Tailing deposition test system

A test system and tailings technology, applied in the field of engineering experiments, can solve the problems of large sidewall interference effect, unclear boundary conditions of model test, and difficulty in meeting similar conditions of scouring and silting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

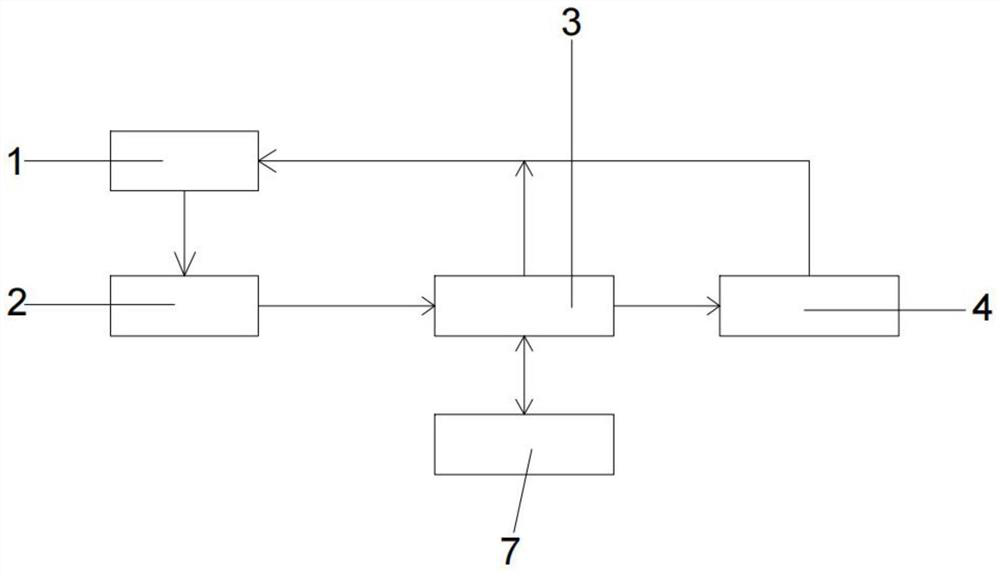

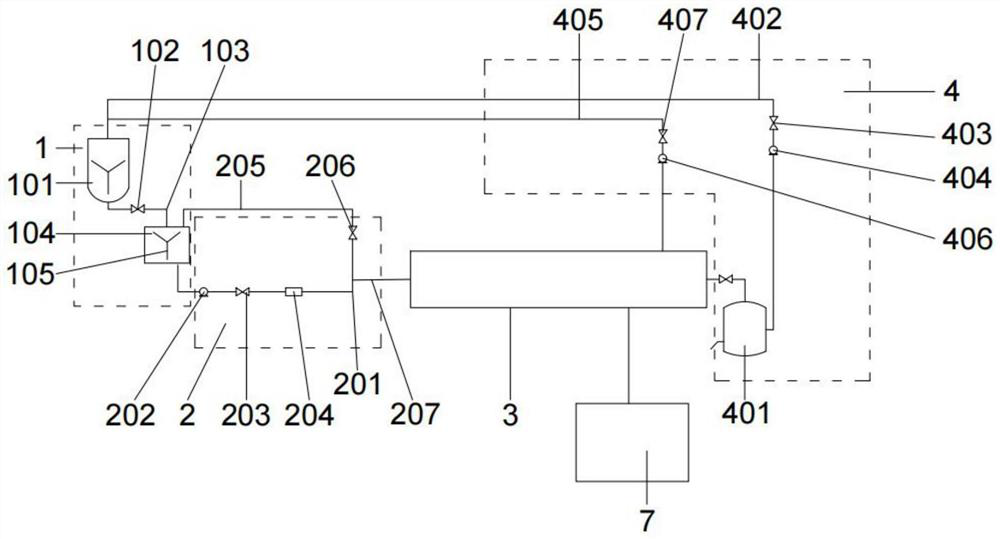

[0048] The present invention discloses a tail deposition test system, including a stirring system 1, a pumping discharge system 2, a deposition model groove 3, a latch reflux cycle system 4, and a monitoring system 7, and a stirring system 1, a pumping discharge system 2, The deposition model slot 3 is sequentially connected by a loose line, and the deposition model groove 3 and the tail flow reflow circulation system 4 are connected to the agitation system 1 by the test line, and the storage pool 104 of the stirring system 1 is provided with a stirrer 105. The deposition model groove 3 is provided with a monitoring system 7.

[0049] The beneficial effect of the above technical solution is:

[0050] By setting the stirring system 1, the pumping discharge system 2, the deposition model groove 3 and the latch circulating cycle system 4, the mineral slurry concentration, the mineral flow, the mineral tube can be used, and the base drainage conditions, etc. The simulation is carried ...

Embodiment 2

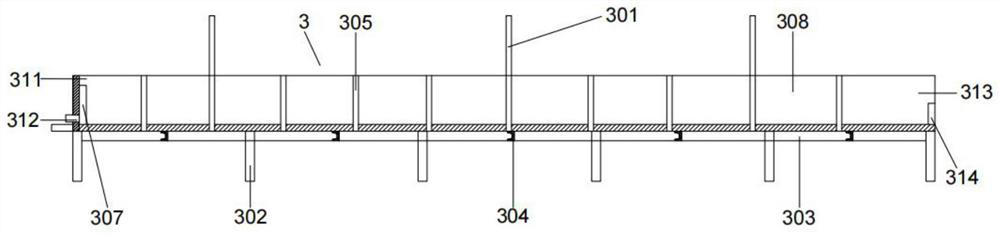

[0054] On the basis of Example 1, the deposition model groove 3 employs a model groove greater than 10 m × 1 m × 0.5 m size, the pumping discharge system 2 discharges the slurry of the stirring system 1 to the deposition model slot 3, in the pump After the emission system 2 is released, the deposition formed by the deposited accumulation of the deposition of the model groove 3 for a period of time, the sample, the sample, the sample, the sample, and the sample, respectively, according to the sample, consolidate and shear test.

[0055]The beneficial effect of the above technical solution is:

[0056] The deposition model groove 3 employs a 20m × 2m × 1 m size model slot, a model slot greater than 10m × 1 m × 0.5 m size, and the length direction can satisfy the sorting deposition of the particles and the formation of dry beach, and the width direction is sufficient. Side-to-sports space, solved the current researchers used in the model slot size used in the tailings deposition, in ...

Embodiment 3

[0061] Based on the first embodiment, the test line includes a loop tube 123, a mineral tube 2 201, a mineral tube three 205, and a discharge tube 4 207, and the agitation system 1 further comprises a stirring cylinder 101, said The discharge tube 103 is connected between the discharge opening and the feed port of the stirring tube 101, and a flow valve one 102 is provided on the release tube 103, and the mixing tube 101 is provided with stirring. The device 105 and a concentration meter.

[0062] The beneficial effect of the above technical solution is:

[0063] The stirring system 1 includes a storage pool 104 of 2 m3 of the stirring cylinder 101, 1 m3, and the full tail mineral and water are poured into the agitating cylinder 101 before the test, and the mixing tube 101 is formulated into a concentration of all-tail slurry. The concentration gauge provided in the agitating cylinder 101 is used to monitor the concentration of the full mine slurry formulated by the agitation tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com