Coloring nozzle

A technology for nozzles and coloring materials, applied in spray devices, cleaning methods using liquids, coatings, etc., can solve problems such as lowering the yield of wire materials, and achieve the effects of preventing vaporization, preventing concentration changes, and preventing leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

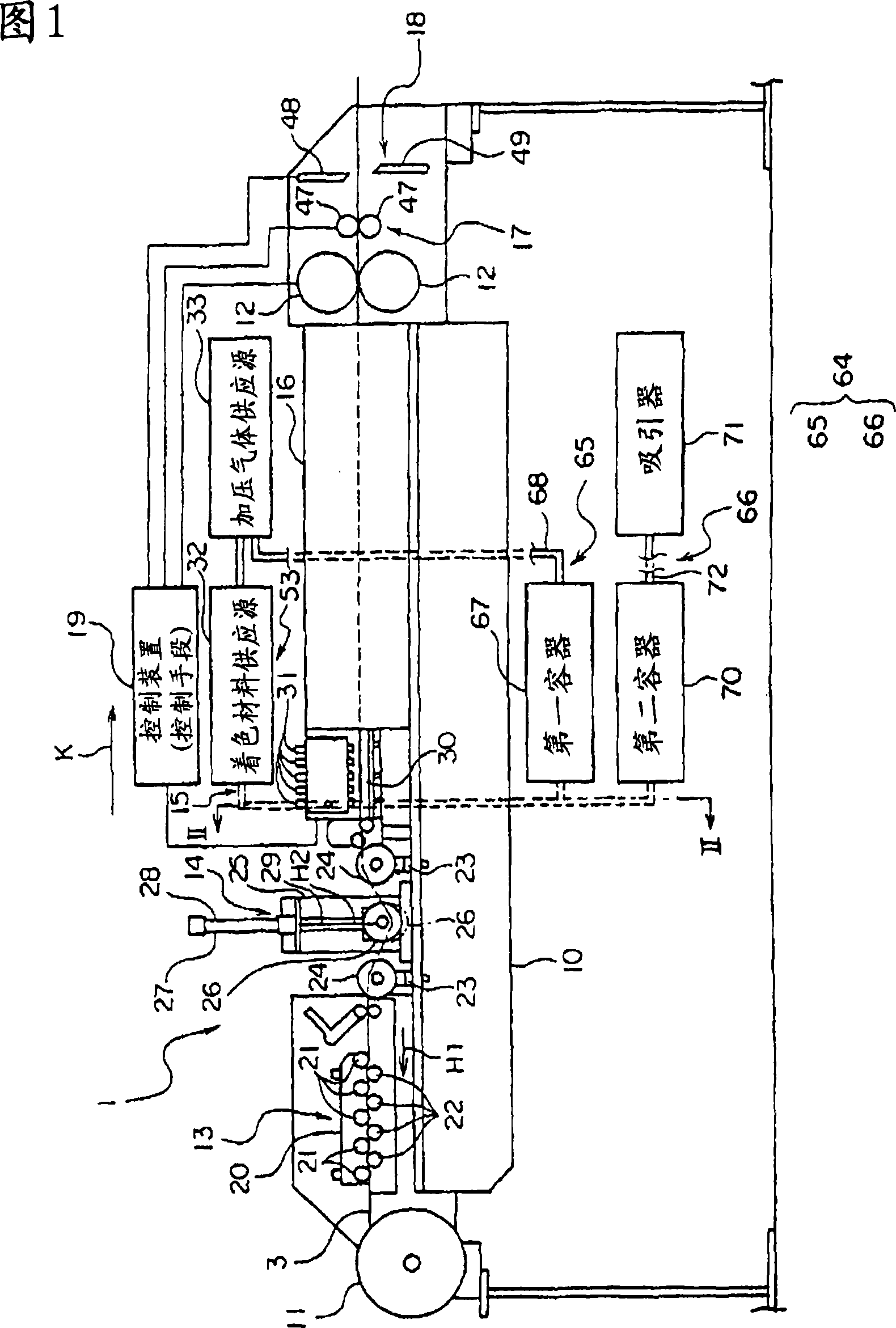

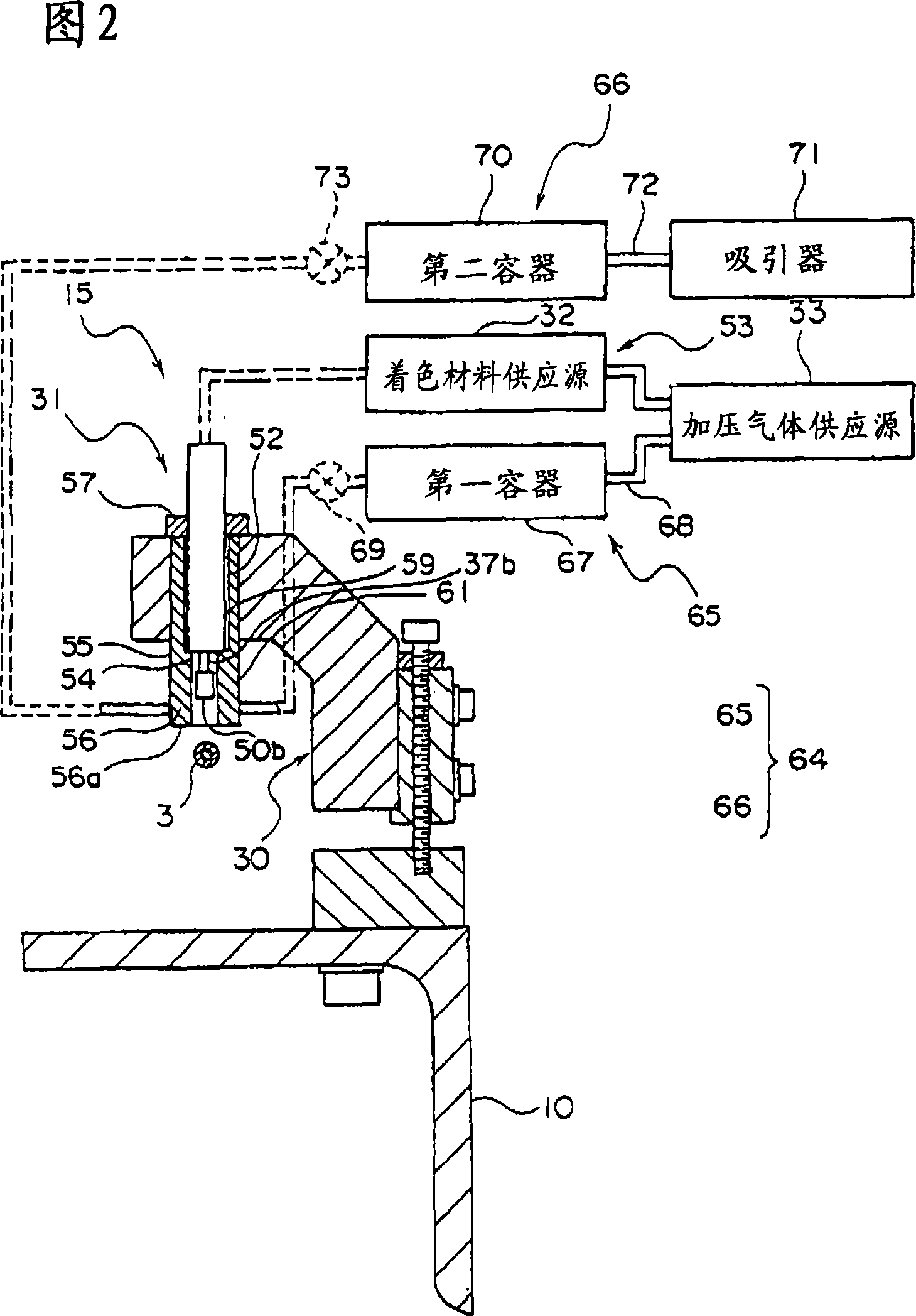

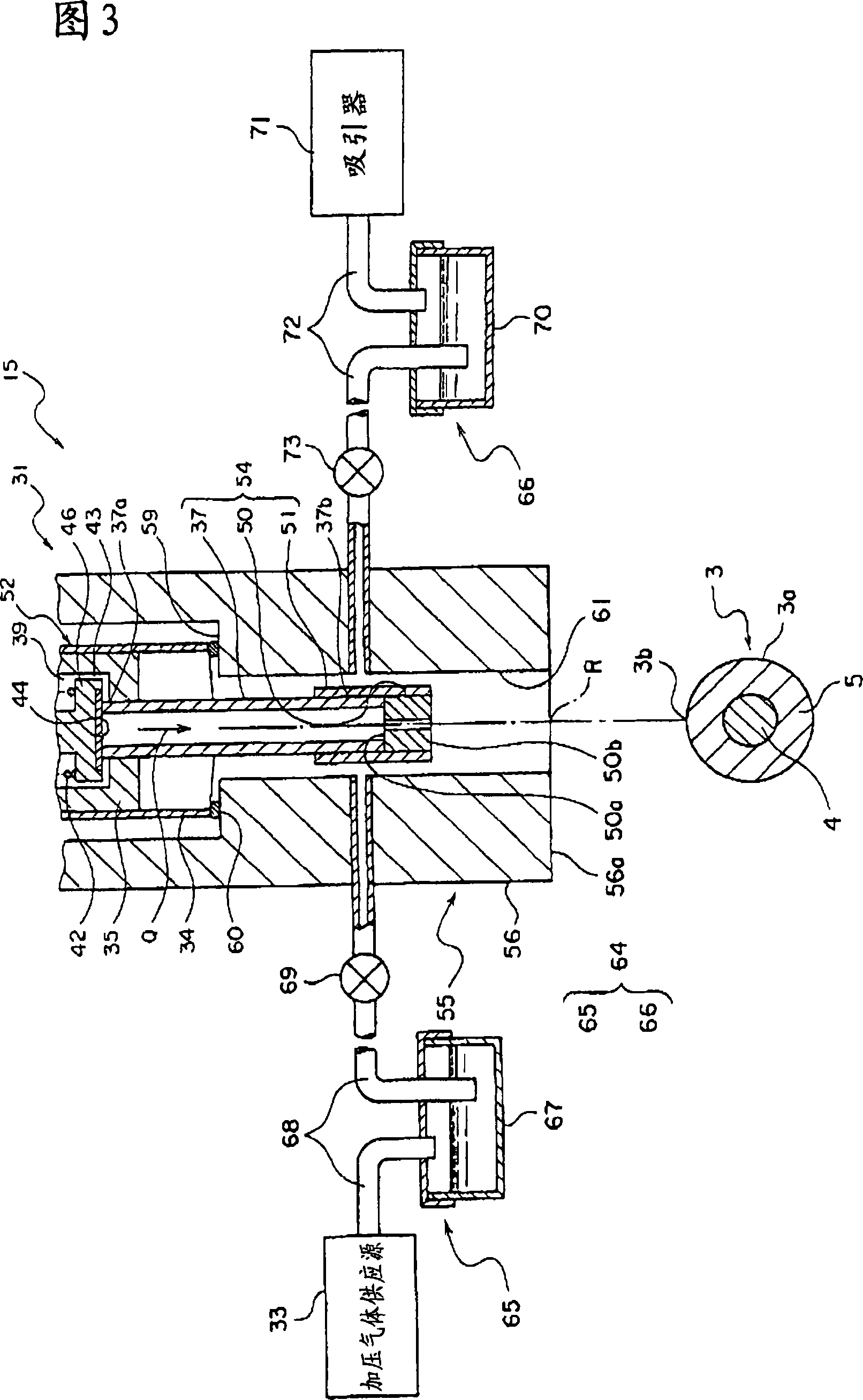

[0064] Next, a coloring nozzle 31 according to an embodiment of the present invention will be described based on FIGS. 1 to 9 . The coloring nozzle 31 shown in FIG. 3 and FIG. device 1). The coloring device 1 is a device that cuts an electric wire 3 as an article into a predetermined length and forms a mark 6 on a part of the outer surface 3 a of the electric wire 3 as an article. That is, the coloring device 1 colors the outer surface 3a of the electric wire 3 as an article, that is, forms a mark (Marking).

[0065] The electric wire 3 as an article constitutes a harness that is arranged on an automobile or the like as a mobile body. As shown in FIG. 5( a ), the electric wire 3 includes a conductive core wire 4 and an insulating coating 5 . The core wire 4 is formed by twisting a plurality of conductive wires together. The conductive wire constituting the core wire 4 is made of conductive metal. In addition, the core wire 4 may also consist of a single wire. The coverin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com