Automatic analyzing device

An automatic analysis device and action technology, applied to the analysis of materials, instruments, etc., can solve the problems of reduced processing capacity, unnegligible decrease in sample concentration, increase in cleaning times of dispensing nozzles, etc., and achieve the effect of preventing concentration changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

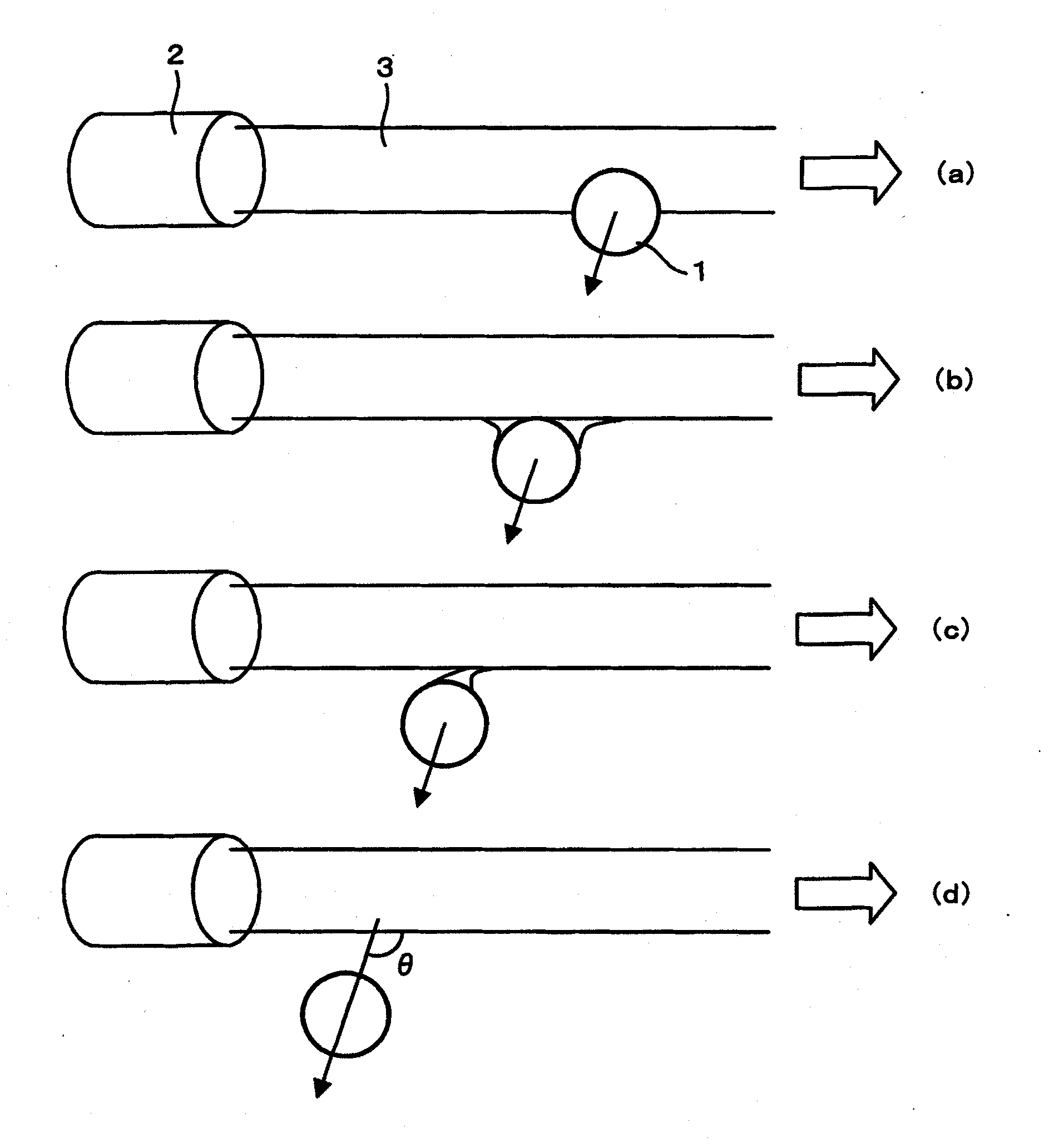

[0036] figure 1 A schematic diagram showing the cleaning operation of the dispensing nozzle using the jet effect. A dispensing nozzle with an outer diameter of 0.25 mm sucks the sample after descending into the sample container to detect the liquid level of the sample. Then, the dispensing nozzle 1 moves to the front of the cleaning nozzle 2 of the cleaning tank. Next, the cleaning liquid flow 3 is discharged from the cleaning nozzle 2 with an inner diameter of 2.5 mm at a flow rate of 1.5 m / s in a direction of 60° downward from the horizontal, and the excess detection fluid attached to the outer wall of the dispensing nozzle 1 is cleaned in the cleaning liquid flow. body. The cleaning liquid flow is preferably a smooth flow with little pulsation and always flowing through a fixed position.

[0037] At this time, the dispensing nozzle 1 moves across the cleaning liquid flow 3 and moves on a plane where the position leaving the cleaning liquid flow is closer to the opening o...

Embodiment 2

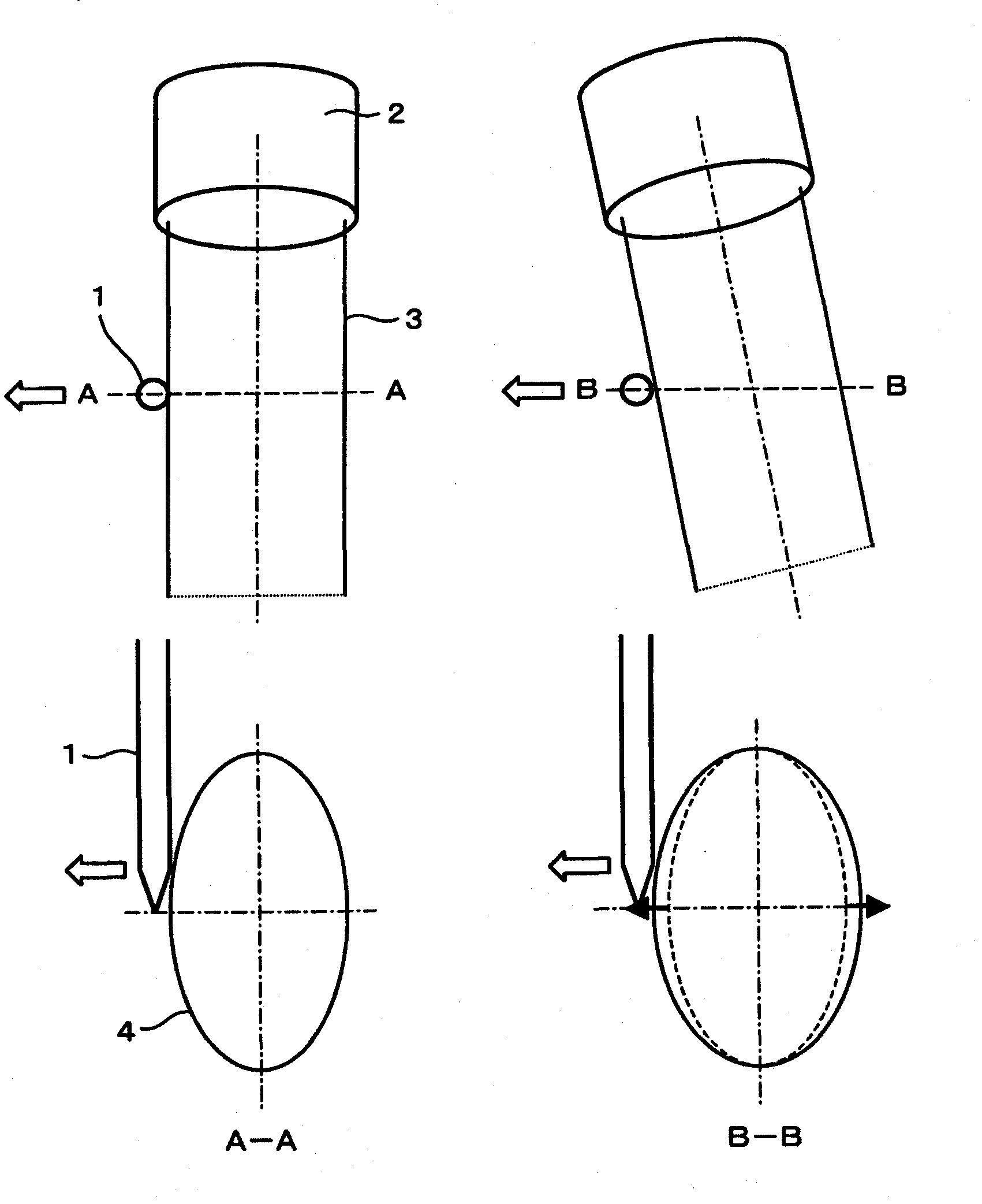

[0041] image 3 A water flow cross section is shown when the dispensing nozzle 1 passes through the cleaning liquid flow 3 discharged from the cleaning nozzle 2 having a discharge port diameter of 2.5 mm in a direction 60° downward from the horizontal. In the case of inter-item cleaning for cleaning the front end of the dispensing nozzle, if the dispensing nozzle 1 only crosses the upper half of the section of the cleaning liquid flow 3 and moves horizontally, the front end of the dispensing nozzle finally moves from the upper half of the elliptical section Disengage (A-A). Since the tip of the dispensing nozzle is sharp, the surface area is small and the force to hold the water droplet is small. Therefore, when the tip of the dispensing nozzle is finally detached from the cleaning liquid flow 3, the amount of adhesion of the cleaning liquid flow 3 to the outer wall of the dispensing nozzle can be reduced.

[0042] In addition, the traveling direction of the dispensing nozzl...

Embodiment 3

[0048] Image 6 Shows a cleaning mechanism that maximizes the spray effect by moving the cleaning liquid flow.

[0049] The cleaning nozzle 2 is connected with an automatic flow switching valve 4 on the connected cleaning liquid pipeline. The cleaning nozzle 2 has a discharge opening diameter of 2.5 mm, and discharges a cleaning liquid flow 3 at 60° downward from the horizontal at a flow velocity of 1.5 m / s. The dispensing nozzle 1 moves toward the cleaning tank and stops at a position about 2.8 mm from the inner upper end of the discharge port of the cleaning nozzle 2 . In the inter-specimen cleaning before starting the analysis, it is necessary to clean the dispensing nozzle 1 as wide as possible, so the automatic flow switching valve 4 is adjusted so that the cleaning liquid flow 3 is discharged as shown by the dotted line, so that the dispensing nozzle is approximately The range of 5mm is in contact with the cleaning solution.

[0050] On the other hand, after aspiratin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com