Electrostatic spinning nanofiber generating device

A nanofiber and generating device technology, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve the problems of uneven electric field distribution, uneven nanofiber products, discharge at both ends, etc., to improve uniformity and production efficiency, suppressing changes in spinning dope concentration, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

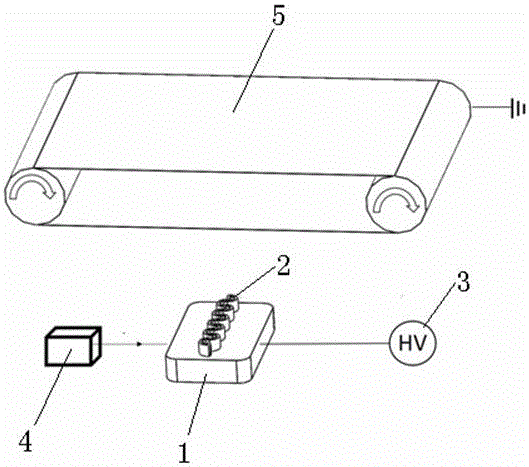

[0058] Such as figure 1 As shown, the fiber collecting device 5 included in the present invention is driven to rotate by a driving device, for example, a motor drives the fiber collecting device 5 to rotate at a speed of 40 rpm. The fiber collection device 5 is connected to the ground electrode of the high voltage generator 3 for receiving the generated nanofibers. The distance between the curved slit of the spinneret 2 and the fiber collection device 5 is 200 mm.

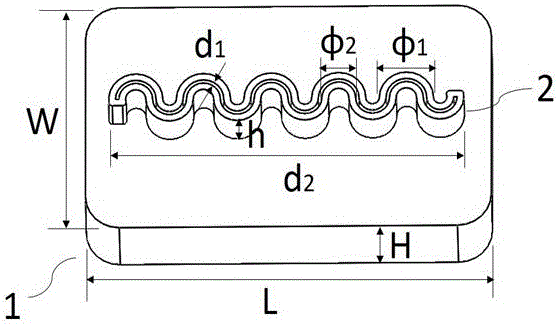

[0059] figure 2 shown as figure 1 A more detailed view of the middle spinneret. The specific shape of the curved slit is arc-shaped, the width d1 of the slit is 2 mm, the diameter ϕ2 of the inner circle where each spinneret slot 2 is located is 8 mm, the diameter ϕ1 of the outer circle is 12 mm, and the diameter ϕ1 of the spinneret slot 2 is 12 mm. The effective length d2 of the slit along the X axis is 100 mm, and the distance h between the top of the slit and the spinning cavity 1 is 10 mm. The length L of ...

Embodiment 2

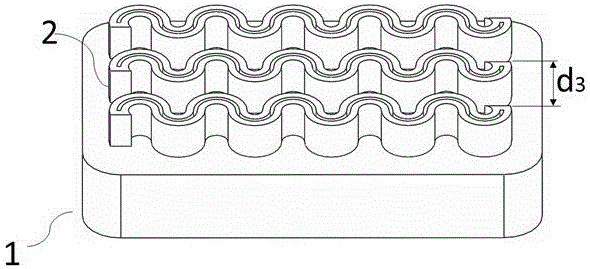

[0065] The spinneret line slot 2 reference that this embodiment uses image 3, the spinneret slot 2 shown in the figure is specifically a parallel arrangement of three curved slits, and the distance d3 between the slits of two adjacent spinneret slots 2 is 10 mm. The law of this parallel arrangement is that the crests of adjacent curved slits are opposite to the crests, and the troughs are opposite to the troughs. The parameters of each curved slit are the same as those in Example 1, and the parameters of the spinning cavity 1 are also the same as those in Example 1. The material of the spinning cavity 1 is polytetrafluoroethylene plastic, and the material of the curved slit is aluminum.

[0066] For experimental purposes, the nanofibers were formed using a polymer solution produced by Sigma-Aldrich with a viscosity of 1800 mPa s containing PVDF (polyvinylidene fluoride, average molecular weight 10,000). During spinning, the applied voltage was 70 kV. The feed rate of the P...

Embodiment 3

[0070] The spinneret line slot 2 reference that this embodiment uses Figure 11 , the spinneret groove 2 shown in the figure is specifically a broken line structure, and the half width d4 of the broken line slit is 10 mm, the inner width d5 of a single repeating unit of the broken line slit is 6 mm, and the outer width d6 is 10 mm. The parameters of the spinning chamber 1 are the same as those in Example 1. The materials of the spinning cavity 1 and the curved slit are polypropylene plastics.

[0071] For experimental purposes, an aqueous polymer solution produced by Sigma-Aldrich with a viscosity of 1200 mPa s containing PVA (polyvinyl alcohol with an average molecular weight of 146,000 to 186,000 and 96% hydrolyzed) was used to form the nanofibers. The device shown in the figure can also use other polymer solutions to produce nanofibers. When spinning, the high voltage generator 3 charges the polymer solution so that a potential difference of 70 kV is generated between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com