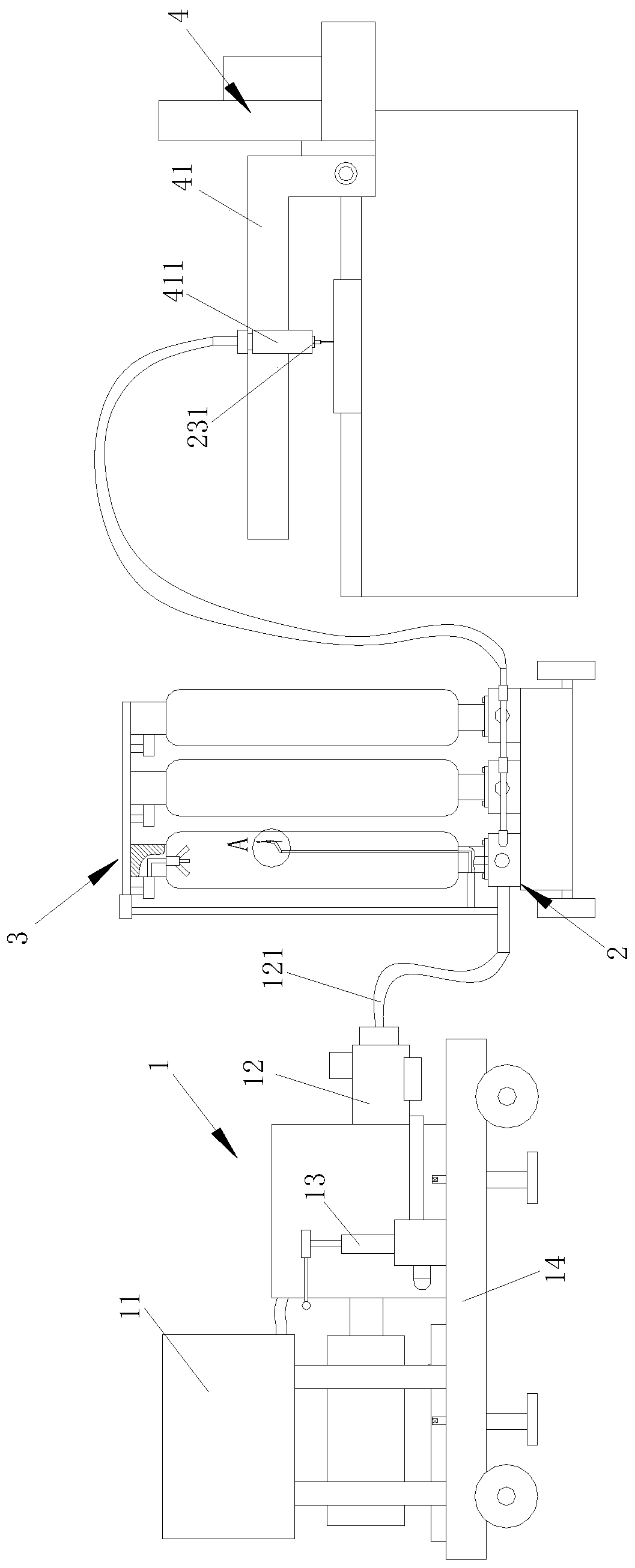

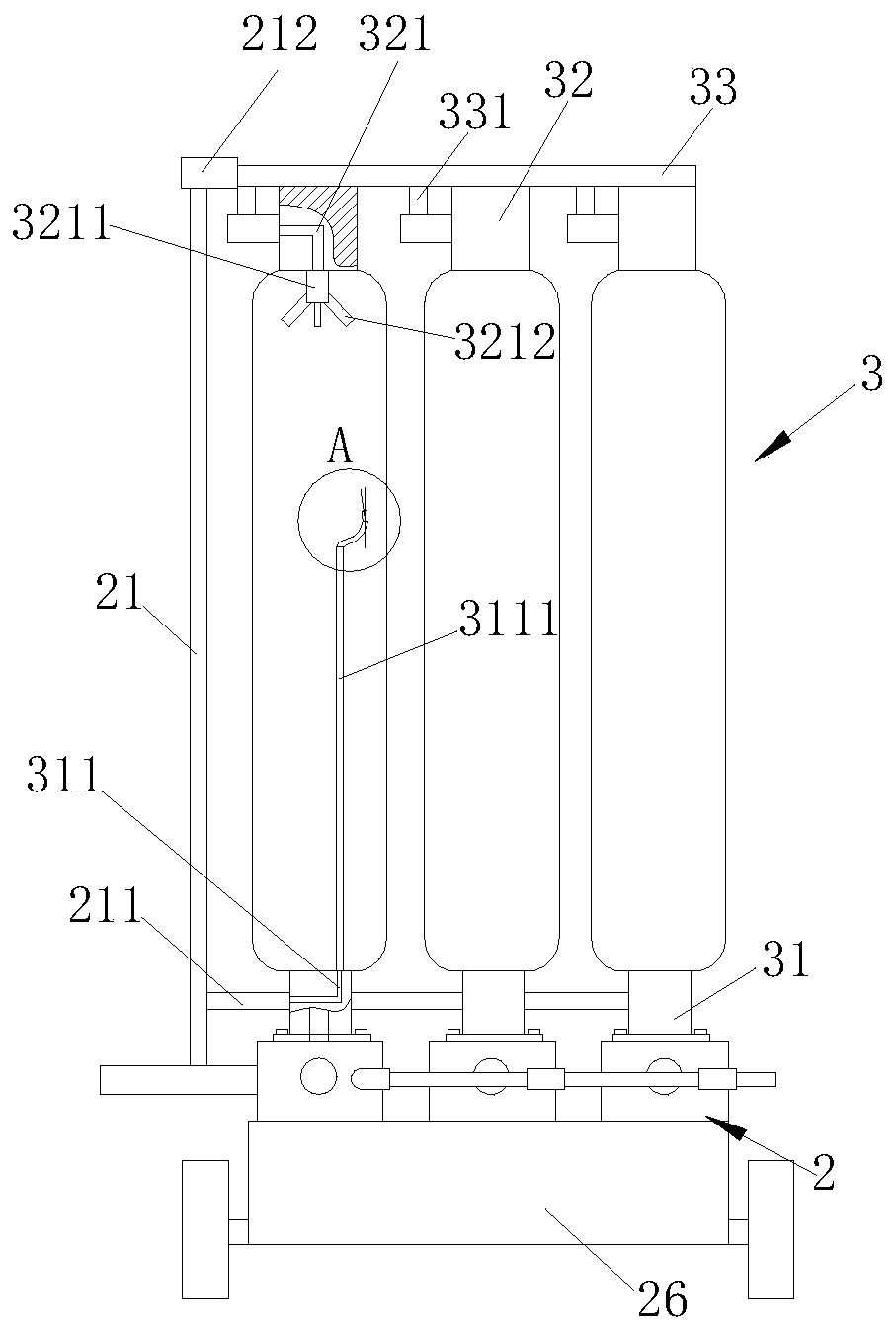

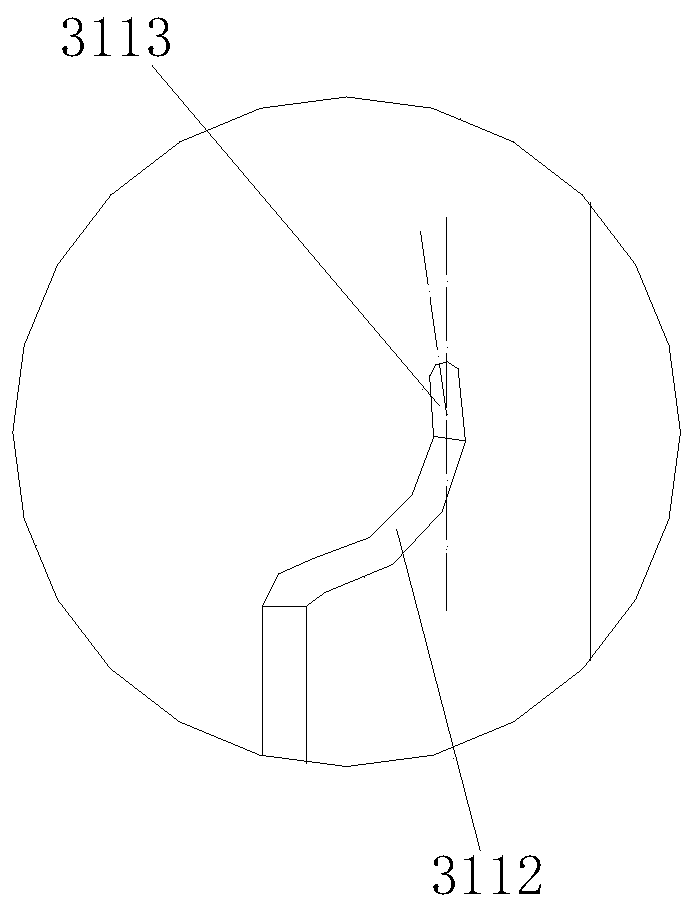

Tailing deposition test system

PendingCN114112299AEasy to useObtain the spatio-temporal distribution lawHydrodynamic testingMaterial analysisMining engineeringSolid particle

The invention provides a tailing deposition test system which comprises a stirring system, a pumping and discharging system, a deposition model tank, a wake flow backflow circulating system and a monitoring system, and the stirring system, the pumping and discharging system and the deposition model tank are sequentially connected through test pipelines. The sedimentary model tank and the wake flow backflow circulation system are respectively connected with the stirring system through test pipelines, a stirrer is arranged in a material storage pool of the stirring system, a monitoring system is arranged on the sedimentary model tank, the stirrer is started during ore drawing, and the situation that particles in tailing pulp deposit in the material storage pool, so that the concentration of ore pulp changes in the ore drawing process is prevented; the technical problem that when ore pulp stored in a storage pool is discharged into a sedimentary model groove through a pumping system, if the storage time of the ore pulp in the storage pool is too long, solid particles in the ore pulp are prone to depositing in the storage pool, and the concentration of the ore pulp changes in the ore drawing process is solved.

Owner:CHINA ACAD OF SAFETY SCI & TECH +1

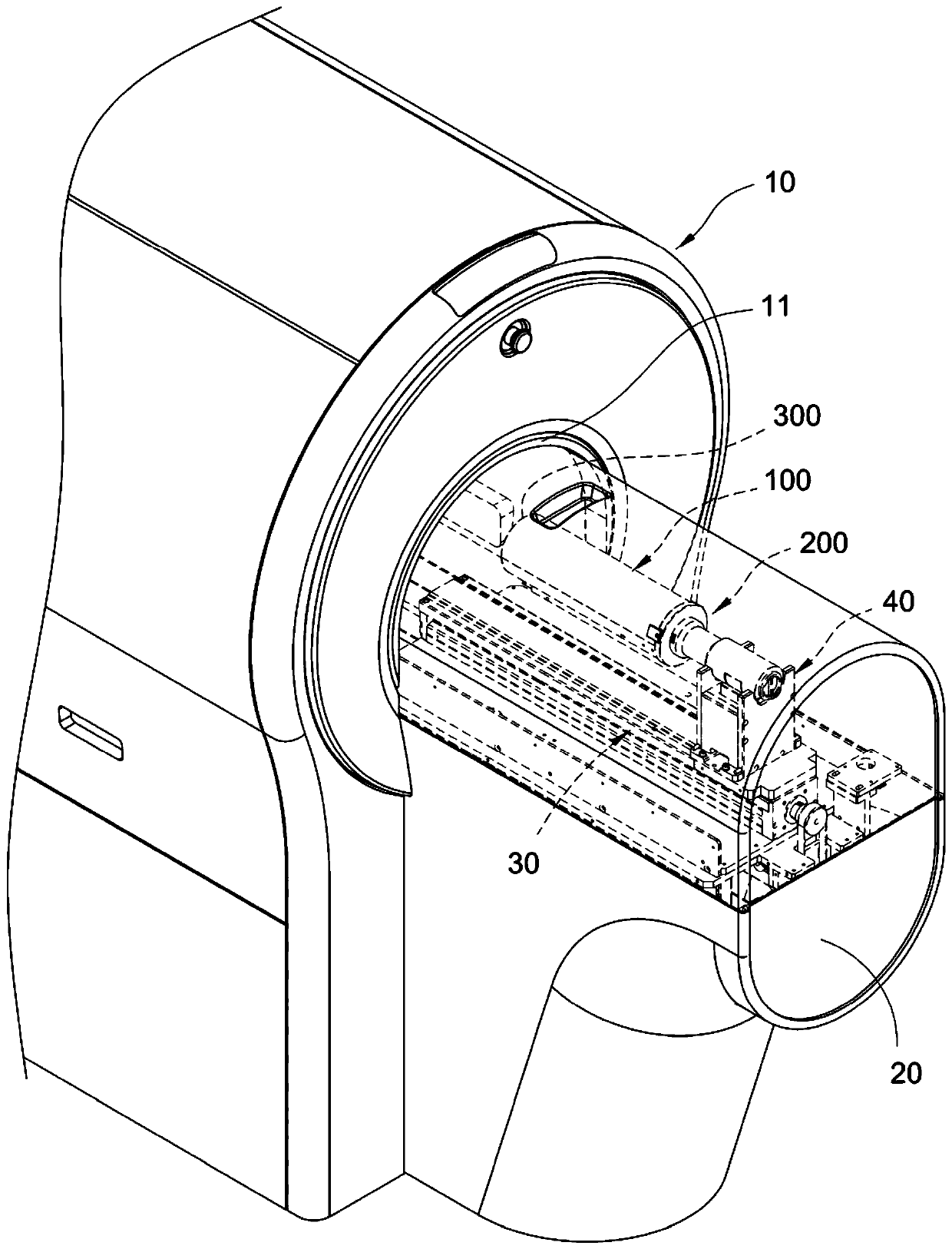

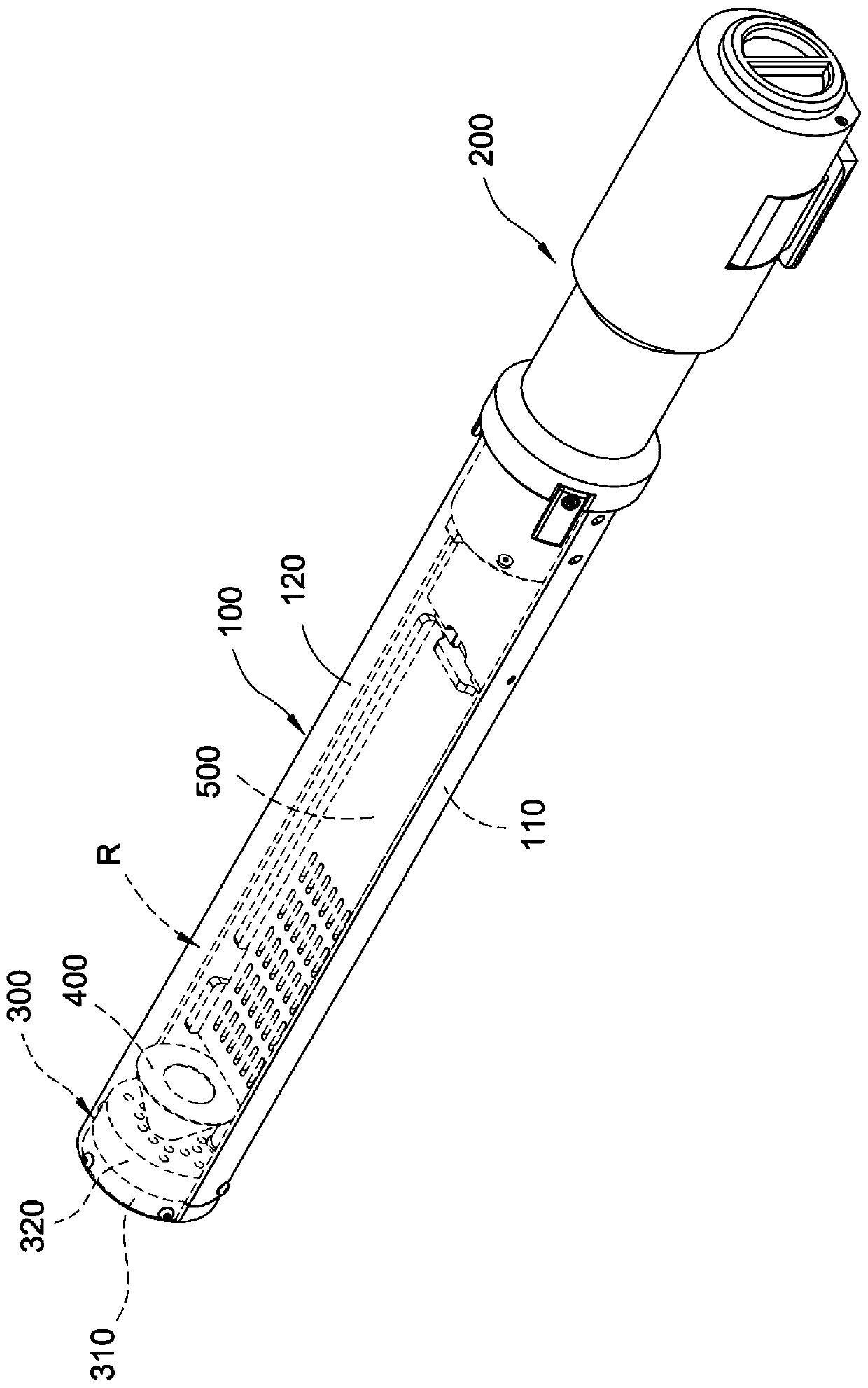

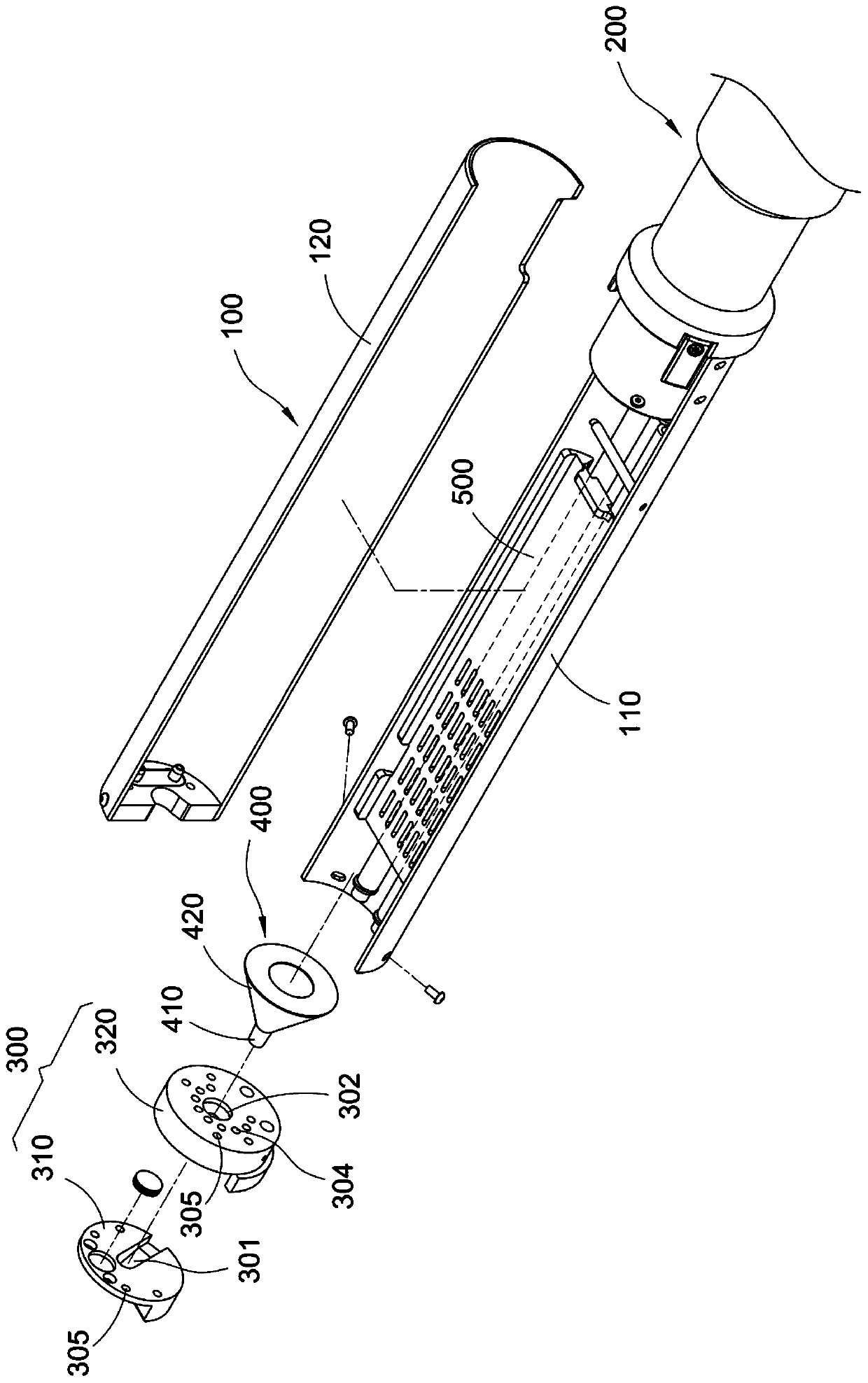

Contrast scanning device and its animal bed

ActiveCN108324404BReduce volumePrevent escapePatient positioning for diagnosticsComputerised tomographsAnimal scienceMedicine

The present invention provides a radiography scanning device and its animal bed. The animal bed includes a tube body, a gas-electric connector and an end cover. The gas-electric connector is arranged at one end of the pipe body. The end cover is arranged on the other end of the pipe body, and the end cover is provided with mutually separated intake flow channels and exhaust flow channels. A plurality of exhaust ports in the body and connected to the exhaust flow channel, the intake flow channel and the exhaust flow channel are respectively connected to the gas-electric connector through the guide tube, and the guide tube is arranged in the tube body.

Owner:DELTA ELECTRONICS INC

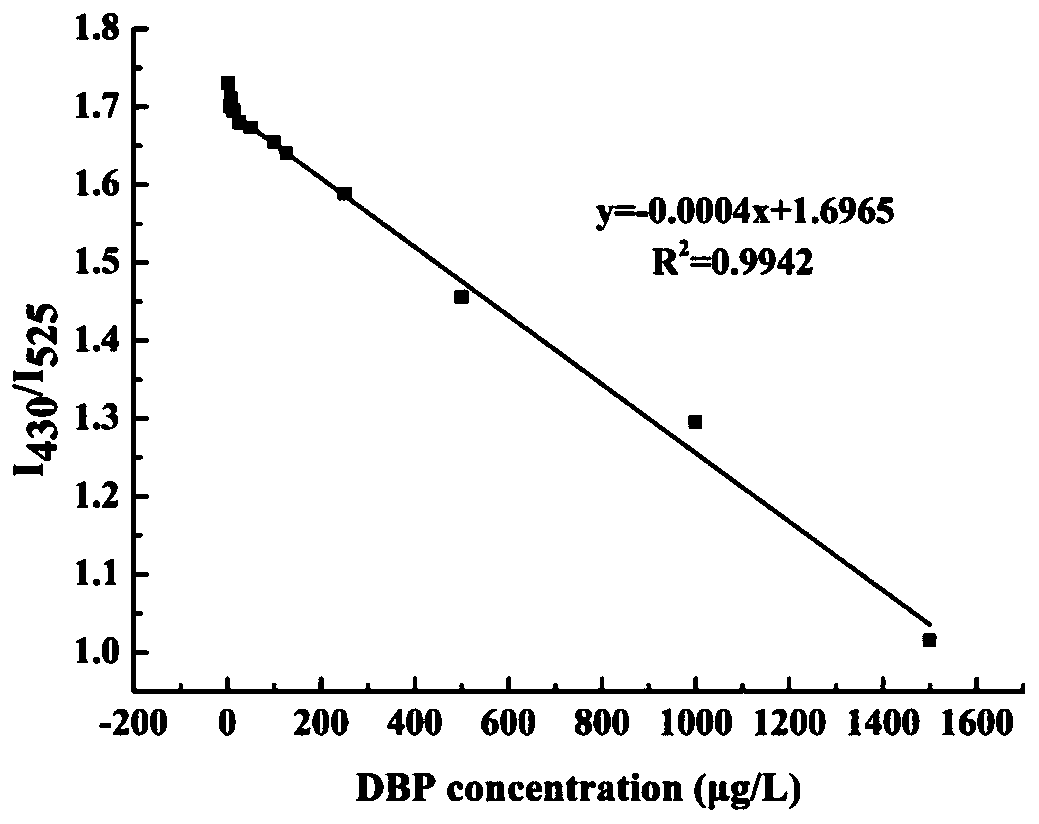

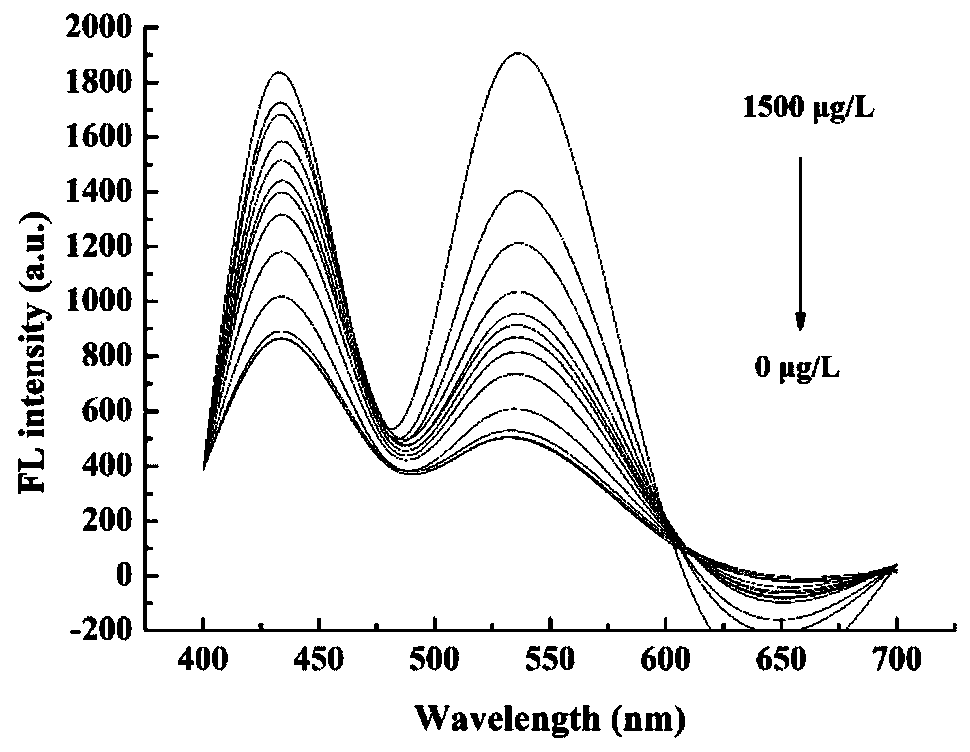

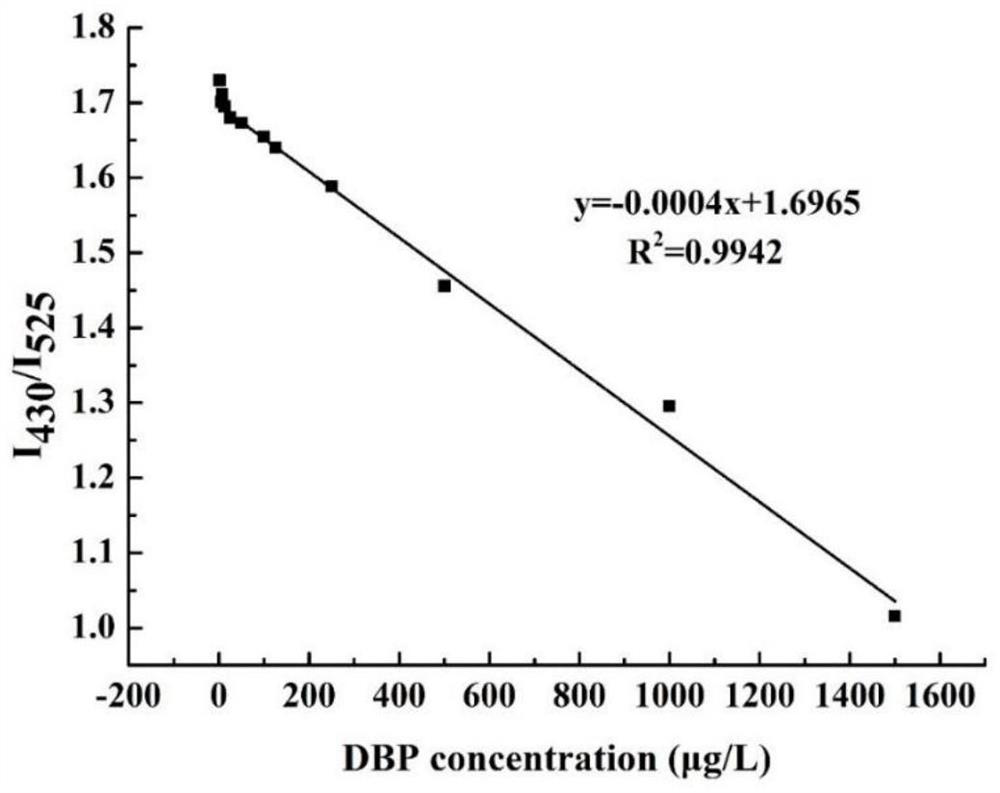

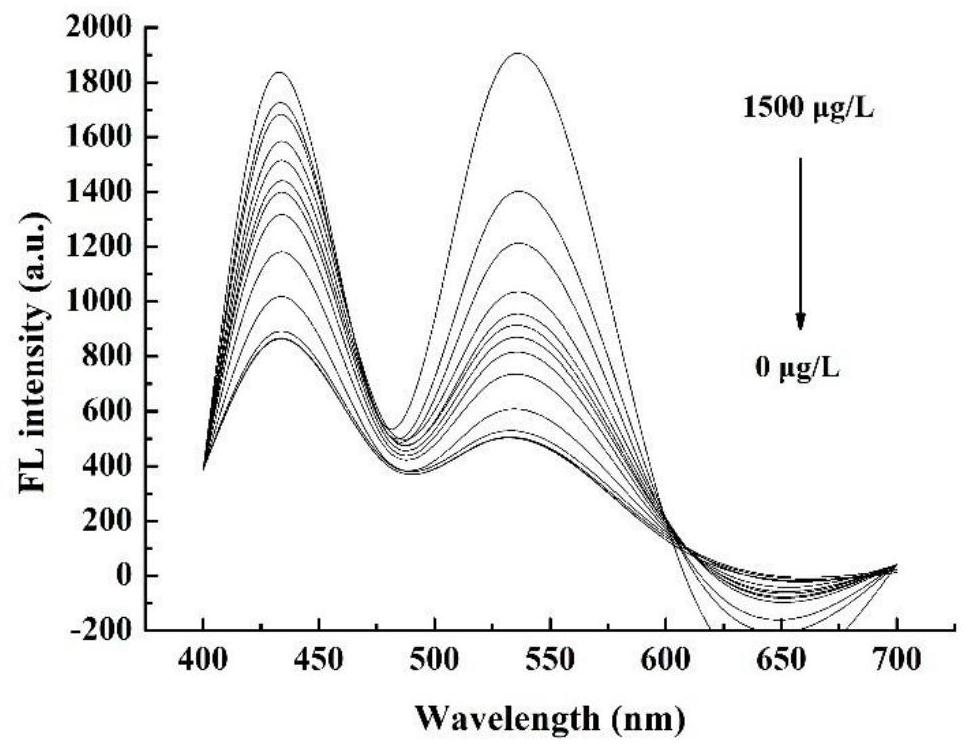

Method for detecting dibutyl phthalate through fluorescence ratio method based on dual-emission carbon quantum dot marked nucleic acid aptamer

ActiveCN110849859AHigh sensitivity and selectivityQuick screeningFluorescence/phosphorescenceDi n butyl phthalateRapid detection

The invention discloses a method for detecting dibutyl phthalate through a fluorescence ratio method based on dual-emission carbon quantum dot marked nucleic acid aptamer. Sensitive detection of dibutyl phthalate is realized by taking dual-emission carbon quantum dots as a marker and combining with an aminated nucleic acid aptamer specifically recognizing dibutyl phthalate; the method is low in detection limit, high in specificity, stable in fluorescent performance and suitable for ultrasensitive quick detection of dibutyl phthalate in food.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

A method for the detection of dibutyl phthalate by fluorescence ratio method based on double-emitting carbon quantum dots-labeled nucleic acid aptamers

ActiveCN110849859BAvoid concentration changesQuick screeningFluorescence/phosphorescenceAptamerFluorescence ratio

The invention discloses a method for detecting dibutyl phthalate through a fluorescence ratio method based on dual-emission carbon quantum dot marked nucleic acid aptamer. Sensitive detection of dibutyl phthalate is realized by taking dual-emission carbon quantum dots as a marker and combining with an aminated nucleic acid aptamer specifically recognizing dibutyl phthalate; the method is low in detection limit, high in specificity, stable in fluorescent performance and suitable for ultrasensitive quick detection of dibutyl phthalate in food.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Magnetic powder flaw detection magnetic suspension containing device

PendingCN112461917AStirring in real timeEasy to operateMaterial magnetic variablesMagnetic powderEngineering

The invention relates to a magnetic powder flaw detection magnetic suspension containing device which comprises a tool box body used for containing magnetic suspension, a liquid pump is arranged in the tool box body, the liquid pump is electrically connected with a corresponding power supply and used for pumping the magnetic suspension in the tool box body, and a plurality of stirring air pipes are arranged in the tool box body and located on the periphery of the liquid pump. One end of the stirring air pipe is immersed and communicated with the magnetic suspension, and the other end of the stirring air pipe is communicated with an air source through a corresponding pipeline and an air valve and used for stirring and stirring the magnetic suspension through compressed air. Manual stirringis replaced, the magnetic suspension is stirred in real time through compressed gas, the concentration change of the magnetic suspension in the using process is avoided, operation is simple and easy,and the stirring strength is adjustable.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

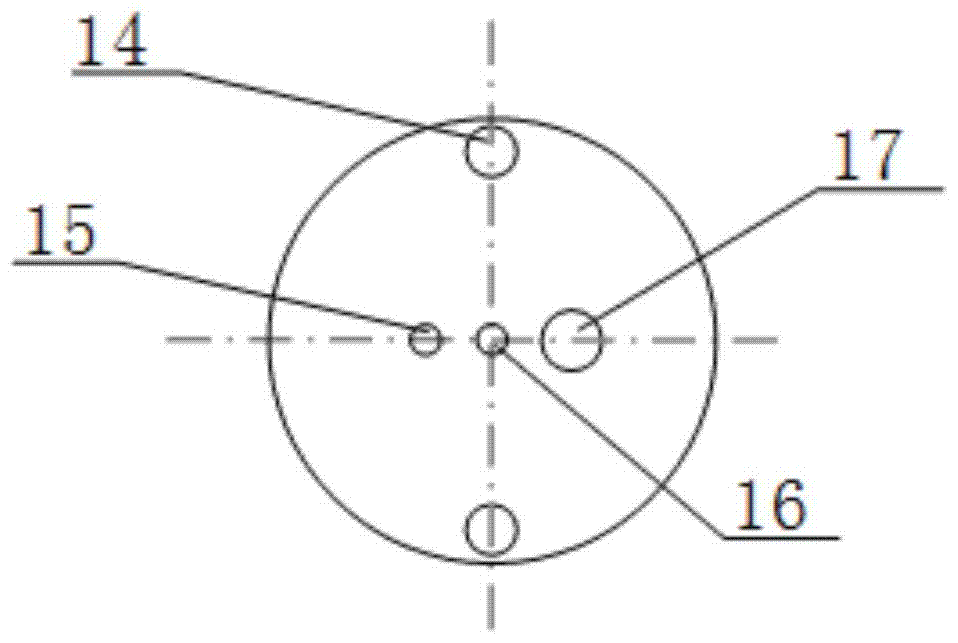

A hybrid integrated ultra-high pressure premixed abrasive jet equipment

ActiveCN109129199BImplement the input functionRealize the fluidization function of circulating mixingAbrasive machine appurtenancesAbrasive blasting machinesUltra high pressureJet flow

The invention discloses series-parallel integrated high-pressure pre-mixing, grinding and jetting equipment. The series-parallel integrated high-pressure pre-mixing, grinding and jetting equipment comprises an ultrahigh-pressure moving pump station and a three-dimensional machine tool platform, and also comprises a tandem mixing valve body and a parallel grinding tank; an input port is formed at the left end of the tandem mixing valve body; a vertical flow dividing pipe is arranged at the upper end of the input port; an low-position input hose is arranged at the lower end of the vertical flowdividing pipe; a high-position input joint is arranged at the upper end of the vertical flow dividing pipe; a transition valve body is arranged at the lower end of the parallel grinding tank; a pure water input pipeline and a mixed liquid output pipeline are arranged on the two sides of the tandem mixing valve body correspondingly; a bias blind channel and a main horizontal channel are formed in the tandem mixing valve body; and a manual cut-off valve rod is arranged on the middle part of the main horizontal channel. The series-parallel integrated high-pressure pre-mixing, grinding and jettingequipment can solve the problem that the pre-mixing, grinding and jetting work has low continuity, can effectively avoid the condition that the equipment cannot work continuously caused by the pump stopping and sand loading process and can improve the operation efficiency of the equipment.

Owner:ANHUI UNIV OF SCI & TECH

An electrospinning nanofiber generating device

ActiveCN106757418BImprove stabilitySuitable for continuous large-scale productionFilament/thread formingFiberViscous liquid

The invention discloses an electrostatic spinning nanofiber generating device. The electrostatic spinning nanofiber generating device comprises a fiber generator, a fiber collecting device and a high-voltage generator, wherein the fiber generator comprises a spinning cavity, silk spray thread slots and a liquid storage tank; a slit is formed in each silk spray thread slot, and is communicated with the inner part of the spinning cavity; the liquid storage tank is communicated with the spinning cavity; each silk spray thread slot adopts a structure with twists and turns; the fiber collecting device is placed right above the silk spray thread slots; the high-voltage generator is provided with a high-voltage terminal and a ground terminal. According to the electrostatic spinning nanofiber generating device disclosed by the invention, nanofibers are produced by using viscous liquid as raw materials and utilizing an electrostatic spinning principle. Compared with the prior art, the core of the electrostatic spinning nanofiber generating device disclosed by the invention is the fiber generator with the bent slits; through the adoption of the fiber generator, the change of the concentration of spinning liquid, which is caused by solvent evaporation, is effectively inhibited, so that the producing stability of the nanofibers is greatly improved; besides, the uniformity and the production efficiency of produced fiber films are improved, so that the electrostatic spinning nanofiber generating device is suitable for the continuous scale production of nanofibers.

Owner:上海云同新材料科技有限公司

Method of Adding Calcium Carbonate Suspension on-line to Decrease Coefficient of Variation of Cigarette Paper Air Permeability

ActiveCN103590279BWide range of regulationAccurate operationInorganic compound additionPulp material addition processesSkin permeabilityMain branch

The invention provides a method for reducing the variation coefficient of the air permeability of cigarette paper through the online addition of a calcium carbonate suspension. The method is characterized in that the method concretely comprises the following steps: processing calcium carbonate and dilution water to prepare a calcium carbonate suspension; allowing the calcium carbonate suspension to go through a calcium carbonate suspension main and a calcium carbonate suspension main branch to enter a headbox dilution water device for mixing with the dilution water to obtain a diluted calcium carbonate suspension, adjusting the opening degree of a calcium carbonate suspension adjusting valve arranged on the calcium carbonate suspension branch according to the online determination result of the variation coefficient of the air permeability of paper, and automatically adjusting the addition amount of the calcium carbonate suspension; and allowing the diluted calcium carbonate suspension and a slurry to enter a turbulence generator together, and carrying out guniting up-papermaking through a lip zone to obtain cigarette paper. The method does not reduce the whiteness, strength, quantification and opacity of the cigarette paper, realizes the uniform distribution of the transverse calcium carbonate concentration of the cigarette paper and reduces the variation coefficient of the air permeability of the cigarette paper.

Owner:CHINA HAISUM ENG

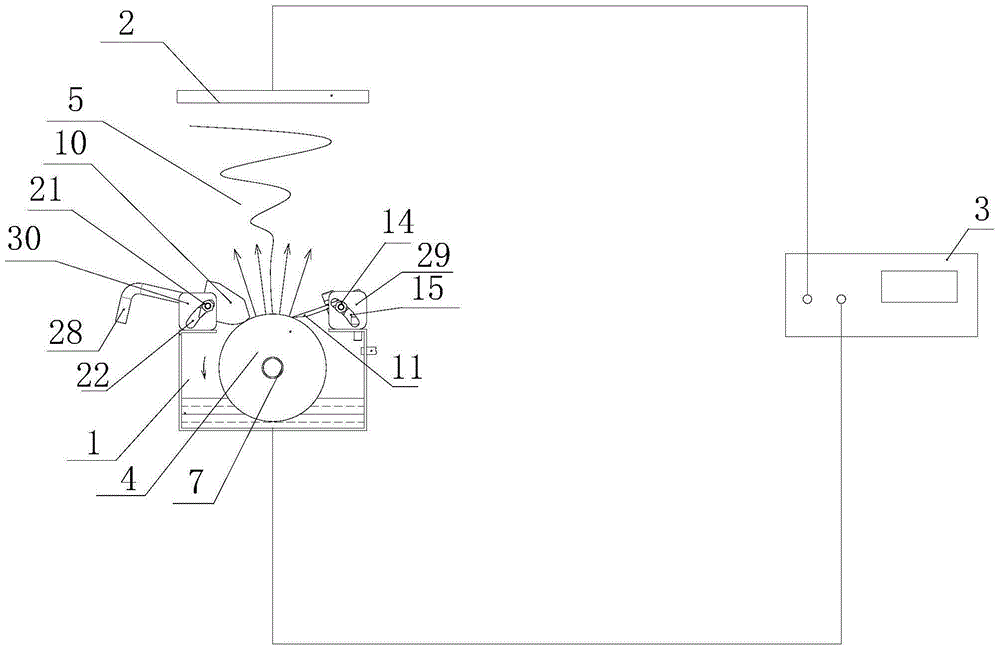

An electrospinning device and equipment with auxiliary airflow

ActiveCN103866403BIncrease productionImprove spinning efficiencyFilament/thread formingElectrospinningLiquid storage tank

The invention discloses an electrostatic spinning device with auxiliary air flow and equipment thereof. A receiving electrode is positioned above a liquid storage tank; a rotary spinning roller is arranged in the liquid storage tank; an electrostatic spinning region is formed between a region where the receiving electrode is orthographically projected to the spinning roller and the receiving electrode; a plurality of through holes are uniformly formed in the spinning roller; an air spraying structure which is kept static is arranged in the spinning roller; an air spraying region of the air spraying structure corresponds to the electrostatic spinning region; the air spraying structure upwards sprays air flow; the air flow is blown into the electrostatic spinning region through the through holes. Under the matching between air flow blowing force and electrostatic force, electrostatic spinning is implemented; compared with the conventional roller type spinning, the electrostatic spinning device disclosed by the invention has the advantages that the yield is increased from 5 times to 10 times, and the spinning efficiency is greatly improved; furthermore, by the adoption of a liquid suction nozzle structure and a scraper structure, a spinning solution in the liquid storage tank is positioned in a sealed environment; therefore concentration change caused by volatilization of a solvent is avoided, and pollution caused by the volatilization of the spinning solution is prevented.

Owner:QINGDAO HSJ ENVIRONMENTAL PROTECTION TECH CO LTD

A photocatalytic in situ monitoring system based on surface-enhanced Raman spectroscopy

ActiveCN109444106BImprove accuracyCompact structurePhysical/chemical process catalystsWater treatment compoundsSurface-enhanced Raman spectroscopyCoupling

The invention discloses a photocatalytic in-situ monitoring system based on surface-enhanced Raman spectroscopy. The monitoring system includes: Raman excitation light source, laser coupling lens, narrow-band filter, total reflection mirror, dichroic mirror, focusing coupling lens, surface-enhanced Raman scattering fiber probe, liquid phase photocatalytic reactor, photocatalytic Light source, Raman collection lens and spectrometer. One end of the common detection part of the surface-enhanced Raman scattering fiber probe extends out of a first fork and a second fork, the extended end of the first fork is coupled to the focusing coupling lens, and the end of the second fork The extension end is coupled with the photocatalytic light source, and the other end of the public detection part is set in the liquid phase photocatalytic reactor. The Raman excitation light and the photocatalytic light are co-transmitted, which greatly reduces the difficulty of the experiment and can effectively avoid the The monitoring error caused by incomplete coincidence can effectively improve the accuracy of Raman dynamic monitoring. The monitoring system has a compact structure and good portability.

Owner:DONGGUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com