Electromotor driven metering pump

A technology for metering pumps and electric motors, applied in machine/engine, pump, pump control, etc., can solve problems such as serious errors, insufficient hydraulic performance, and inability to adjust precision, to improve resistance, increase flexibility, and reduce the impact of dust Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

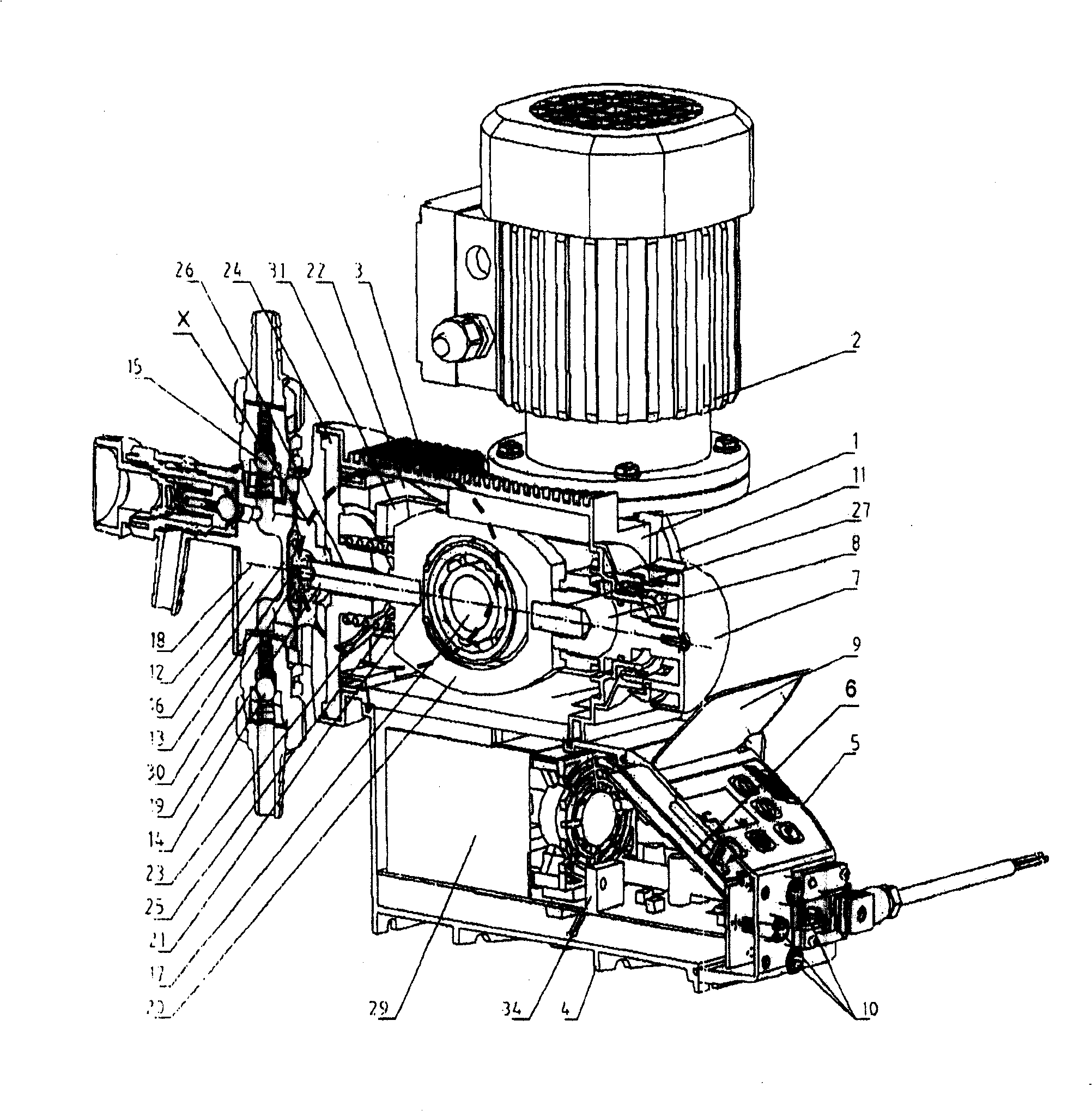

[0057] figure 1 The structure of a motor-driven metering pump is shown (partial cutaway). As generally known, a motor-driven metering pump basically consists of three groups of elements, namely the drive motor 2 with transmission, the cam driver in the cam housing 1, and the electronic control unit housed therein with the on-board electronic module And the electronic housing 28 of the block. Below the electronic housing 28 there is a support plate 4 with a fixing hole; the cam housing 1 positioned on and fixed to the electronic housing carries the drive motor 2 with a transmission, which is attached, for example, with screws. The drive motor is fixed to the cam housing.

[0058] The housing consisting of the cam housing 1 and the electronics housing 28 has the elements of the cam drive on its upper part, ie on the cam housing 1 . The individual elements of the cam drive are accommodated in a cam carrier 22 which ensures that the individual elements are accurately positioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com