Combustor

A technology of burners and gas turbines, which is applied in the direction of burners, combustion chambers, gas fuel burners, etc., and can solve the problems of increasing the number of injection holes, interfering with air flow, and difficulty in supplying air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Some embodiments of the present invention will be described below with reference to the accompanying drawings. In each figure, the same components are denoted by the same reference numerals. The scale of these figures has been changed for ease of understanding.

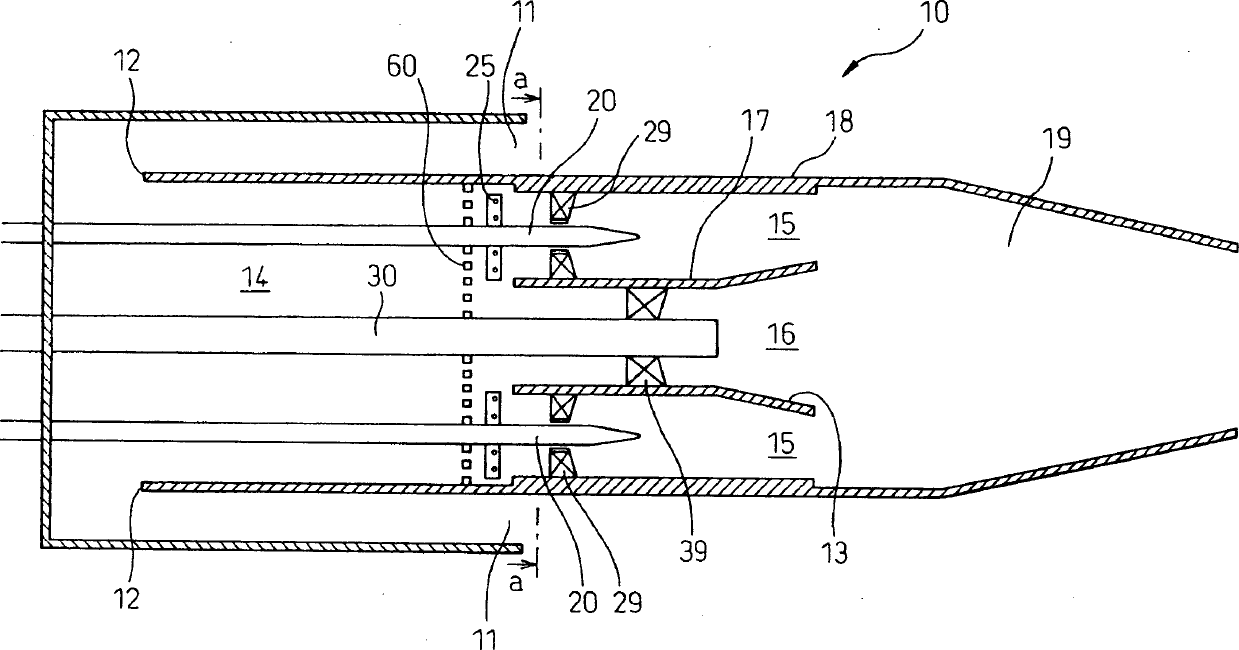

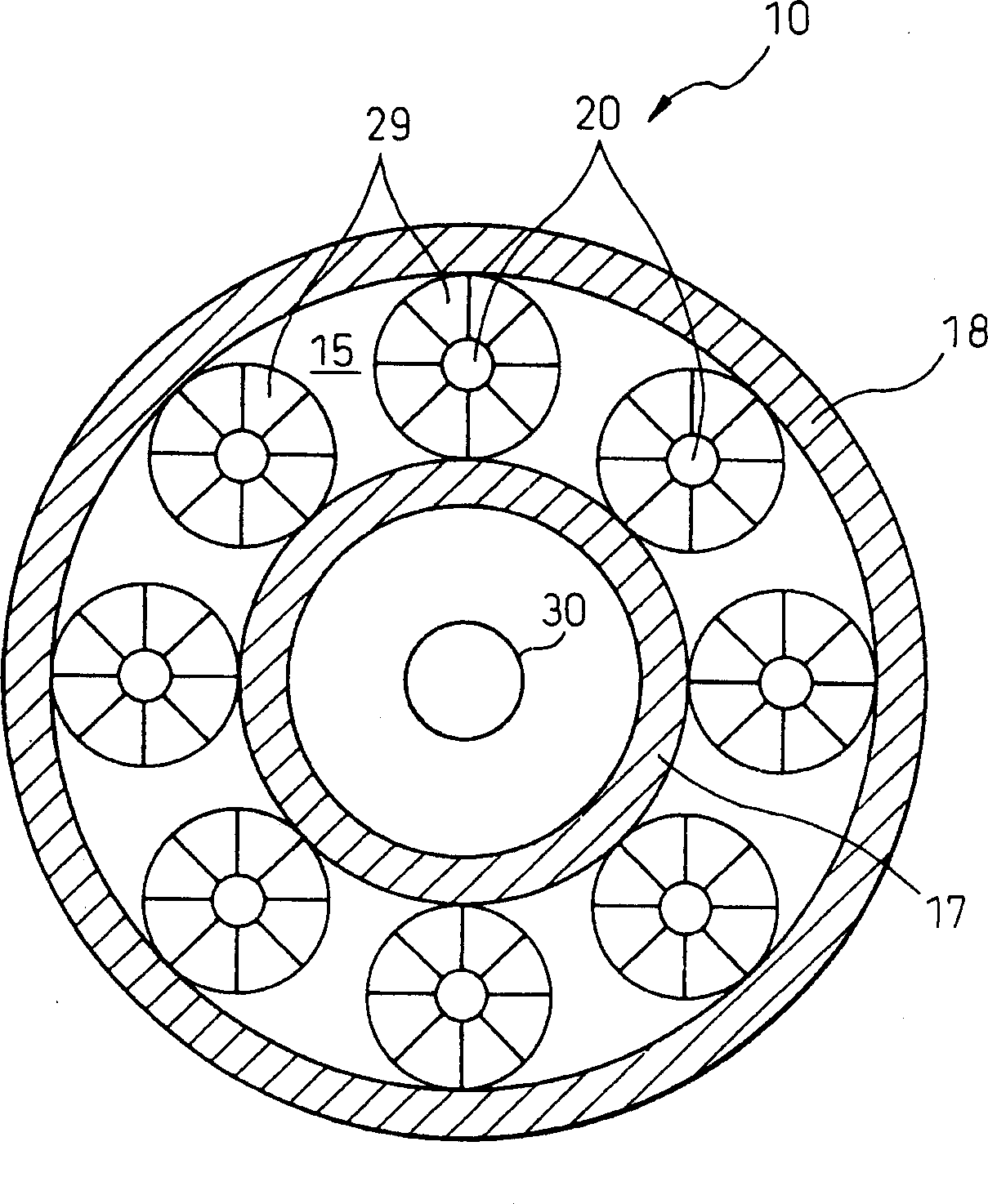

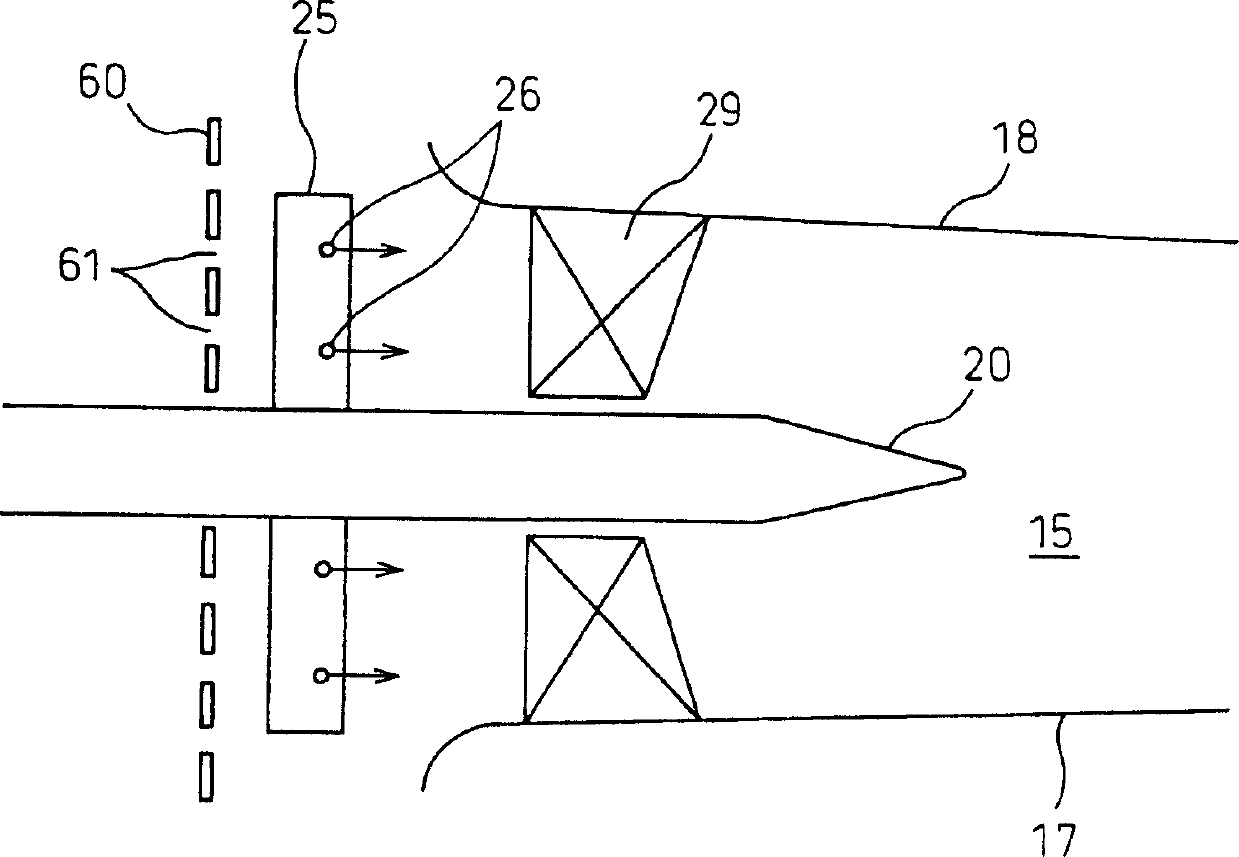

[0028] Fig. 1 shows a partial longitudinal sectional view of a burner according to a first embodiment of the present invention. Fig. 2 is a sectional view taken along the line a-a in Fig. 1 . Similar to the above-described embodiments, a pilot nozzle 30 is disposed on the central axis of the inner tube 18 of a combustor 10 . As can be seen from FIG. 2 , a number of fuel nozzles are spaced equidistantly in the circumferential direction around the priming nozzle 30 . A swirl vane or a swirler 29 is arranged around the rod-shaped body of the fuel nozzle 20 . A plurality of hollow cylinders 25 are provided on the fuel nozzle 20 . The hollow cylinder 25 extends radially outward from the sidewall of the fuel noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com