Spinning solvent circulating equipment and circulating method for producing polypropylene threads by dry method

A technology of spinning solvent and circulation equipment, which is applied in the spinning solvent circulation equipment and circulation field of polypropylene yarn produced by dry method, which can solve the problems that affect the solidification rate of polypropylene fiber filaments, polypropylene filaments are easy to break, and solvents cannot be vaporized, etc., to achieve Avoid the change of solvent concentration, ensure the quality of polypropylene fiber, and facilitate the effect of solvent volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

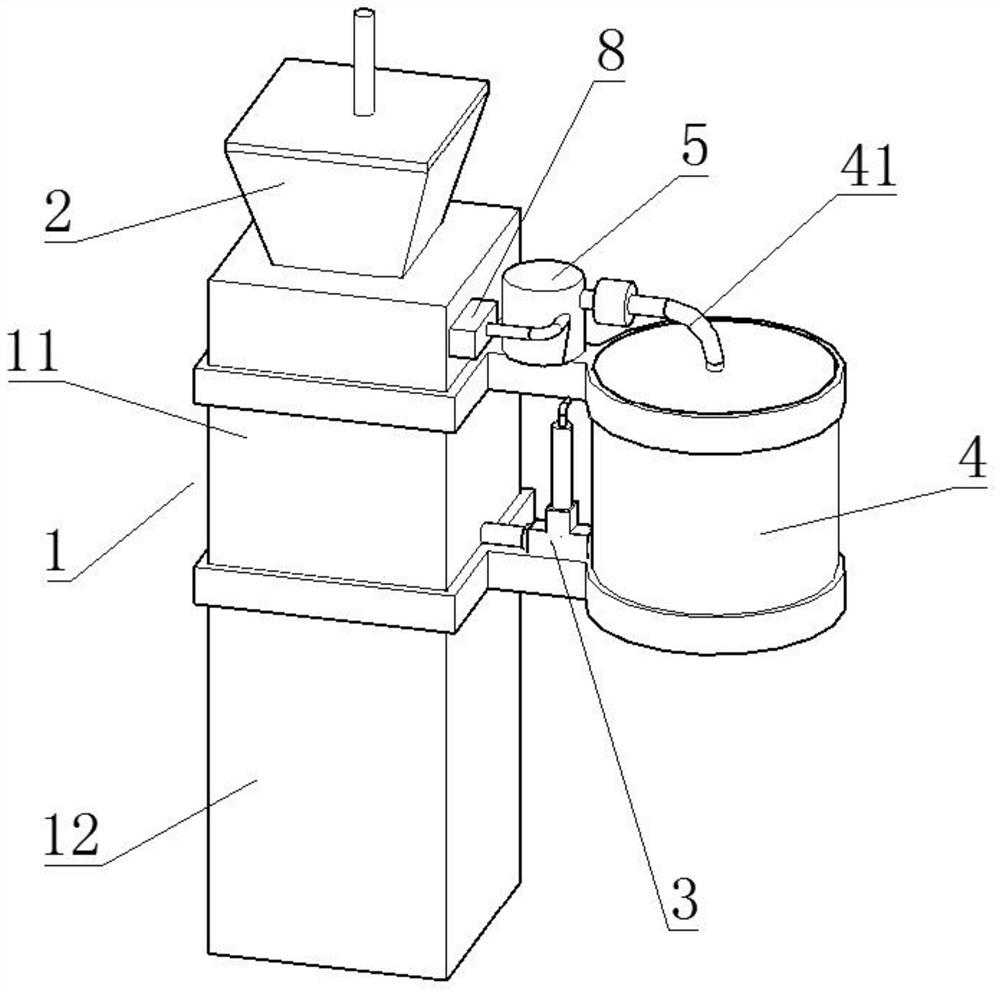

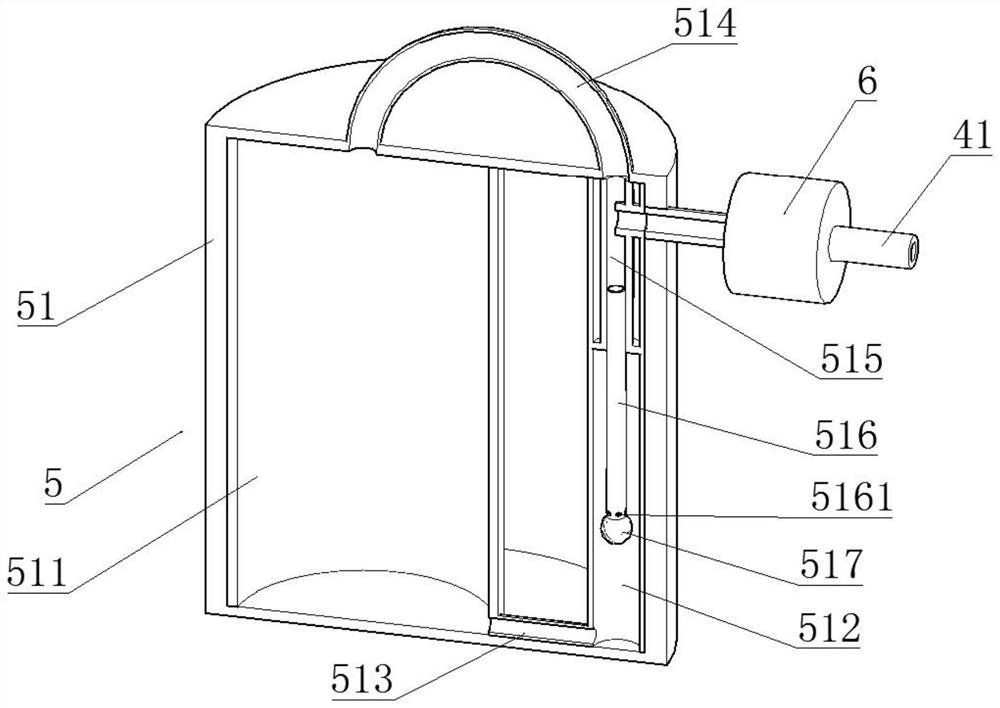

[0032] Such as Figure 1-2 As shown, a spinning solvent circulation equipment for dry production of polypropylene yarn, the spinning tunnel 1 is divided into a curing tunnel 11 and a silk discharging tunnel 12 by a sealed silk outlet mechanism 7, and the bottom of the curing tunnel 11 passes through the exhaust mechanism 3 and the air storage cylinder In communication, the air storage cylinder is communicated with the solvent supply cylinder 5 through the hot air supply pipe 41, and a communicator is arranged in the solvent supply cylinder 5, that is, the large container 511 is set in the cylinder wall 51 and the bottom end of the small container 512 is communicated through a thin tube 513, and The top is communicated with the top connecting pipe 514, and the solvent is added into the large container 511, so that the solvent liquid level in the small container 512 is flush with the solvent liquid level in the large container 511, and a heating wire is arranged in the hot air su...

Embodiment 2

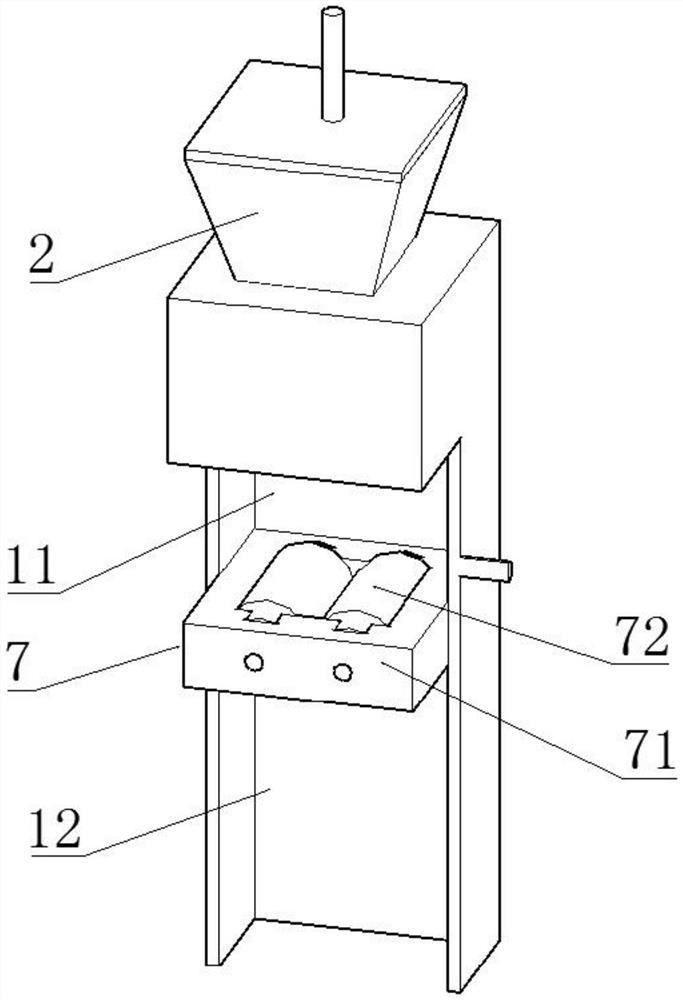

[0035] Such as Figure 1-4 As shown, a spinning solvent circulation equipment for dry production of polypropylene yarn, wherein the sealing sleeve 71 is sealed and fixedly connected to the junction of the curing tunnel 11 and the silk outlet tunnel 12, and the sealing sleeve 71 is internally rotated and connected with two parallel fittings. The wire outlet wheel 72, the wire outlet wheel 72 includes a wheel shaft 721 that is rotatably connected to the sealing sleeve 71, the wheel shaft 721 is fixedly connected to the support tube 722, and two seal rings 723 are fixedly connected to the support tube 722, and the two seal rings 723 pass through the side The sealing ring 724 is connected so that there is a water flow channel between the sealing ring 724 and the supporting cylinder 722. The sealing ring 723 is provided with a through hole that runs through its two ends, and the through hole communicates with the water transfer ring 725 that is sealed and rotated on the supporting c...

Embodiment 3

[0038] Such as Figure 1-6 As shown, a spinning solvent circulation equipment for dry production of polypropylene yarn, the solidification shaft 11 and the T-shaped cylinder are connected through the pressure pipe. The cylinder 9 is connected, and the piston is slidably connected in the cylinder 9. A fixed plate 33 is arranged at the joint between the straight cylinder 31 and the support cylinder 32. When the plate 331 is in a horizontal state, the left end of the straight tube 31 is relatively sealed with the support tube 32. When the second rotating plate 332 is in a horizontal state, the right side of the support tube 32 is in a relatively sealed state with the support tube 32. The first rotating plate 331, the second The rotating plates 332 are respectively rotatably connected to the fixed plate 33 through hinges 333, and the upper part of the first rotating plate 331 is connected to the hinge 333, and the bottom of the second rotating plate 332 is connected to another hin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com