Patents

Literature

106results about How to "Prevent gasification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device and method for suppressing refuse end gas injurant using pyrolysis and aerification technology

InactiveCN1769397ANo emissionsPrevent gasificationThermal non-catalytic crackingSolid waste disposalThermal dissociationVaporization

Owner:TIANJIN UNIV

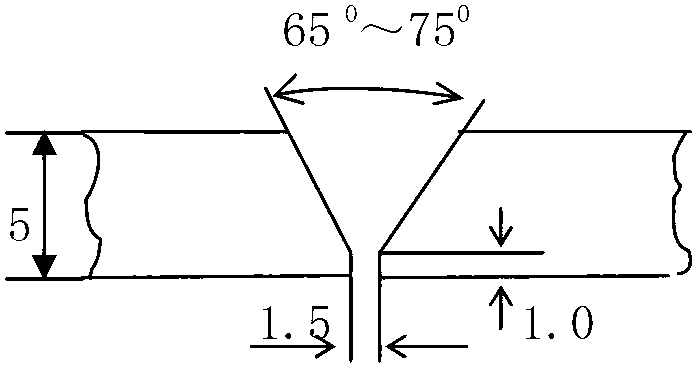

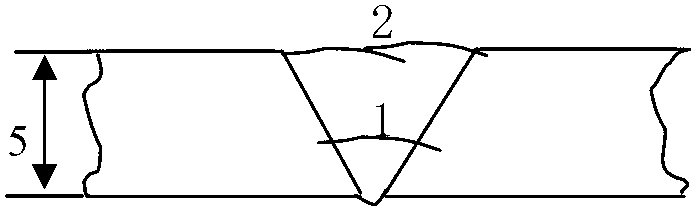

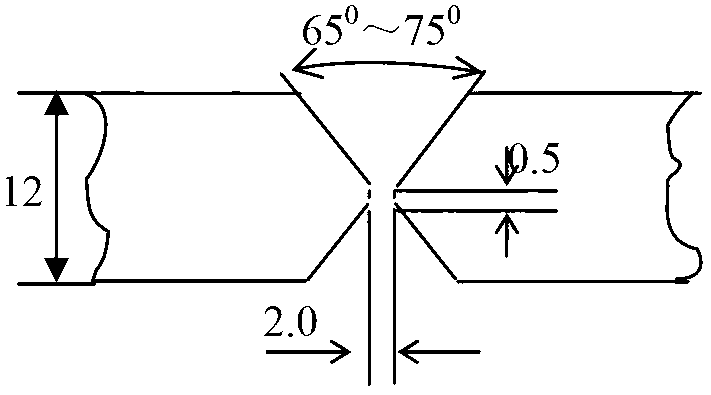

Welding process method of brass H62

ActiveCN102699496AReduce evaporationImprove welding qualityArc welding apparatusWelding/soldering/cutting articlesSurface layerEngineering

The invention discloses a welding process method of brass H62, which uses a welding wire Scu6810A and a soldering flux CJ301, and uses a manual argon tungsten-arc welding method. The welding process method of the brass H62 comprises the following steps of: firstly, machining a groove of a welding piece, wherein a groove angle is 32.5-37.5 degrees; controlling a truncated edge within a range of 0-1.5 mm; cleaning the welding surface of a welding piece and a welding wire; coating soldering flux paste of the soldering flux CJ301 on the groove of the clean welding piece and an area within a 30-mm range near the groove, as well as the surface of the welding wire; assembling the welding piece with an assembly clearance of 1.5-3.0 mm; pre-heating the welding piece to 200-300 DEG C before welding; welding a welding bead at a bottom layer by using a high-frequency arc striking technology; cleaning the surface of the welding bead at the bottom layer after the welding bead at the bottom layer is welded; coating the CJ301 soldering flux paste on the surface of the welding bead at the bottom layer; welding a filling layer, cleaning the surface of the filling layer after the filling layer is welded, and coating the CJ301 soldering flux paste after cleaning the surface of the filling layer; welding a cover surface layer; welding a weld joint and then pickling, and washing the weld joint with water; and drying with hot air.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

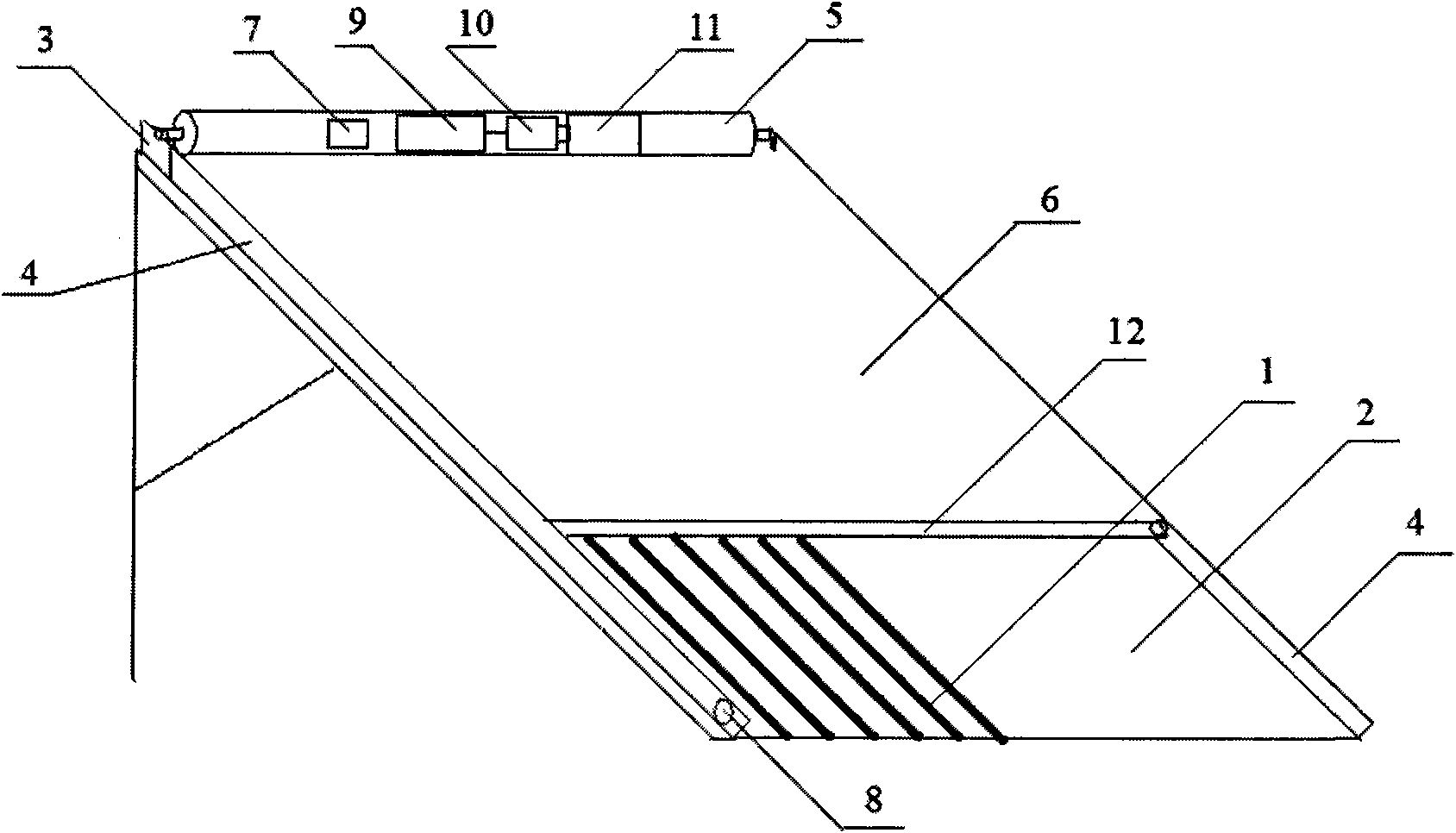

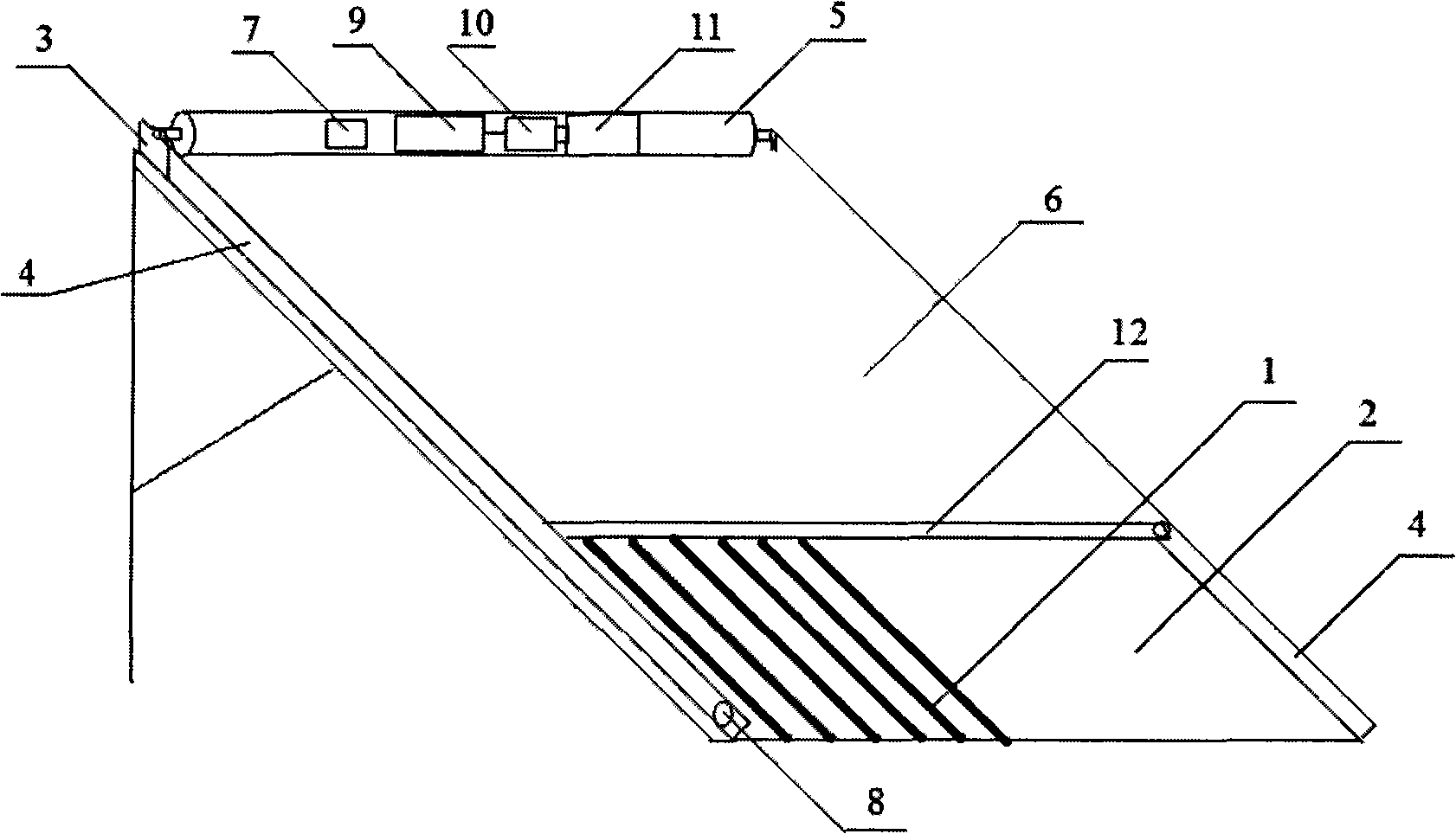

Shading device of solar heat collector

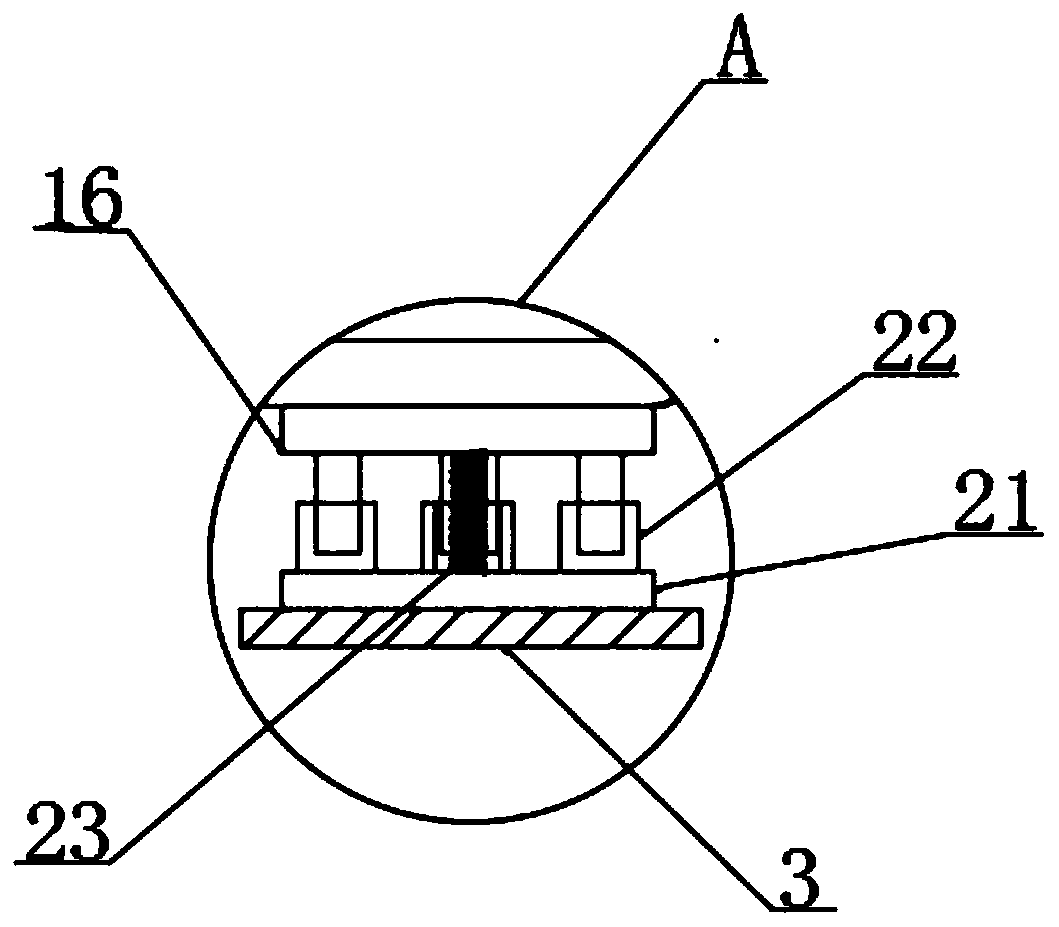

InactiveCN101984307AAvoid long-term exposure to high temperaturePrevent gasificationSolar heating energySolar heat devicesRemote controlSafe operation

The invention discloses a shading device of a solar heat collector. A bracket (3) is installed at the top of a base (2); rails (4) are installed at two sides of the bracket (3); each rail (4) is higher than the heat collecting surface of a solar heat collector (1); a remote control receiver (7), a cell (9) and a motor (10) which are mutually connected into an electric loop are installed on the bracket (3); a transmission tube (5) is sleeved outside the motor (10) and is connected with the shaft of the motor (10); one end of a shading curtain (6) is connected with and wound on the transmission tube (5); and two sides of the shading curtain (6) are inserted into the rails (4) at the two sides of the bracket (3). The invention intelligently realizes the purposes of opening and closing the shading device, prevents the solar heat collector from being in a high temperature state for a long time, prevents the liquid in the solar heat collector from being gasified, ensures the safe operation of a system, and prolongs the service life of the system.

Owner:靳灏

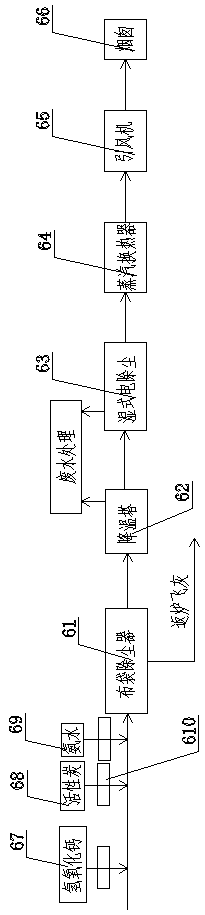

Plasma gasification and melting system for solid waste centralized processing

ActiveCN108097703AReduce the amount of dustPrevent regenerationWaste processingTransportation and packagingFuranCombustion chamber

The invention discloses a plasma gasification and melting system for solid waste centralized processing, and relates to the technical field of solid waste thermochemical treatment. The system comprises a plasma gasification and melting furnace, a synthesis gas outlet of the plasma gasification and melting furnace is connected with a secondary combustion chamber, a high-temperature smoke outlet ofthe secondary combustion chamber is sequentially connected with a waste heat recycling system and a smoke purifying system, and the synthesis gas outlet of the plasma gasification and melting furnaceis further connected with a reforming chamber, a high-temperature synthesis gas outlet of the reforming chamber is sequentially connected with a heat exchange system and a synthesis gas purifying system. The controlled oxygen combustion technology is adopted in the plasma gasification and melting furnace, the excessive air coefficient of primary air is about 0.3 to 0.5, the dust amount in rough synthesis gas can be effectively reduced, re-generation of toxic and harmful substances of dioxin and furan can be restrained, and the production of flying ash amount can be reduced.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

Catalytic cracking method and equipment for hydrocarbon oil

InactiveCN102453500AAvoid the problem of insufficient activityAvoid coolingTreatment with plural serial cracking stages onlyContact reactionHydrocarbon

The invention discloses a catalytic cracking method for hydrocarbon oil. The method is characterized by comprising the following steps of: (1) undergoing a first contact reaction on a hydrocarbon oil raw material and a first cracking catalyst in a first reactor, and performing first oil-agent separation on a mixture of oil gas and the catalyst after the first contact reaction; (2) undergoing a second contact reaction on oil gas obtained after first oil-agent separation and a second newly-added cracking catalyst in a second reactor, and performing second oil-agent separation; and (3) feeding a part of or all of a spent catalyst obtained in the step (2) into the first reactor. The invention further provides catalytic cracking equipment for hydrocarbon oil. Due to the adoption of the method and the equipment, the problem of poor activity in the second reactor caused by great reduction in the activity of the catalyst discharged from the first reactor is solved, and the yields of dry gas and coke can be lowered greatly.

Owner:CHINA PETROLEUM & CHEM CORP +1

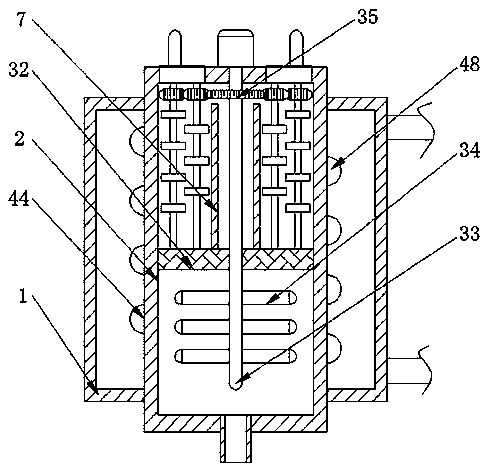

Halogen generator

ActiveCN103903660AGenerating range is wideHelp gasificationNuclear energy generationNuclear monitoringGeneration rateHalogen

The invention relates to leakage testing equipment in the nuclear field, and in particular relates to a halogen generator for inspecting leakage rate of iodine adsorber machinery in a ventilation and purification system of a nuclear facility. The halogen generator structurally comprises a pressure-bearing storage tank used for storing a freon liquid reagent, wherein the pressure-bearing storage tank is respectively connected with a compressed air pipeline, a freon charging pipeline and a freon gasification outlet pipeline, the compressed air pipeline comprises two gas flow paths, one of the gas flow paths is connected with the pressure-bearing storage tank through a three-way switch valve, the other gas flow path is connected with the freon gasification outlet pipeline, and a heater is arranged on the freon gasification outlet pipeline. The halogen generator provided by the invention can continuously and uniformly generate halogen gas with stable concentration, can easily generation conditions, is wide in gas generation range, stable in generation rate, convenient and rapid to operate, and good in adaptability to the scene.

Owner:CHINA INST FOR RADIATION PROTECTION

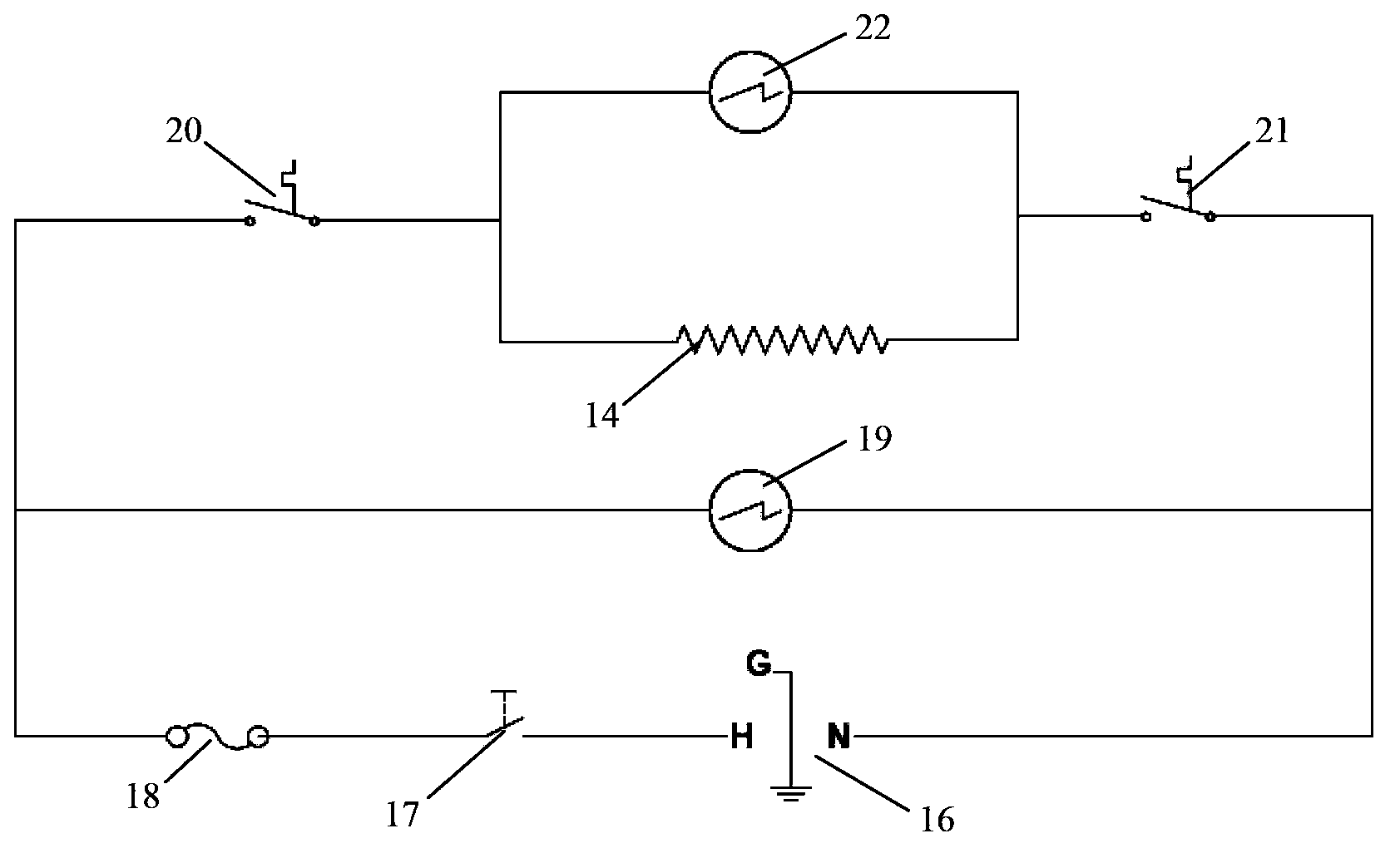

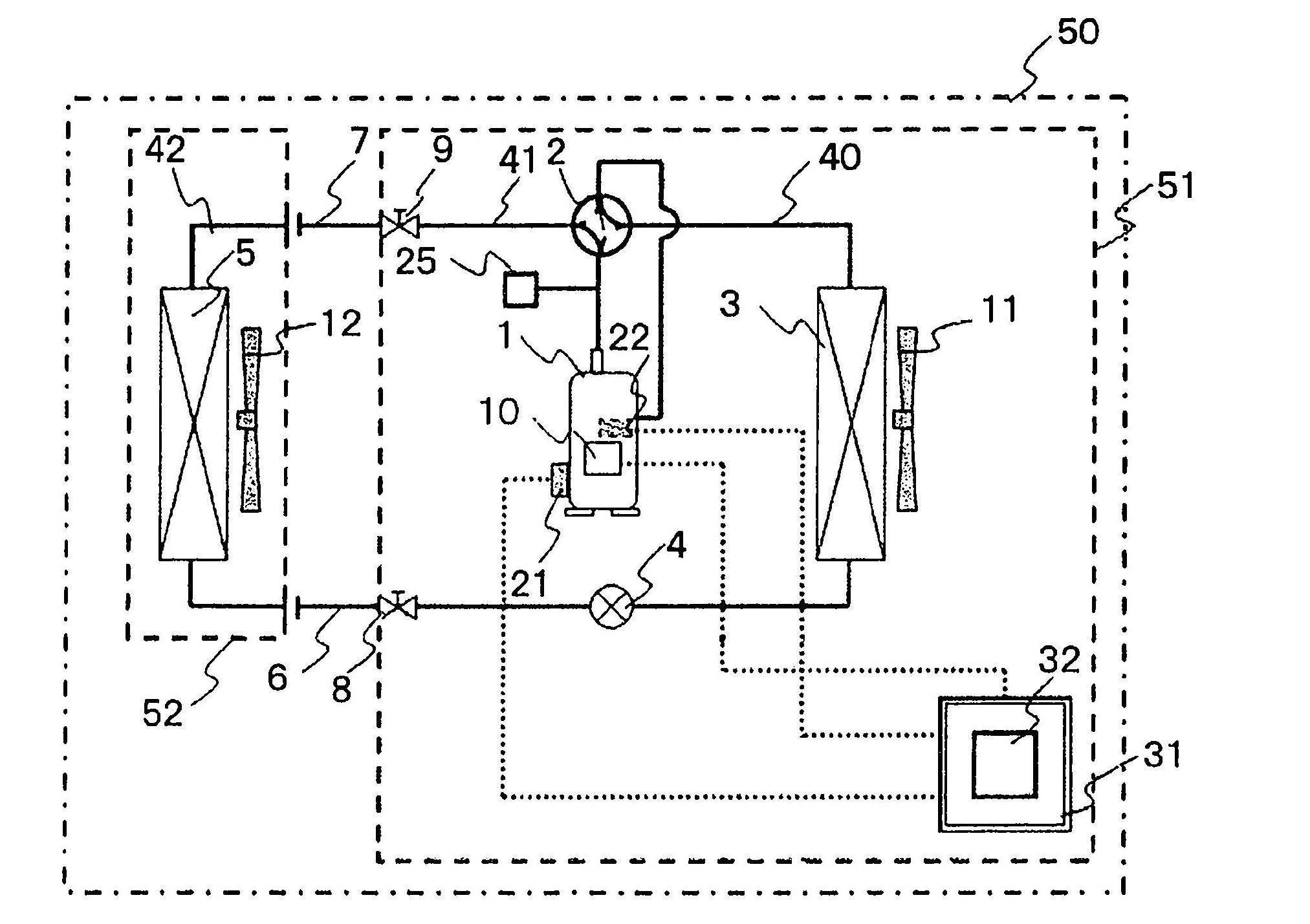

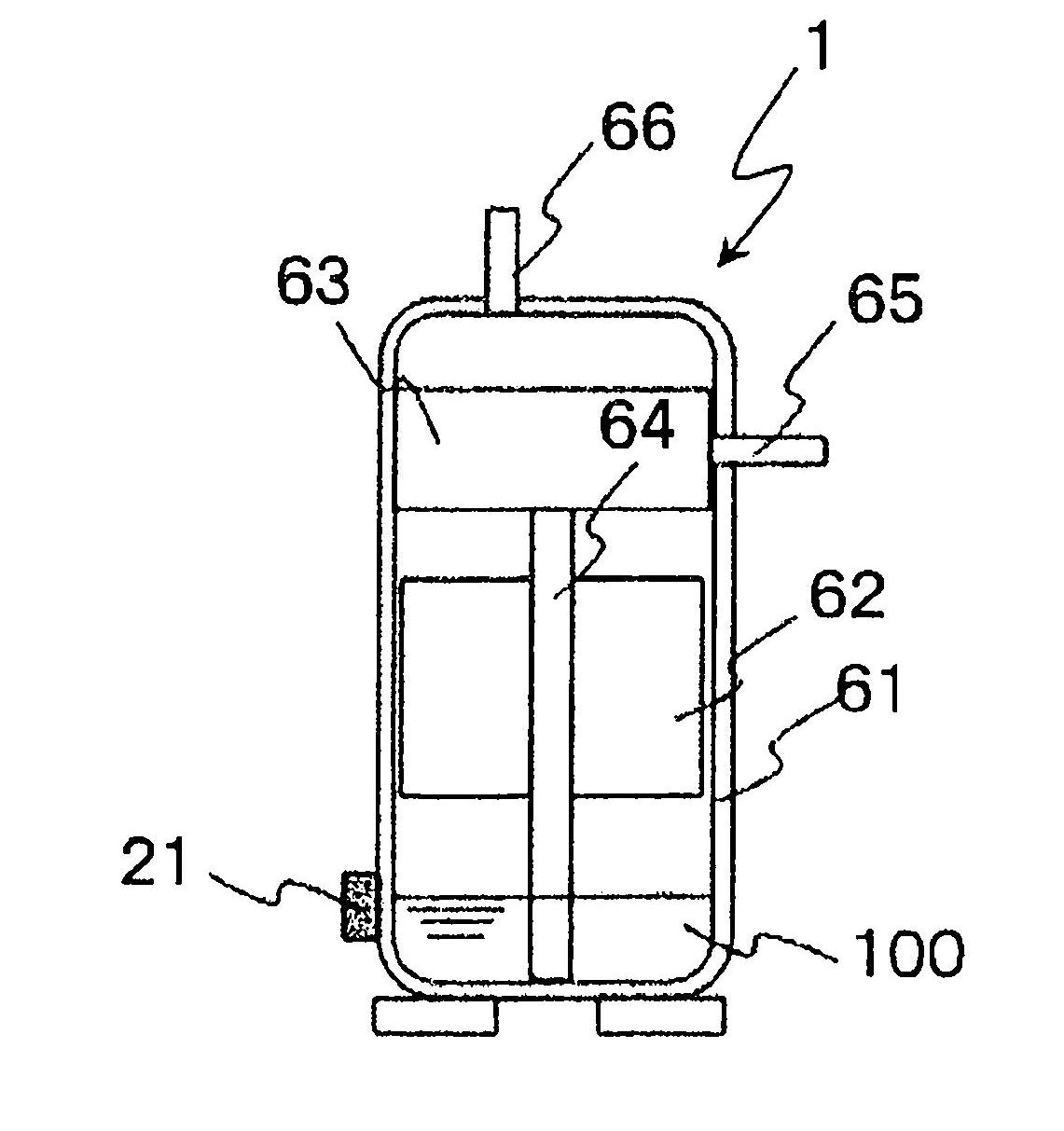

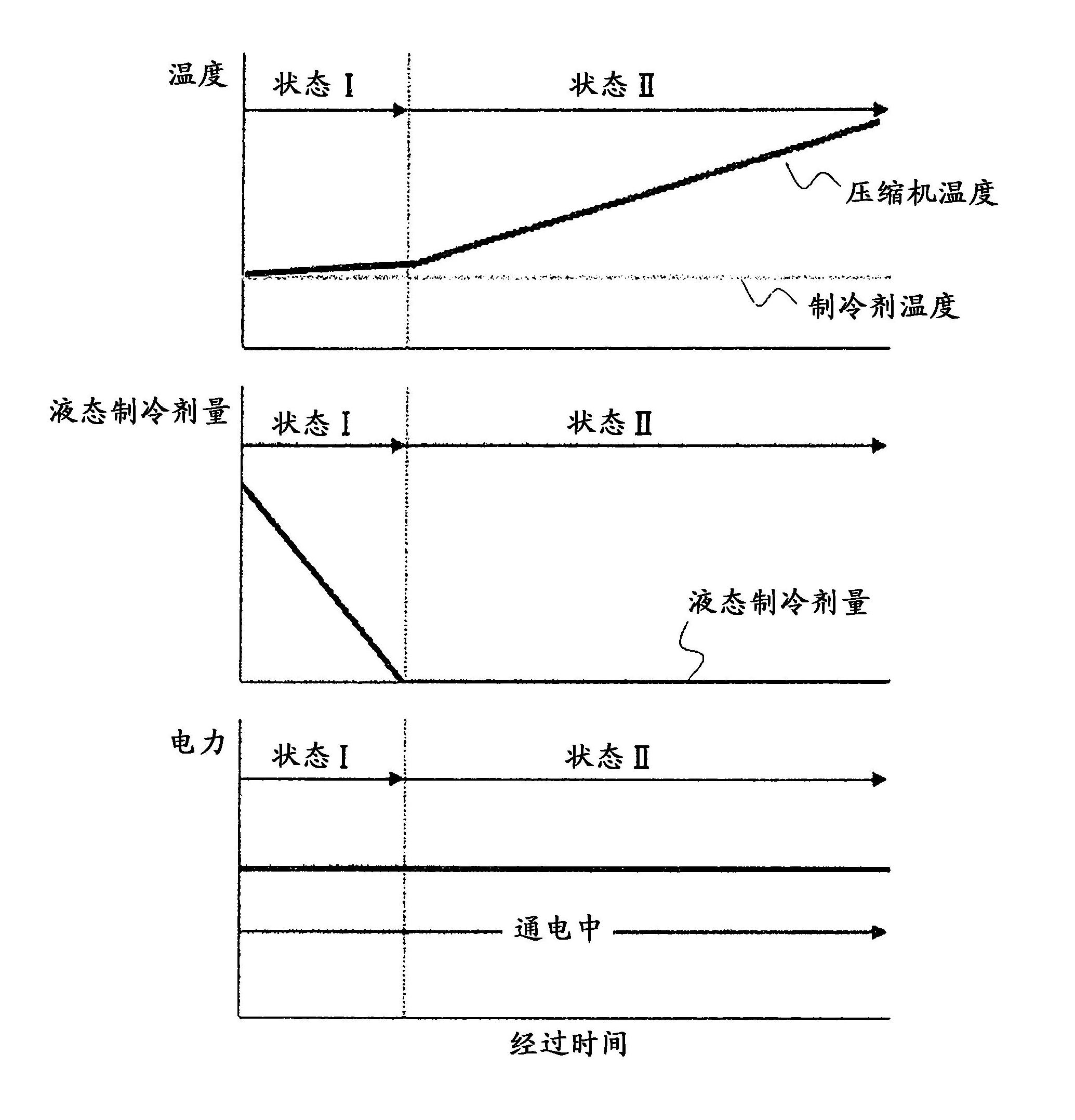

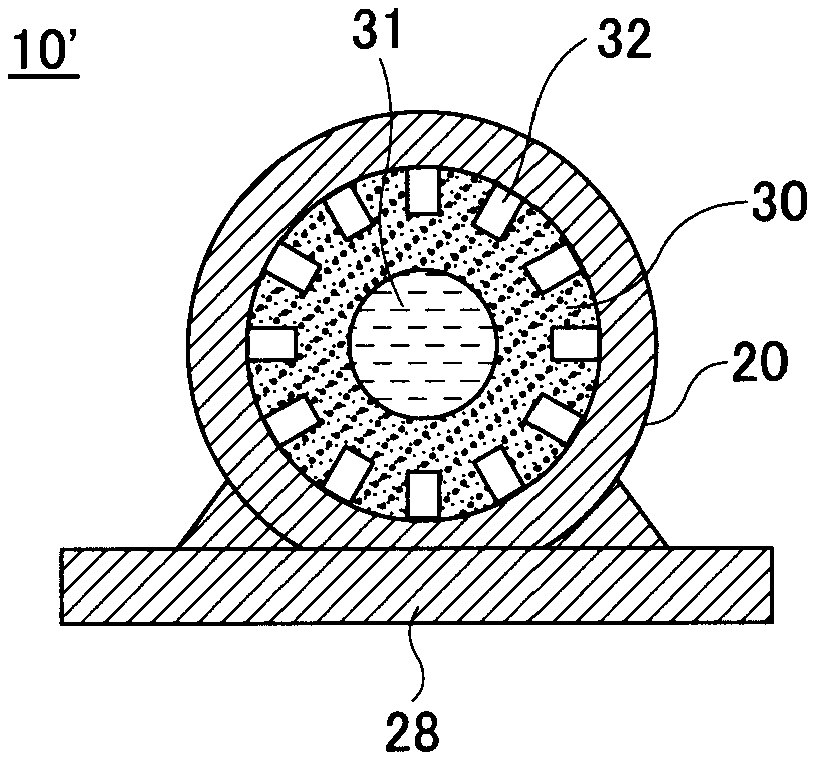

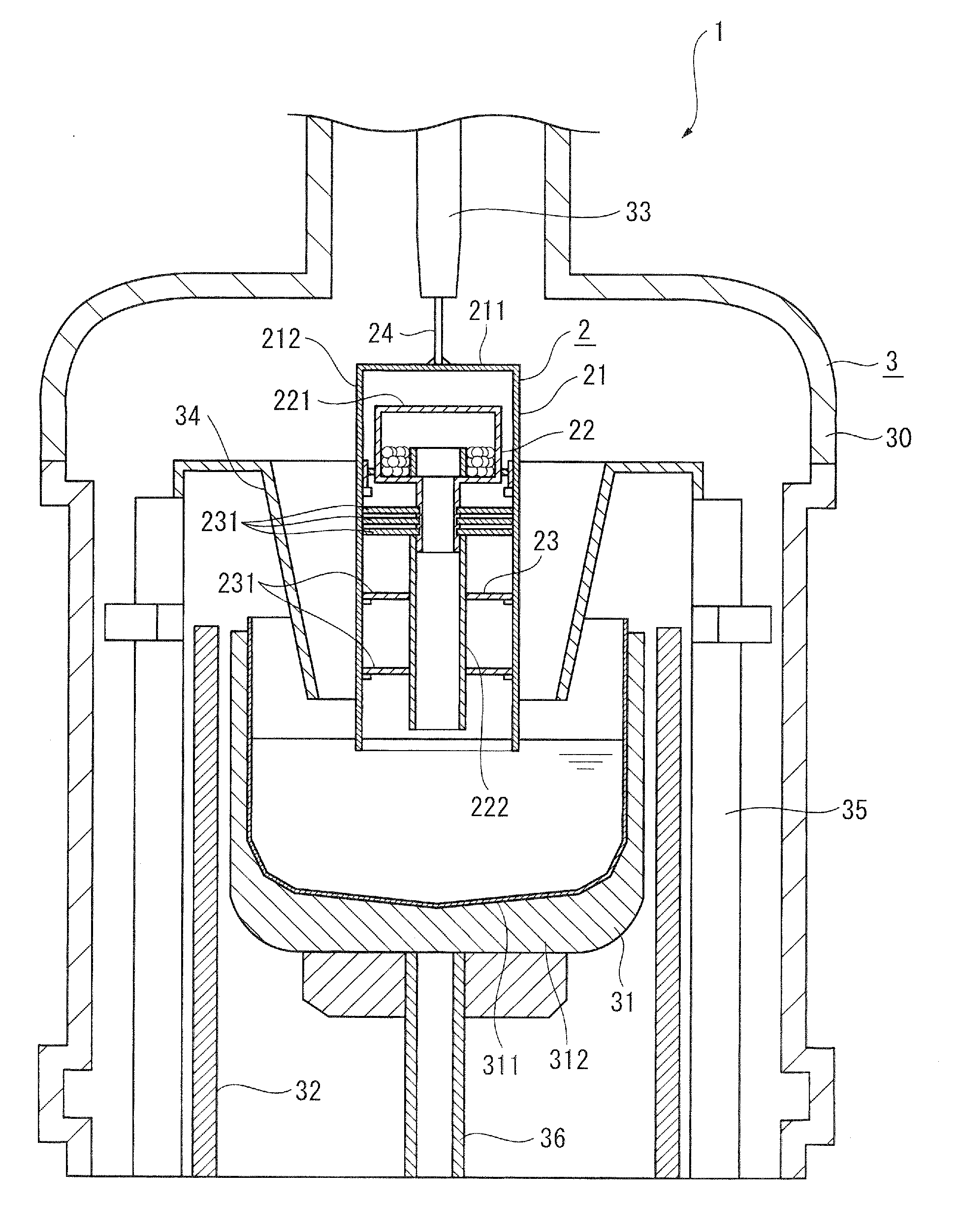

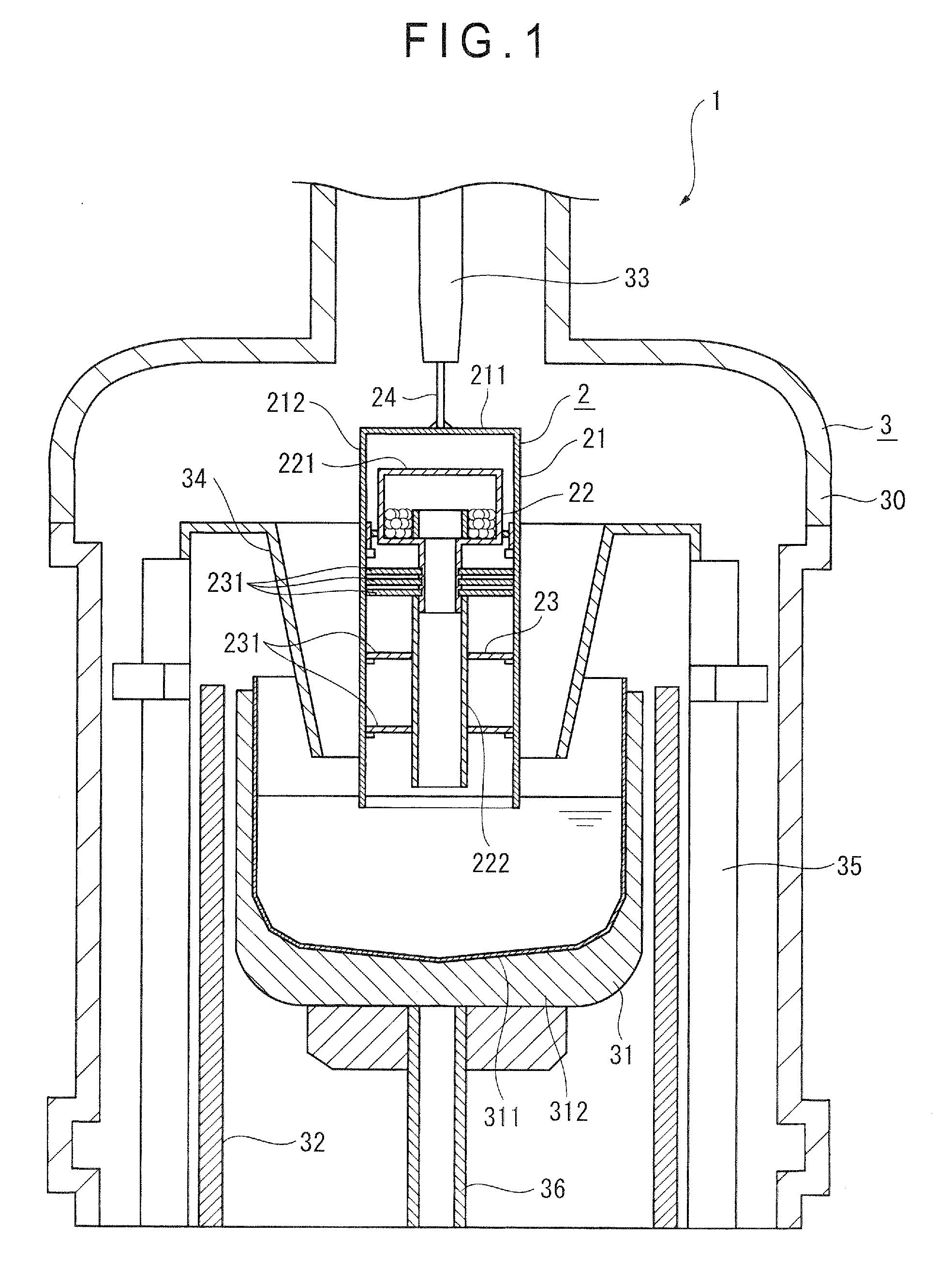

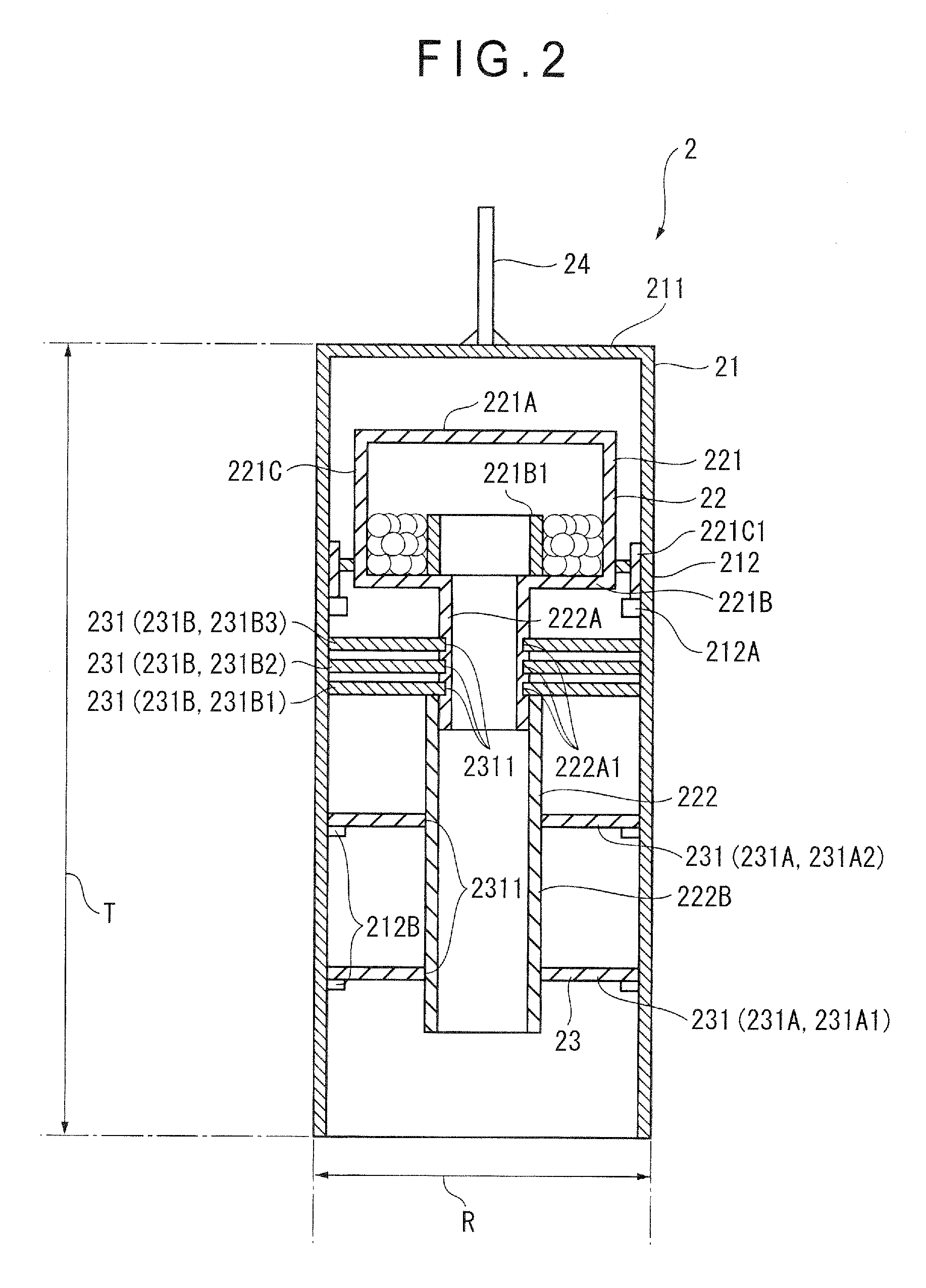

Air conditioner

ActiveCN102597659ASuppress powerPrevent gasificationCompressorCompression machines with non-reversible cycleEngineeringRefrigerant

Provided is an air conditioner which appropriately determines accumulation of refrigerant in a compressor, and minimizes power consumption during a period when the air conditioner is stopped to operate. Upon determining that the compressor temperature change rate (Rc1) is larger than the refrigerant temperature change rate (Rr1), a control apparatus (31) determines that liquid refrigerant contained in lubricant oil (100) inside a compressor (1) has all evaporated, and stops a current from being applied to an electric motor unit (62), whereby operation for heating the compressor (1) is terminated.

Owner:MITSUBISHI ELECTRIC CORP

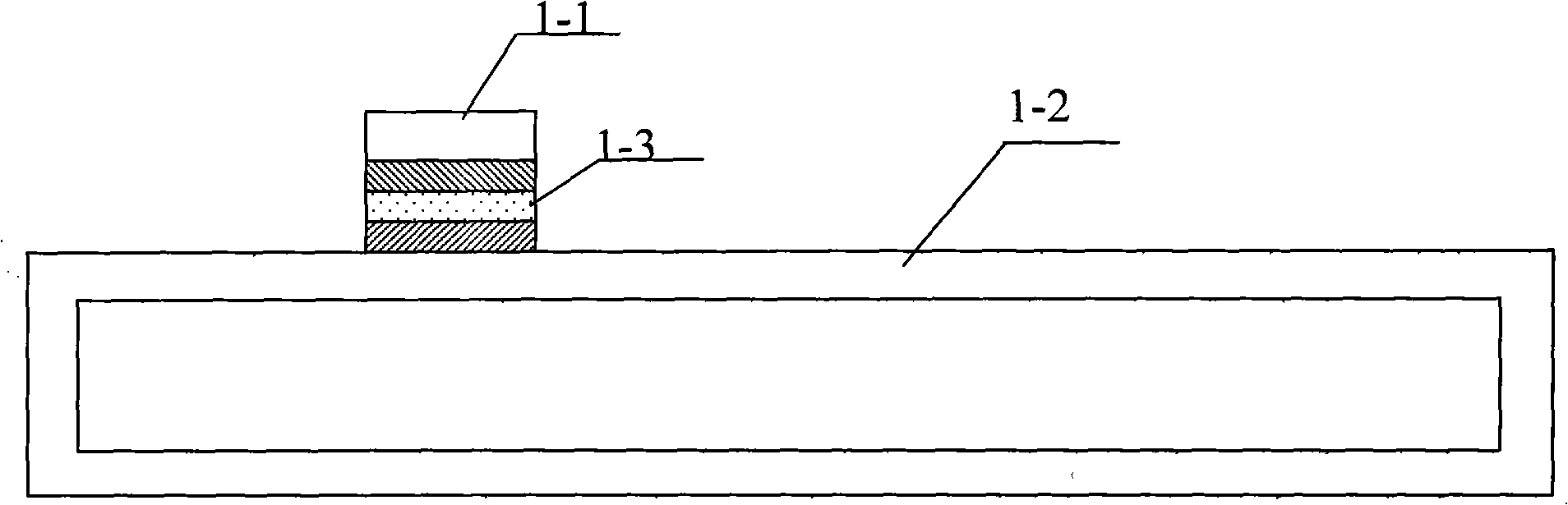

LED heating heat sink rear using laser and heat sink bonding method

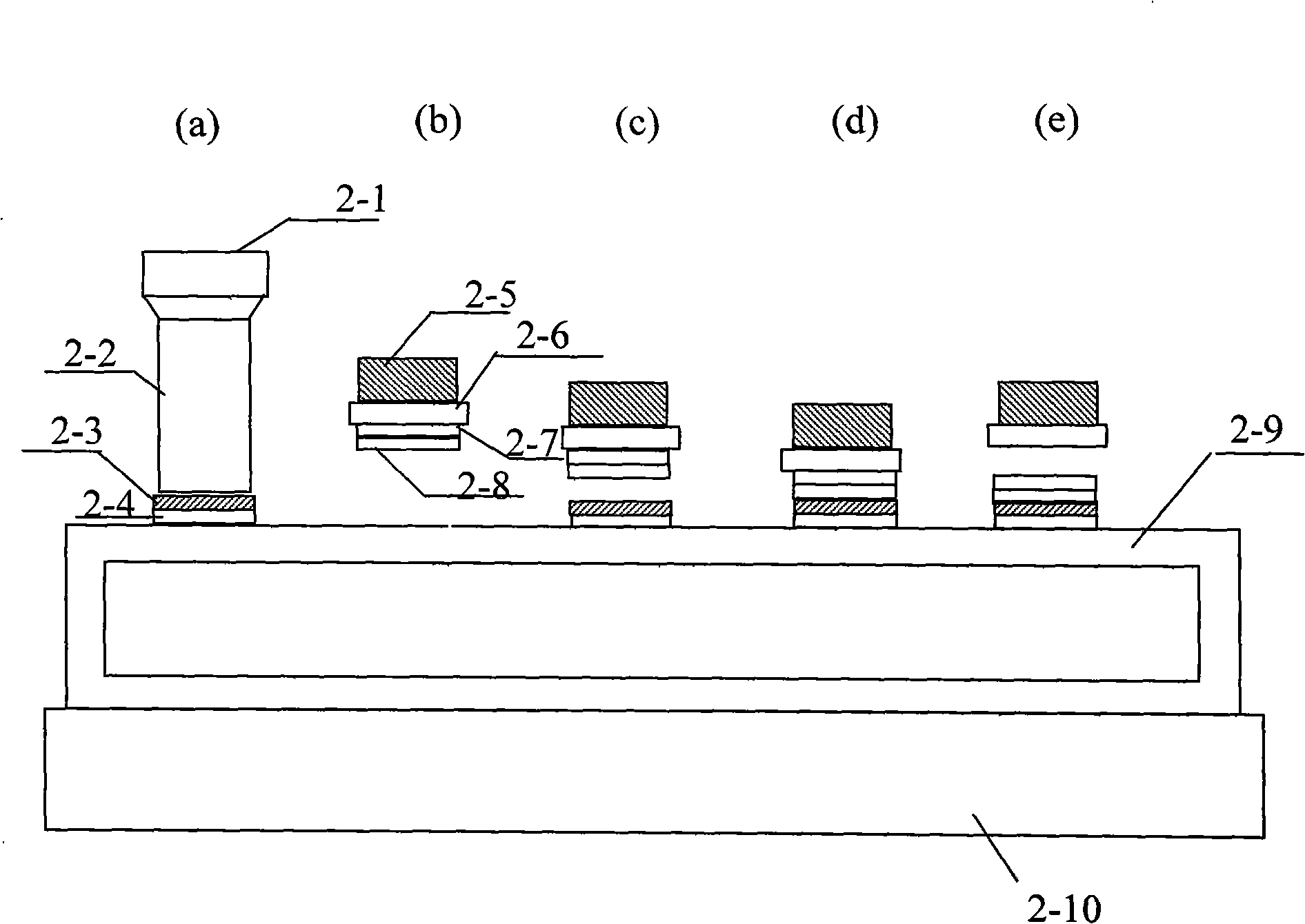

InactiveCN101304064APrevent oxidationPrevent gasificationSoldering apparatusSemiconductor/solid-state device manufacturingOptoelectronicsVaporization

The invention relates to a method for bonding an LED chip and heat sink by adopting laser to heat the back of the heat sink, in particular to a method for bonding an LED chip and heat sink; the method solves the problems that when the laser beams directly radiate on a brazing filler metal layer, the brazing filler metal is to undergo oxidization and even vaporization due to rapid temperature raising in a short time, and the reliable bonding of the LED chip and heat sink cannot be ensured. The specific steps of the method are as follows: first, the metal Au is plated on the back of the LED chip and the bonding pad of the heat sink; then, the brazing filler metal layer is plated or printed on the Au-plated bonding pad; the LED chip is attached on the brazing filler metal layer of the Au-plated bonding pad; laser beams are pointed to the position on the back of the heat sink where the LED chip is positioned until the brazing filler metal is melted. The method has the advantages that: the laser beams heat the position on the back of the heat sink where the chip is positioned to avoid oxidation and vaporization of the brazing filler metal; a plurality of chips can be attached on the position waiting for bonding in advance and then bonding can be conducted. The method can be applied to the field of LED chip packaging.

Owner:HARBIN INST OF TECH +1

Traditional Chinese medicine composition for preventing and treating asthenopia

InactiveCN107158076AReduce drynessRelieve eye fatigueSenses disorderHydroxy compound active ingredientsWhole bodyAdemetionine

The invention provides a traditional Chinese medicine composition for preventing and treating asthenopia. The traditional Chinese medicine composition comprises honeysuckle flower, cassia seed, senecio scandens, celosia seeds, pale butterfly bush flower, mint and borneol. The method employs a pure traditional Chinese medicine low-temperature extraction technology, gasification of the active components due to temperature is prevented, and the active component of the traditional Chinese medicines can be kept in a maximum degree. During a packaging process, aseptic operation is carried out during a whole course, one time usage is realized after sealing, the traditional Chinese medicine composition does not contain an antiseptic, and injury of eye lacrimal film and cornea due to the antiseptic can be effectively prevented. The product is sprayed on the eyelid of the users, through transdermal absorption, the traditional Chinese medicine composition is directly effected on the eyes, efficacy insufficiency due to liver detoxifcation function and whole body cycle metabolism can be avoided, application amount is less, the targeting effect is high, and the absorption efficiency is high.

Owner:贵州优视一号生物科技有限公司

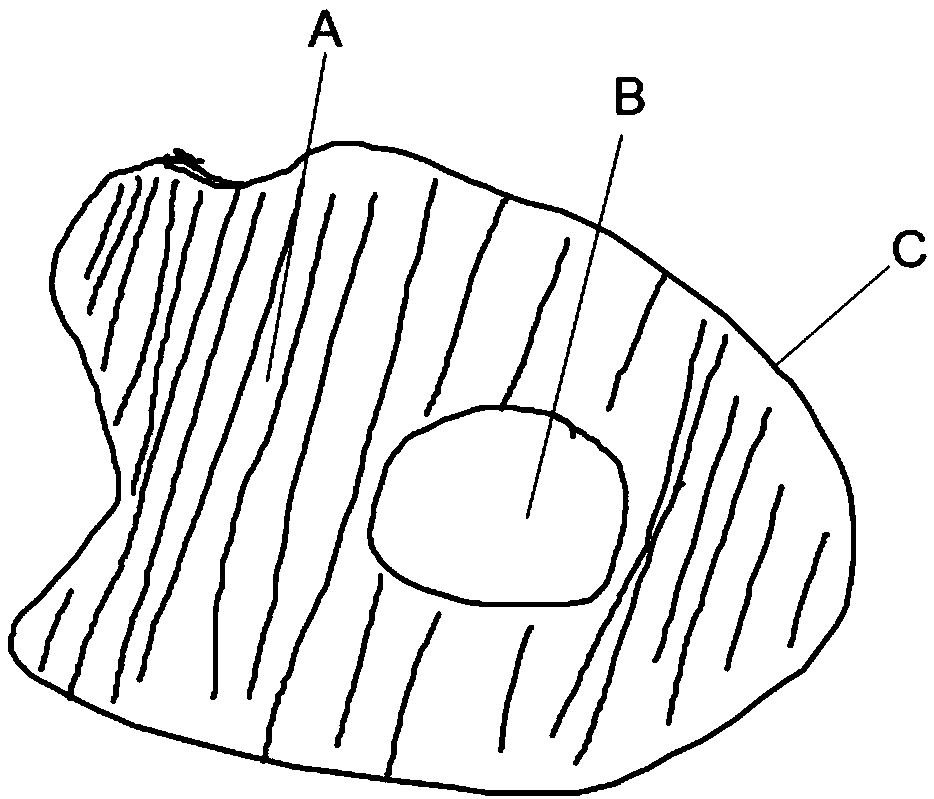

Preparation method of magnesium matrix composite bone implant and product thereof

InactiveCN109364292AEffective control of corrosion resistanceImprove corrosion resistanceAdditive manufacturing apparatusPharmaceutical delivery mechanismMagnesium matrix compositeAdhesive

The invention belongs to the field of bio-implant materials and discloses a preparation method of a magnesium matrix composite bone implant and a product thereof. The preparation method of the magnesium matrix composite bone implant comprises (a) structuring a three-dimensional structure of the bone implant, selecting spherical magnesium alloy powder and nano-hydroxyapatite (HA) as raw materials,ball-milling the two materials to prepare uniformly-mixed magnesium matrix composite powder; (b) performing shaping treatment on the magnesium matrix composite powder according to the three-dimensional structure through a three-dimensional jet printing process to obtain a green body of the bone implant; (c) vacuum-sintering the green body to evaporate adhesives inside the green body to obtain therequired customized bone implant with a porous structure. The preparation method of the magnesium matrix composite bone implant saves additional support and is low in requirements on printing environment, capable of avoiding burning loss of powder elements, few in impurities, high in efficiency and low in cost.

Owner:HUAZHONG UNIV OF SCI & TECH

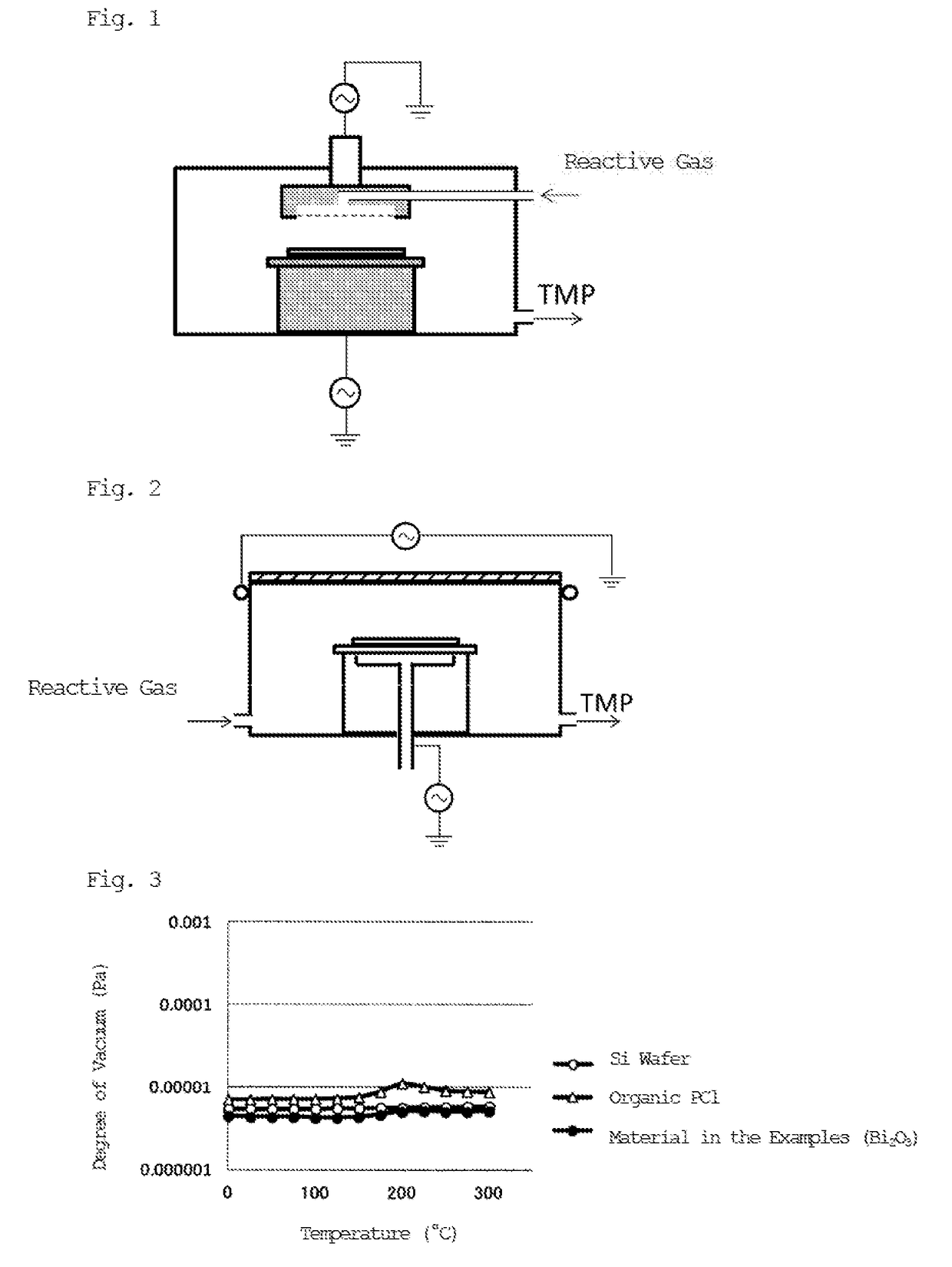

Plasma processing detection indicator using inorganic substance as a color-change layer

ActiveUS20170153174A1Prevent gasificationImprove cleaning environmentMaterial analysis by observing effect on chemical indicatorElectric discharge tubesDevice PropertiesMedicine

The present invention provides a plasma treatment detection indicator including a color-changing layer that changes color by plasma treatment, exhibiting excellent heat resistance, with the gasification of the color-changing layer or the scattering of the fine debris of the color-changing layer caused by the plasma treatment being suppressed to such a degree as to not affect the electronic device properties. Specifically, the present invention provides a plasma treatment detection indicator including a color-changing layer that changes color by plasma treatment, the color-changing layer containing at least one metal element selected from the group consisting of Mo, W, Sn, V, Ce, Te, and Bi in the form of a simple substance and / or an inorganic compound containing at least one metal element selected from the group consisting of Mo, W, Sn, V, Ce, Te, and Bi.

Owner:SAKURA COLOR PRODUCTS CORPORATION

Method for preparing ethanolamine hydrochlorides and coproduct ethanolamine

InactiveCN102304055APrevent gasificationMaximize your conversion rateOrganic compound preparationAmino-hyroxy compound preparationSodium methoxideEthylene oxide

The invention provides a method for preparing ethanolamine hydrochlorides and a coproduct ethanolamine, which comprises the following steps: carrying out addition reaction on ammonium chloride, which is used as a raw material, and EO (ethylene oxide), adjusting to a proper ratio to firstly synthesizing MEA.HCl (monoethanolamine hydrochloride) and DEA.HCl (diethanolamine hydrochloride), and separating out the MEA.HCl by utilizing the differences of physical properties; continuing adding the EO into the filtrate, sealing the reaction kettle, and gradually heating to react, wherein the reaction pressure must be sufficient to prevent the EO from gasifying at the reaction temperature, and the reaction temperature can be raised to 100 DEG C or so, so that the conversion rate of the TEA.HCl (triethanolamine hydrochloride) is maximized; cooling to room temperature, filtering, and drying to obtain the TEA.HCl; and merging the washing liquid and the filtrate, and dehydrating to obtain the DEA.HCl. The ethanolamine hydrochloride can be respectively dissociated in the presence of sodium hydroxide or sodium methoxide to obtain the MEA, DEA and TEA according to market demands.

Owner:薛荔

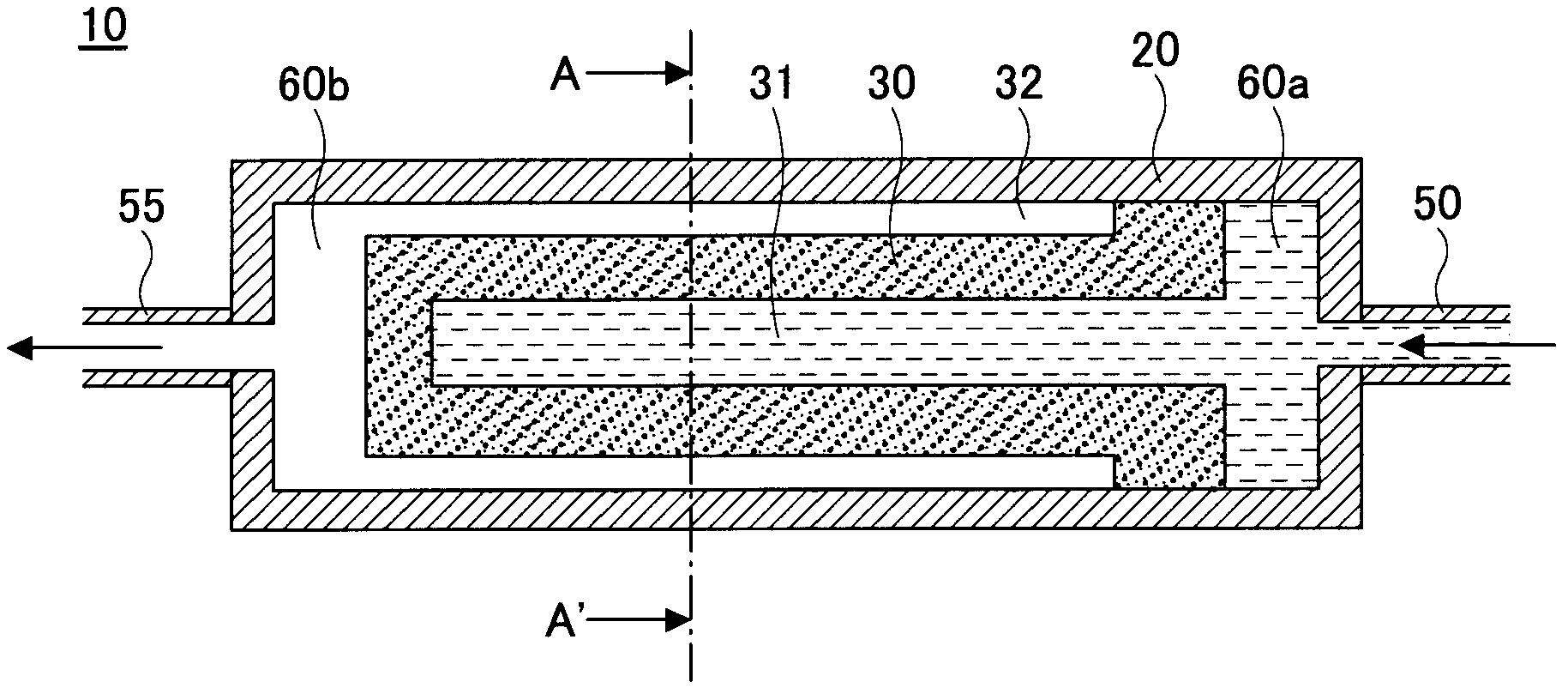

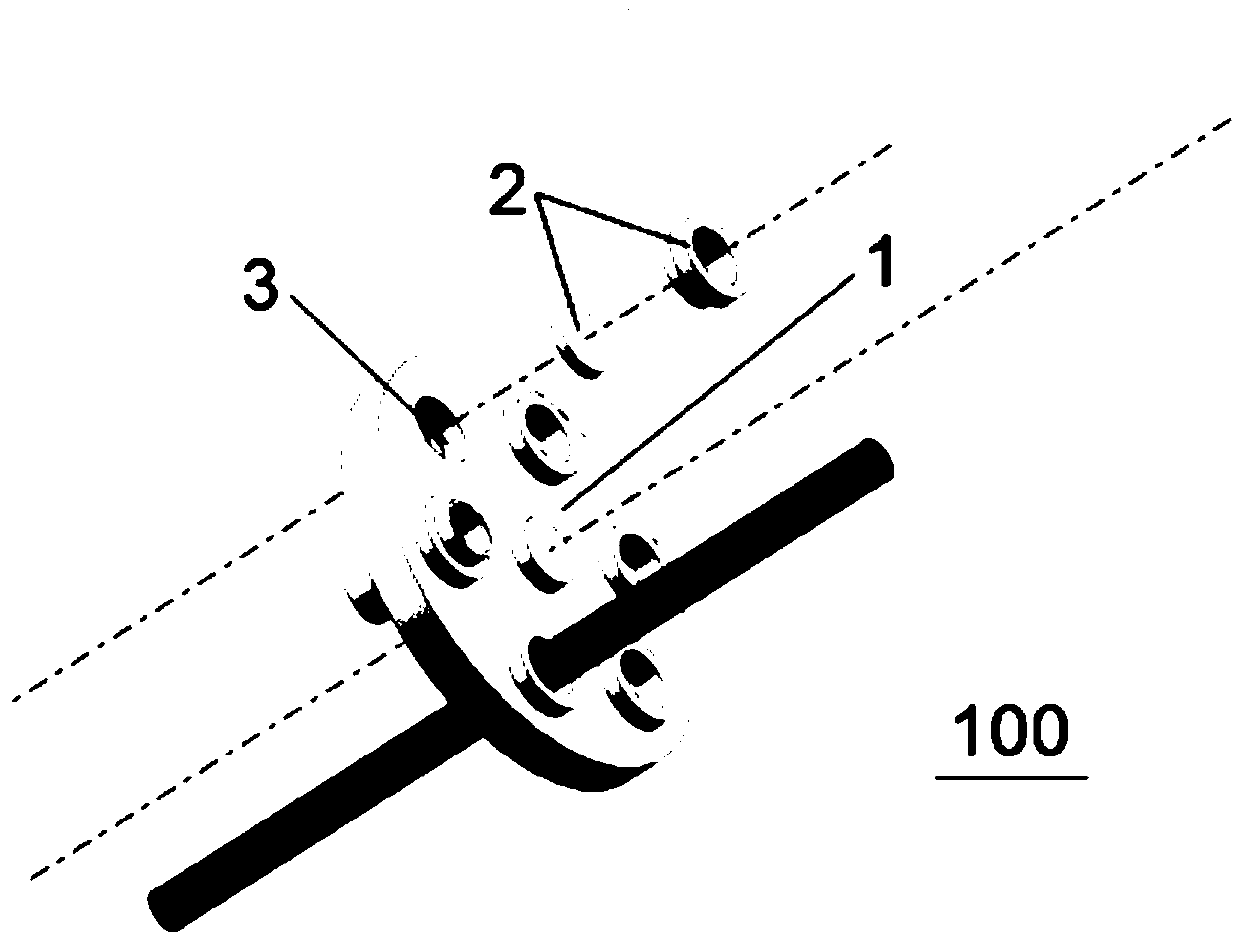

Loop-shaped heat pipe and electronic device

ActiveCN103080689AAvoid conductionPrevent gasificationIndirect heat exchangersWorking fluidVaporization

An evaporator (110) of a loop-shaped heat pipe comprises: a case (121, 122) which is provided with a fluid inlet and a steam outlet; and at least one porous body (130) which is arranged in the case and through which a liquid-phase working fluid is introduced onto the inner surface of the case. The evaporator (110) additionally comprises a liquid supply tube (140) which is arranged in the case (121, 122) and through which the working fluid is introduced from the fluid inlet to the at least one porous body (130). The liquid supply tube (140) comprises a material having a lower heat conductivity than that of a material that constitutes the case (121, 122). The vaporization of the working fluid that flows into the evaporator (110) can be prevented before the working fluid reaches the porous body (130), and therefore the steady circulation of the working fluid can be achieved.

Owner:FUJITSU LTD

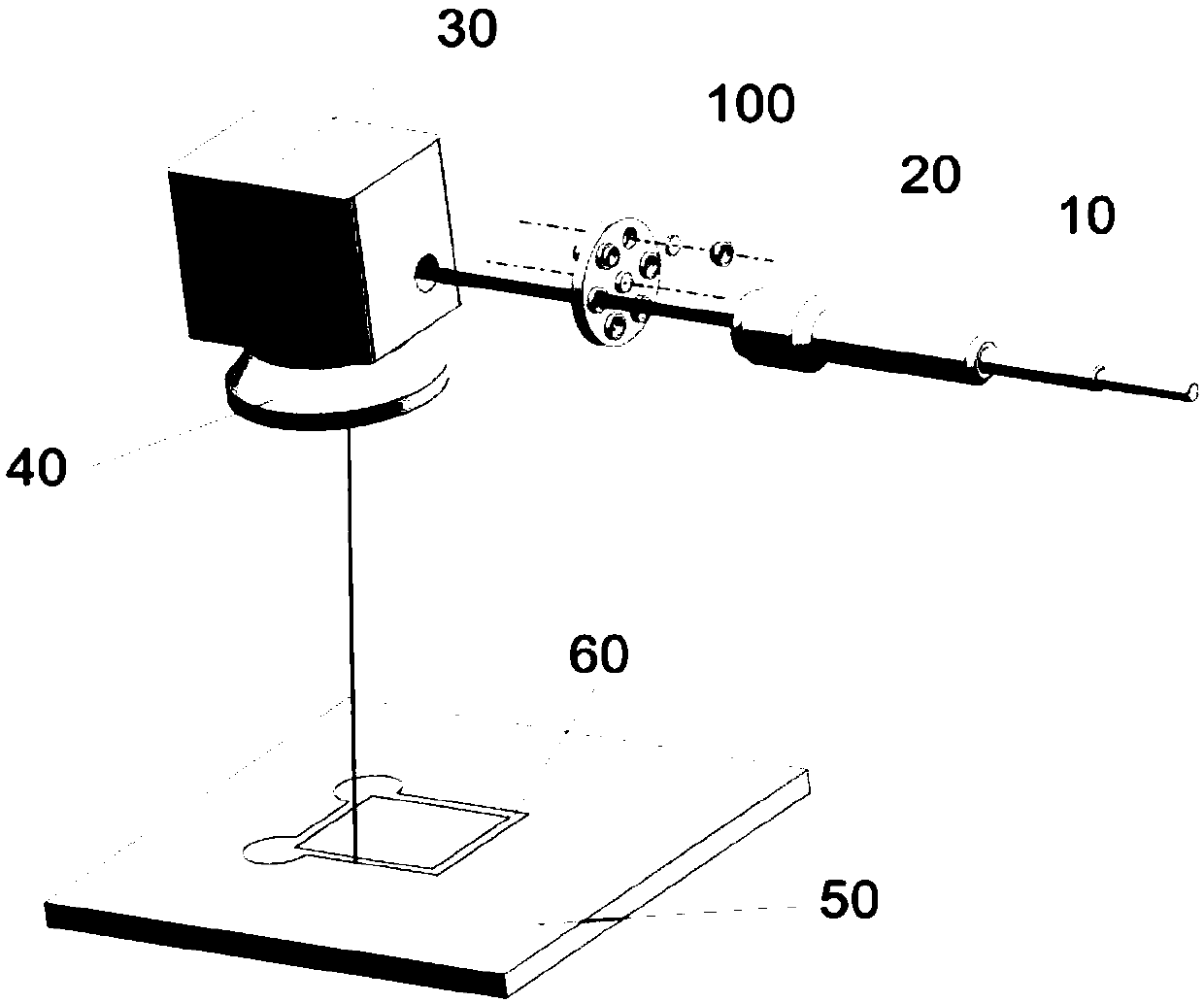

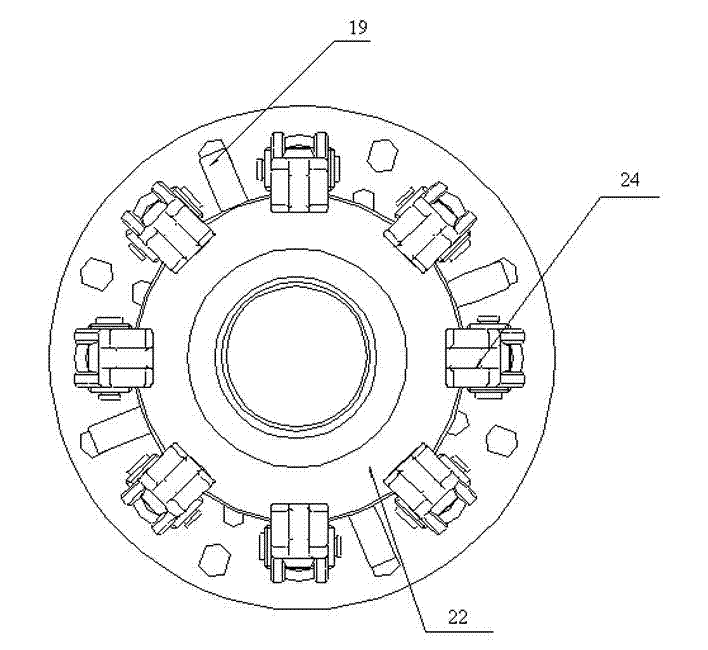

Beam shaping mechanism, laser source system and laser 3D printing equipment and method

PendingCN110733176AImprove processing efficiencyAdd featureAdditive manufacturing apparatusCeramic shaping apparatusErbium lasersLight source

The embodiment of the invention relates to a beam shaping mechanism used for laser processing equipment. The beam shaping mechanism comprises a rotary wheel and one or more beam shapers, and the beamshapers are arranged on the rotary wheel and are used for shaping laser beams emitted by a laser. The rotary wheel is provided with a plurality of holes in the circumferential direction. The center lines of the holes are parallel to the center shaft of the rotary wheel. The distances between the center lines of all the holes and the center shaft of the rotary wheel are equal. The beam shapers arearranged at the holes. The optical axes of the beam shapers coincide with the center lines of the holes where the beam shapers are located. Through the beam shaping mechanism, the condition that a single-mode laser beam is not suitable for an actual workpiece is avoided, and laser processing efficiency and product quality are improved.

Owner:福建国锐中科光电有限公司

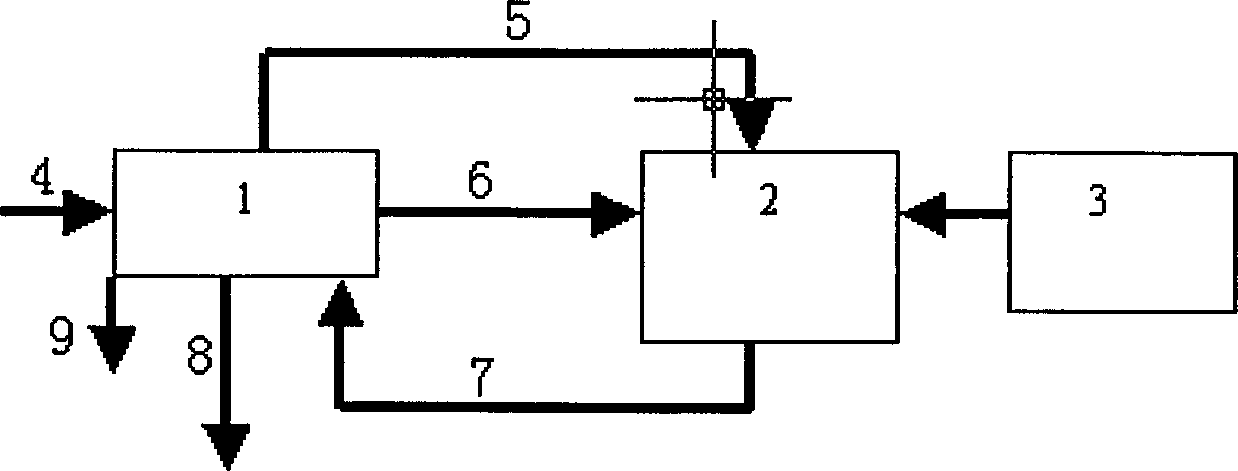

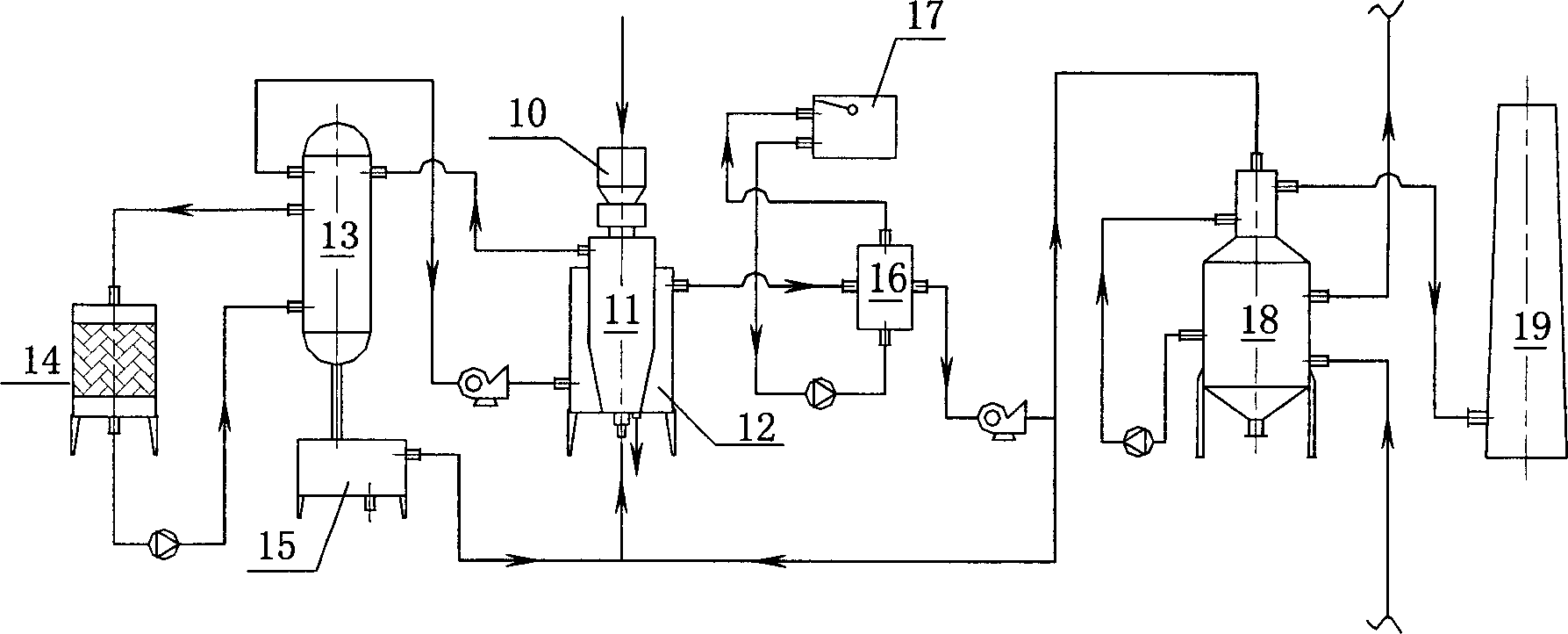

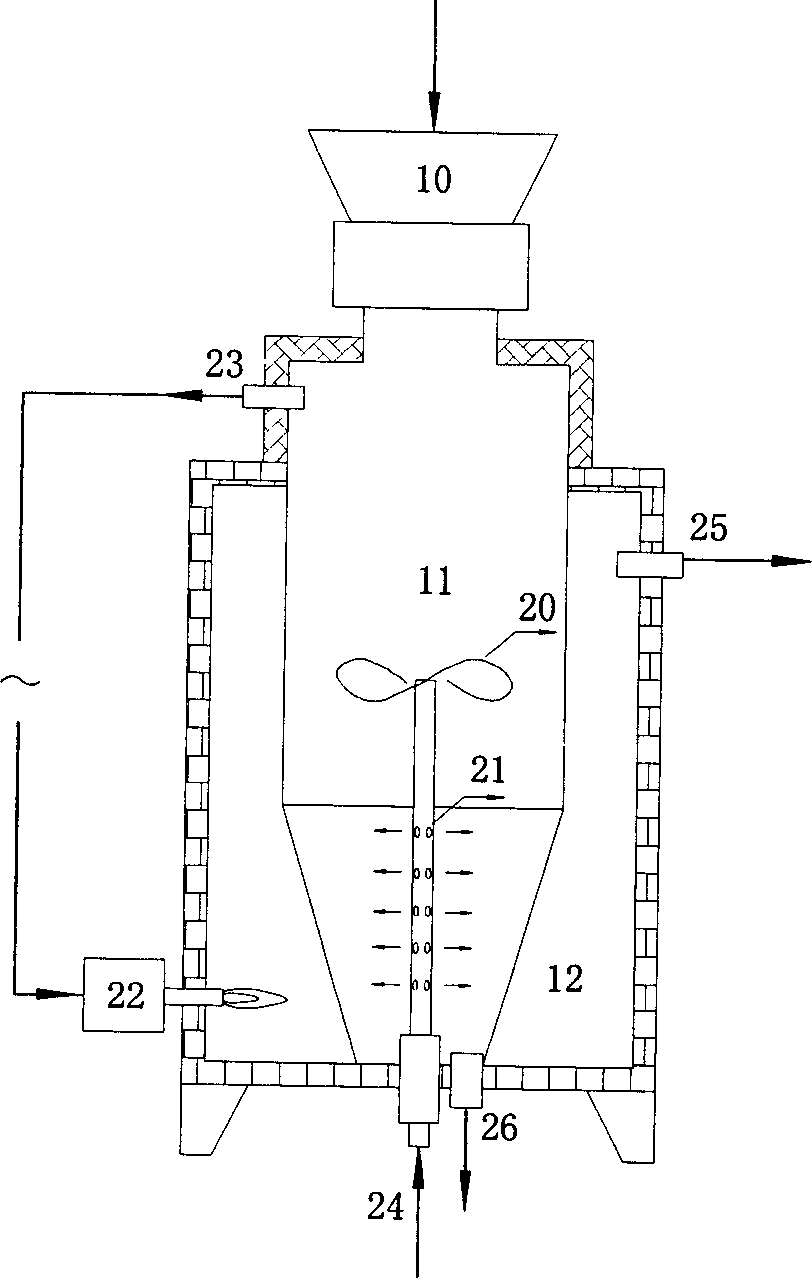

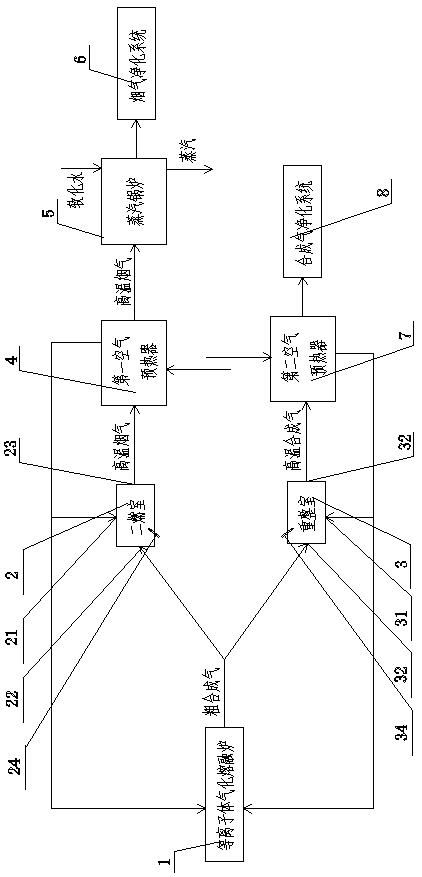

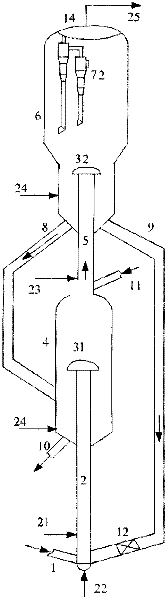

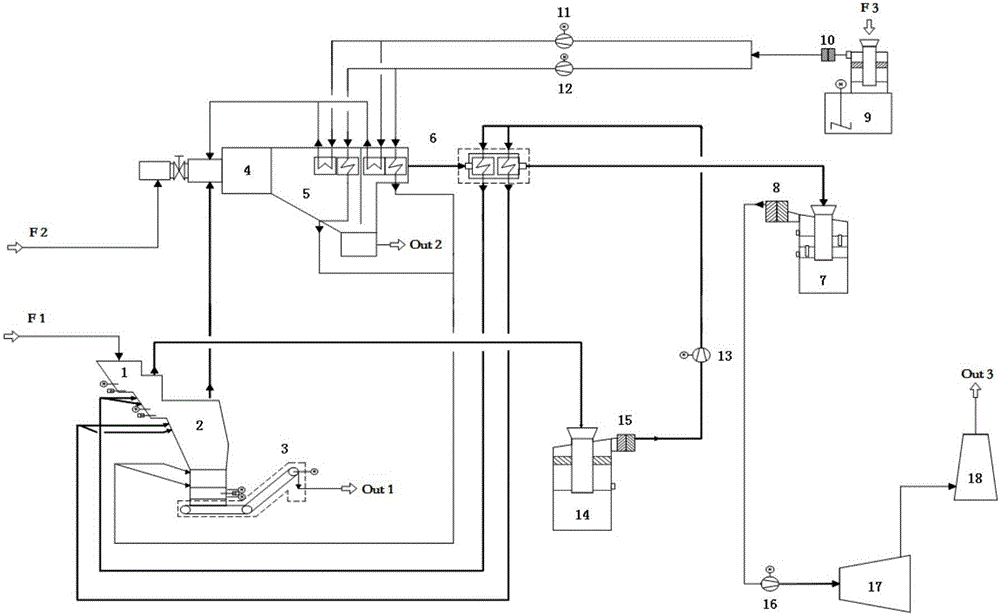

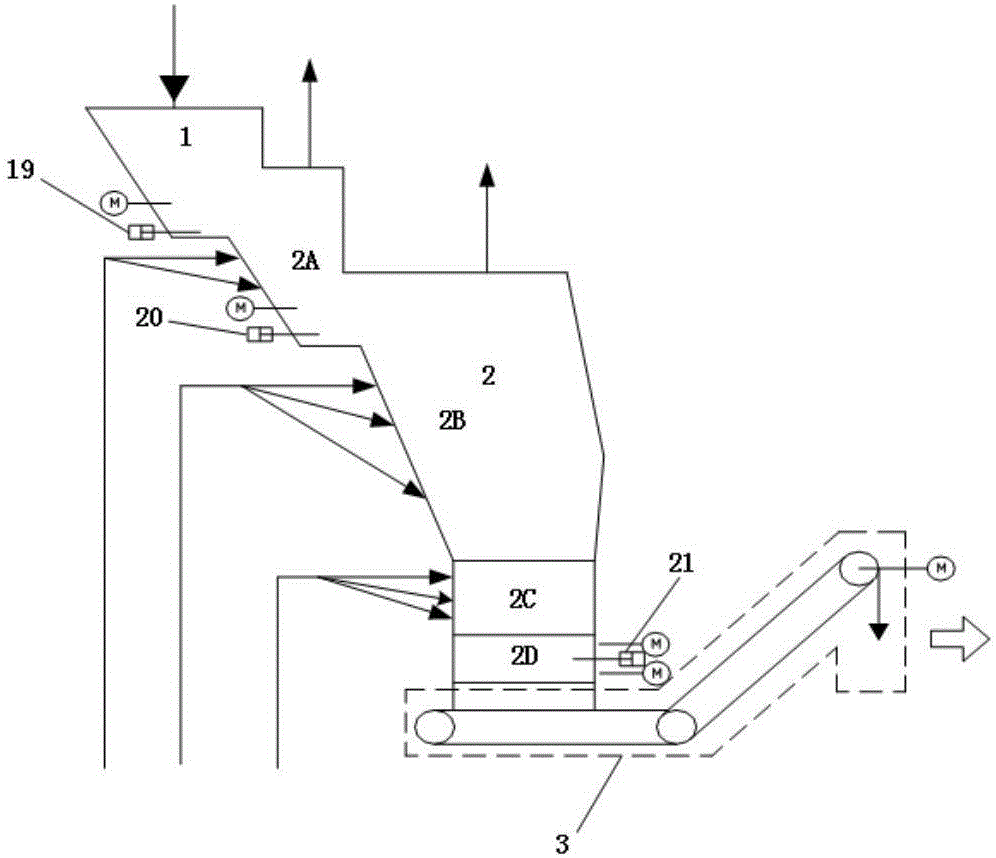

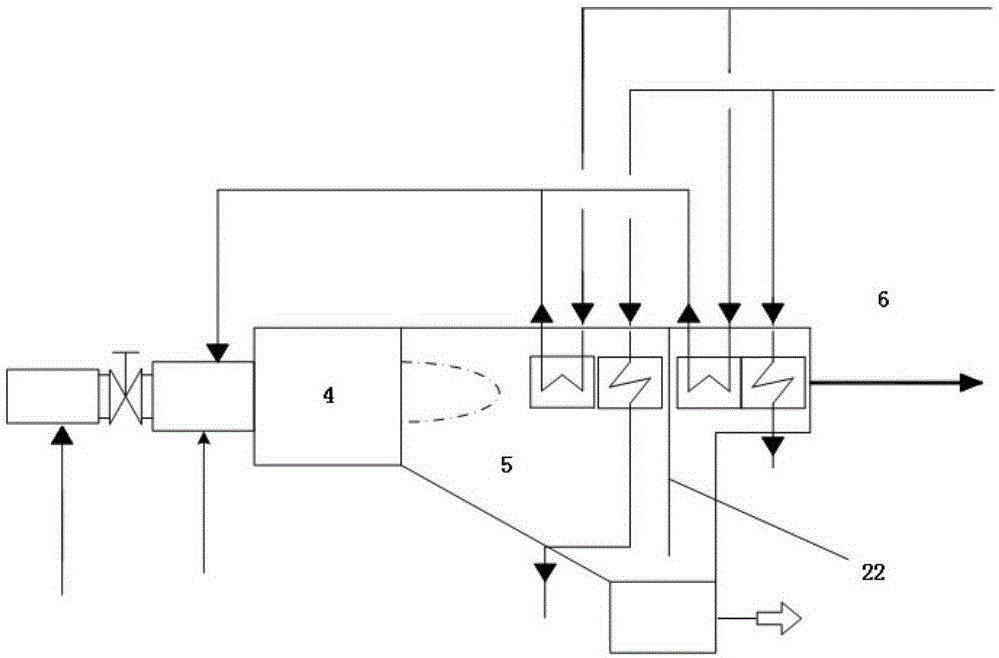

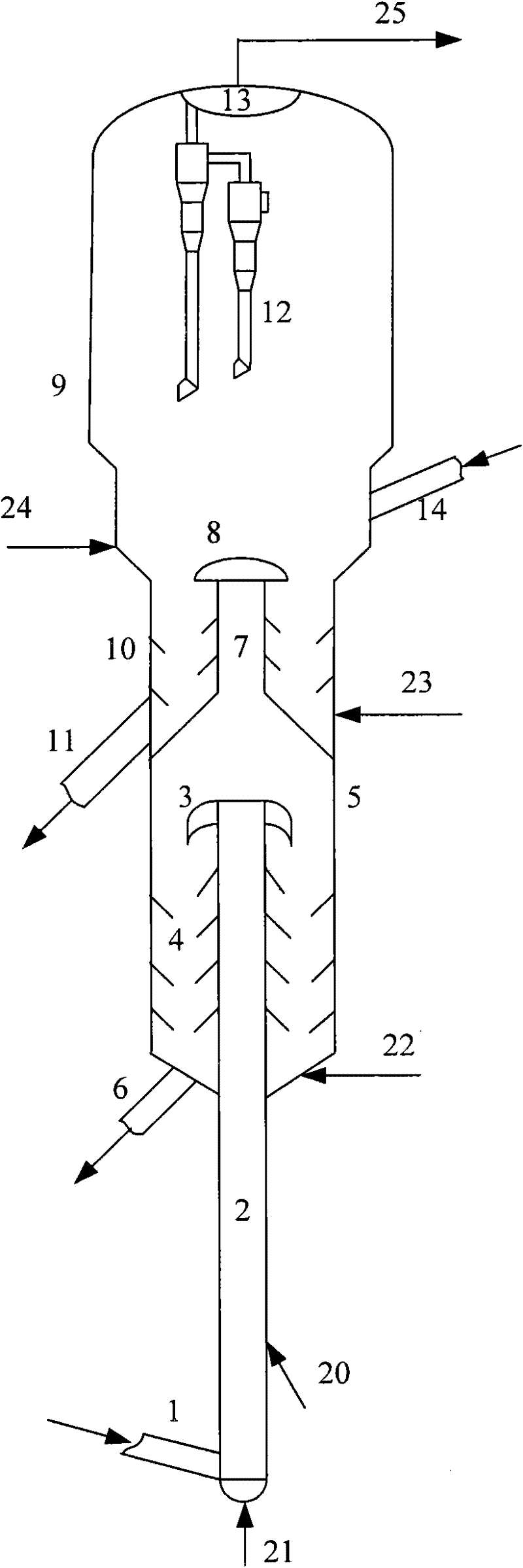

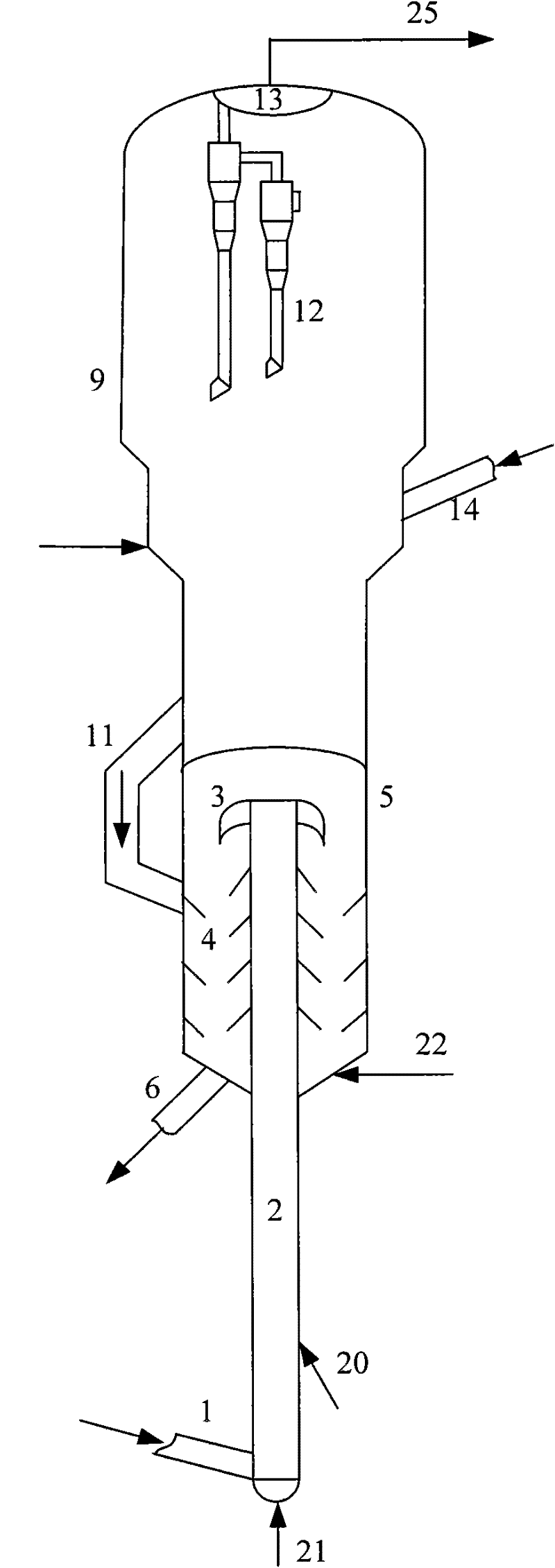

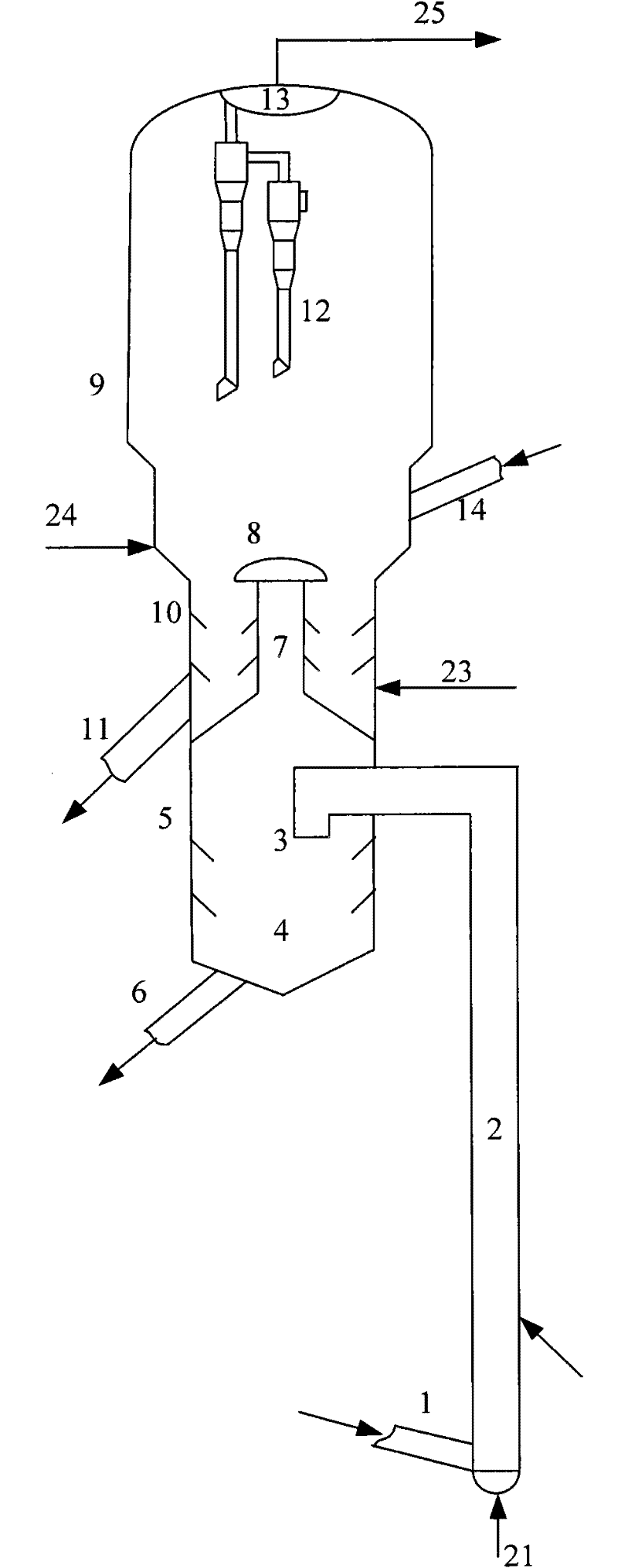

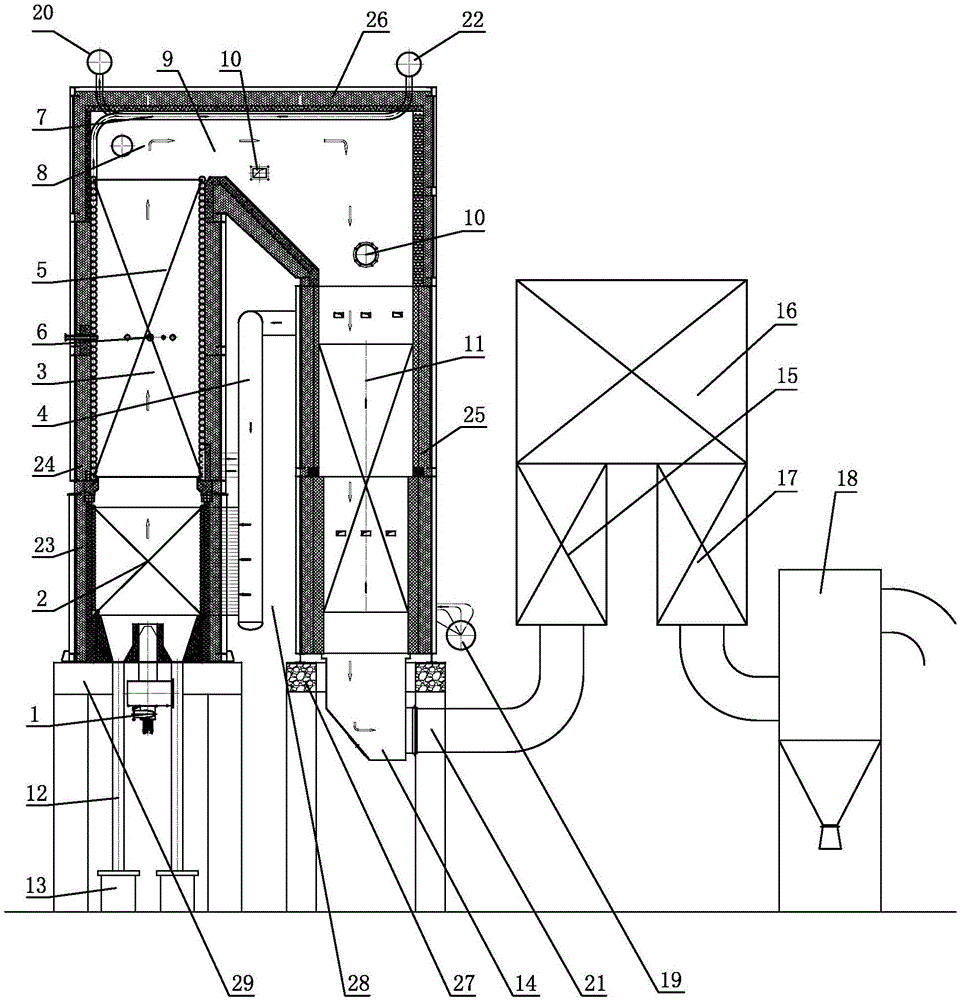

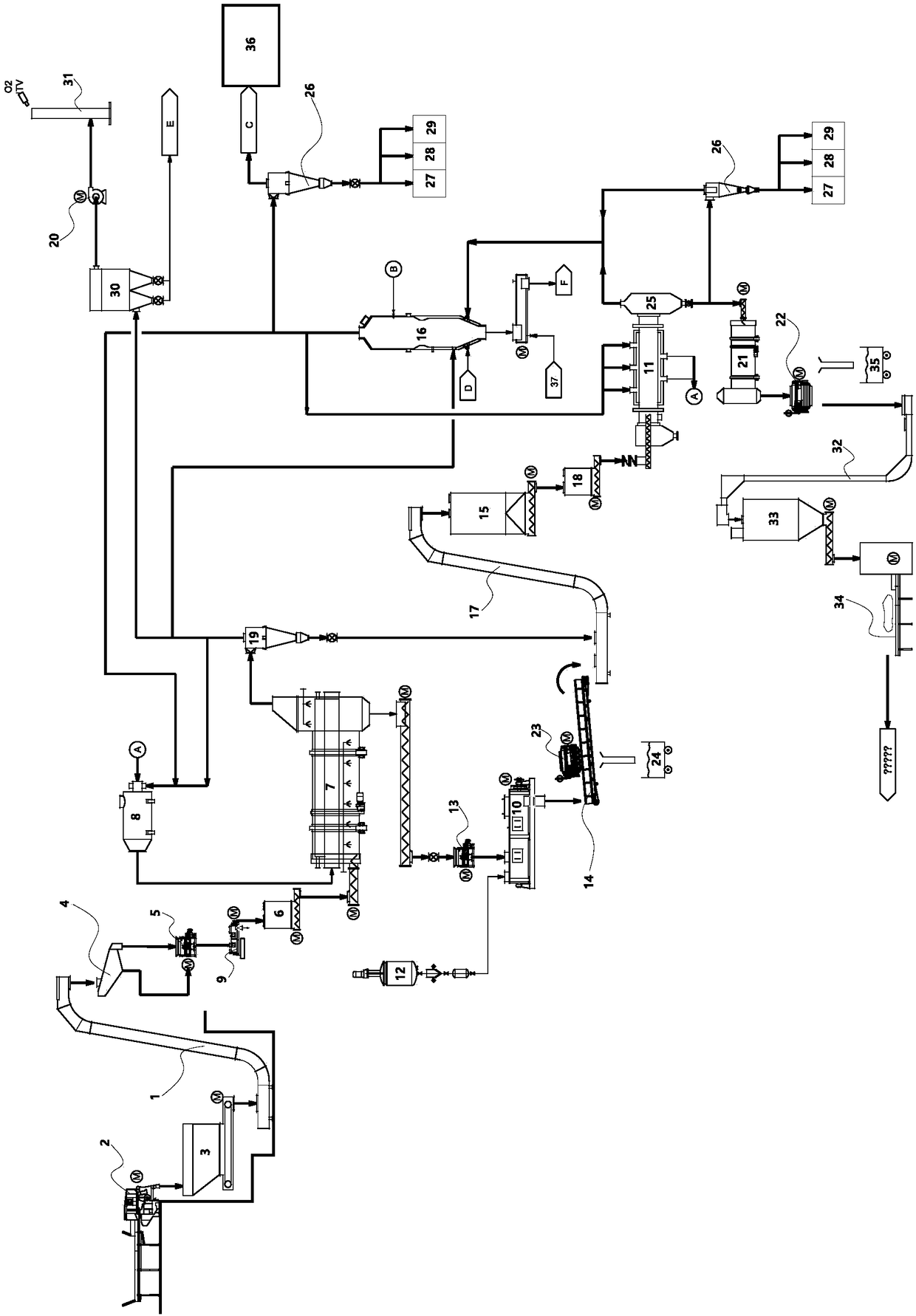

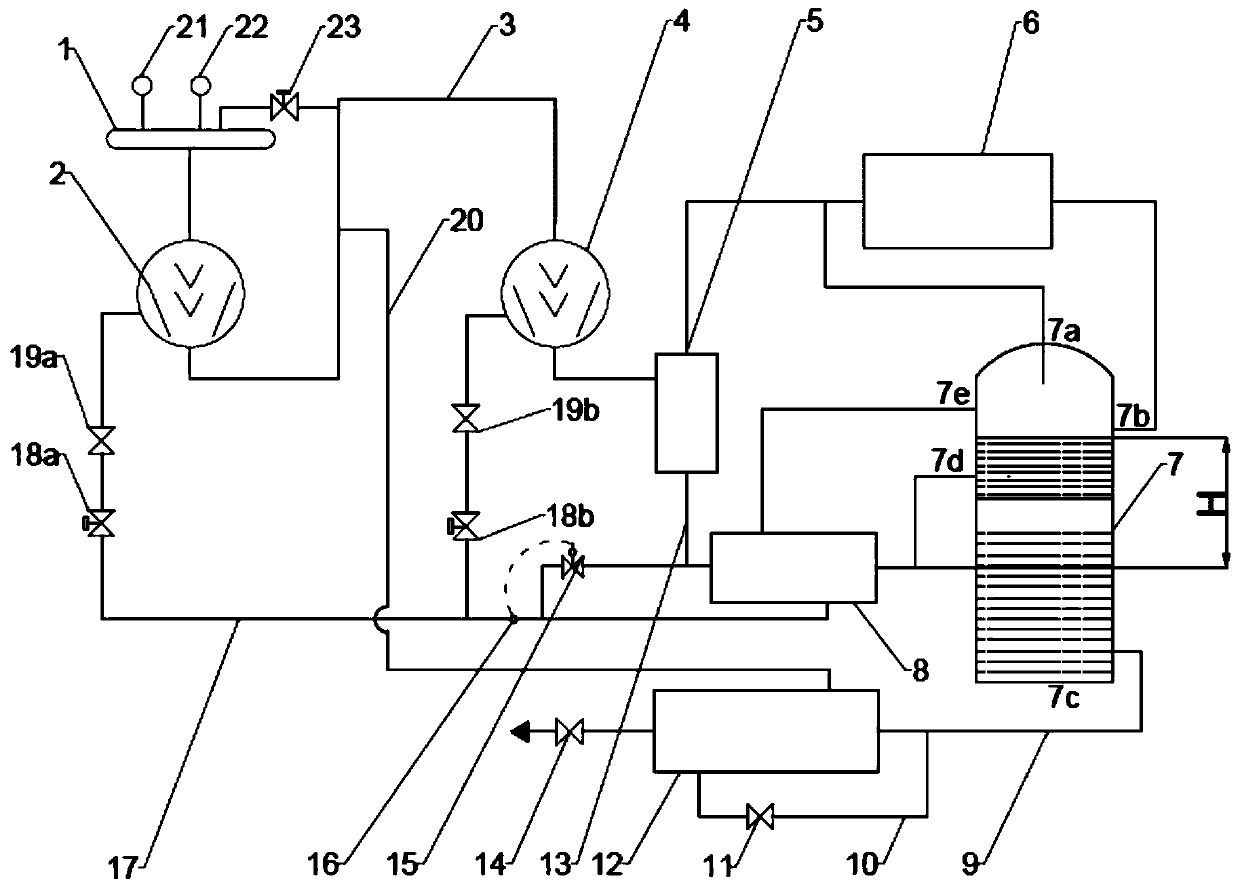

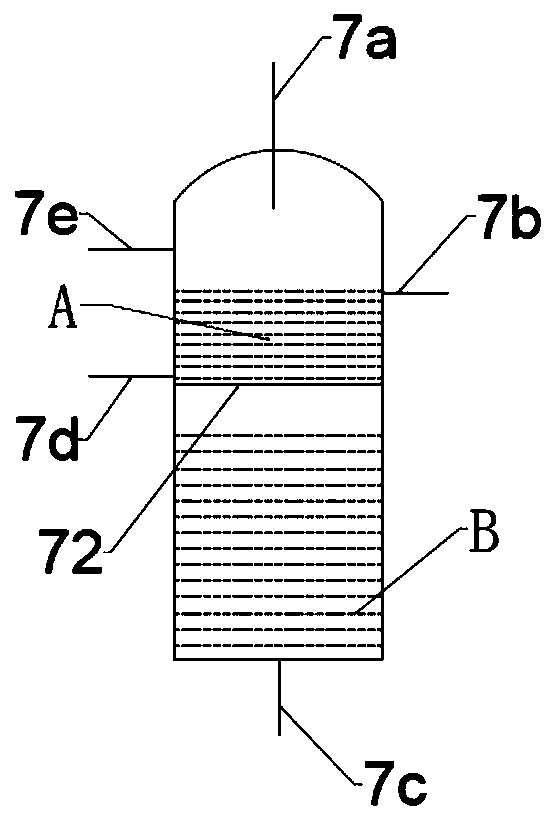

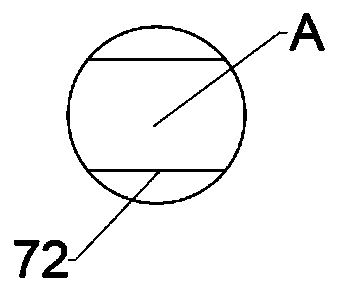

Classified gasification system of solid wastes

PendingCN106765142AReduce loadReduce processing costsAir/fuel supply for combustionIncinerator apparatusAir blowerMoving bed

The invention discloses a classified gasification system of solid wastes. The classified gasification system is formed by connecting a feeding system, a self-flowing type moving bed gasification furnace, a high-temperature plasma torch, a high-temperature reforming purification furnace, a primary air blower, a secondary air blower I, a secondary air blower II, a clean fuel gas draught fan, a heat recycling system, a gas washing tower, a washing and drying tower, a degassing tower, a first de-foaming and defogging device, a second de-foaming and defogging device, a third de-foaming and defogging device and a fuel gas power generation and heat supply system. A heat exchange system is mounted at the tail part of the plasma assisted high-temperature reforming purification furnace, so that heat needed by reaction of the moving bed gasification furnace can be recycled as much as possible, and the comprehensive utilization rate of energy is improved; secondary pollution or blocking problems and the like caused by dioxin, gasified tar and (or) heavy metal, and the like are avoided. The system disclosed by the invention has the characteristics of wide raw material adaptability, high gasification efficiency, no pollution, simplicity in installation and maintenance, easiness of being popularized and the like.

Owner:SOUND ENVIRONMENTAL RESOURCES

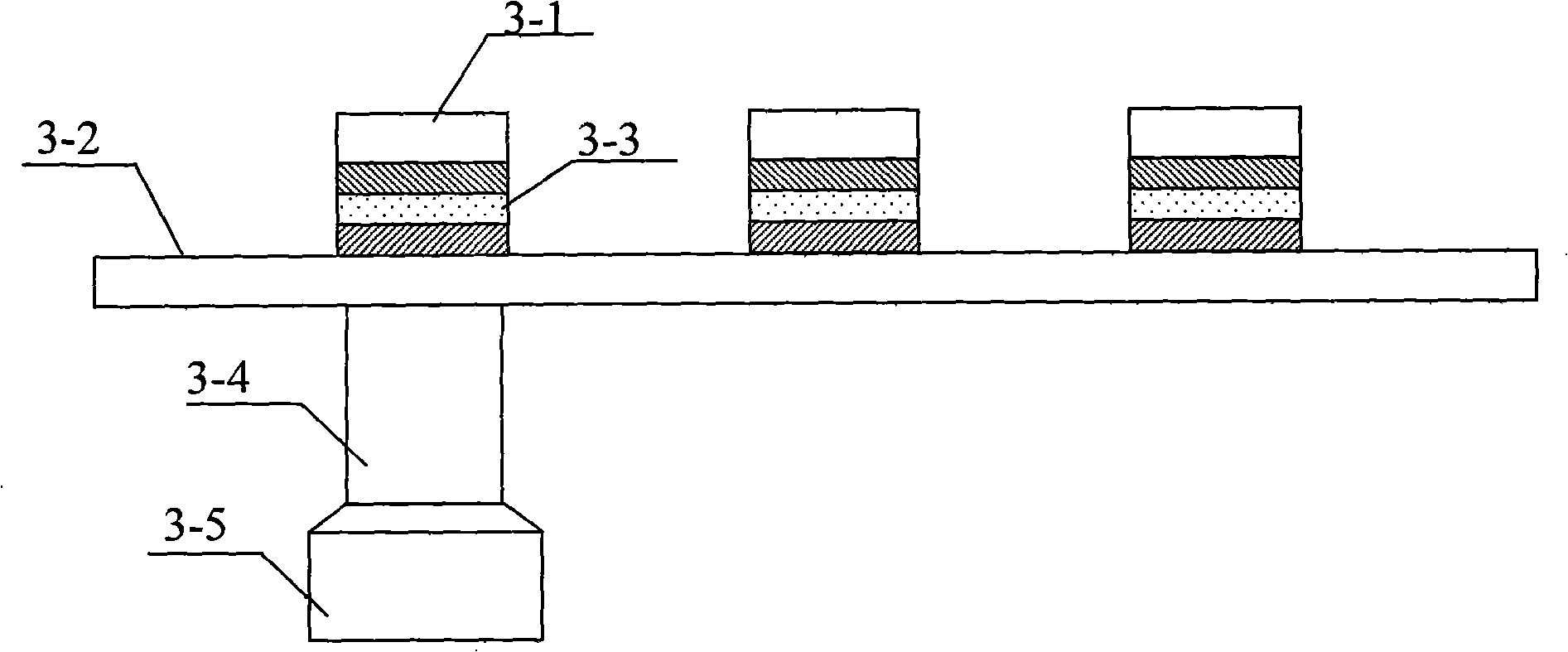

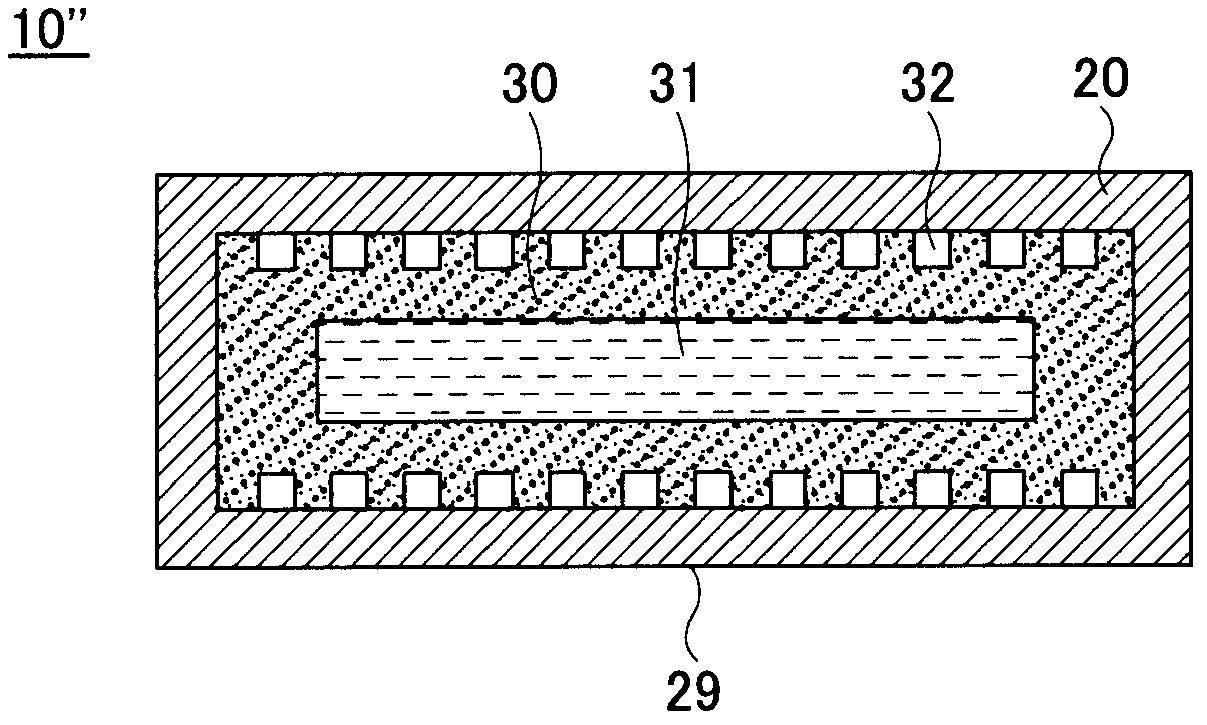

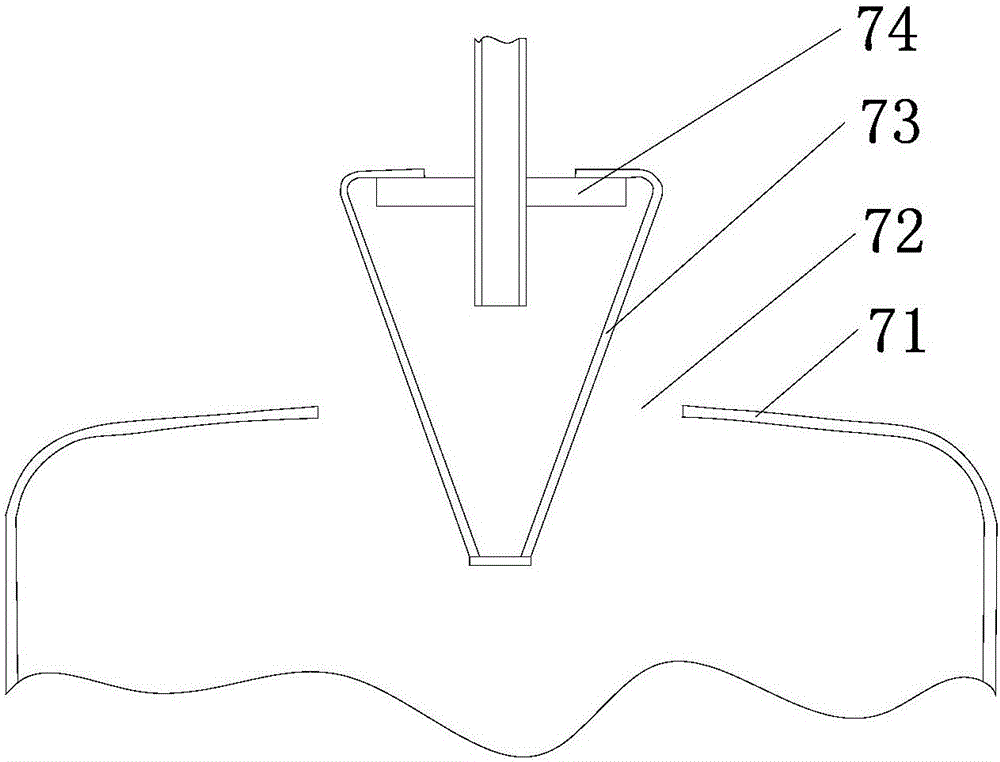

Method of injecting dopant gas

InactiveUS20090145350A1Diffuse fullyFacilitated DiffusionAfter-treatment apparatusPolycrystalline material growthDopantCrucible

According to an dopant-injection method for injecting volatilized dopant gas into semiconductor melt in a crucible (31), the crucible (31) is rotated alternately clockwise and counterclockwise around a support shaft (36) extending in a flowing direction of the dopant gas, so that the dopant gas is blown against the semiconductor melt white the crucible is rotated. Rotating the crucible (31) causes convection currents in the semiconductor melt therein, thereby facilitating diffusion of the blown dopant in the semiconductor melt.

Owner:SUMCO TECHXIV

Ultralow temperature vacuum insulation quick connector and production method thereof

InactiveCN102865428AQuick and safe connection and detachmentAvoid malfunctioningThermal insulationCouplingsLoading armLiquefied natural gas

The invention discloses an ultralow temperature vacuum insulation quick connector and a production method thereof. The connector comprises a pull rod, a vacuum cavity, a first outer pipe, a second outer pipe, a third outer pipe, a piston rod, a first oil orifice, a cylinder and the like. The pull rod is integrated with a jaw. The pull rod can be connected with a piston pin through a connecting shaft. The vacuum cavity is located among the first outer pipe, the second outer pipe, the third outer pipe and an inner corrugated pipe. The first oil orifice is located at the front end of the cylinder. A second oil orifice is located at the rear of the cylinder. The cylinder is connected with the piston rod. A vacuum opening is connected with the third outer pipe and communicated with the vacuum cavity. A counter flange and a connecting flange are welded with two ends of the inner corrugated pipe respectively. A support ring is located in the vacuum cavity between the inner corrugated pipe and the third outer pipe. A guide plate and a guide rod are welded to an annular rotator and fixed on the first outer pipe. By the ultralow temperature vacuum insulation quick connector, fast and safe connection and separation of a pipeline or a loading arm with a tank-truck or a LNG (liquefied natural gas) ship during ultralow-temperature liquid loading and unloading are achieved.

Owner:李宏

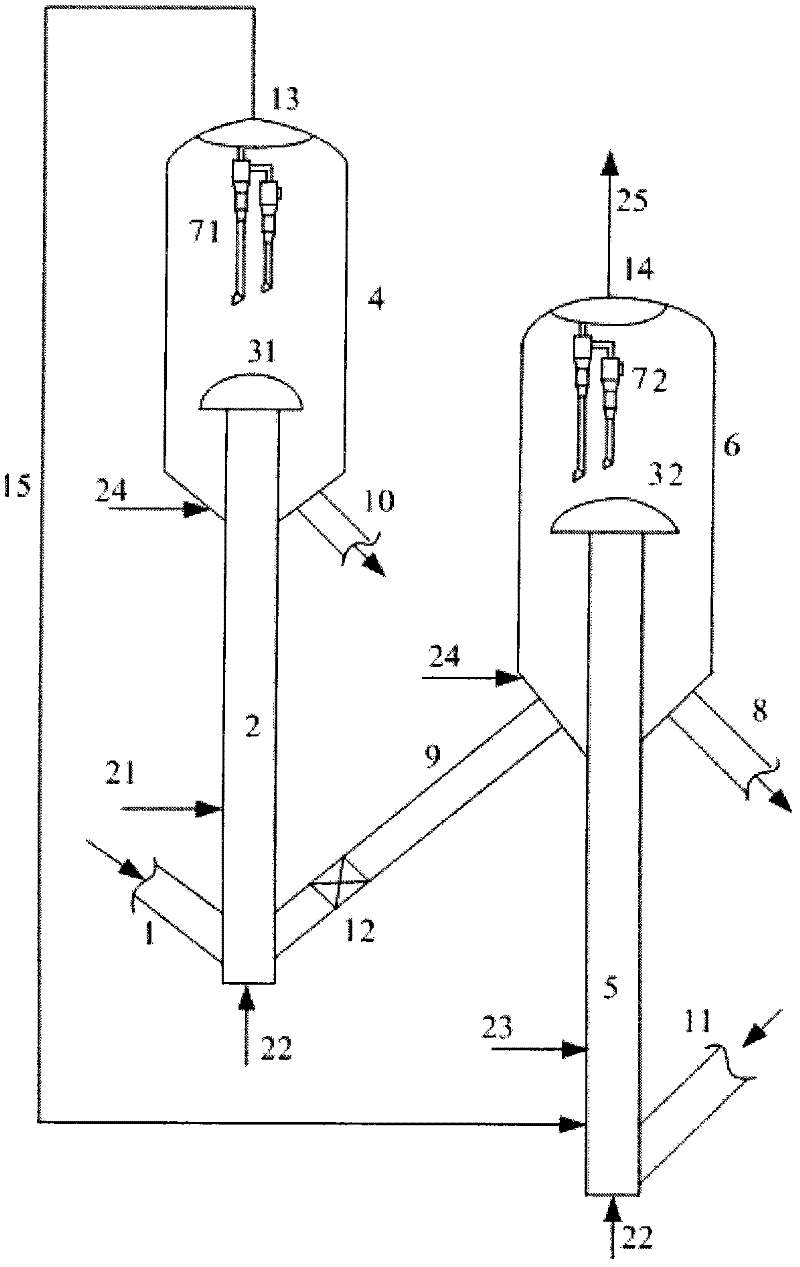

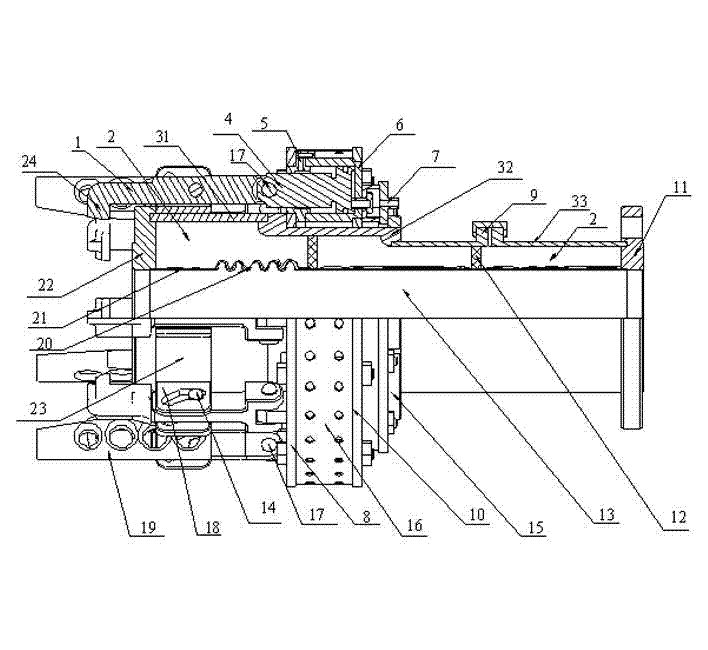

Hydrocarbon oil catalytic cracking method and equipment

ActiveCN102443419AAvoid the problem of insufficient activityAvoid coolingTreatment with plural serial cracking stages onlyFluidized bedOil separation

The invention relates to a hydrocarbon oil catalytic cracking method which is characterized by comprising the following steps of: (1) carrying out first contact reaction on a hydrocarbon oil raw material and a first cracking catalyst in a lifting pipe reactor and carrying out first oil separation on a mixture of oil gas and a catalyst obtained after the first contact reaction; (2) carrying out a second contact reaction on the oil gas obtained after the first oil separation and a newly added second cracking catalyst in a fluidized bed reactor and carrying out second oil separation. The invention also provides hydrocarbon oil catalytic cracking equipment. On one hand, the problem of inadequate activity in the fluidized bed reactor, caused by the great reduction of the activity of the catalyst discharged out of the lifting pipe reactor, can be avoided, on the other hand, because the product obtained after reaction in the lifting pipe reactor is directly conveyed into the fluidized bed reactor without separation, the defect of increase of energy consumption, caused by repeated cooling and gasifying of feed materials can be avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

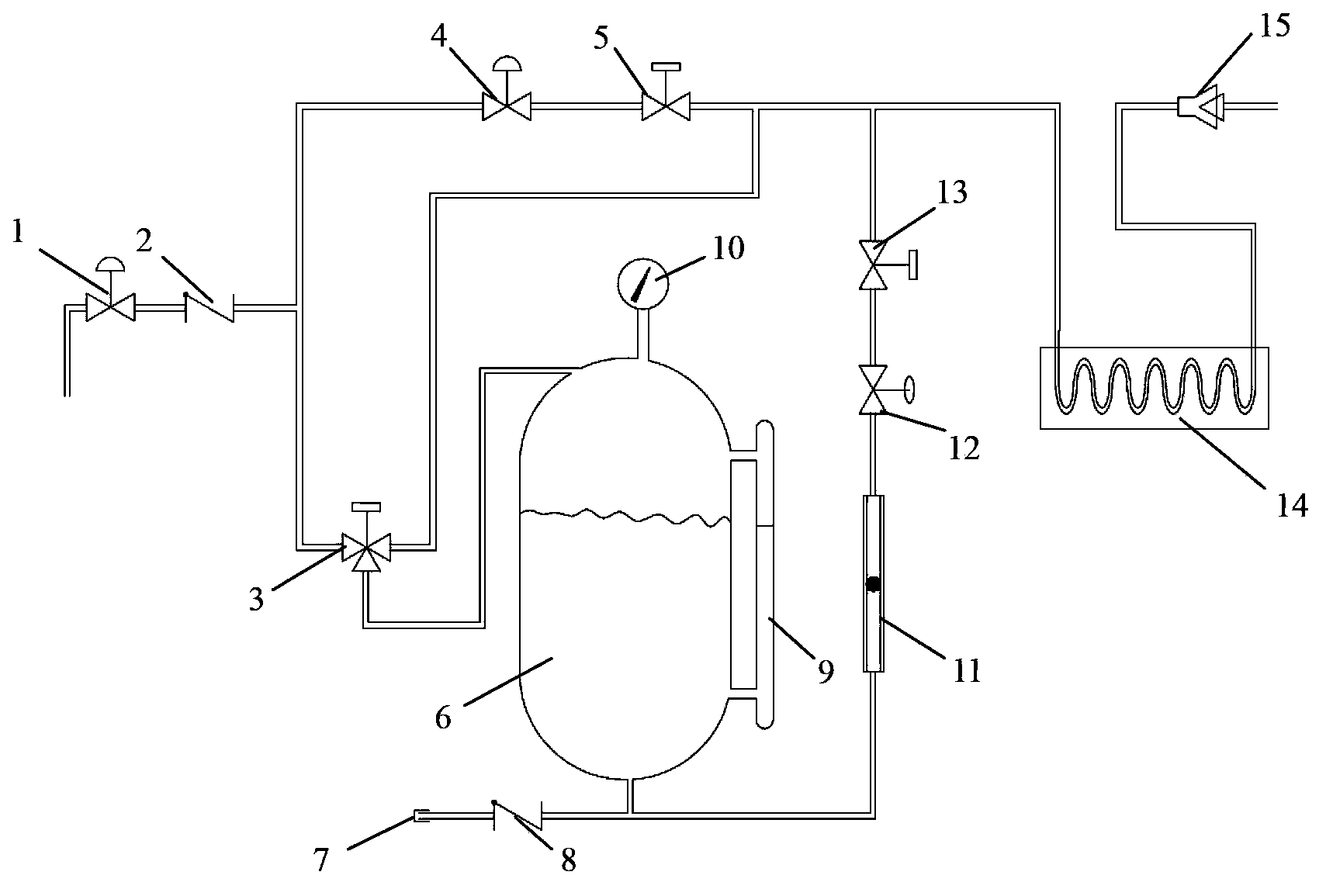

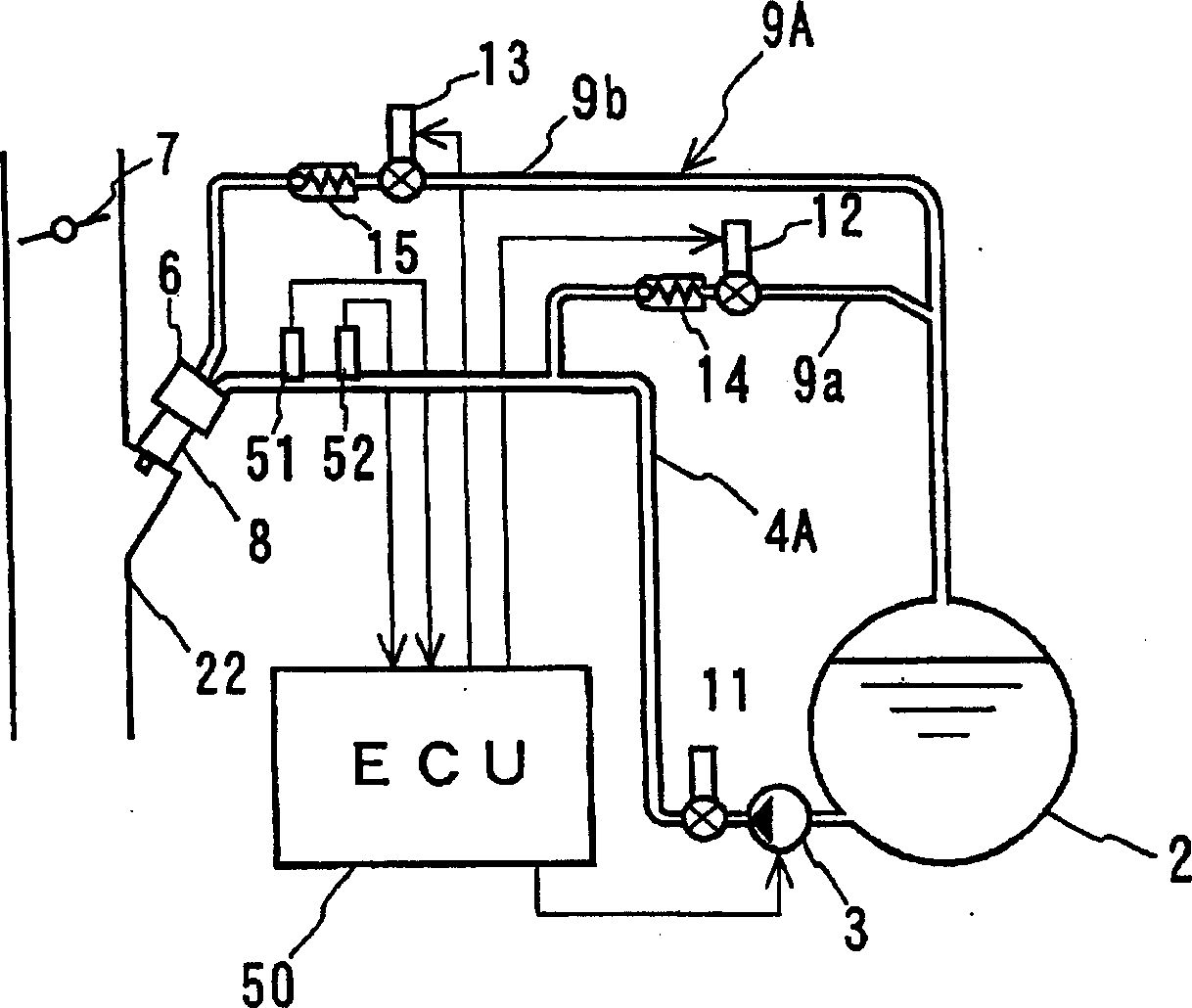

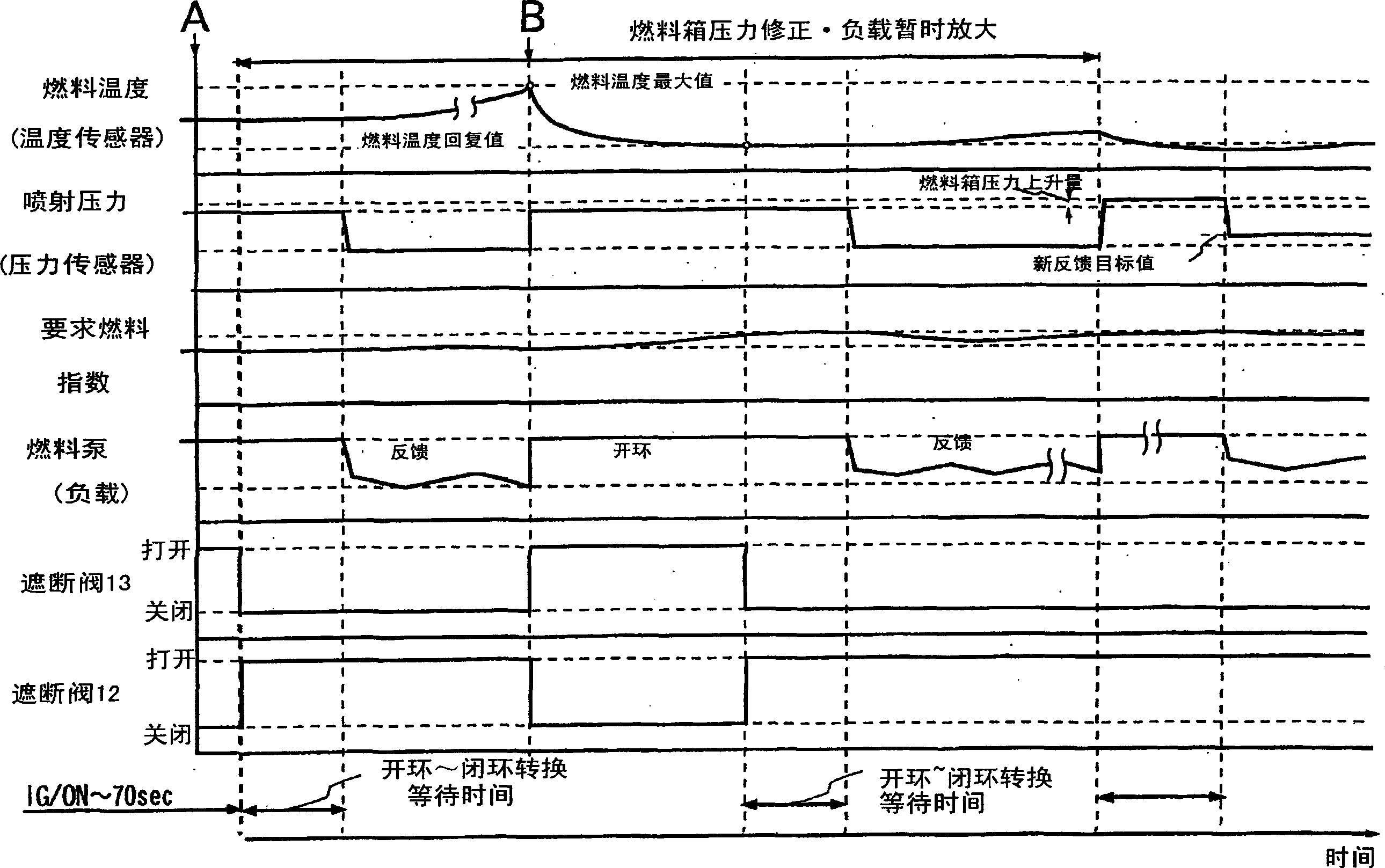

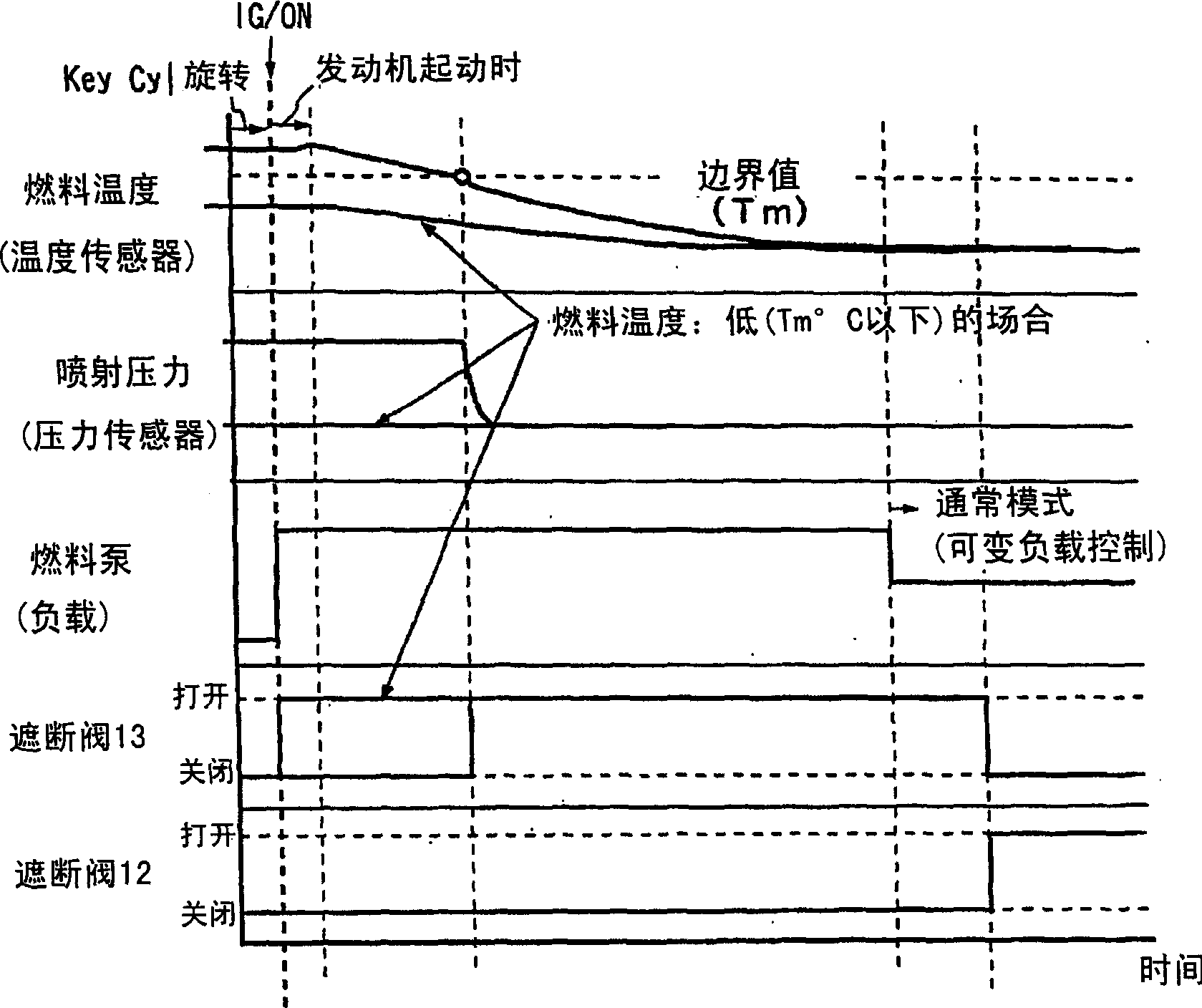

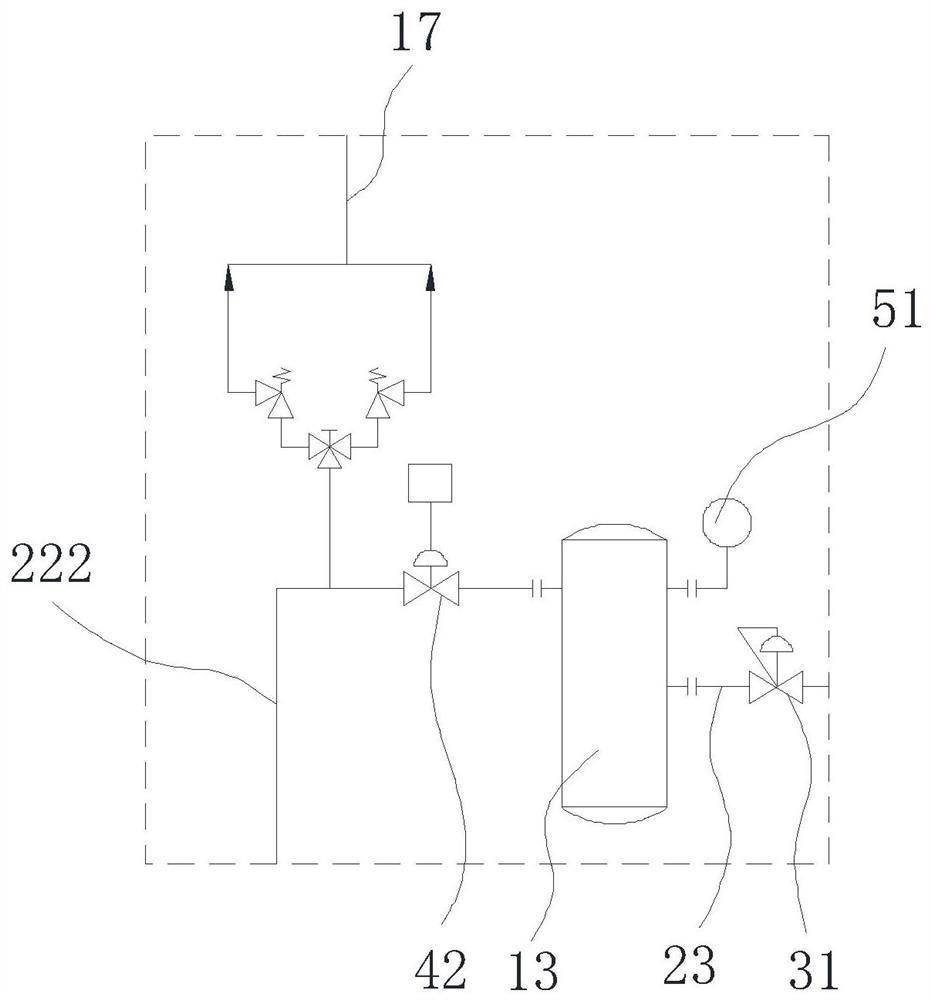

Engine fuel feed device

InactiveCN1847641AEasy output controlCorrect operating conditionsInternal combustion piston enginesLiquid fuel feedersFuel tankVaporization

PROBLEM TO BE SOLVED: To provide an engine fuel supply device that changes over a liquefied gas fuel supply system between a return mode and a returnless mode, avoiding excessive temperature rise in a fuel tank by controlling return fuel to be minimized while surely avoiding the vaporization of supply fuel. SOLUTION: The engine fuel supply device comprises a first fuel return pipeline 9a branching on the way of a fuel supply pipeline and a second fuel return pipeline 9b for returning fuel, not injected by an injector 8, both of which have shut-off valves 14, 15, respectively, and are connected to a fuel tank 2. A fuel pressure sensor 52 and a fuel temperature sensor 51 are arranged in the fuel supply pipeline near the injector 8 and a fuel rail 6. An electronic control unit 50 for detecting their output signals executes control into the return mode when determining that injected fuel may be in a vaporized condition and at starting the engine and into the returnless mode during normal operation.

Owner:NIKKI CO LTD

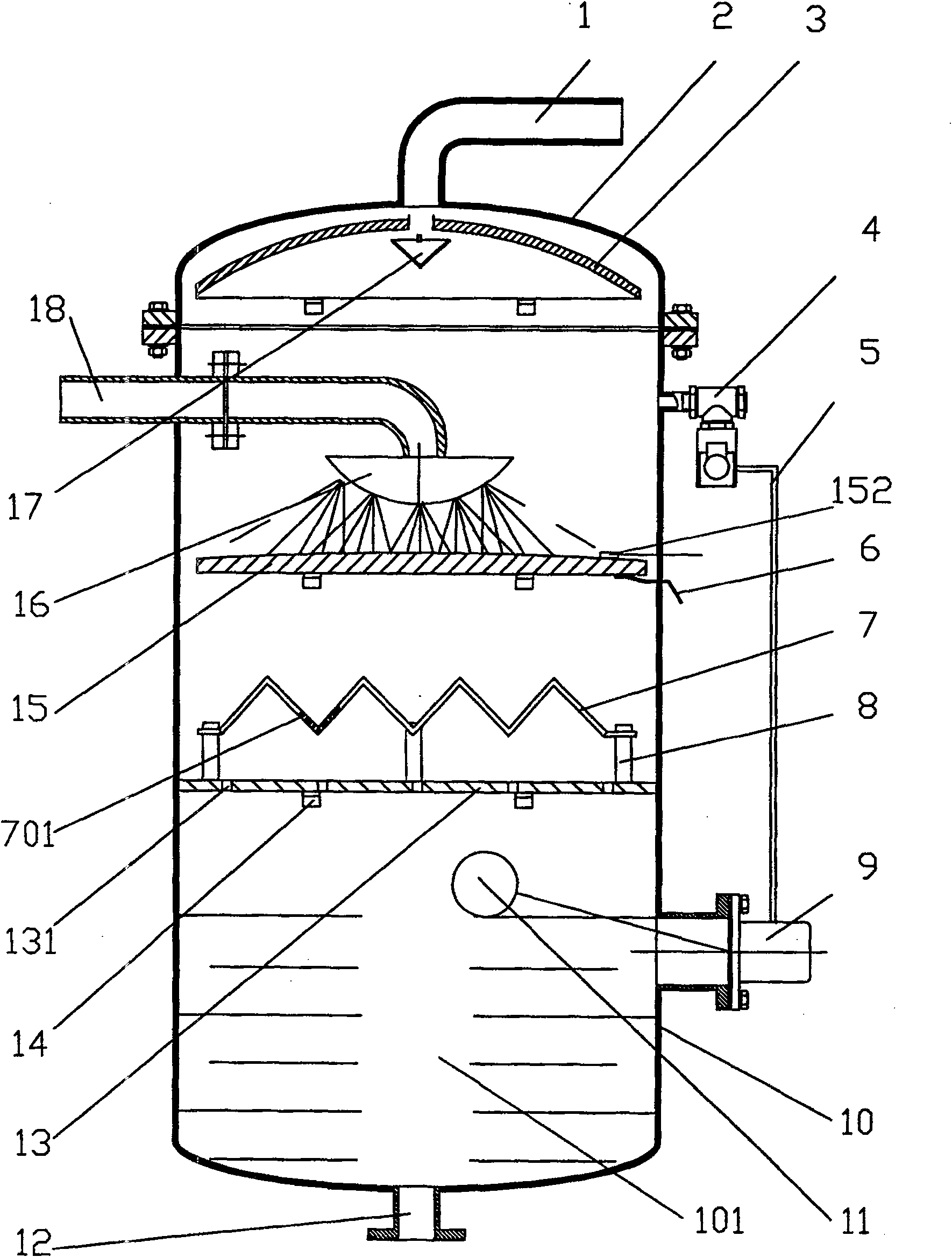

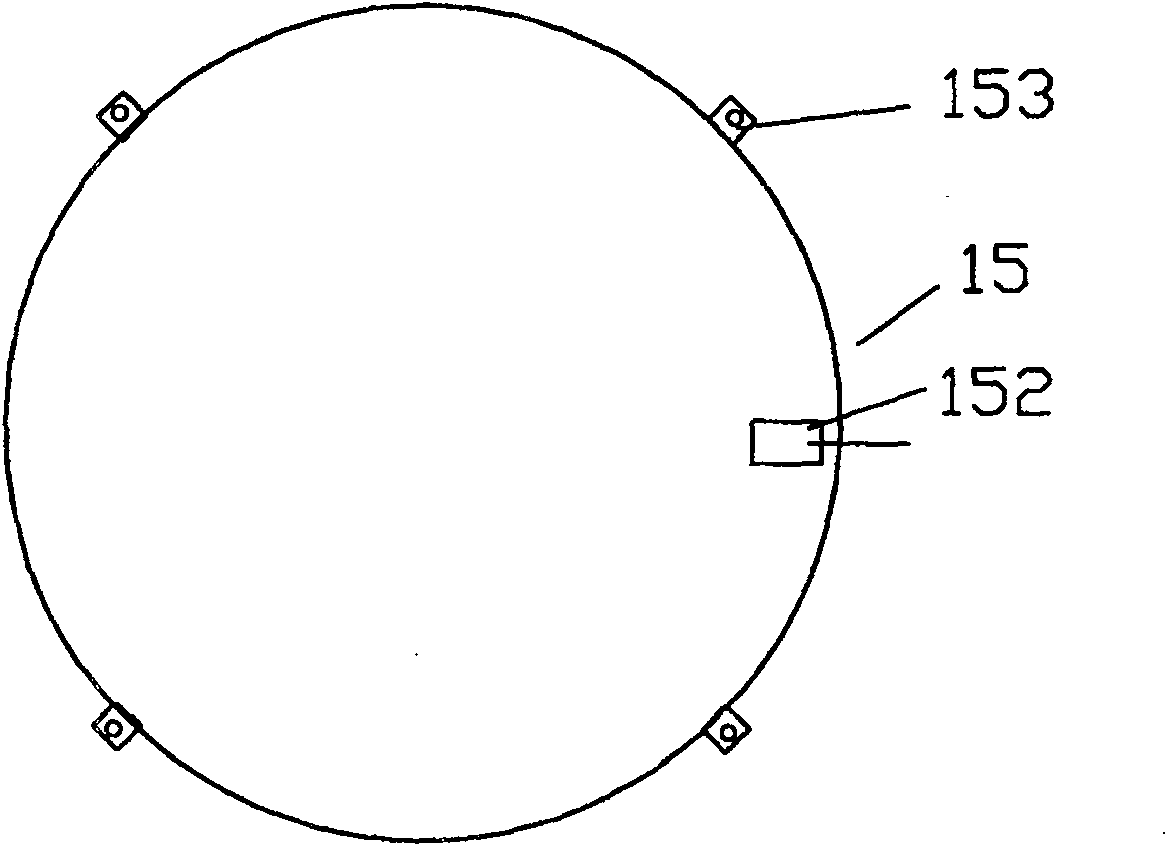

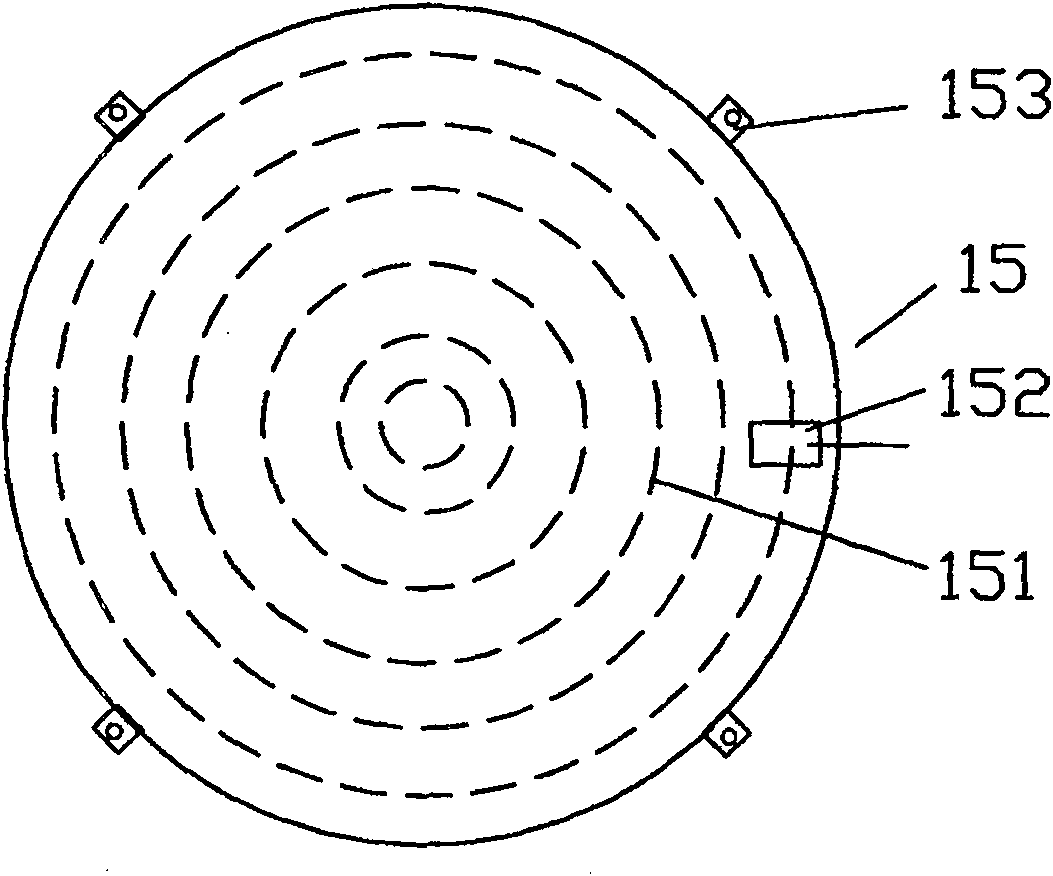

Specific gravity vacuum net oil segregator with built-in electric hot tray

InactiveCN100586524CVaporization fastFast evaporationLiquid degasificationVacuum distillation separationElectricitySprayer

Owner:豆远奎

Low-nitrogen pulverized coal organic heat carrier boiler

InactiveCN105465774AReduce contentBurn evenlyFluidized bed combustionApparatus for fluidised bed combustionAir preheaterHeat carrier

The invention discloses a vertical low-nitrogen pulverized coal organic heat carrier boiler which comprises a burner, a lower part radiation section pipe manifold, an upper part radiation section pipe manifold, a connecting pipe, a hearth, a tertiary air pipe, a roof pipe manifold, an explosion door, a hearth smoke outlet, an access door, a high-low temperature convection bank, ash falling pipes, slag extractors, a longitudinal channel, a high-temperature air preheater, waste heat equipment, a low-temperature air preheater and a dust collector, wherein the hearth is internally provided with the lower part radiation section pipe manifold, the upper part radiation section pipe manifold and the roof pipe manifold; the high-low temperature convection bank is arranged in the longitudinal channel communicated with the hearth smoke outlet; the high-low temperature convection bank, and the connecting pipe, the lower part radiation section pipe manifold, the upper part radiation section pipe manifold and the roof pipe manifold are sequentially communicated to form a closed heating medium circulation system. Heating surfaces are arranged in the whole hearth, so that a noncoking state can be ensured at nominal output. In addition, the burning is uniform, the temperature difference between the front and back is low, so that the reduction of the content of NOx can be facilitated. The connecting pipe is arranged outside the hearth, and is free from heat, so that heat transfer oil can be prevented from being gasified.

Owner:HANGZHOU JUNENG BOILER

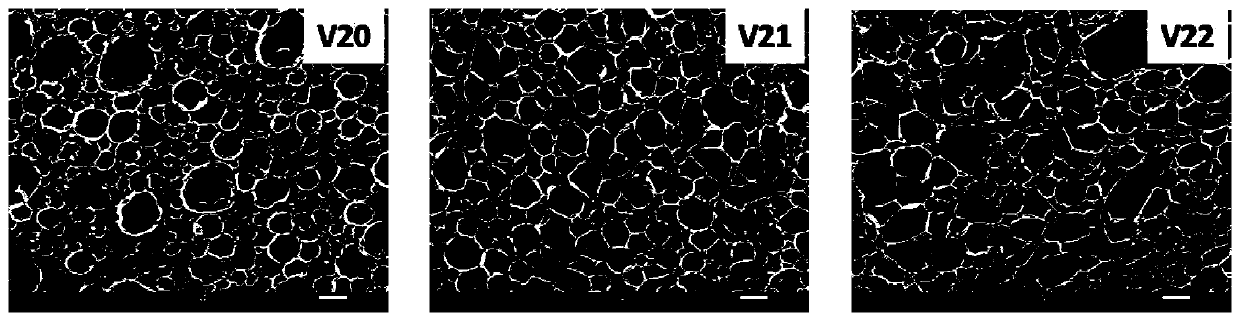

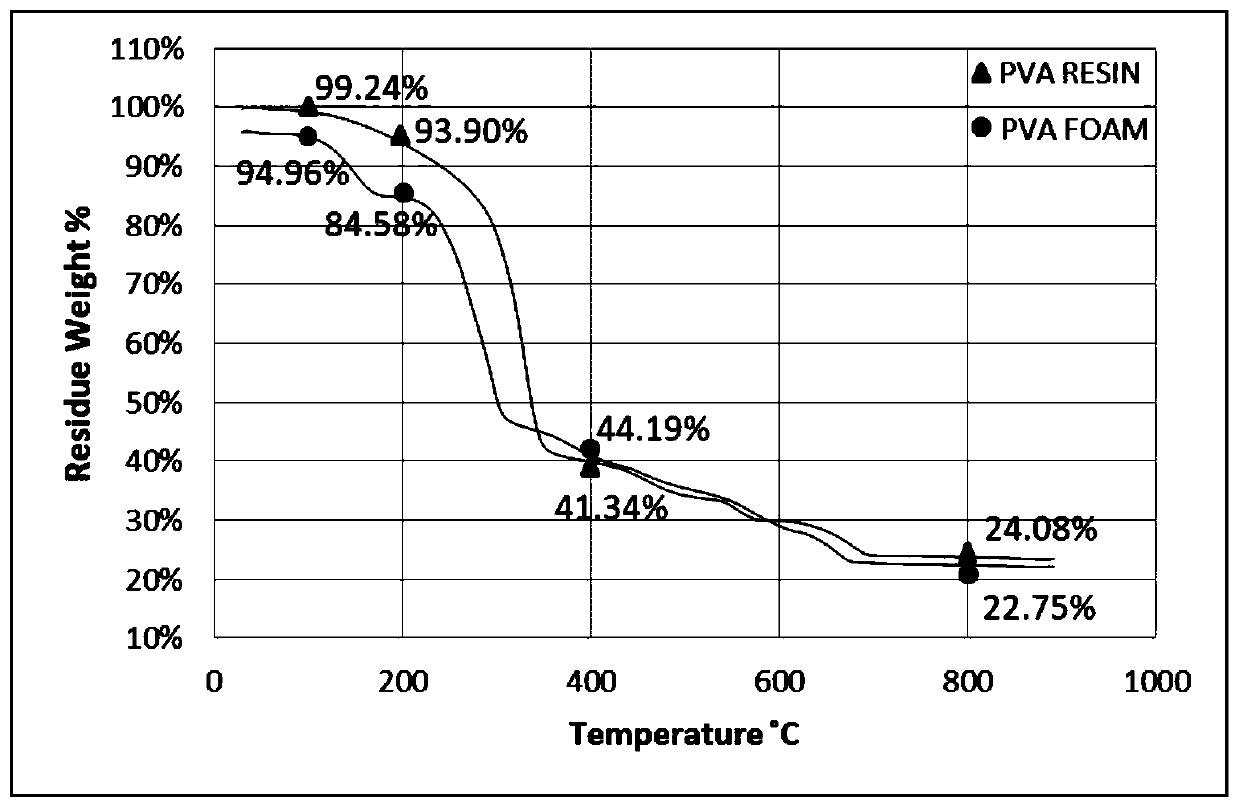

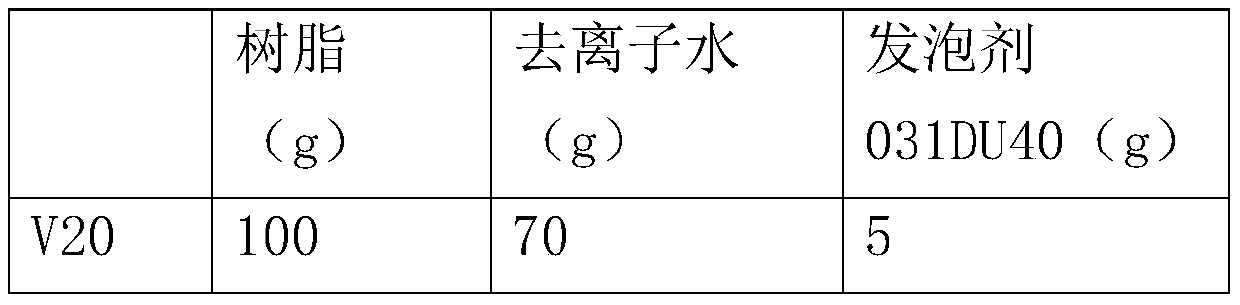

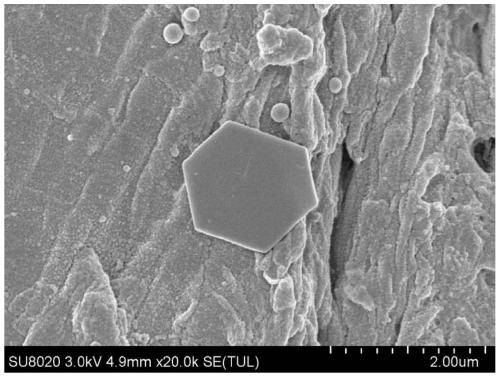

PVA foaming material and foaming method thereof

The invention discloses a PVA foaming material and a foaming method thereof. The foaming material is provided to overcome the difficulty of continuous extrusion foaming of existing. The hydrolytic characteristic of the PVA is utilized to make the PVA foamed at a temperature lower than the boiling point of PVA in a hydrolytic swelling state. Water is used as a medium, a micro-porous expansion foaming agent is added in a swelling state, and foaming is carried out at the temperature below the boiling point of the PVA, so that PVA gasification is avoided, extrusion molding is realized, and the operation process is simple; and a prepared finished product has the advantages of light weight (low density), high compressive strength (reaching up to 259 KPa), high degradable component content and environmental friendliness.

Owner:SRJJ LTD

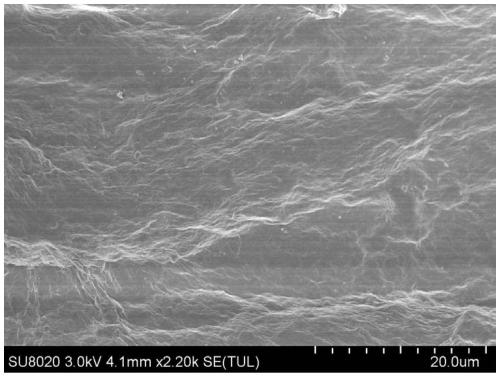

Magnesium-aluminum layered double hydroxide/graphene oxide/wood-based composite material as well as preparation method and application thereof

InactiveCN111267193AReduce energy consumptionWith early warning functionPressure wood treatmentWood treatment detailsMagnesium saltComposite lumber

The invention belongs to the technical field of wood composite materials, and provides a preparation method of a magnesium-aluminum layered double hydroxide / graphene oxide / wood-based composite material, which comprises the following steps: immersing wood in an aqueous solution containing magnesium salt, aluminum salt and urea, and carrying out a reaction under low-temperature hydrothermal conditions; and carrying out vacuum drying on the wood for 12 h at the temperature of 50 DEG C, thereby preparing the magnesium-aluminum layered double hydroxide modified wood; adding graphene oxide into water, and carrying out mechanical stirring and ultrasonic treatment to obtain a graphene oxide suspension; dropping the graphene oxide suspension on the surface of the wood, drying the wood at 50 DEG C for 3 hours, and repeating the operations for 3-6 times. The composite wood with fire early warning and flame retarding functions is prepared by adopting a low-temperature hydrothermal reaction combined with a dripping method, the process is simple, the energy consumption is low, the material structure is stable, and meanwhile, the synergistic flame retarding effect of graphene oxide and inorganicmetal is realized.

Owner:ZHEJIANG FORESTRY UNIVERSITY

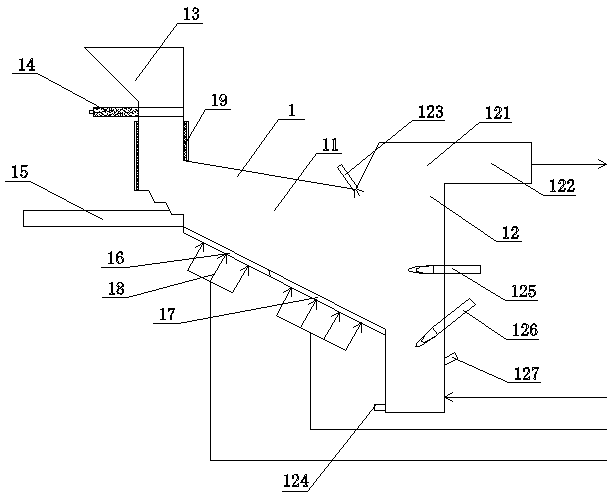

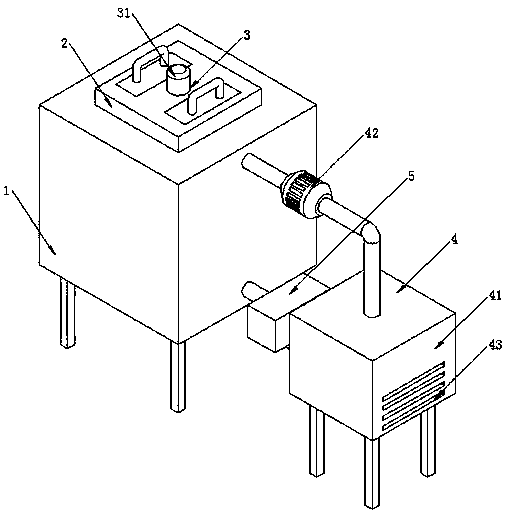

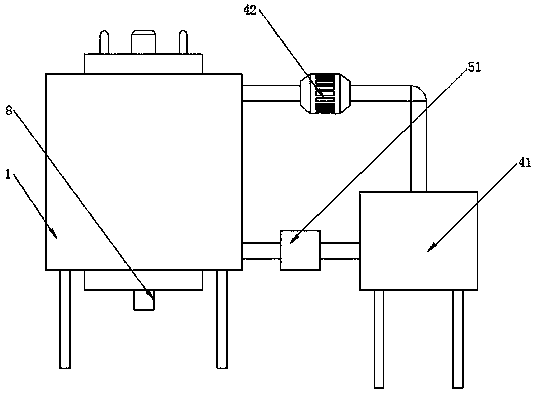

Device for preparing clean coal by thermally decomposing, gasifying and semi-carbonizing waste

PendingCN108467740AReduce moisture contentReduce contentDirect heating destructive distillationBiofuelsSpontaneous combustionFood additive

The invention discloses a device for preparing clean coal by pyrolyzing, gasifying and semi-carbonizing a waste. The device comprises a material supply system, a material pre-treatment system, a thermal decomposition and semi-carbonization device, a combustion and gasification device, a food additive addition device, a clean coal cooling and collecting system and a synthesis gas reuse system, wherein the material supply system and the material pre-treatment system are connected, a food additive is arranged in the food additive addition device, both the food additive addition device and the material pre-treatment system are connected with the thermal decomposition and semi-carbonization device, both the synthesis gas reuse system and the thermal decomposition and semi-carbonization device are connected with the combustion and gasification device, and the thermal decomposition and semi-carbonization device is connected with the clean coal cooling and collecting system. The device for preparing the clean coal by pyrolyzing, gasifying and semi-carbonizing the waste is simple in structure, produces the clean coal by fully using the low-grade coal and the agricultural waste, and effectively saves the energy, the surface of the powdered coal is coated with an addition biomass, the combustion efficiency is stable, the gas emission is low, the spontaneous combustion is prevented, and the occurrence of fire and explosion is avoided.

Owner:李奎范 +4

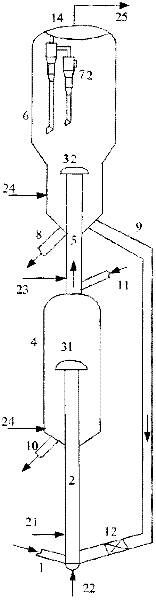

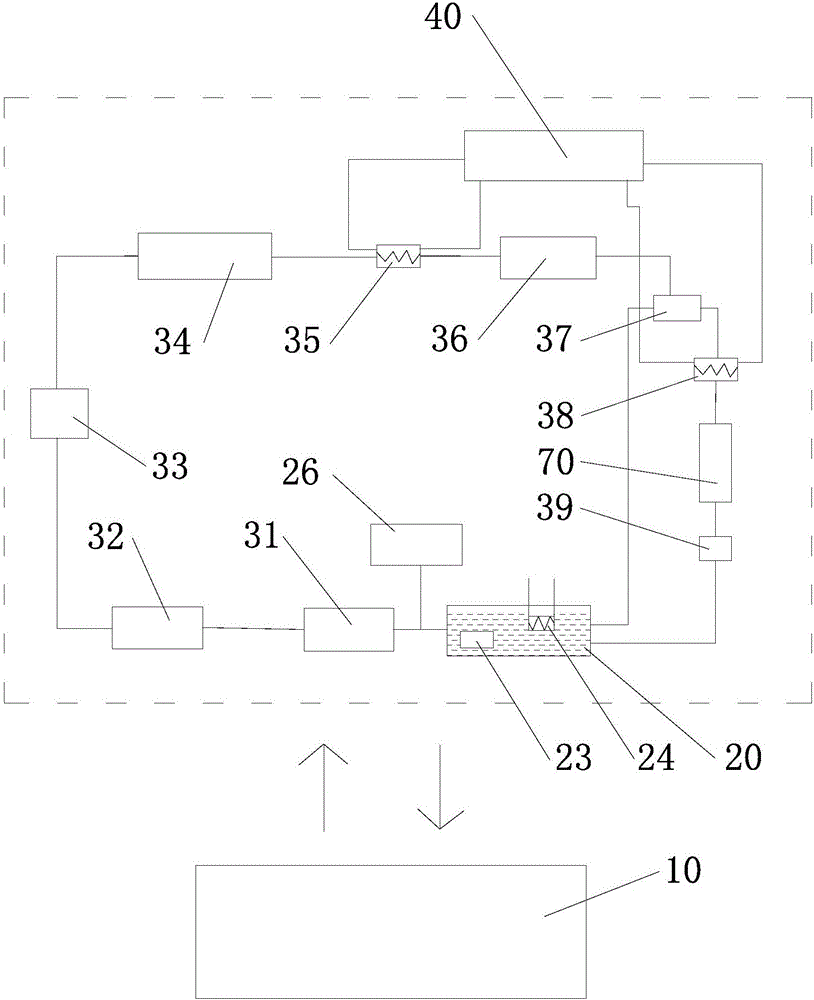

Instrument detection device

ActiveCN106153161AReduce testing costsPrevent gasificationTesting/calibration apparatusCalorimeterControl systemInlet valve

The invention provides an instrument detection device. The instrument detection device comprises a control system, a sealing water tank, a water pump, a pressure stabilizing module, a water inlet valve, an instrument clamping device, a first cooler, a standard flow meter and a reversing valve, wherein the reversing valve comprises a first water outlet and a second water outlet; the first water outlet is connected with a water return port of the sealing water tank; a second cooler is connected onto the second water outlet; a weighing module is connected onto a water outlet of the second cooler; a control valve is connected onto a water outlet of the weighing module; a water outlet of the control valve is connected with the water return port of the sealing water tank; the sealing water tank is further connected with a turbocharging heating pump. With the adoption of the detection device, the accuracy and the durability of a heat meter can be detected, the accuracy and the durability of a water meter can further be detected, the heat meter or the water meter can be detected with a standard meter method as well as a weighing method, the device has multiple purposes, and the detection cost is relatively low.

Owner:泉州七洋机电有限公司

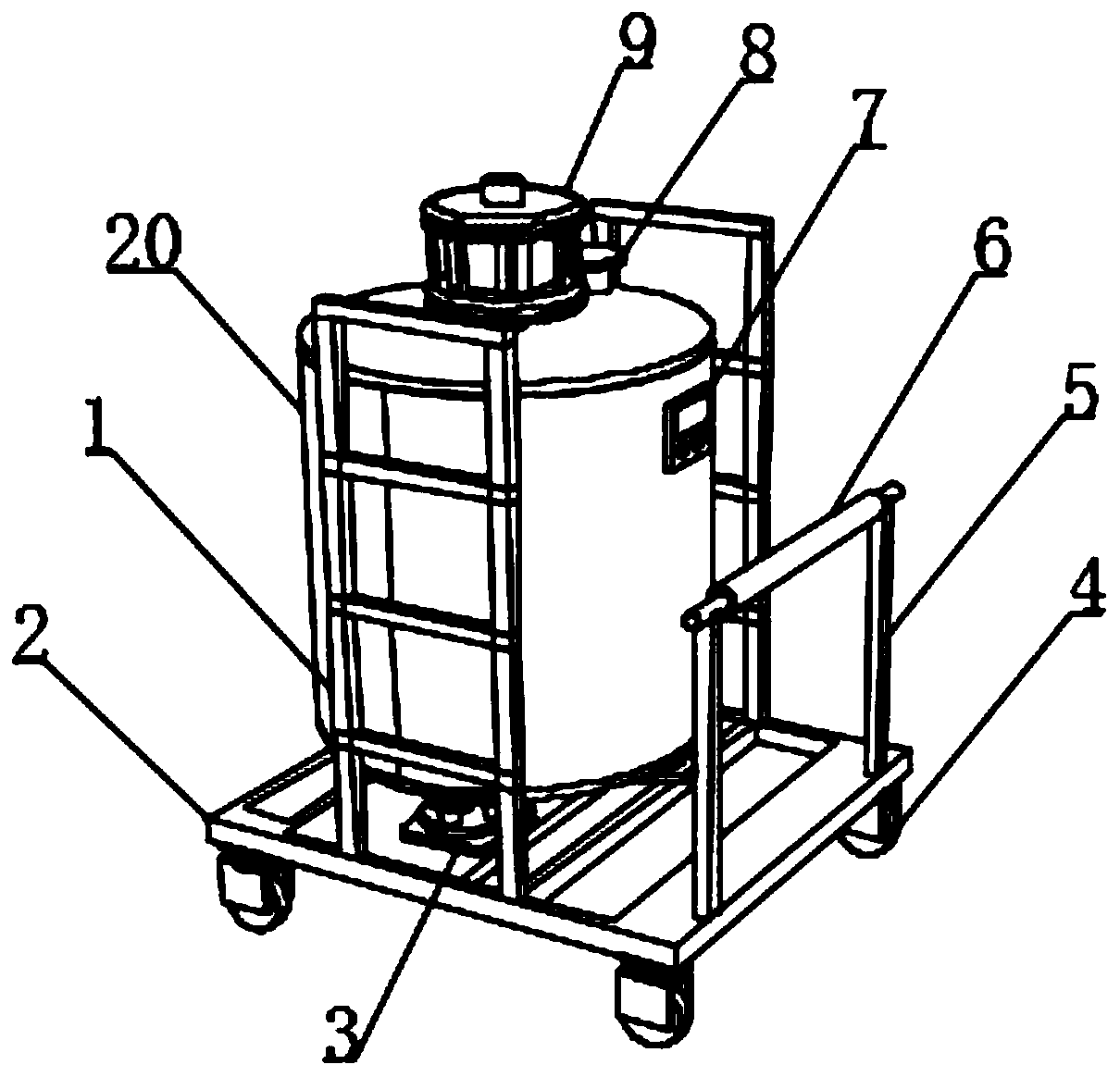

Movable carbon dioxide storage tank used for coal mine

InactiveCN110145683APrevent gasificationEasy to storeVessel wallsContainer filling methodsStable stateAgricultural engineering

The invention discloses a movable carbon dioxide storage tank used for a coal mine, and relates to the technical field of carbon dioxide storage equipment. The movable carbon dioxide storage tank usedfor the coal mine comprises a movable frame and a storage tank body arranged on the movable frame. Ladder frames are fixedly arranged on the two sides of the upper end of the movable frame. A pushinghandle is fixedly arranged at one end of the movable frame. An air compressor is fixedly arranged above the storage tank body. A connecting pipe is fixedly connected between the air compressor and the storage tank body. An electromagnetic valve is fixedly arranged on the side face of the connecting pipe. According to the movable carbon dioxide storage tank used for the coal mine, the storage tankbody, the connecting pipe, an air pressure sensor, the air compressor, the electromagnetic valve and a control processor are arranged so that the air pressure in the storage tank body can be monitored, regulated and controlled in real time and is kept stable; and the situation that liquid carbon dioxide stored in the storage tank body is gasified due to the fact that the air pressure in the storage tank body is lower than a preset value range is prevented, and the liquid carbon dioxide can be better stored in the storage tank body.

Owner:GUIZHOU UNIV

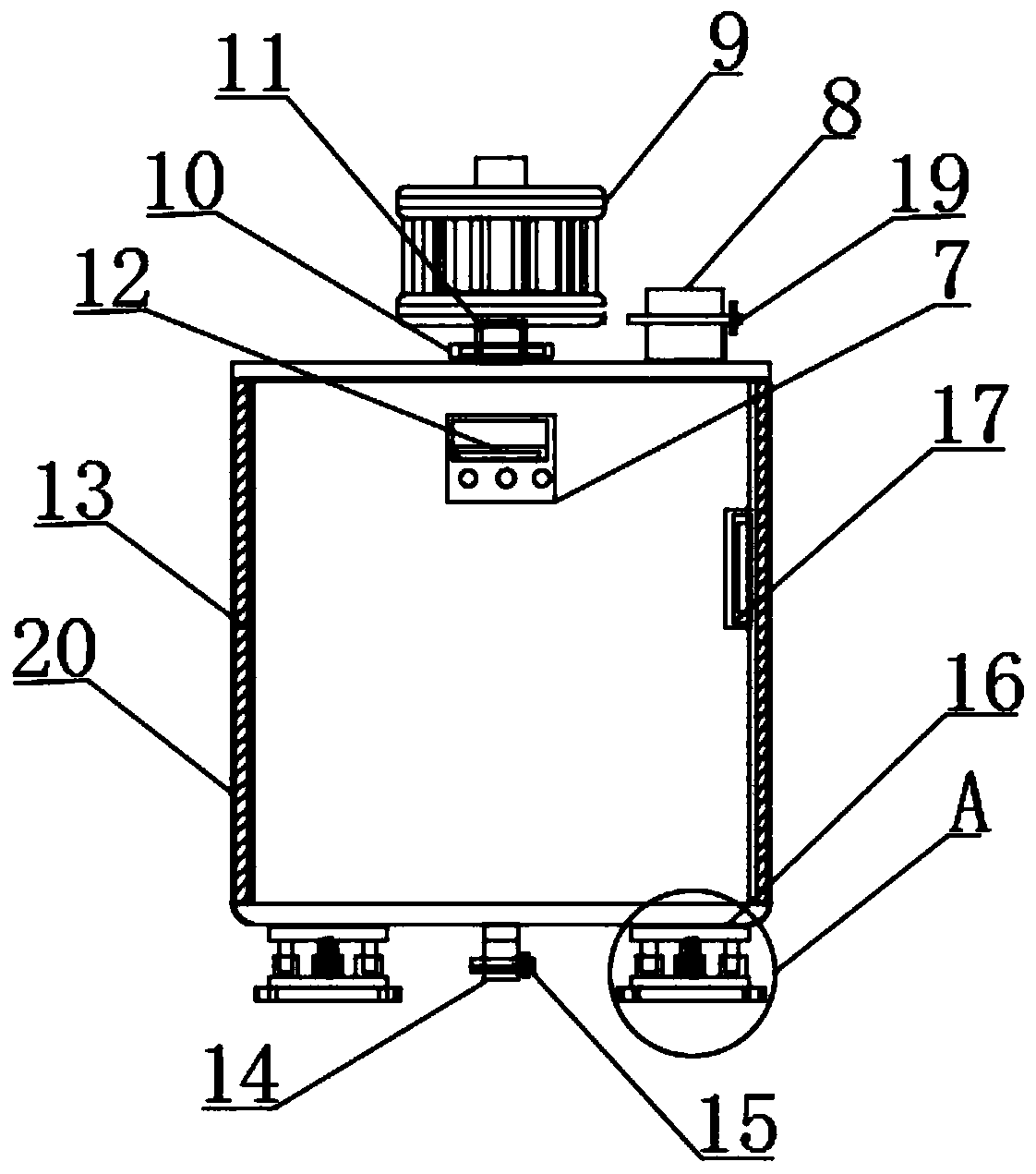

Stirring and condensing device for preparing acrylic ester and silicon-acrylic compound emulsion

PendingCN109224951AFast dissolutionFully contactedTransportation and packagingRotary stirring mixersEmulsionElectric machinery

The invention discloses a stirring and condensing device for preparing acrylic ester and silicon-acrylic compound emulsion. The stirring and condensing device comprises a rectangular outer box, a rectangular inner box, a stirring component, a condensing component, a throttling component, an electric heating tube, a separating plate and a liquid outlet pipe. The rectangular outer box is sheathed atthe outer side of the rectangular inner box. The rectangular inner box is provided with the stirring component. One side of the rectangular outer box is provided with the condensing component. The stirring component comprises a servo motor, a filtering plate, a rotating shaft a, a stirring rod, a first straight gear, a second straight gear, a third straight gear, an extruding wheel a, an extruding wheel b, a rotating shaft b and a rotating shaft c. The stirring and condensing device is beneficial to improve a dissolution rate of a material, and realizes more adequate contact between the materials;is beneficial to continuous condensing work, and capable of preventing gasifying solution because of an excessively high heating temperature, and transmitting heat through cooling liquid, enabling the condensing effect to be more uniform; and beneficial to reduce a flow rate of refrigerant fluid, and capable of enabling time of the refrigerant fluid remained in a spiral pipe to be longer, andimproving the refrigeration effect.

Owner:彭骁

Two-stage compression refrigerating unit for multi-temperature refrigeration storage and control method thereof

InactiveCN111336748AReduce volumeNo loss of cooling capacityCompressorMechanical apparatusOil separationRefrigerant

The invention discloses a two-stage compression refrigerating unit for a multi-temperature refrigeration storage and a control method thereof. The two-stage compression refrigerating unit comprises alow-pressure compressor unit, a high-pressure compressor unit, an oil separator, a condenser, a high-pressure liquid storage device, a subcooler and an oil cooler. An oil cooling loop of the oil cooler uses the gravity difference between a high-level-energy refrigerant liquid and gas as power, and the reliable and economical oil cooling circulation is achieved; a bypass and a flow regulating valveare arranged between an oil outlet pipeline and an oil return main pipeline of the oil separator to accurately control the oil supply temperature of a compressor; and two different working modes areset to solve the problem that due to the frequent changes and the seasonal changes of the load of each storehouse of the multi-temperature refrigeration storage, the too high return air pressure of arefrigerant possibly occur to easily cause the damage of the high-pressure compressor unit.

Owner:ANHUI MELUCK REFRIGERATION EQUIP

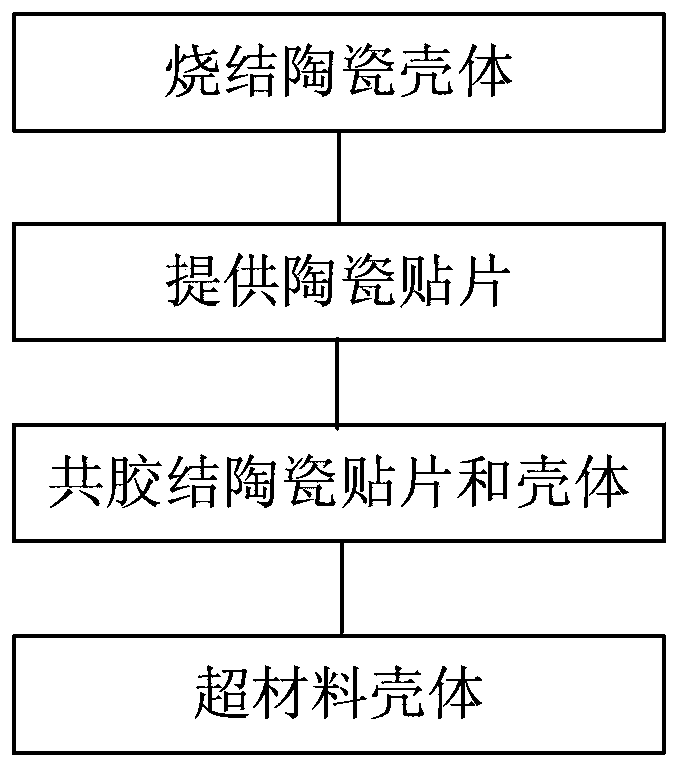

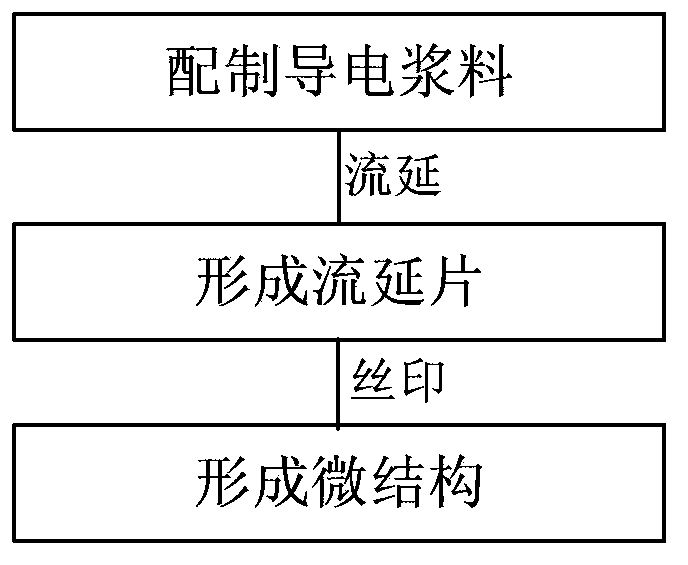

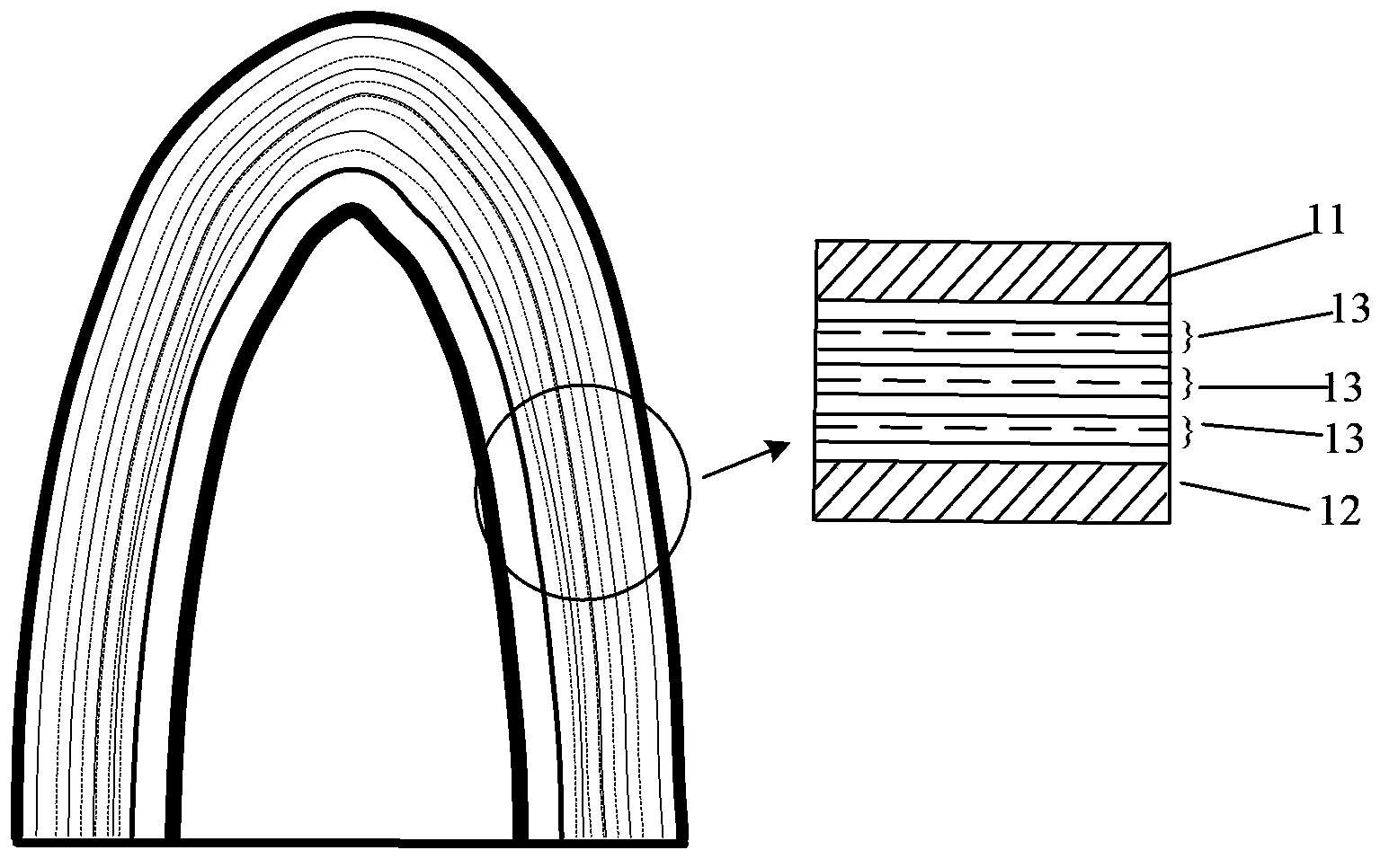

Metamaterial and manufacturing method thereof

The invention provides a metamaterial and a manufacturing method thereof. The manufacturing method includes the steps that a medium shell with a space geometrical shape and a ceramic shell with a space geometrical shape are manufactured, and the medium shell and the ceramic shell are formed; medium patches with at least one conductive geometric structure are manufactured; at least one medium patch and the medium shell are bonded; the medium shell which is provided with the medium patches in a bonding mode and the ceramic shell are combined into a whole. According to the metamaterial and the manufacturing method thereof, the medium shell which is provided with the medium patches in the bonding mode and the ceramic shell are combined into a whole, and thus gasification of the conductive geometric structures can be avoided.

Owner:KUANG CHI INST OF ADVANCED TECH

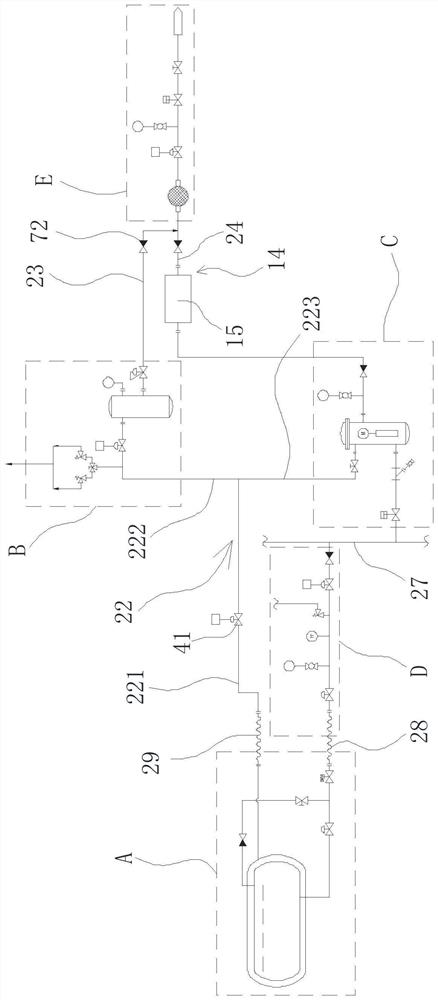

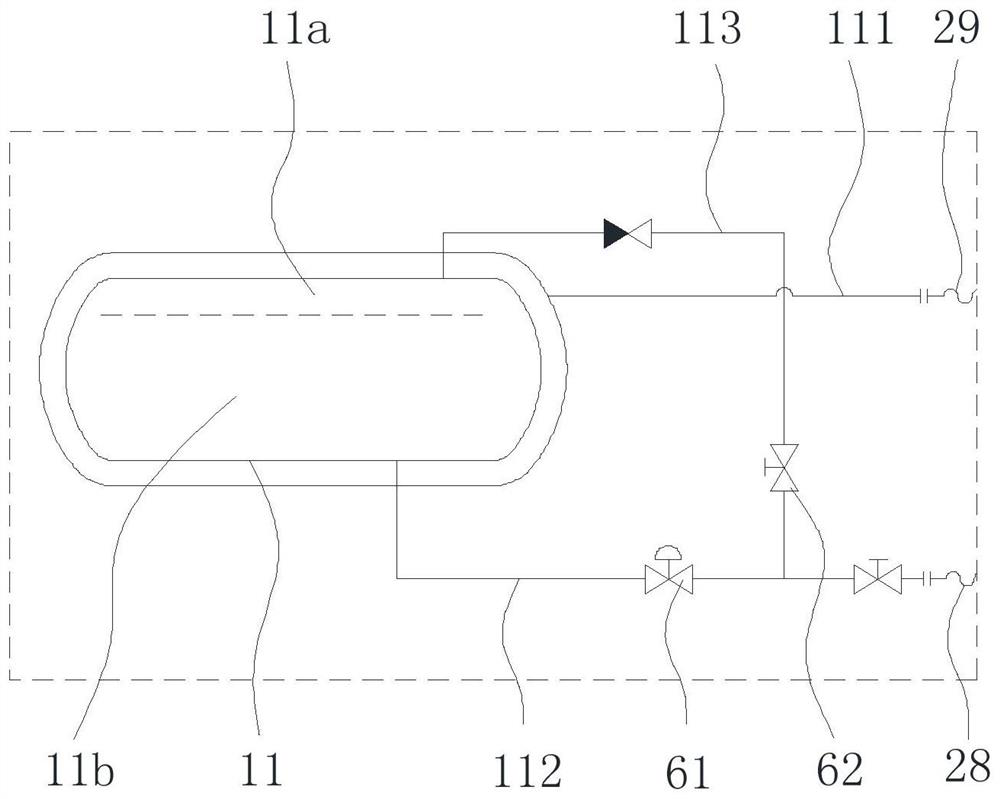

LNG fuel gas supply system and ship

PendingCN112412664AGuaranteed pressurePrevent gasificationInternal combustion piston enginesFuel supply apparatusLiquid storage tankGas holder

The invention relates to a ship and an LNG fuel gas supply system. The ship comprises a ship body, an engine and the LNG fuel gas supply system; the LNG fuel gas supply system comprises a liquid storage tank, a pressure pump, a gas storage tank and a gasification mechanism, the liquid storage tank is provided with a gas pipe and a liquid pipe, and an inlet of the gas storage tank communicates withthe gas pipe of the liquid storage tank; and a liquid inlet, a liquid discharging outlet and an exhaust port are formed in the pressure pump, the liquid inlet communicates with the liquid pipe of theliquid storage tank, and the exhaust port communicates with the gas pipe of the liquid storage tank and the inlet of the gas storage tank so as to selectively convey BOG in the pressure pump into theliquid storage tank or the gas storage tank. The liquid storage tank, the gas storage tank and the pressure pump are utilized to form a closed space with a fixed volume, the BOG is continuously increased in the closed space, the BOG is self-compressed by utilizing pressure between the BOG gas, peripheral pressure equipment does not need to be added, and the BOG can also obtain pressure required by combustion.

Owner:CIMC SHIP OCEAN ENG DESIGN & RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com